电池无损检测监测方法分析

Analysis of battery nondestructive testing and monitoring methods

电池无损检测监测方法分析 |

| 郝奕帆, 祝夏雨, 王静, 邱景义, 明海, 方振华 |

|

Analysis of battery nondestructive testing and monitoring methods |

| Yifan HAO, Xiayu ZHU, Jing WANG, Jingyi QIU, Hai MING, Zhenhua FANG |

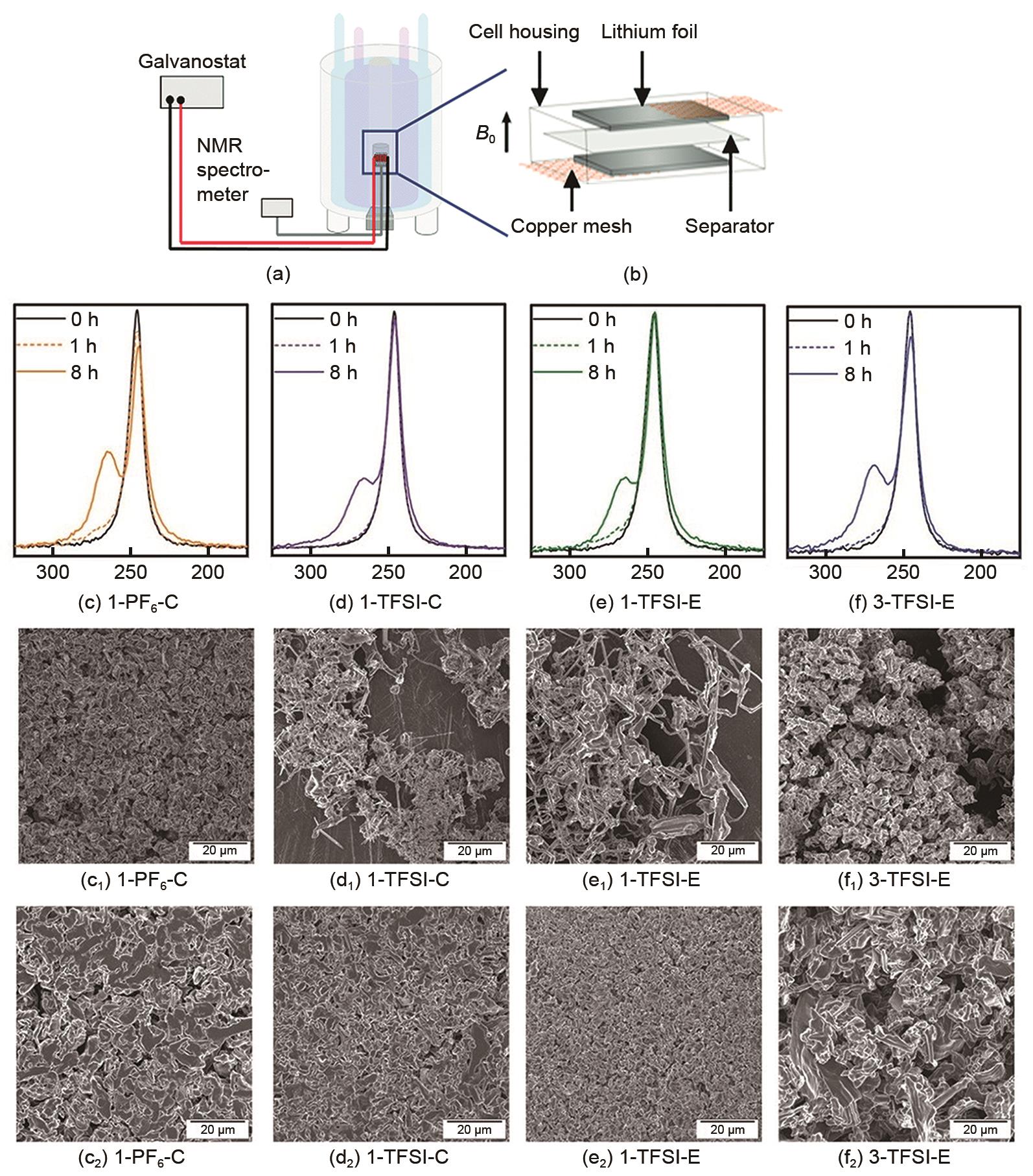

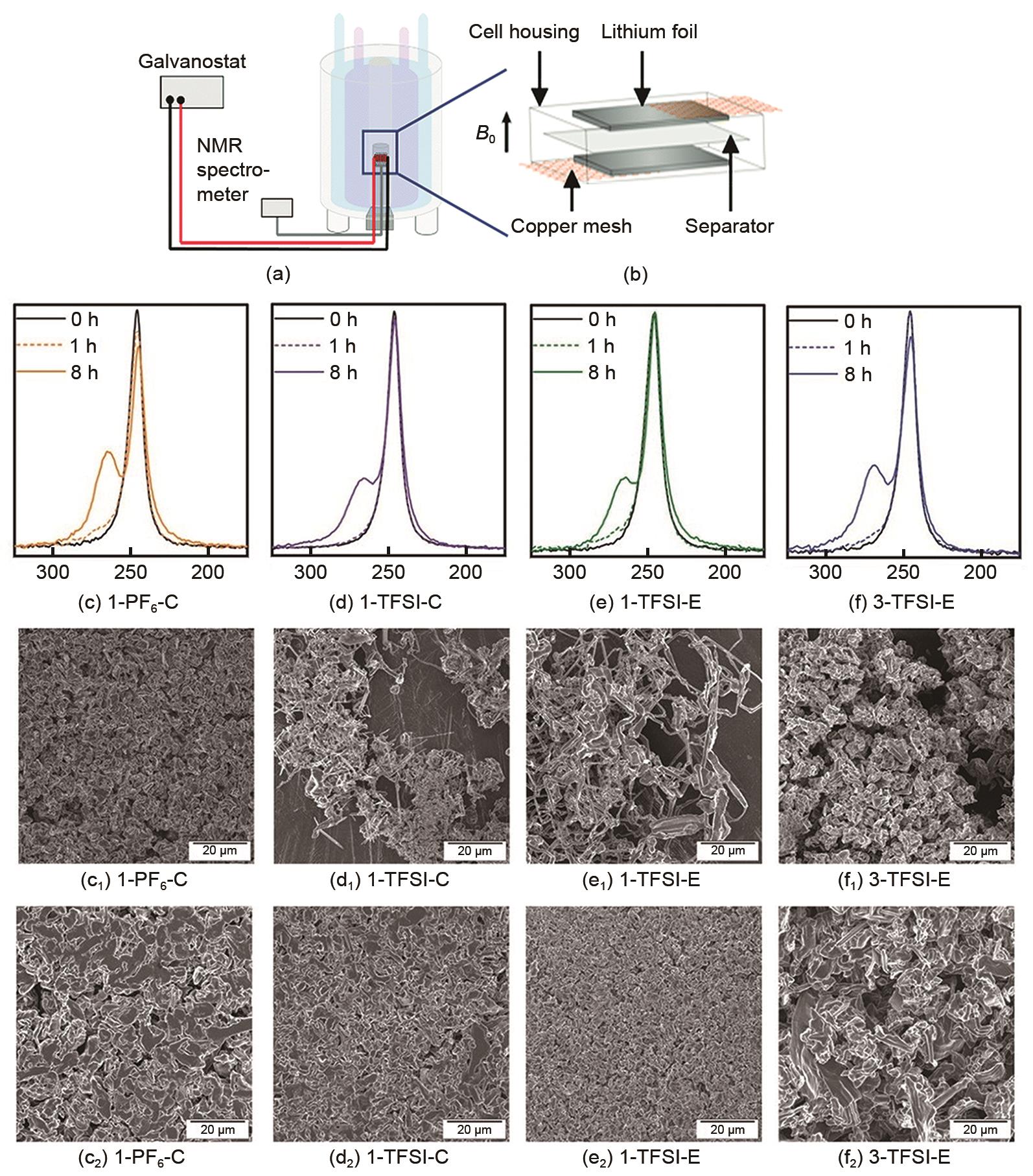

| 图10 (a) 测量装置示意图,将薄膜软包电池放置在核磁共振设备的线圈中,连接到电池循环器; (b) 薄膜软包电池的结构图; (c)~(f) 在0.5 mA/cm2 电流密度下,薄膜软包电池电极在不同电解质中(1-PF6-C、1-TFSI-C:分别将1 mol/L的六氟磷酸锂,1 mol/L的双三氟甲磺酰亚胺锂溶于质量比为3∶7的碳酸乙烯酯和碳酸二乙酯中;1-TFSI-E、3-TFSI-E:分别将1 mol/L和3 mol/L的双三氟甲磺酰亚胺锂溶于质量比为1∶1的乙二醇二甲醚和二氧戊环中)经过1 h和8 h电沉积后的 7Li-NMR光谱图像以及1 h后(c1~f1)和8 h电沉积后(c2~f2)的SEM图像[ |

| Fig. 10 (a) Schematic depiction of the measurement setup with a thin film pouch cell placed in the coil of a NMR device, connected to a battery cycler; (b) Schematic thin film pouch cell; (c)—(f) 7Li-NMR spectra of thin film pouch cells and SEM images of the corresponding electrodes after (c1—f1) and (c2—f2) 8 hours of electrodeposition at 0.5 mA/cm2 containing 1-PF6-C, 1-TFSI-C, 1-TFSI-E and 3-TFSI-E[ |

|