Energy Storage Science and Technology ›› 2024, Vol. 13 ›› Issue (10): 3388-3399.doi: 10.19799/j.cnki.2095-4239.2024.0669

• Energy Storage Materials and Devices • Previous Articles Next Articles

Xianfeng DONG1( ), Zhiguo ZHANG1(

), Zhiguo ZHANG1( ), Huaqing LI2, Li WANG1, Xiangming HE1

), Huaqing LI2, Li WANG1, Xiangming HE1

Received:2024-07-18

Online:2024-10-28

Published:2024-10-30

Contact:

Zhiguo ZHANG

E-mail:dxf24@mails.tsinghua.edu.cn;zhangzhiguohit@gmail.com

CLC Number:

Xianfeng DONG, Zhiguo ZHANG, Huaqing LI, Li WANG, Xiangming HE. Challenges and improvement measures of plastic film composite current collectors for lithium-ion batteries[J]. Energy Storage Science and Technology, 2024, 13(10): 3388-3399.

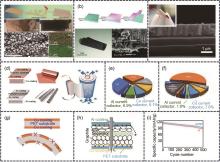

Fig. 1

Main types of current collectors and the structure and characteristics of PFCC: (a)—(c) Metal-based, conductive carbon material-based and plastic film composite current collector; (d) PFCC schematic diagram; (e), (f) Mass proportion and cost proportion of each battery component; (g), (h) Improve extrusion and acupuncture safety; (i) Improve cycle stability"

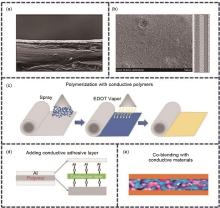

Fig. 6

Technical measures to improve the conductivity of PFCC: (a) Strengthening the conductivity of the metal layer from multiple angles; (b) Constructing a through-hole structure of the polymer base film; (c) Composite conductive polymer; (d) Additional conductive adhesive layer; (e) Doping conductive materials"

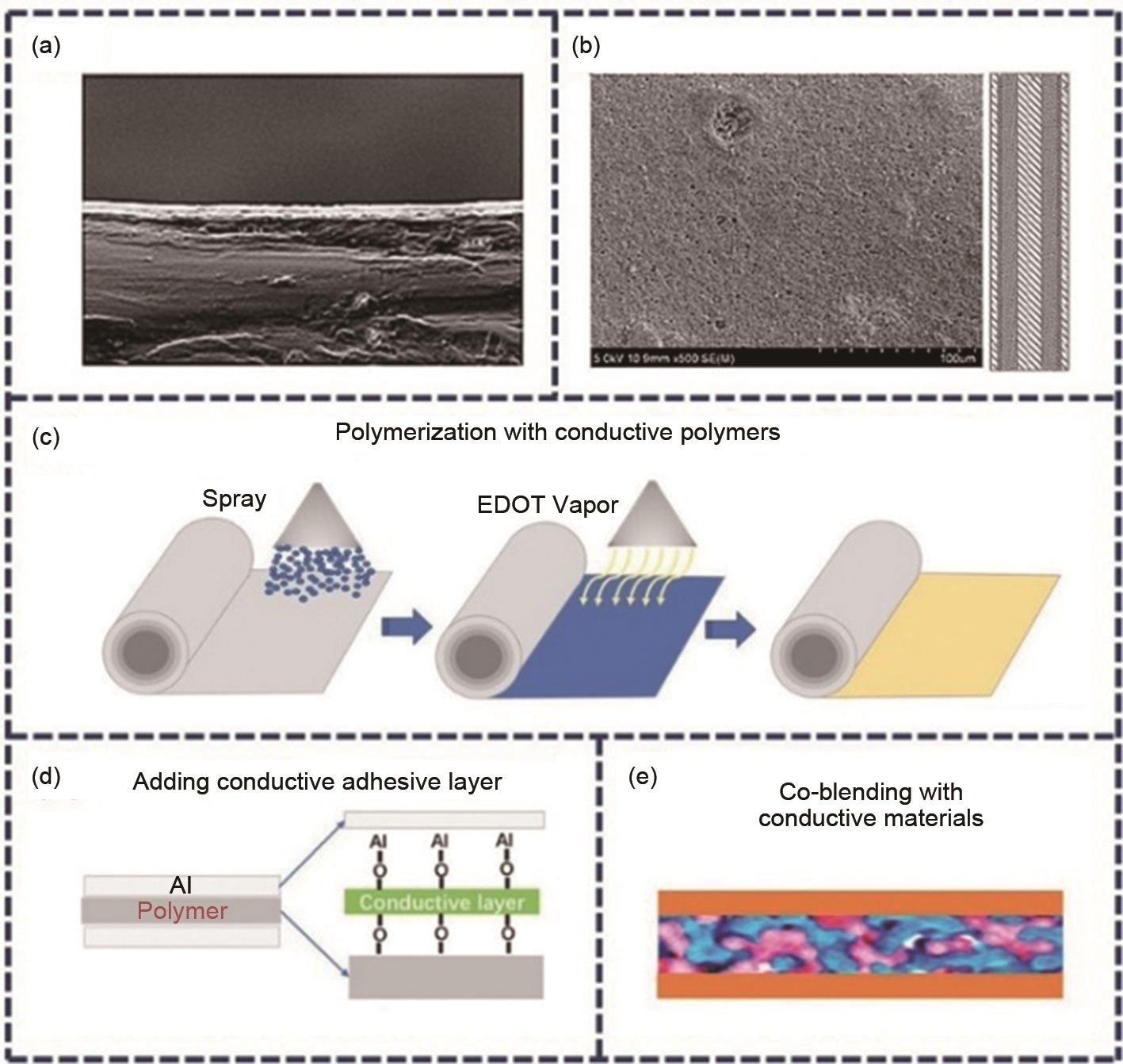

Fig. 7

Technical measures to strengthen the corrosion resistance of PFCC: (a) Form a dense Al2O3 layer on the metal surface; (b) Set a regular rough morphology on the metal surface; (c), (d) Set up an interlayer corrosion-resistant strengthening layer; (e) Control the electrolyte solvation environment"

| 1 | WANG Q Y, ZHU M, CHEN G R, et al. High-performance microsized Si anodes for lithium-ion batteries: Insights into the polymer configuration conversion mechanism[J]. Advanced Materials, 2022, 34(16): e2109658. DOI: 10.1002/adma.202109658. |

| 2 | HAN B, XU D W, CHI S S, et al. 500 wh/kg class Li metal battery enabled by a self-organized core-shell composite anode[J]. Advanced Materials, 2020, 32(42): 2004793. DOI: 10.1002/adma.202004793. |

| 3 | 高鹏飞, 杨军. 锂离子电池硅复合负极材料研究进展[J]. 化学进展, 2011, 23(S1): 264-274. |

| GAO P F, YANG J. Si-based composite anode materials for Li-ion batteries[J]. Progress in Chemistry, 2011, 23(S1): 264-274. | |

| 4 | 张玉坤, 邹朝辉, 张云霞. 锂离子电池用先进集流体的应用研究[J]. 有色金属加工, 2023, 52(4): 1-5. DOI: 10.3969/j.issn.1671-6795.2023.04.001. |

| ZHANG Y K, ZOU C H, ZHANG Y X. Application research of advanced fluid collector for lithium ion battery[J]. Nonferrous Metals Processing, 2023, 52(4): 1-5. DOI: 10.3969/j.issn.1671-6795.2023.04.001. | |

| 5 | ZHU P C, GASTOL D, MARSHALL J, et al. A review of current collectors for lithium-ion batteries[J]. Journal of Power Sources, 2021, 485: 229321. DOI: 10.1016/j.jpowsour.2020.229321. |

| 6 | 熊明华, 冯连朋, 李华清. 电池集流体材料的研发与应用[J]. 化工新型材料, 2023, 51(S1): 241-247. DOI: 10.19817/j.cnki.issn1006-3536.2023.S1.043. |

| XIONG M H, FENG L P, LI H Q. Development and application of battery current collector materials[J]. New Chemical Materials, 2023, 51(S1): 241-247. DOI: 10.19817/j.cnki.issn1006-3536.2023.S1.043. | |

| 7 | 齐大志, 程滋平, 刘慧芳, 等. 一种复合集流体极耳连接结构: CN219779156U[P]. 2023-09-29. |

| 8 | 李凯, 李昭, 张辉, 等. 复合集流体基膜、复合集流体以及电芯: CN116706087A[P]. 2023-09-05. |

| 9 | 张稚国, 李华清, 王莉, 等. 锂离子电池塑料-金属复合集流体的特性及制备研究进展[J]. 储能科学与技术, 2024, 13(3): 749-758. |

| ZHANG Z G, LI H Q, WANG L, et al. Characteristics and preparation of metallized plastic current collectors for lithium-ion batteries[J]. Energy Storage Science and Technology, 2024, 13(3): 749-758. | |

| 10 | 田海玉. 一种复合箔极片集流体及其制备方法: CN116581300A[P]. 2023-08-11. |

| 11 | 刘畅, 周海平, 吴孟强, 等. 一种复合集流体的制备方法: CN116676556A[P]. 2023-09-01. |

| 12 | 王成豪, 李学法, 张国平. 低溶胀的复合集流体及其制备方法: CN114864953A[P]. 2022-08-05. |

| 13 | CHEN J Y, LI S J, QIAO X, et al. Integrated porous Cu host induced high-stable bidirectional Li plating/stripping behavior for practical Li metal batteries[J]. Small, 2022, 18(6): e2105999. DOI: 10.1002/smll.202105999. |

| 14 | 程杰, 孙世强, 曹高萍, 等. 一种耐腐蚀复合集流体及其制作方法: CN101192669A[P]. 2008-06-04. |

| 15 | HO P S. Chemistry and adhesion of metal-polymer interfaces[J]. Applied Surface Science, 1990, 41: 559-566. DOI: 10.1016/0169-4332(89)90122-0. |

| 16 | PAIK K W, RUOFF A L. Adhesion enhancement of thin copper film on polyimide modified by oxygen reactive ion beam etching[J]. Journal of Adhesion Science and Technology, 1990, 4(1): 465-474. DOI: 10.1163/156856190x00432. |

| 17 | STRULLER C F, KELLY P J, COPELAND N J. Aluminum oxide barrier coatings on polymer films for food packaging applications[J]. Surface and Coatings Technology, 2014, 241: 130-137. DOI: 10.1016/j.surfcoat.2013.08.011. |

| 18 | KOUICEM M M, TOMASELLA E, BOUSQUET A, et al. An investigation of adhesion mechanisms between plasma-treated PMMA support and aluminum thin films deposited by PVD[J]. Applied Surface Science, 2021, 564: 150322. DOI: 10.1016/j.apsusc.2021.150322. |

| 19 | MWEMA F M, OLADIJO O P, AKINLABI S A, et al. Properties of physically deposited thin aluminium film coatings: A review[J]. Journal of Alloys and Compounds, 2018, 747: 306-323. DOI: 10.1016/j.jallcom.2018.03.006. |

| 20 | ZHANG Z G, SONG Y Z, ZHANG B, et al. Metallized plastic foils: A promising solution for high-energy lithium-ion battery current collectors[J]. Advanced Energy Materials, 2023, 13(36): 2302134. DOI: 10.1002/aenm.202302134. |

| 21 | 范琼. 一种新型复合集电体及其制备方法: CN115498193A[P]. 2022-12-20. |

| 22 | 胡华胜, 朱行威, 胡耀强. 一种复合结构柔性集流体及其制备方法: CN114784291A[P]. 2022-07-22. |

| 23 | 崔言明, 许晓雄, 丁少, 等. 一种复合集流体的焊接结构: CN217983404U[P]. 2022-12-06. |

| 24 | ZAMESHIN A, POPOV M, MEDVEDEV V, et al. Electrical conductivity of nanostructured and C60-modified aluminum[J]. Applied Physics A, 2012, 107(4): 863-869. DOI: 10.1007/s00339-012-6805-x. |

| 25 | YOON E, LEE J, BYUN S, et al. Passivation failure of Al current collector in LiPF6-based electrolytes for lithium-ion batteries[J]. Advanced Functional Materials, 2022, 32(22): 2200026. DOI: 10.1002/adfm.202200026. |

| 26 | LOGAN E R, HEBECKER H, ELDESOKY A, et al. Performance and degradation of LiFePO4/graphite cells: The impact of water contamination and an evaluation of common electrolyte additives[J]. Journal of the Electrochemical Society, 2020, 167(13): 130543. DOI: 10.1149/1945-7111/abbbbe. |

| 27 | BUECHELE S, LOGAN E, BOULANGER T, et al. Reversible self-discharge of LFP/graphite and NMC811/graphite cells originating from redox shuttle generation[J]. Journal of the Electrochemical Society, 2023, 170(1): 010518. DOI: 10.1149/1945-7111/acb10c. |

| 28 | BUECHELE S, ADAMSON A, ELDESOKY A, et al. Identification of redox shuttle generated in LFP/graphite and NMC811/graphite cells[J]. Journal of the Electrochemical Society, 2023, 170(1): 010511. DOI: 10.1149/1945-7111/acaf44. |

| 29 | ADAMSON A, TUUL K, BÖTTICHER T, et al. Improving lithium-ion cells by replacing polyethylene terephthalate jellyroll tape[J]. Nature Materials, 2023, 22(11): 1380-1386. DOI: 10.1038/s41563-023-01673-3. |

| 30 | 陈海. 锂离子电池正极铝集流体耐蚀性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2009.CHEN H. Study on the anti-corrosion of alumium current collector for lithium-ion battery[D]. Harbin: Harbin Institute of Technology, 2009. |

| 31 | 吕东生, 李伟善, 周震涛. 锂离子蓄电池铝集流体腐蚀的研究进展[J]. 电源技术, 2007, 31(10): 830-832. DOI: 10.3969/j.issn.1002-087X.2007.10.020. |

| LV D S, LI W S, ZHOU Z T. Development progress of corrosion of aluminum used as current collector for Li-ion battery[J]. Chinese Journal of Power Sources, 2007, 31(10): 830-832. DOI: 10.3969/j.issn.1002-087X.2007.10.020. | |

| 32 | YOON T, SOON J, LEE T J, et al. Dissolution of cathode–electrolyte interphase deposited on LiNi0.5Mn1.5O4 for lithium-ion batteries[J]. Journal of Power Sources, 2021, 503: 230051. DOI: 10.1016/j.jpowsour.2021.230051. |

| 33 | 翟兰兰, 凌国平, 郦剑. 金属/高分子涂层附着机理的研究方法[J]. 材料导报, 2006, 20(S2): 274-277. DOI: 10.3321/j.issn: 1005-023X.2006.z2.080. |

| ZHAI L L, LING G P, LI J. Review on the research techniques about the adhesion mechanisms of metals/polymer coatings[J]. Materials Reports, 2006, 20(S2): 274-277. DOI: 10.3321/j.issn: 1005-023X.2006.z2.080. | |

| 34 | LEE H Y, QU J M. Microstructure, adhesion strength and failure path at a polymer/roughened metal interface[J]. Journal of Adhesion Science and Technology, 2003, 17(2): 195-215. DOI: 10.1163/156856103762302005. |

| 35 | LEE H Y, KIM Y H, CHANG Y K. Fracture behaviors of nanowire-coated metal/polymer systems under mode-I loading condition[J]. Acta Materialia, 2004, 52(20): 5815-5828. DOI: 10.1016/j.actamat.2004.08.040. |

| 36 | SUN C, ZHANG D, WADSWORTH L C. Corona treatment of polyolefin films—A review[J]. Advances in Polymer Technology, 1999, 18(2): 171-180. |

| 37 | NEMANI S K, ANNAVARAPU R K, MOHAMMADIAN B, et al. Surface modification of polymers: Methods and applications[J]. Advanced Materials Interfaces, 2018, 5(24): 1801247. DOI: 10.1002/admi.201801247. |

| 38 | CHOI J Y, LEE D J, LEE Y M, et al. Silicon nanofibrils on a flexible current collector for bendable lithium-ion battery anodes[J]. Advanced Functional Materials, 2013, 23(17): 2108-2114. DOI: 10.1002/adfm.201202458. |

| 39 | PARK S J, KO T J, YOON J, et al. Highly adhesive and high fatigue-resistant copper/PET flexible electronic substrates[J]. Applied Surface Science, 2018, 427: 1-9. DOI: 10.1016/j.apsusc.2017.08.195. |

| 40 | 庄志, 王纯, 郭桂略, 等. 一种带有U型焊接区的复合集流体的制备方法: CN116072882A[P]. 2023-05-05. |

| 41 | WANG Z L, FURUYA A, YASUDA K, et al. Adhesion improvement of electroless copper to a polyimide film substrate by combining surface microroughening and imide ring cleavage[J]. Journal of Adhesion Science and Technology, 2002, 16(8): 1027-1040. DOI: 10.1163/156856102760146147. |

| 42 | WANG Y, NI L J, YANG F, et al. Facile preparation of a high-quality copper layer on epoxy resin via electroless plating for applications in electromagnetic interference shielding[J]. Journal of Materials Chemistry C, 2017, 5(48): 12769-12776. DOI: 10.1039/C7TC03823B. |

| 43 | CHEN X C, YOU B, ZHOU S X, et al. Surface and interface characterization of polyester-based polyurethane/nano-silica composites[J]. Surface and Interface Analysis, 2003, 35(4): 369-374. DOI: 10.1002/sia.1544. |

| 44 | 武佳, 冯庆, 贾波, 等. 一种PET铜箔、化学镀制备方法及其应用: CN116607134A[P]. 2023-08-18. |

| 45 | 陈兆平, 李凯, 张辉, 等. 纳米金属涂层及应用、复合集流体基膜和复合集流体: CN116487601A[P]. 2023-07-25. |

| 46 | 杨晓兵. 复合集流体、应用所述复合集流体的电池和电子装置: CN113795954B[P]. 2022-08-26. |

| 47 | 陈启武, 许涛, 王磊, 等. 一种超薄复合集流体的制备方法: CN114015994A[P]. 2022-02-08. |

| 48 | YAN L B, CHOUW N, JAYARAMAN K. Lateral crushing of empty and polyurethane-foam filled natural flax fabric reinforced epoxy composite tubes[J]. Composites Part B: Engineering, 2014, 63: 15-26. DOI: 10.1016/j.compositesb.2014.03.013. |

| 49 | LEPAGE D, SAVIGNAC L, SAULNIER M, et al. Modification of aluminum current collectors with a conductive polymer for application in lithium batteries[J]. Electrochemistry Communications, 2019, 102: 1-4. DOI: 10.1016/j.elecom.2019.03.009. |

| 50 | TRINH N D, SAULNIER M, LEPAGE D, et al. Conductive polymer film supporting LiFePO4 as composite cathode for lithium ion batteries[J]. Journal of Power Sources, 2013, 221: 284-289. DOI: 10.1016/j.jpowsour.2012.08.006. |

| 51 | SHENG L, ZHU D, YANG K, et al. Unraveling the hydrolysis mechanism of LiPF6 in electrolyte of lithium ion batteries[J]. Nano Letters, 2024, 24(2): 533-540. DOI: 10.1021/acs.nanolett.3c01682. |

| 52 | DI CENSO D, EXNAR I, GRAETZEL M. Non-corrosive electrolyte compositions containing perfluoroalkylsulfonyl imides for high power Li-ion batteries[J]. Electrochemistry Communications, 2005, 7(10): 1000-1006. DOI: 10.1016/j.elecom.2005.07.005. |

| 53 | 文越华, 任子涵, 邵玲, 等. 一种金属/碳复合集流体材料及其制备方法: CN106876716A[P]. 2017-06-20. |

| 54 | 陈鹏, 任宁, 姬学敏, 等. 涂炭铝箔在石墨/磷酸铁锂电池中的应用研究[J]. 新能源进展, 2017, 5(2): 157-162. DOI: 10.3969/j.issn.2095-560X.2017.02.013. |

| CHEN P, REN N, JI X M, et al. Investigation on graphite/LiFePO4 batteries fabircated by carbon-coated aluminum foil current collector[J]. Advances in New and Renewable Energy, 2017, 5(2): 157-162. DOI: 10.3969/j.issn.2095-560X.2017.02.013. | |

| 55 | CAO L J, LI L L, XUE Z, et al. The aluminum current collector with honeycomb-like surface and thick Al2O3 film increased durability and enhanced safety for lithium-ion batteries[J]. Journal of Porous Materials, 2020, 27(6): 1677-1683. DOI: 10.1007/s10934-020-00942-9. |

| 56 | 王帅, 朱中亚, 夏建中, 等. 复合集流体: CN218498103U[P]. 2023-02-17. |

| 57 | 周婷, 晁承鹏. 一种耐电解液的复合集流体: CN219163433U[P]. 2023-06-09. |

| 58 | 朱中亚, 王帅, 夏建中, 等. 耐溶胀型聚酯复合膜及其制备方法和应用: CN115447246A[P]. 2022-12-09. |

| [1] | Zhonglin SUN, Jiabo LI, Di TIAN, Zhixuan WANG, Xiaojing XING. Useful life prediction for lithium-ion batteries based on COA-LSTM and VMD [J]. Energy Storage Science and Technology, 2024, 13(9): 3254-3265. |

| [2] | Jizhong LU, Simin PENG, Xiaoyu LI. State-of-health estimation of lithium-ion batteries based on multifeature analysis and LSTM-XGBoost model [J]. Energy Storage Science and Technology, 2024, 13(9): 2972-2982. |

| [3] | Xuefeng HU, Xianlei CHANG, Xiaoxiao LIU, Wei XU, Wenbin ZHANG. SOC estimation of lithium-ion batteries under multiple temperatures conditions based on MIARUKF algorithm [J]. Energy Storage Science and Technology, 2024, 13(9): 2983-2994. |

| [4] | Siyuan SHEN, Yakun LIU, Donghuang LUO, Yujun LI, Wei HAO. Transient overvoltage protection design and circuit development for energy storage lithium-ion battery modules [J]. Energy Storage Science and Technology, 2024, 13(9): 3277-3286. |

| [5] | Yuan CHEN, Siyuan ZHANG, Yujing CAI, Xiaohe HUANG, Yanzhong LIU. State-of-health estimation of lithium batteries based on polynomial feature extension of the CNN-transformer model [J]. Energy Storage Science and Technology, 2024, 13(9): 2995-3005. |

| [6] | Ruihe XING, Suting WENG, Yejing LI, Jiayi ZHANG, Hao ZHANG, Xuefeng WANG. AI-assisted battery material characterization and data analysis [J]. Energy Storage Science and Technology, 2024, 13(9): 2839-2863. |

| [7] | Hongsheng GUAN, Cheng QIAN, Bo SUN, Yi REN. Predicting capacity degradation trajectory for lithium-ion batteries under limited data conditions [J]. Energy Storage Science and Technology, 2024, 13(9): 3084-3093. |

| [8] | Xue KE, Huawei HONG, Peng ZHENG, Zhicheng LI, Peixiao FAN, Jun YANG, Yuzheng GUO, Chunguang KUAI. Estimating lithium-ion battery health using automatic feature extraction and channel attention mechanisms for multi-timescale modeling [J]. Energy Storage Science and Technology, 2024, 13(9): 3059-3071. |

| [9] | Chengwen TIAN, Bingxiang SUN, Xinze ZHAO, Zhicheng FU, Shichang MA, Bo ZHAO, Xubo ZHANG. Accelerated life prediction of lithium-ion batteries using data-driven approaches [J]. Energy Storage Science and Technology, 2024, 13(9): 3103-3111. |

| [10] | Qingbo LI, Maohui ZHANG, Ying LUO, Taolin LYU, Jingying XIE. Lithium-ion battery state of charge estimation based on equivalent circuit model [J]. Energy Storage Science and Technology, 2024, 13(9): 3072-3083. |

| [11] | Bingxiang SUN, Xin YANG, Xingzhen ZHOU, Shichang MA, Zhihao WANG, Weige ZHANG. Comparative parametric study of metaheuristics based on impedance modeling for lithium-ion batteries [J]. Energy Storage Science and Technology, 2024, 13(9): 2952-2962. |

| [12] | Yufeng HUANG, Huanchao LIANG, Lei XU. Kalman filter optimize Transformer method for state of health prediction on lithium-ion battery [J]. Energy Storage Science and Technology, 2024, 13(8): 2791-2802. |

| [13] | Zheng CHEN, Bo YANG, Zhigang ZHAO, Jiangwei SHEN, Renxin XIAO, Xuelei XIA. State of charge estimation considering lithium battery temperature and aging [J]. Energy Storage Science and Technology, 2024, 13(8): 2813-2822. |

| [14] | Guohe CHEN, Peizhao LYU, Menghan LI, Zhonghao RAO. Research progress on thermal runaway propagation characteristics of lithium-ion batteries and its inhibiting strategies [J]. Energy Storage Science and Technology, 2024, 13(7): 2470-2482. |

| [15] | Chengxin LIU, Ziheng LI, Zeyu CHEN, Pengxiang LI, Qingyi TAO. Characterization study on overheat-induced thermal runaway for lithium-ion battery in energy storage [J]. Energy Storage Science and Technology, 2024, 13(7): 2425-2431. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||