储能科学与技术 ›› 2025, Vol. 14 ›› Issue (3): 947-964.doi: 10.19799/j.cnki.2095-4239.2024.1161

卢功勋1,2( ), 袁华栋1, 罗剑敏1, 王垚1, 刘育京1, 石鹏3, 邹世辉1, 周光敏2, 陶新永1(

), 袁华栋1, 罗剑敏1, 王垚1, 刘育京1, 石鹏3, 邹世辉1, 周光敏2, 陶新永1( ), 佴建威1(

), 佴建威1( )

)

收稿日期:2024-12-06

修回日期:2025-01-22

出版日期:2025-03-28

发布日期:2025-04-28

通讯作者:

陶新永,佴建威

E-mail:gongxunlu96@gmail.com;tao@zjut.edu.cn;jwnai@zjut.edu.cn

作者简介:卢功勋(1996-),男,博士,研究方向为金属锂电池材料与技术,E-mail:gongxunlu96@gmail.com;

基金资助:

Gongxun LU1,2( ), Huadong YUAN1, Jianmin LUO1, Yao WANG1, Yujing LIU1, Peng SHI3, Shihui ZOU1, Guangmin ZHOU2, Xinyong TAO1(

), Huadong YUAN1, Jianmin LUO1, Yao WANG1, Yujing LIU1, Peng SHI3, Shihui ZOU1, Guangmin ZHOU2, Xinyong TAO1( ), Jianwei NAI1(

), Jianwei NAI1( )

)

Received:2024-12-06

Revised:2025-01-22

Online:2025-03-28

Published:2025-04-28

Contact:

Xinyong TAO, Jianwei NAI

E-mail:gongxunlu96@gmail.com;tao@zjut.edu.cn;jwnai@zjut.edu.cn

摘要:

锂金属负极因具有极高的比容量和最低的电化学平衡电位,其应用一直受到人们的广泛关注。然而,锂枝晶在重复循环过程中引起的寿命短和安全性问题阻碍了锂金属电池的实用化。锂金属与电解质之间的复杂界面在调节锂沉积和提高电池循环稳定性方面起着非常重要的作用。通过对近期相关文献的探讨,综述了当前构建保护层作为人工SEI的有效预处理策略的关键进展,着重介绍了不同物质状态的处理策略及人工界面稳定锂金属负极的作用机制。最后展望未来预处理技术与锂金属负极的应用,包含开发先进策略、探索应用前景、解析影响机制等方面,提出了高能量密度锂金属电池当前的挑战、机遇和可能研究方向。

中图分类号:

卢功勋, 袁华栋, 罗剑敏, 王垚, 刘育京, 石鹏, 邹世辉, 周光敏, 陶新永, 佴建威. 锂金属表面预处理策略:进展与展望[J]. 储能科学与技术, 2025, 14(3): 947-964.

Gongxun LU, Huadong YUAN, Jianmin LUO, Yao WANG, Yujing LIU, Peng SHI, Shihui ZOU, Guangmin ZHOU, Xinyong TAO, Jianwei NAI. Surface pre-treatment strategies for lithium metal: Advancement and perspective[J]. Energy Storage Science and Technology, 2025, 14(3): 947-964.

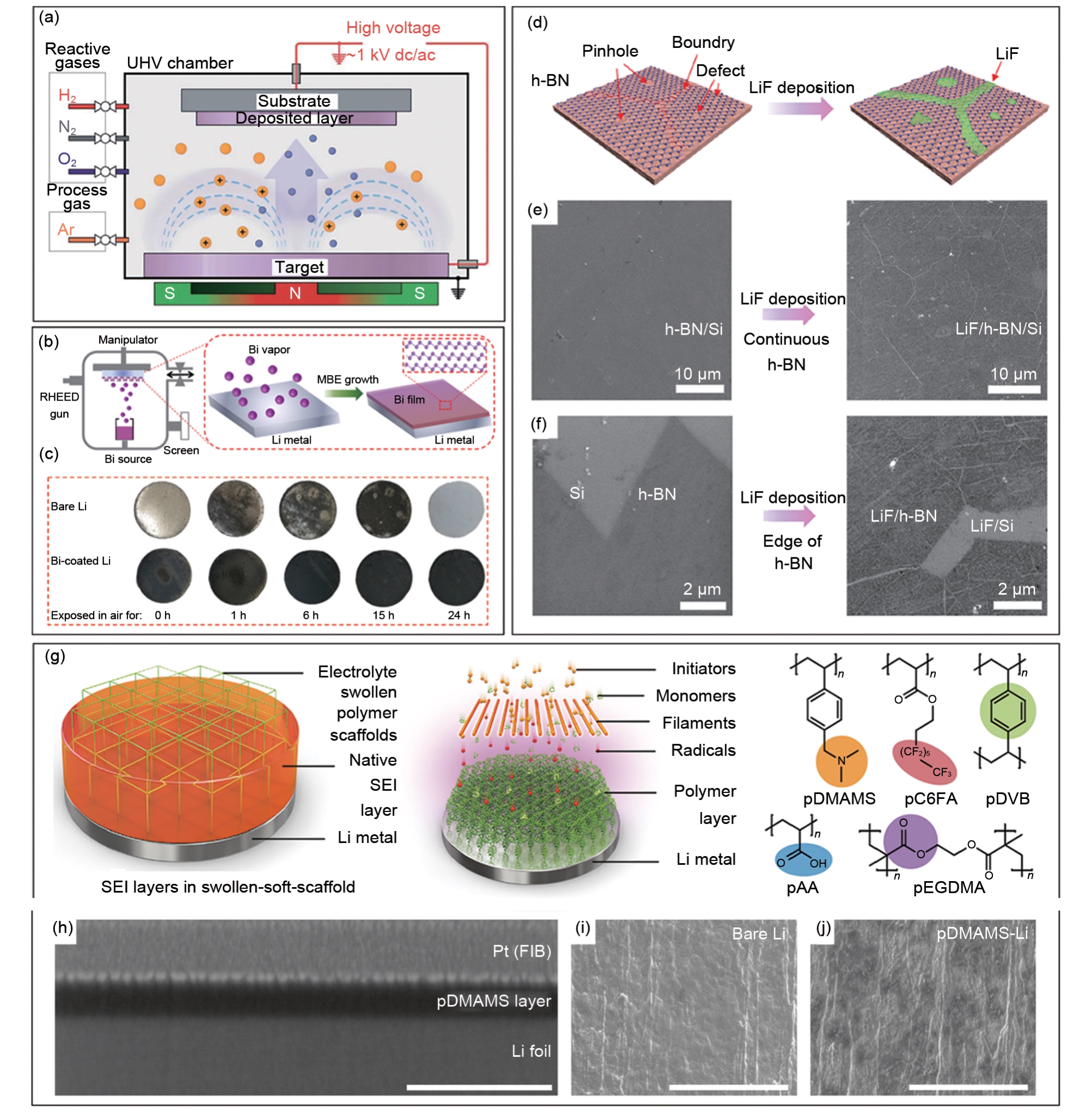

图7

(a) 磁控溅射装置的简要说明和磁控溅射原理[94],(b) 通过蒸发Bi金属前体在锂基底上生长均匀薄Bi膜[95],(c) 裸露的锂箔和Bi涂层锂箔在空气中暴露后的光学照片,(d) 在h-BN上选择性ALD LiF沉积的示意图,(e) 在连续h-BN上进行50次ALD LiF沉积的SEM表征,(f) SEM表征h-BN边缘50次ALD LiF沉积循环[96],(g) 膨胀软支架策略增强LMA原生SEI层的示意图,(h) 被100 nm pDMAMS层覆盖的锂金属的横截面FIB-SEM图像,比例尺,500 nm,(i), (j) 裸锂和100 nm pDMAMS-Li的自上而下的SEM图像。比例尺,20 µm[97]"

| 1 | LIN D C, LIU Y Y, CUI Y. Reviving the lithium metal anode for high-energy batteries[J]. Nature Nanotechnology, 2017, 12(3): 194-206. DOI: 10.1038/nnano.2017.16. |

| 2 | CANO Z P, BANHAM D, YE S Y, et al. Batteries and fuel cells for emerging electric vehicle markets[J]. Nature Energy, 2018, 3: 279-289. DOI: 10.1038/s41560-018-0108-1. |

| 3 | CHENG X B, ZHANG R, ZHAO C Z, et al. Toward safe lithium metal anode in rechargeable batteries: A review[J]. Chemical Reviews, 2017, 117(15): 10403-10473. DOI: 10.1021/acs.chemrev.7b00115. |

| 4 | ZHANG X, YANG Y A, ZHOU Z. Towards practical lithium-metal anodes[J]. Chemical Society Reviews, 2020, 49(10): 3040-3071. DOI: 10.1039/c9cs00838a. |

| 5 | ALBERTUS P, BABINEC S, LITZELMAN S, et al. Status and challenges in enabling the lithium metal electrode for high-energy and low-cost rechargeable batteries[J]. Nature Energy, 2018, 3: 16-21. DOI: 10.1038/s41560-017-0047-2. |

| 6 | WU H P, JIA H, WANG C M, et al. Recent progress in understanding solid electrolyte interphase on lithium metal anodes[J]. Advanced Energy Materials, 2021, 11(5): 2003092. DOI: 10.1002/aenm.202003092. |

| 7 | XU W, WANG J L, DING F, et al. Lithium metal anodes for rechargeable batteries[J]. Energy & Environmental Science, 2014, 7(2): 513-537. DOI: 10.1039/C3EE40795K. |

| 8 | LU G X, WU X R, HUANG M F, et al. A self-adsorption molecule passivated interface enables efficient and stable lithium metal batteries[J]. Energy & Environmental Science, 2024, 17(24): 9555-9565. DOI: 10.1039/D4EE02903H. |

| 9 | LI T, ZHANG X Q, SHI P, et al. Fluorinated solid-electrolyte interphase in high-voltage lithium metal batteries[J]. Joule, 2019, 3(11): 2647-2661. DOI: 10.1016/j.joule.2019.09.022. |

| 10 | LIU W, LIU P, MITLIN D. Review of emerging concepts in SEI analysis and artificial SEI membranes for lithium, sodium, and potassium metal battery anodes [J]. Advanced Energy Materials, 2020, 10(43): 2002297. |

| 11 | WANG H, YU D D, KUANG C W, et al. Alkali metal anodes for rechargeable batteries[J]. Chem, 2019, 5(2): 313-338. DOI: 10.1016/j.chempr.2018.11.005. |

| 12 | WAN H L, XU J J, WANG C S. Designing electrolytes and interphases for high-energy lithium batteries[J]. Nature Reviews Chemistry, 2024, 8(1): 30-44. DOI: 10.1038/s41570-023-00557-z. |

| 13 | CHOI J W, AURBACH D. Promise and reality of post-lithium-ion batteries with high energy densities[J]. Nature Reviews Materials, 2016, 1(4): 16013. DOI: 10.1038/natrevmats.2016.13. |

| 14 | WEI S Y, CHOUDHURY S, TU Z Y, et al. Electrochemical interphases for high-energy storage using reactive metal anodes[J]. Accounts of Chemical Research, 2018, 51(1): 80-88. DOI: 10.1021/acs.accounts.7b00484. |

| 15 | JIN C B, LIU T F, SHENG O W, et al. Rejuvenating dead lithium supply in lithium metal anodes by iodine redox[J]. Nature Energy, 2021, 6: 378-387. DOI: 10.1038/s41560-021-00789-7. |

| 16 | KONZ Z M, MCCLOSKEY B D. Lithium quantified, dead or alive[J]. Nature Energy, 2022, 7: 1005-1006. DOI: 10.1038/s41560-022-01142-2. |

| 17 | ZOU P C, SUI Y M, ZHAN H C, et al. Polymorph evolution mechanisms and regulation strategies of lithium metal anode under multiphysical fields[J]. Chemical Reviews, 2021, 121(10): 5986-6056. DOI: 10.1021/acs.chemrev.0c01100. |

| 18 | LIU Y J, TAO X Y, WANG Y, et al. Self-assembled monolayers direct a LiF-rich interphase toward long-life lithium metal batteries[J]. Science, 2022, 375(6582): 739-745. DOI: 10.1126/science.abn1818. |

| 19 | ZHENG G Y, LEE S W, LIANG Z, et al. Interconnected hollow carbon nanospheres for stable lithium metal anodes[J]. Nature Nanotechnology, 2014, 9(8): 618-623. DOI: 10.1038/nnano. 2014.152. |

| 20 | YIN Y C, WANG Q, YANG J T, et al. Metal chloride perovskite thin film based interfacial layer for shielding lithium metal from liquid electrolyte[J]. Nature Communications, 2020, 11(1): 1761. DOI: 10.1038/s41467-020-15643-9. |

| 21 | LU G X, NAI J W, LUAN D Y, et al. Surface engineering toward stable lithium metal anodes[J]. Science Advances, 2023, 9(14): eadf1550. DOI: 10.1126/sciadv.adf1550. |

| 22 | ZHANG Q K, LIU S, LU Y T, et al. Artificial interphases enable dendrite-free Li-metal anodes[J]. Journal of Energy Chemistry, 2021, 58: 198-206. DOI: 10.1016/j.jechem.2020.09.030. |

| 23 | TAN J, MATZ J, DONG P, et al. A growing appreciation for the role of LiF in the solid electrolyte interphase[J]. Advanced Energy Materials, 2021, 11(16): 2100046. DOI: 10.1002/aenm.2021 00046. |

| 24 | TAKEHARA Z I, OGUMI Z, UCHIMOTO Y, et al. Modification of lithium/electrolyte interface by plasma polymerization of 1,1-difluoroethene[J]. Journal of Power Sources, 1993, 44(1/2/3): 377-383. DOI: 10.1016/0378-7753(93)80177-Q. |

| 25 | PARK J, JEONG J, LEE Y J, et al. Micro-patterned lithium metal anodes with suppressed dendrite formation for post lithium-ion batteries[J]. Advanced Materials Interfaces, 2016, 3(11): 1600140. DOI: 10.1002/admi.201600140. |

| 26 | SHEN X W, LI Y T, QIAN T, et al. Lithium anode stable in air for low-cost fabrication of a dendrite-free lithium battery[J]. Nature Communications, 2019, 10(1): 900. DOI: 10.1038/s41467-019-08767-0. |

| 27 | JU Z J, NAI J W, WANG Y, et al. Biomacromolecules enabled dendrite-free lithium metal battery and its origin revealed by cryo-electron microscopy[J]. Nature Communications, 2020, 11(1): 488. DOI: 10.1038/s41467-020-14358-1. |

| 28 | ZHAI P B, WANG T S, JIANG H N, et al. 3D artificial solid-electrolyte interphase for lithium metal anodes enabled by insulator-metal-insulator layered heterostructures[J]. Advanced Materials, 2021, 33(13): e2006247. DOI: 10.1002/adma.2020 06247. |

| 29 | JU Z J, TAO X Y, WANG Y, et al. A self-healing Li-crosslinked elastomer promotes a highly robust and conductive solid-electrolyte interphase[J]. Energy & Environmental Science, 2024, 17(13): 4703-4713. DOI: 10.1039/D4EE01359J. |

| 30 | LIANG X, PANG Q, KOCHETKOV I R, et al. A facile surface chemistry route to a stabilized lithium metal anode[J]. Nature Energy, 2017, 2(9): 17119. DOI: 10.1038/nenergy.2017.119. |

| 31 | GU Y, WANG W W, LI Y J, et al. Designable ultra-smooth ultra-thin solid-electrolyte interphases of three alkali metal anodes[J]. Nature Communications, 2018, 9(1): 1339. DOI: 10.1038/s41467-018-03466-8. |

| 32 | GAO Y, YAN Z F, GRAY J L, et al. Polymer-inorganic solid-electrolyte interphase for stable lithium metal batteries under lean electrolyte conditions[J]. Nature Materials, 2019, 18(4): 384-389. DOI: 10.1038/s41563-019-0305-8. |

| 33 | LU G X, QIAO Q Q, ZHANG M T, et al. High-voltage electrosynthesis of organic-inorganic hybrid with ultrahigh fluorine content toward fast Li-ion transport[J]. Science Advances, 2024, 10(32): eado7348. DOI: 10.1126/sciadv.ado7348. |

| 34 | LIN D C, LIU Y Y, CHEN W, et al. Conformal lithium fluoride protection layer on three-dimensional lithium by nonhazardous gaseous reagent Freon[J]. Nano Letters, 2017, 17(6): 3731-3737. DOI: 10.1021/acs.nanolett.7b01020. |

| 35 | CHA E, PATEL M D, PARK J, et al. 2D MoS2 as an efficient protective layer for lithium metal anodes in high-performance Li-S batteries[J]. Nature Nanotechnology, 2018, 13(4): 337-344. DOI: 10.1038/s41565-018-0061-y. |

| 36 | CHEN K, PATHAK R, GURUNG A, et al. Flower-shaped lithium nitride as a protective layer via facile plasma activation for stable lithium metal anodes[J]. Energy Storage Materials, 2019, 18: 389-396. DOI: 10.1016/j.ensm.2019.02.006. |

| 37 | ZHAO Y, AMIRMALEKI M, SUN Q, et al. Natural SEI-inspired dual-protective layers via atomic/molecular layer deposition for long-life metallic lithium anode[J]. Matter, 2019, 1(5): 1215-1231. DOI: 10.1016/j.matt.2019.06.020. |

| 38 | STALIN S, CHEN P Y, LI G J, et al. Ultrathin zwitterionic polymeric interphases for stable lithium metal anodes[J]. Matter, 2021, 4(11): 3753-3773. DOI: 10.1016/j.matt.2021.09.025. |

| 39 | CAO S L, HE X, NIE L L, et al. CF4 plasma-generated LiF-Li2C2 artificial layers for dendrite-free lithium-metal anodes[J]. Advanced Science, 2022, 9(21): e2201147. DOI: 10.1002/advs. 202201147. |

| 40 | WANG H, HU P, LIU X T, et al. Sowing silver seeds within patterned ditches for dendrite-free lithium metal batteries[J]. Advanced Science, 2021, 8(14): e2100684. DOI: 10.1002/advs.202100684. |

| 41 | RYOU M H, LEE Y M, LEE Y J, et al. Mechanical surface modification of lithium metal: Towards improved Li metal anode performance by directed Li plating[J]. Advanced Functional Materials, 2015, 25(6): 834-841. DOI: 10.1002/adfm.201402953. |

| 42 | WAN M T, KANG S J, WANG L, et al. Mechanical rolling formation of interpenetrated lithium metal/lithium tin alloy foil for ultrahigh-rate battery anode[J]. Nature Communications, 2020, 11(1): 829. DOI: 10.1038/s41467-020-14550-3. |

| 43 | CAO J Q, SHI Y S, GAO A S, et al. Hierarchical Li electrochemistry using alloy-type anode for high-energy-density Li metal batteries[J]. Nature Communications, 2024, 15(1): 1354. DOI: 10.1038/s41467-024-45613-4. |

| 44 | LI Q, QUAN B G, LI W J, et al. Electro-plating and stripping behavior on lithium metal electrode with ordered three-dimensional structure[J]. Nano Energy, 2018, 45: 463-470. DOI: 10.1016/j.nanoen.2018.01.019. |

| 45 | KIM H, GONG Y J, YOO J, et al. Highly stable lithium metal battery with an applied three-dimensional mesh structure interlayer[J]. Journal of Materials Chemistry A, 2018, 6(32): 15540-15545. DOI: 10.1039/C8TA05069D. |

| 46 | WANG D, LUAN C, ZHANG W, et al. Zipper-inspired SEI film for remarkably enhancing the stability of Li metal anode via nucleation barriers controlled weaving of lithium pits[J]. Advanced Energy Materials, 2018, 8(21): 1800650. DOI: 10.1002/aenm. 201800650. |

| 47 | XU H, LI S, ZHANG C, et al. Roll-to-roll prelithiation of Sn foil anode suppresses gassing and enables stable full-cell cycling of lithium ion batteries[J]. Energy & Environmental Science, 2019, 12(10): 2991-3000. DOI: 10.1039/C9EE01404G. |

| 48 | WANG H S, LIN D C, LIU Y Y, et al. Ultrahigh-current density anodes with interconnected Li metal reservoir through overlithiation of mesoporous AlF3 framework[J]. Science Advances, 2017, 3(9): e1701301. DOI: 10.1126/sciadv.1701301. |

| 49 | LIU S F, JI X, YUE J, et al. High interfacial-energy interphase promoting safe lithium metal batteries[J]. Journal of the American Chemical Society, 2020, 142(5): 2438-2447. DOI: 10.1021/jacs.9b11750. |

| 50 | PENG Z, ZHAO N, ZHANG Z G, et al. Stabilizing Li/electrolyte interface with a transplantable protective layer based on nanoscale LiF domains[J]. Nano Energy, 2017, 39: 662-672. DOI: 10.1016/j.nanoen.2017.07.052. |

| 51 | LEE D, SUN S, KWON J, et al. Copper nitride nanowires printed Li with stable cycling for Li metal batteries in carbonate electrolytes[J]. Advanced Materials, 2020, 32(7): 1905573. DOI: 10.1002/adma.201905573. |

| 52 | YE S F, WANG L F, LIU F F, et al. g-C3N4 derivative artificial organic/inorganic composite solid electrolyte interphase layer for stable lithium metal anode[J]. Advanced Energy Materials, 2020, 10(44): 2002647. DOI: 10.1002/aenm.202002647. |

| 53 | XIA S X, LI C R, YUWONO J A, et al. Scalable production of thin and durable practical Li metal anode for high-energy-density batteries[J]. Angewandte Chemie International Edition, 2024, 63(48): e202409327. DOI: 10.1002/anie.202409327. |

| 54 | HAN B, FENG D Y, LI S, et al. Self-regulated phenomenon of inorganic artificial solid electrolyte interphase for lithium metal batteries[J]. Nano Letters, 2020, 20(5): 4029-4037. DOI: 10.1021/acs.nanolett.0c01400. |

| 55 | CHENG X B, HOU T Z, ZHANG R, et al. Dendrite-free lithium deposition induced by uniformly distributed lithium ions for efficient lithium metal batteries[J]. Advanced Materials, 2016, 28(15): 2888-2895. DOI: 10.1002/adma.201506124. |

| 56 | ZHENG G Y, WANG C, PEI A, et al. High-performance lithium metal negative electrode with a soft and flowable polymer coating[J]. ACS Energy Letters, 2016, 1(6): 1247-1255. DOI: 10.1021/acsenergylett.6b00456. |

| 57 | LIU H H, TAO R M, GUO C, et al. Lithiated halloysite nanotube/cross-linked network polymer composite artificial solid electrolyte interface layer for high-performance lithium metal batteries[J]. Chemical Engineering Journal, 2022, 429: 132239. DOI: 10.1016/j.cej.2021.132239. |

| 58 | WANG T Y, LI Y B, ZHANG J Q, et al. Immunizing lithium metal anodes against dendrite growth using protein molecules to achieve high energy batteries[J]. Nature Communications, 2020, 11(1): 5429. DOI: 10.1038/s41467-020-19246-2. |

| 59 | GAO R M, YANG H, WANG C Y, et al. Fatigue-resistant interfacial layer for safe lithium metal batteries[J]. Angewandte Chemie International Edition, 2021, 60(48): 25508-25513. DOI: 10.1002/anie.202111199. |

| 60 | ZHANG D, YIN Y L, LIU C H, et al. Modified secondary lithium metal batteries with the polyaniline-carbon nanotube composite buffer layer[J]. Chemical Communications, 2015, 51(2): 322-325. DOI: 10.1039/c4cc08083a. |

| 61 | KIM M S, KIM M S, DO V, et al. Designing solid-electrolyte interphases for lithium sulfur electrodes using ionic shields[J]. Nano Energy, 2017, 41: 573-582. DOI: 10.1016/j.nanoen.2017.10.018. |

| 62 | MA C, ZOU S H, WU Y X, et al. A triply-periodic-minimal-surface structured interphase based on fluorinated polymers strengthening high-energy lithium metal batteries[J]. Angewandte Chemie International Edition, 2024, 63(20): e202402910. DOI: 10.1002/anie.202402910. |

| 63 | YAN C, XU R, XIAO Y, et al. Toward critical electrode/electrolyte interfaces in rechargeable batteries[J]. Advanced Functional Materials, 2020, 30(23): 1909887. DOI: 10.1002/adfm.201909887. |

| 64 | CHEN P Y, YAN C, CHEN P Y, et al. Selective permeable lithium-ion channels on lithium metal for practical lithium-sulfur pouch cells[J]. Angewandte Chemie International Edition, 2021, 60(33): 18031-18036. DOI: 10.1002/anie.202101958. |

| 65 | GAO Y, ZHAO Y M, LI Y C, et al. Interfacial chemistry regulation via a skin-grafting strategy enables high-performance lithium-metal batteries[J]. Journal of the American Chemical Society, 2017, 139(43): 15288-15291. DOI: 10.1021/jacs.7b06437. |

| 66 | LIU H, ZHEN F X, YIN X K, et al. Ultra-tough dynamic supramolecular ion-conducting elastomer induced uniform Li+ transport and stabilizes interphase ensures dendrite-free lithium metal anodes[J]. Angewandte Chemie International Edition, 2025, 64(2): e202414599. DOI: 10.1002/anie.202414599. |

| 67 | HU P, CHEN W, WANG Y, et al. Fatigue-free and skin-like supramolecular ion-conductive elastomeric interphases for stable lithium metal batteries[J]. ACS Nano, 2023, 17(16): 16239-16251. DOI: 10.1021/acsnano.3c06171. |

| 68 | WU J Y, RAO Z X, LIU X T, et al. Polycationic polymer layer for air-stable and dendrite-free Li metal anodes in carbonate electrolytes[J]. Advanced Materials, 2021, 33(12): e2007428. DOI: 10.1002/adma.202007428. |

| 69 | HUANG H Y, LIU S S, XIE Y X, et al. Constructing an artificial interface as a bifunctional promoter for the Li anode and the NCM cathode in lithium metal batteries[J]. Journal of the American Chemical Society, 2024, 146(45): 31137-31149. DOI: 10.1021/jacs.4c11012. |

| 70 | DENG C L, YANG B B, LIANG Y H, et al. Bipolar polymeric protective layer for dendrite-free and corrosion-resistant lithium metal anode in ethylene carbonate electrolyte[J]. Angewandte Chemie International Edition, 2024, 63(17): e202400619. DOI: 10.1002/anie.202400619. |

| 71 | YAO Y Z, ZHAO X H, RAZZAQ A A, et al. Mosaic rGO layers on lithium metal anodes for the effective mediation of lithium plating and stripping[J]. Journal of Materials Chemistry A, 2019, 7(19): 12214-12224. DOI: 10.1039/C9TA03679B. |

| 72 | LIU W, XIA Y T, WANG W W, et al. Pristine or highly defective? Understanding the role of graphene structure for stable lithium metal plating[J]. Advanced Energy Materials, 2019, 9(3): 1802918. DOI: 10.1002/aenm.201802918. |

| 73 | CHEN Y T, ABBAS S A, KAISAR N, et al. Mitigating metal dendrite formation in lithium-sulfur batteries via morphology-tunable graphene oxide interfaces[J]. ACS Applied Materials & Interfaces, 2019, 11(2): 2060-2070. DOI: 10.1021/acsami.8b18379. |

| 74 | YE L, LIAO M, CHENG X R, et al. Lithium-metal anodes working at 60 mA·cm-2 and 60 mA·cm-2 through nanoscale lithium-ion adsorbing[J]. Angewandte Chemie International Edition, 2021, 60(32): 17419-17425. DOI: 10.1002/anie.202106047. |

| 75 | YAN C, CHENG X B, TIAN Y, et al. Dual-layered film protected lithium metal anode to enable dendrite-free lithium deposition[J]. Advanced Materials, 2018, 30(25): e1707629. DOI: 10.1002/adma.201707629. |

| 76 | CHEN J, DENG X T, JIA X, et al. Li+ ion-dipole interaction-enabled a dynamic supramolecular elastomer interface layer for dendrite-free lithium metal anodes[J]. Journal of the American Chemical Society, 2024, 146(45): 30836-30847. DOI: 10.1021/jacs.4c08766. |

| 77 | POKHAREL J, CRESCE A, PANT B, et al. Manipulating the diffusion energy barrier at the lithium metal electrolyte interface for dendrite-free long-life batteries[J]. Nature Communications, 2024, 15(1): 3085. DOI: 10.1038/s41467-024-47521-z. |

| 78 | XIE Y X, HUANG Y X, ZHANG Y G, et al. Surface modification using heptafluorobutyric acid to produce highly stable Li metal anodes[J]. Nature Communications, 2023, 14(1): 2883. DOI: 10.1038/s41467-023-38724-x. |

| 79 | YUE L G, WANG X Y, CHEN L, et al. In situ interface engineering of highly nitrogen-rich triazine-based covalent organic frameworks for an ultra-stable, dendrite-free lithium-metal anode[J]. Energy & Environmental Science, 2024, 17(3): 1117-1131. DOI: 10.1039/D3EE02803H. |

| 80 | SUN Z H, WANG Y K, SHEN S Y, et al. Directing (110) oriented lithium deposition through high-flux solid electrolyte interphase for dendrite-free lithium metal batteries[J]. Angewandte Chemie International Edition, 2023, 62(41): e202309622. DOI: 10.1002/anie.202309622. |

| 81 | JIN C B, HUANG Y Y, LI L H, et al. A corrosion inhibiting layer to tackle the irreversible lithium loss in lithium metal batteries[J]. Nature Communications, 2023, 14(1): 8269. DOI: 10.1038/s41467-023-44161-7. |

| 82 | CHEN C, LIANG Q W, WANG G, et al. Grain-boundary-rich artificial SEI layer for high-rate lithium metal anodes[J]. Advanced Functional Materials, 2022, 32(4): 2107249. DOI: 10.1002/adfm.202107249. |

| 83 | HU A J, CHEN W, DU X C, et al. An artificial hybrid interphase for an ultrahigh-rate and practical lithium metal anode[J]. Energy & Environmental Science, 2021, 14(7): 4115-4124. DOI: 10.1039/D1EE00508A. |

| 84 | GUO W, HAN Q, JIAO J R, et al. In situ construction of robust biphasic surface layers on lithium metal for lithium-sulfide batteries with long cycle life[J]. Angewandte Chemie International Edition, 2021, 60(13): 7267-7274. DOI: 10.1002/anie.202015049. |

| 85 | LIN L, SUO L, HU Y, et al. Epitaxial induced plating current-collector lasting lifespan of anode-free lithium metal battery[J]. Advanced Energy Materials, 2021, 11(9): 2003709. DOI: 10.1002/aenm.202003709 |

| 86 | ZHAO Y M, LI G X, GAO Y, et al. Stable Li metal anode by a hybrid lithium polysulfidophosphate/polymer cross-linking film[J]. ACS Energy Letters, 2019, 4(6): 1271-1278. DOI: 10.1021/acsenergylett.9b00539. |

| 87 | XU R, CHENG X B, YAN C, et al. Artificial interphases for highly stable lithium metal anode[J]. Matter, 2019, 1(2): 317-344. DOI: 10.1016/j.matt.2019.05.016. |

| 88 | WANG W W, GU Y, YAN H, et al. Evaluating solid-electrolyte interphases for lithium and lithium-free anodes from nanoindentation features[J]. Chem, 2020, 6(10): 2728-2745. DOI: 10.1016/j.chempr.2020.07.014. |

| 89 | LIN X D, GU Y, SHEN X R, et al. An oxygen-blocking oriented multifunctional solid-electrolyte interphase as a protective layer for a lithium metal anode in lithium-oxygen batteries[J]. Energy & Environmental Science, 2021, 14(3): 1439-1448. DOI: 10.1039/D0EE02931A. |

| 90 | GU Y, WANG W W, HE J W, et al. Electrochemical polishing of lithium metal surface for highly demanding solid-electrolyte interphase[J]. ChemElectroChem, 2019, 6(1): 181-188. DOI: 10.1002/celc.201800907. |

| 91 | LU G X, NAI J W, YUAN H D, et al. In-situ electrodeposition of nanostructured carbon strengthened interface for stabilizing lithium metal anode[J]. ACS Nano, 2022, 16(6): 9883-9893. DOI: 10.1021/acsnano.2c04025. |

| 92 | LU G X, LI S, YUE K, et al. Electrolytic construction of nanosphere-assembled protective layer toward stable lithium metal anode[J]. Battery Energy, 2023, 2(6): 20230044. DOI: 10.1002/bte2.20230044. |

| 93 | ZHANG X Q, CHENG X B, ZHANG Q. Advances in interfaces between Li metal anode and electrolyte[J]. Advanced Materials Interfaces, 2018, 5(2): 1701097. DOI: 10.1002/admi.201701097. |

| 94 | REYES JIMÉNEZ A, KLÖPSCH R, WAGNER R, et al. A step toward high-energy silicon-based thin film lithium ion batteries[J]. ACS Nano, 2017, 11(5): 4731-4744. DOI: 10.1021/acsnano.7b00922. |

| 95 | CHEN T, MENG F B, ZHANG Z W, et al. Stabilizing lithium metal anode by molecular beam epitaxy grown uniform and ultrathin bismuth film[J]. Nano Energy, 2020, 76: 105068. DOI: 10.1016/j.nanoen.2020.105068. |

| 96 | XIE J, LIAO L, GONG Y J, et al. Stitching h-BN by atomic layer deposition of LiF as a stable interface for lithium metal anode[J]. Science Advances, 2017, 3(11): eaao3170. DOI: 10.1126/sciadv.aao3170. |

| 97 | BAE J, CHOI K, SONG H, et al. Reinforcing native solid-electrolyte interphase layers via electrolyte-swellable soft-scaffold for lithium metal anode[J]. Advanced Energy Materials, 2023, 13(16): 2203818. DOI: 10.1002/aenm.202203818. |

| 98 | LI P L, FENG W L, DONG X L, et al. A new strategy of constructing a highly fluorinated solid-electrolyte interface towards high-performance lithium anode[J]. Advanced Materials Interfaces, 2020, 7(11): 2000154. DOI: 10.1002/admi.202000154. |

| 99 | GAO C H, DONG Q Y, ZHANG G, et al. Antimony-doped lithium phosphate artificial solid electrolyte interphase for dendrite-free lithium-metal batteries[J]. ChemElectroChem, 2019, 6(4): 1134-1138. DOI: 10.1002/celc.201801410. |

| 100 | HAO X, ZHAO Q, SU S, et al. Constructing multifunctional interphase between Li1.4Al0.4Ti1.6(PO4)3 and Li metal by magnetron sputtering for highly stable solid-state lithium metal batteries[J]. Advanced Energy Materials, 2019, 9(34): 1901604. DOI: 10.1002/aenm.201901604. |

| 101 | PATHAK R, CHEN K, GURUNG A, et al. Ultrathin bilayer of graphite/SiO2 as solid interface for reviving Li metal anode[J]. Advanced Energy Materials, 2019, 9(36): 1901486. DOI: 10.1002/aenm.201901486. |

| 102 | ZHANG Y J, LIU X Y, BAI W Q, et al. Magnetron sputtering amorphous carbon coatings on metallic lithium: Towards promising anodes for lithium secondary batteries[J]. Journal of Power Sources, 2014, 266: 43-50. DOI: 10.1016/j.jpowsour. 2014.04.147. |

| 103 | YAN K, LEE H W, GAO T, et al. Ultrathin two-dimensional atomic crystals as stable interfacial layer for improvement of lithium metal anode[J]. Nano Letters, 2014, 14(10): 6016-6022. DOI: 10.1021/nl503125u. |

| 104 | WANG M M, CHENG X P, CAO T C, et al. Constructing ultrathin TiO2 protection layers via atomic layer deposition for stable lithium metal anode cycling[J]. Journal of Alloys and Compounds, 2021, 865: 158748. DOI: 10.1016/j.jallcom. 2021.158748. |

| 105 | KOZEN A C, LIN C F, PEARSE A J, et al. Next-generation lithium metal anode engineering via atomic layer deposition[J]. ACS Nano, 2015, 9(6): 5884-5892. DOI: 10.1021/acsnano.5b02166. |

| 106 | ZHAO Y, SUN X L. Molecular layer deposition for energy conversion and storage[J]. ACS Energy Letters, 2018, 3(4): 899-914. DOI: 10.1021/acsenergylett.8b00145. |

| 107 | SUN Y P, ZHAO Y, WANG J W, et al. A novel organic "polyurea" thin film for ultralong-life lithium-metal anodes via molecular-layer deposition[J]. Advanced Materials, 2019, 31(4): 1806541. DOI: 10.1002/adma.201806541. |

| 108 | SUN Y P, AMIRMALEKI M, ZHAO Y, et al. Tailoring the mechanical and electrochemical properties of an artificial interphase for high-performance metallic lithium anode[J]. Advanced Energy Materials, 2020, 10(28): 2001139. DOI: 10.1002/aenm.202001139. |

| 109 | SUN Y P, ZHAO C T, ADAIR K R, et al. Regulated lithium plating and stripping by a nano-scale gradient inorganic-organic coating for stable lithium metal anodes[J]. Energy & Environmental Science, 2021, 14(7): 4085-4094. DOI: 10.1039/D1EE01140E. |

| 110 | ZHAO J, LIAO L, SHI F F, et al. Surface fluorination of reactive battery anode materials for enhanced stability[J]. Journal of the American Chemical Society, 2017, 139(33): 11550-11558. DOI: 10.1021/jacs.7b05251. |

| 111 | LI Y B, SUN Y M, PEI A, et al. Robust pinhole-free Li3N solid electrolyte grown from molten lithium[J]. ACS Central Science, 2018, 4(1): 97-104. DOI: 10.1021/acscentsci.7b00480. |

| 112 | LIN Y X, WEN Z P, LIU J X, et al. Constructing a uniform lithium iodide layer for stabilizing lithium metal anode[J]. Journal of Energy Chemistry, 2021, 55: 129-135. DOI: 10.1016/j.jechem.2020.07.003. |

| 113 | NAN Y, LI S M, ZHU M Q, et al. Endowing the lithium metal surface with self-healing property via an in situ gas-solid reaction for high-performance lithium metal batteries[J]. ACS Applied Materials & Interfaces, 2019, 11(32): 28878-28884. DOI: 10.1021/acsami.9b07942. |

| 114 | CHEN H, PEI A, LIN D C, et al. Uniform high ionic conducting lithium sulfide protection layer for stable lithium metal anode[J]. Advanced Energy Materials, 2019, 9(22): 1900858. DOI: 10.1002/aenm.201900858. |

| 115 | LIU F F, WANG L F, ZHANG Z W, et al. A mixed lithium-ion conductive Li2S/Li2Se protection layer for stable lithium metal anode[J]. Advanced Functional Materials, 2020, 30(23): 2001607. DOI: 10.1002/adfm.202001607. |

| 116 | LIU F, XIAO Q F, WU H B, et al. Fabrication of hybrid silicate coatings by a simple vapor deposition method for lithium metal anodes[J]. Advanced Energy Materials, 2018, 8(6): 1701744. DOI: 10.1002/aenm.201701744. |

| 117 | ZHANG L T, JO S, SHIN K H, et al. Novel artificial hybrid LiF/h-BN protective layer constructed on solid polymer electrolyte for highly durable Li metal batteries[J]. Journal of Power Sources, 2024, 615: 235068. DOI: 10.1016/j.jpowsour.2024.235068. |

| 118 | ZHENG J, YANG R, XIE L, et al. Plasma-assisted approaches in inorganic nanostructure fabrication[J]. Advanced Materials, 2010, 22(13): 1451-1473. DOI: 10.1002/adma.200903147. |

| 119 | LIANG H F, MING F W, ALSHAREEF H N. Applications of plasma in energy conversion and storage materials[J]. Advanced Energy Materials, 2018, 8(29): 1801804. DOI: 10.1002/aenm. 201801804. |

| [1] | 梁毅, 韦韬, 殷广达, 黄德权. 亲锂Ag-3D-Cu电极的设计及电化学性质[J]. 储能科学与技术, 2025, 14(2): 515-524. |

| [2] | 石敏, 蒋鹏杰, 徐琛, 贺鑫, 梁宵. 抑制锂金属负极枝晶的电解液调控策略[J]. 储能科学与技术, 2024, 13(5): 1620-1634. |

| [3] | 李文彪, 耿海涛, 高一博, 高召顺, 王宝. Cu-In/Bi合金中亲锂位点诱导均匀锂成核实现高倍率锂金属电池[J]. 储能科学与技术, 2023, 12(9): 2735-2745. |

| [4] | 韩雨, 曹盛玲, 宁靖, 王康丽, 蒋凯, 周敏. 聚合物改性锂金属电池界面策略研究综述[J]. 储能科学与技术, 2023, 12(8): 2491-2503. |

| [5] | 沈馨, 张睿, 赵辰孜, 武鹏, 张羽彤, 张俊东, 范丽珍, 刘全兵, 陈爱兵, 张强. 金属锂电池中力-电化学机制研究进展[J]. 储能科学与技术, 2022, 11(9): 2781-2797. |

| [6] | 乔东格, 刘训良, 温治, 豆瑞峰, 周文宁. 升温和脉冲充电对锂枝晶生长抑制作用的数值分析[J]. 储能科学与技术, 2022, 11(3): 1008-1018. |

| [7] | 娄永钢, 吴大勇, 蔡博然, 梁卫华, 杨璐烨, 何磊, 操建华. 芳纶-固态离子导体复合隔膜的制备与性能[J]. 储能科学与技术, 2022, 11(10): 3112-3122. |

| [8] | 高金辉, 陈英龙, 孟繁慧, 丁美超, 王莉, 许刚, 何向明. 锂离子电池原位光学显微观测[J]. 储能科学与技术, 2022, 11(1): 53-59. |

| [9] | 许卓, 郑莉莉, 陈兵, 张涛, 常修亮, 韦守李, 戴作强. 固态电池复合电解质研究综述[J]. 储能科学与技术, 2021, 10(6): 2117-2126. |

| [10] | 刘洋洋, 王旭阳, 徐谢宇, 王永静, 熊仕昭, 宋忠孝. 锂金属负极用集流体改性研究及进展[J]. 储能科学与技术, 2021, 10(4): 1261-1272. |

| [11] | 李伟辉, 钟兴国, 李会巧. 金属锂的钝化保护及应用[J]. 储能科学与技术, 2021, 10(3): 974-986. |

| [12] | 冯建文, 胡时光, 韩 兵, 肖映林, 邓永红, 王朝阳. 锂金属电池电解液组分调控的研究进展[J]. 储能科学与技术, 2020, 9(6): 1629-1640. |

| [13] | 方聪聪, 刘雯, 王勇, 郭瑞, 裴海娟, 于升学, 解晶莹. 金属锂电极的原位物理表征[J]. 储能科学与技术, 2018, 7(S1): 54-62. |

| [14] | 张魏栋,范 磊,朱守圃,陆盈盈. 高容量锂硫电池近期研究进展[J]. 储能科学与技术, 2017, 6(3): 534-549. |

| [15] | 石 凯,安德成,贺艳兵,李宝华,康飞宇. 基于聚合物电解质固态锂硫电池的研究进展和发展趋势[J]. 储能科学与技术, 2017, 6(3): 479-492. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||