储能科学与技术 ›› 2022, Vol. 11 ›› Issue (6): 1760-1771.doi: 10.19799/j.cnki.2095-4239.2022.0193

燕乔一1( ), 吴锋1,2(

), 吴锋1,2( ), 陈人杰1,2, 李丽1,2(

), 陈人杰1,2, 李丽1,2( )

)

收稿日期:2022-04-08

修回日期:2022-04-29

出版日期:2022-06-05

发布日期:2022-06-13

通讯作者:

吴锋,李丽

E-mail:yanqiaoyi627@163.com;wufeng863@bit.edu.cn;lily863@bit.edu.cn

作者简介:燕乔一(1999—),女,硕士研究生,主要研究方向为锂离子电池负极回收再利用,E-mail: yanqiaoyi627@163.com;

基金资助:

YAN Qiaoyi1( ), WU Feng1,2(

), WU Feng1,2( ), CHEN Renjie1,2, LI Li1,2(

), CHEN Renjie1,2, LI Li1,2( )

)

Received:2022-04-08

Revised:2022-04-29

Online:2022-06-05

Published:2022-06-13

Contact:

WU Feng, LI Li

E-mail:yanqiaoyi627@163.com;wufeng863@bit.edu.cn;lily863@bit.edu.cn

摘要:

新能源汽车的普及是推动绿色发展、保障能源安全的战略选择,是汽车行业碳减排的重要举措,并且对于我国实现碳中和、碳达峰的目标意义重大。锂离子动力电池作为新能源汽车的核心驱动力,其退役后的清洁处理和高效利用,关系到电动汽车行业能否实现绿色可持续发展。石墨具有可逆容量高、循环稳定性好等优点,被广泛地用于制备锂离子电池负极材料。因此,石墨负极材料的回收处理与资源循环应该引起高度重视。本文从深度净化、选择性提锂和残存电解质去除等角度,对废锂离子电池负极石墨回收处理技术进行了归纳和总结,梳理出再生石墨及其产品的资源循环利用途径,并基于全生命周期评价技术分析石墨回收技术的优缺点。最后,对锂离子电池负极石墨未来的回收处理与资源循环技术挑战和发展趋势进行展望,提出未来应着眼于厘清电池失效机理、实现全组分高效回收、坚持绿色化学新理念、拓宽高值化应用市场的四位一体发展模式。

中图分类号:

燕乔一, 吴锋, 陈人杰, 李丽. 锂离子电池负极石墨回收处理及资源循环[J]. 储能科学与技术, 2022, 11(6): 1760-1771.

YAN Qiaoyi, WU Feng, CHEN Renjie, LI Li. Recovery and resource recycling of graphite anode materials for spent lithium-ion batteries[J]. Energy Storage Science and Technology, 2022, 11(6): 1760-1771.

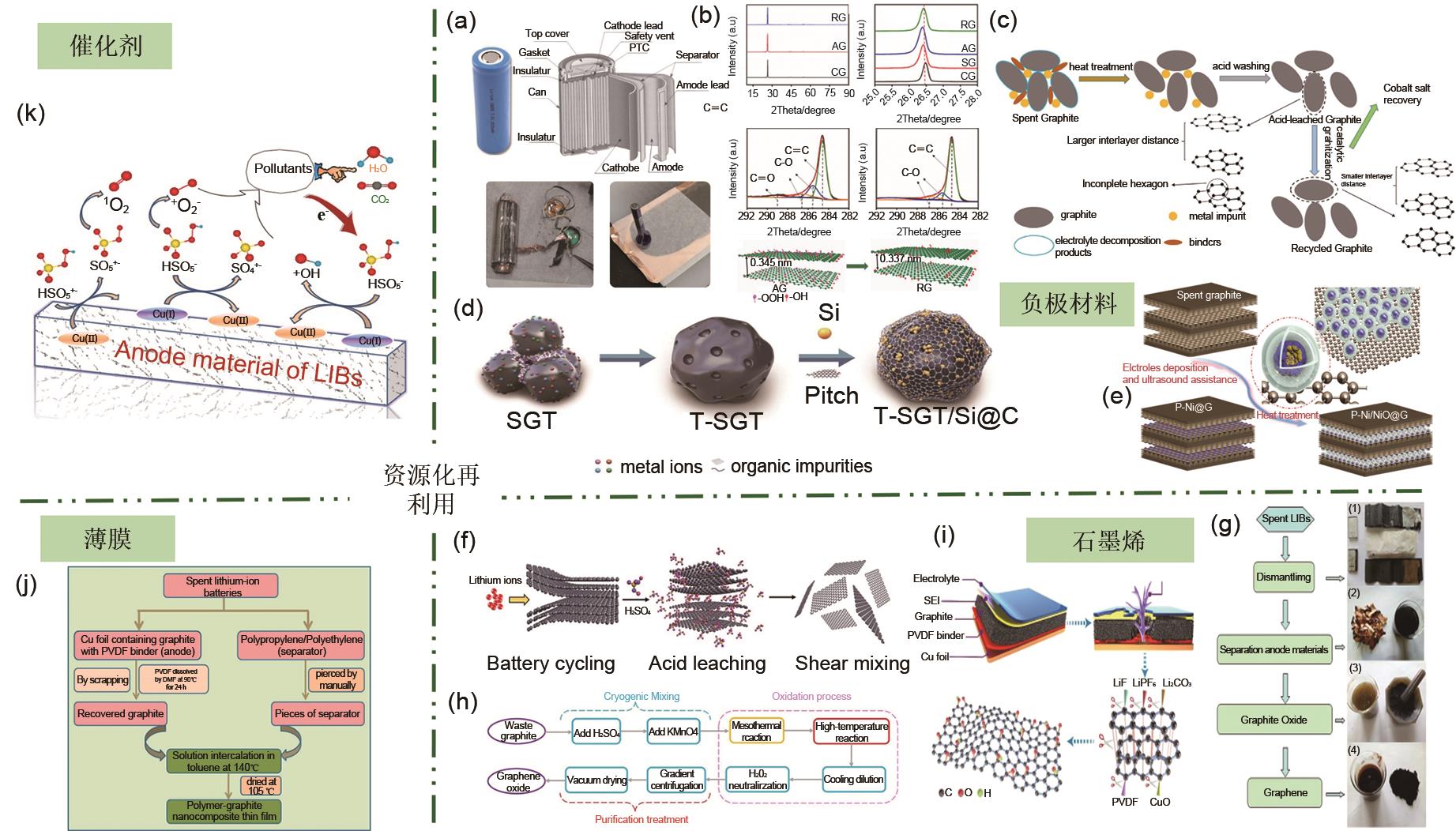

图3

(a) 18650电池和内部示意图,拆卸上、下盖和打开罐后的18650电池以及完成RAM阳极层压板;(b) CG、AG和RG的XRD谱图、(002)峰值反射、XPS高分辨率光谱以及不同夹层间距的AG和RG结构模型;(c) 废锂离子电池石墨再生过程示意图;(d) T-SGT/Si@C负极材料的合成工艺示意图;(e) P-Ni/NiO@G电极的合成工艺;(f) 电池循环和酸浸石墨晶格膨胀示意图;(g) 废旧锂离子电池石墨烯的制备方法;(h) 改进Hummers法制备氧化石墨烯实验步骤示意图;(i) 利用废石墨制备氧化石墨烯的模型;(j) 聚合物-石墨纳米复合薄膜的制备流程;(k) AM/PMS体系中PMS活化和RhB降解的反应机理[38,42-43,46-49,51,53-54]"

| 1 | 陆浩, 刘柏男, 禇赓, 等. 锂离子电池负极材料产业化技术进展[J]. 储能科学与技术, 2016, 5(2): 109-119. |

| LU Hao, LIU Bonan, CHU Geng, et al. Technology review of anode materials for lithium ion batteries[J]. Energy Storage Science and Technology, 2016, 5(2): 109-119. | |

| 2 | ZHANG B L, XIE H W, LU B H, et al. A green electrochemical process to recover Co and Li from spent LiCoO2-based batteries in molten salts[J]. ACS Sustainable Chemistry & Engineering, 2019, 7(15): 13391-13399. |

| 3 | ETACHERI V, MAROM R, ELAZARI R, et al. Challenges in the development of advanced Li-ion batteries: A review[J]. Energy & Environmental Science, 2011, 4(9): 3243-3262. |

| 4 | DAI Q, SPANGENBERGER J, AHMED S, et al. EverBatt: A closed-loop battery recycling cost and environmental impacts model[R]. Office of Scientific and Technical Information (OSTI), 2019. |

| 5 | COMMISSION E. Critical raw materials resilience: Charting a path towards greater security and sustainability[J/OL]. [2022-01-12].https://ec.europa.eu/docsroom/documents/42849. |

| 6 | 高驰. 中汽协预测:2022年中国汽车销量同比增长5.4%,新能源车突破500万辆[J]. 汽车与配件, 2022(1): 47. |

| 7 | LI L, FAN E S, GUAN Y B, et al. Sustainable recovery of cathode materials from spent lithium-ion batteries using lactic acid leaching system[J]. ACS Sustainable Chemistry & Engineering, 2017, 5(6): 5224-5233. |

| 8 | NIESE N, PIEPER C, ARORA A, et al. The case for a circular economy in electric vehicle batteries[EB/OL]. [2021-08-31]. https://www. bcg. com/en-ca/publications/2020/case-for-circular-economy-in-electricvehicle-batteries, 2020. |

| 9 | HALLEUX V. New EU regulatory framework for batteries—Setting sustainability requirements[J]. European Parliamentary Research Service: Brussels, Belgium, 2021. |

| 10 | SWAIN B. Recovery and recycling of lithium: A review[J]. Separation and Purification Technology, 2017, 172: 388-403. |

| 11 | WU F, XU S M, LI L Y, et al. Recovery of valuable metals from anode material of hydrogen-nickel battery[J]. Transactions of Nonferrous Metals Society of China, 2009, 19(2): 468-473. |

| 12 | ZHANG X X, LI L, FAN E S, et al. Toward sustainable and systematic recycling of spent rechargeable batteries[J]. Chemical Society Reviews, 2018, 47(19): 7239-7302. |

| 13 | DUNN J B, GAINES L, BARNES M, et al. Material and energy flows in the materials production, assembly, and end-of-life stages of the automotive lithium-ion battery life cycle[R]. Office of Scientific and Technical Information (OSTI), 2012. |

| 14 | ZENG X L, LI J H, SINGH N. Recycling of spent lithium-ion battery: A critical review[J]. Critical Reviews in Environmental Science and Technology, 2014, 44(10): 1129-1165. |

| 15 | 高工锂电. 负极石墨化涨价追踪[EB/OL]. [2021-08-31]. https://www.gg-lb.com/art-43416.html. |

| 16 | YANG J B, FAN E S, LIN J, et al. Recovery and reuse of anode graphite from spent lithium-ion batteries via citric acid leaching[J]. ACS Applied Energy Materials, 2021, 4(6): 6261-6268. |

| 17 | BARIK S P, PRABAHARAN G, KUMAR L. Leaching and separation of Co and Mn from electrode materials of spent lithium-ion batteries using hydrochloric acid: Laboratory and pilot scale study[J]. Journal of Cleaner Production, 2017, 147: 37-43. |

| 18 | TAKACOVA Z, HAVLIK T, KUKURUGYA F, et al. Cobalt and lithium recovery from active mass of spent Li-ion batteries: Theoretical and experimental approach[J]. Hydrometallurgy, 2016, 163: 9-17. |

| 19 | WANG F, SUN R, XU J, et al. Recovery of cobalt from spent lithium ion batteries using sulphuric acid leaching followed by solid-liquid separation and solvent extraction[J]. RSC Advances, 2016, 6(88): 85303-85311. |

| 20 | TANONG K, COUDERT L, MERCIER G, et al. Recovery of metals from a mixture of various spent batteries by a hydrometallurgical process[J]. Journal of Environmental Management, 2016, 181: 95-107. |

| 21 | BARBIERI E M S, LIMA E P C, CANTARINO S J, et al. Recycling of spent ion-lithium batteries as cobalt hydroxide, and cobalt oxide films formed under a conductive glass substrate, and their electrochemical properties[J]. Journal of Power Sources, 2014, 269: 158-163. |

| 22 | BARBIERI E M S, LIMA E P C, LELIS M F F, et al. Recycling of cobalt from spent Li-ion batteries as β-Co(OH)2 and the application of Co3O4 as a pseudocapacitor[J]. Journal of Power Sources, 2014, 270: 158-165. |

| 23 | YANG Y, SONG S L, LEI S Y, et al. A process for combination of recycling lithium and regenerating graphite from spent lithium-ion battery[J]. Waste Management, 2019, 85: 529-537. |

| 24 | GAO Y, WANG C Y, ZHANG J L, et al. Graphite recycling from the spent lithium-ion batteries by sulfuric acid curing-leaching combined with high-temperature calcination[J]. ACS Sustainable Chemistry & Engineering, 2020, 8(25): 9447-9455. |

| 25 | YI C X, YANG Y, ZHANG T, et al. A green and facile approach for regeneration of graphite from spent lithium ion battery[J]. Journal of Cleaner Production, 2020, 277: doi 10.1016/j.jclepro.2020.12385. |

| 26 | CAO N, ZHANG Y L, CHEN L L, et al. An innovative approach to recover anode from spent lithium-ion battery[J]. Journal of Power Sources, 2021, 483: doi: 10.1016/j.jpowsur.2020.229163. |

| 27 | WANG F F, ZHANG T, HE Y Q, et al. Recovery of valuable materials from spent lithium-ion batteries by mechanical separation and thermal treatment[J]. Journal of Cleaner Production, 2018, 185: 646-652. |

| 28 | MESHRAM P, PANDEY B D, MANKHAND T R. Extraction of lithium from primary and secondary sources by pre-treatment, leaching and separation: A comprehensive review[J]. Hydrometallurgy, 2014, 150: 192-208. |

| 29 | AN S J, LI J, DANIEL C, et al. The state of understanding of the lithium-ion-battery graphite solid electrolyte interphase (SEI) and its relationship to formation cycling[J]. Carbon, 2016, 105: 52-76. |

| 30 | GUO Y, LI F, ZHU H C, et al. Leaching lithium from the anode electrode materials of spent lithium-ion batteries by hydrochloric acid (HCl)[J]. Waste Management, 2016, 51: 227-233. |

| 31 | LI J L, HE Y Q, FU Y P, et al. Hydrometallurgical enhanced liberation and recovery of anode material from spent lithium-ion batteries[J]. Waste Management, 2021, 126: 517-526. |

| 32 | GRÜTZKE M, KRÜGER S, KRAFT V, et al. Investigation of the storage behavior of shredded lithium-ion batteries from electric vehicles for recycling purposes[J]. ChemSusChem, 2015, 8(20): 3433-3438. |

| 33 | LAIN M J. Recycling of lithium ion cells and batteries[J]. Journal of Power Sources, 2001, 97/98: 736-738. |

| 34 | BANKOLE O E, GONG C X, LEI L X. Battery recycling technologies: Recycling waste lithium ion batteries with the impact on the environment in-view[J]. Journal of Environment and Ecology, 2013, 4(1): 14. |

| 35 | NOWAK S, WINTER M. The role of sub- and supercritical CO2 as "processing solvent" for the recycling and sample preparation of lithium ion battery electrolytes[J]. Molecules (Basel, Switzerland), 2017, 22(3): 403. |

| 36 | GRÜTZKE M, KRAFT V, WEBER W, et al. Supercritical carbon dioxide extraction of lithium-ion battery electrolytes[J]. The Journal of Supercritical Fluids, 2014, 94: 216-222. |

| 37 | ROTHERMEL S, EVERTZ M, KASNATSCHEEW J, et al. Graphite recycling from spent lithium-ion batteries[J]. ChemSusChem, 2016, 9(24): 3473-3484. |

| 38 | SABISCH J E C, ANAPOLSKY A, LIU G, et al. Evaluation of using pre-lithiated graphite from recycled Li-ion batteries for new LiB anodes[J]. Resources, Conservation and Recycling, 2018, 129: 129-134. |

| 39 | ARAVINDAN V, JAYARAMAN S, TEDJAR F, et al. From electrodes to electrodes: Building high-performance Li-ion capacitors and batteries from spent lithium-ion battery carbonaceous materials[J]. ChemElectroChem, 2019, 6(5): 1407-1412. |

| 40 | KAYAKOOL F A, GANGAJA B, NAIR S, et al. Li-based all‑carbon dual-ion batteries using graphite recycled from spent Li-ion batteries[J]. Sustainable Materials and Technologies, 2021, 28: e00262. |

| 41 | ZHANG J, LI X L, SONG D W, et al. Effective regeneration of anode material recycled from scrapped Li-ion batteries[J]. Journal of Power Sources, 2018, 390: 38-44. |

| 42 | LIU K, YANG S L, LUO L Q, et al. From spent graphite to recycle graphite anode for high-performance lithium ion batteries and sodium ion batteries[J]. Electrochimica Acta, 2020, 356: doi: 10.1016/j.electacta.2020.136856. |

| 43 | CHEN Q H, HUANG L W, LIU J B, et al. A new approach to regenerate high-performance graphite from spent lithium-ion batteries[J]. Carbon, 2022, 189: 293-304. |

| 44 | XU L, ZHANG X X, CHEN R J, et al. P-doped Ni/NiO heterostructured yolk-shell nanospheres encapsulated in graphite for enhanced lithium storage[J]. Small, 2022, 18(7): doi: 10.1002/smll.202105897. |

| 45 | YE L, WANG C H, CAO L, et al. Effective regeneration of high-performance anode material recycled from the whole electrodes in spent lithium-ion batteries via a simplified approach[J]. Green Energy & Environment, 2021, 6(5): 725-733. |

| 46 | RUAN D S, WU L, WANG F M, et al. A low-cost silicon-graphite anode made from recycled graphite of spent lithium-ion batteries[J]. Journal of Electroanalytical Chemistry, 2021, 884: doi: 10.1016/j.jelechem.2021.115073. |

| 47 | ZHAO Y L, WANG H, LI X D, et al. Recovery of CuO/C catalyst from spent anode material in battery to activate peroxymonosulfate for refractory organic contaminants degradation[J]. Journal of Hazardous Materials, 2021, 420: doi: 10.1016/j.jhazmat.2021.126552. |

| 48 | ZHANG Y Y, SONG N N, HE J J, et al. Lithiation-aided conversion of end-of-life lithium-ion battery anodes to high-quality graphene and graphene oxide[J]. Nano Letters, 2019, 19(1): 512-519. |

| 49 | YANG L, YANG L, XU G R, et al. Separation and recovery of carbon powder in anodes from spent lithium-ion batteries to synthesize graphene[J]. Scientific Reports, 2019, 9: 9823. |

| 50 | HE K, ZHANG Z Y, ZHANG F S. Synthesis of graphene and recovery of lithium from lithiated graphite of spent Li-ion battery[J]. Waste Management, 2021, 124: 283-292. |

| 51 | YU J D, LIN M S, TAN Q Y, et al. High-value utilization of graphite electrodes in spent lithium-ion batteries: From 3D waste graphite to 2D graphene oxide[J]. Journal of Hazardous Materials, 2021, 401: doi: 10.1016/j.jhazmat.2021.123715. |

| 52 | NATARAJAN S, BAJAJ H C, ARAVINDAN V. Template-free synthesis of carbon hollow spheres and reduced graphene oxide from spent lithium-ion batteries towards efficient gas storage[J]. Journal of Materials Chemistry A, 2019, 7(7): 3244-3252. |

| 53 | NATARAJAN S, LAKSHMI D S, BAJAJ H C, et al. Recovery and utilization of graphite and polymer materials from spent lithium-ion batteries for synthesizing polymer-graphite nanocomposite thin films[J]. Journal of Environmental Chemical Engineering, 2015, 3(4): 2538-2545. |

| 54 | MA X T, CHEN M Y, CHEN B, et al. High-performance graphite recovered from spent lithium-ion batteries[J]. ACS Sustainable Chemistry & Engineering, 2019, 7(24): 19732-19738. |

| 55 | KIRCHAIN R E Jr, GREGORY J R, OLIVETTI E A. Environmental life-cycle assessment[J]. Nature Materials, 2017, 16(7): 693-697. |

| 56 | ARSHAD F, LIN J, MANURKAR N, et al. Life cycle assessment of lithium-ion batteries: A critical review[J]. Resources, Conservation and Recycling, 2022, 180: doi: 10.1016/j.resconrelc.2022.106164. |

| 57 | REY I, VALLEJO C, SANTIAGO G, et al. Environmental impacts of graphite recycling from spent lithium-ion batteries based on life cycle assessment[J]. ACS Sustainable Chemistry & Engineering, 2021, 9(43): 14488-14501. |

| [1] | 李海涛, 孔令丽, 张欣, 余传军, 王纪威, 徐琳. N/P设计对高镍NCM/Gr电芯性能的影响[J]. 储能科学与技术, 2022, 11(7): 2040-2045. |

| [2] | 刘显茜, 孙安梁, 田川. 基于仿生翅脉流道冷板的锂离子电池组液冷散热[J]. 储能科学与技术, 2022, 11(7): 2266-2273. |

| [3] | 陈龙, 夏权, 任羿, 曹高萍, 邱景义, 张浩. 多物理场耦合下锂离子电池组可靠性研究现状与展望[J]. 储能科学与技术, 2022, 11(7): 2316-2323. |

| [4] | 易顺民, 谢林柏, 彭力. 基于VF-DW-DFN的锂离子电池剩余寿命预测[J]. 储能科学与技术, 2022, 11(7): 2305-2315. |

| [5] | 祝庆伟, 俞小莉, 吴启超, 徐一丹, 陈芬放, 黄瑞. 高能量密度锂离子电池老化半经验模型[J]. 储能科学与技术, 2022, 11(7): 2324-2331. |

| [6] | 王宇作, 王瑨, 卢颖莉, 阮殿波. 孔结构对软碳负极储锂性能的影响[J]. 储能科学与技术, 2022, 11(7): 2023-2029. |

| [7] | 孔为, 金劲涛, 陆西坡, 孙洋. 对称蛇形流道锂离子电池冷却性能[J]. 储能科学与技术, 2022, 11(7): 2258-2265. |

| [8] | 霍思达, 薛文东, 李新丽, 李勇. 基于CiteSpace知识图谱的锂电池复合电解质可视化分析[J]. 储能科学与技术, 2022, 11(7): 2103-2113. |

| [9] | 邓健想, 赵金良, 黄成德. 高能量锂离子电池硅基负极黏结剂研究进展[J]. 储能科学与技术, 2022, 11(7): 2092-2102. |

| [10] | 欧宇, 侯文会, 刘凯. 锂离子电池中的智能安全电解液研究进展[J]. 储能科学与技术, 2022, 11(6): 1772-1787. |

| [11] | 韩俊伟, 肖菁, 陶莹, 孔德斌, 吕伟, 杨全红. 致密储能:基于石墨烯的方法学和应用实例[J]. 储能科学与技术, 2022, 11(6): 1865-1873. |

| [12] | 辛耀达, 李娜, 杨乐, 宋维力, 孙磊, 陈浩森, 方岱宁. 锂离子电池植入传感技术[J]. 储能科学与技术, 2022, 11(6): 1834-1846. |

| [13] | 沈秀, 曾月劲, 李睿洋, 李佳霖, 李伟, 张鹏, 赵金保. γ射线辐照交联原位固态化阻燃锂离子电池[J]. 储能科学与技术, 2022, 11(6): 1816-1821. |

| [14] | 丁奕, 杨艳, 陈锴, 曾涛, 黄云辉. 锂离子电池智能消防及其研究方法[J]. 储能科学与技术, 2022, 11(6): 1822-1833. |

| [15] | 张言, 王海, 刘朝孟, 张德柳, 王佳东, 李建中, 高宣雯, 骆文彬. 锂离子电池富镍三元正极材料NCM的研究进展[J]. 储能科学与技术, 2022, 11(6): 1693-1705. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||