Energy Storage Science and Technology ›› 2022, Vol. 11 ›› Issue (5): 1608-1616.doi: 10.19799/j.cnki.2095-4239.2021.0514

• Energy Storage Test: Methods and Evaluation • Previous Articles Next Articles

Yuanxia DONG1( ), Hengyun ZHANG1(

), Hengyun ZHANG1( ), Jiajun ZHU1, Xiaobin XU1, Shunliang ZHU1,2

), Jiajun ZHU1, Xiaobin XU1, Shunliang ZHU1,2

Received:2021-10-08

Revised:2021-10-21

Online:2022-05-05

Published:2022-05-07

Contact:

Hengyun ZHANG

E-mail:1329464216@qq.com;zhanghengyun@sues.edu.cn

CLC Number:

Yuanxia DONG, Hengyun ZHANG, Jiajun ZHU, Xiaobin XU, Shunliang ZHU. Numerical simulation study on thermal runaway propagation mitigation structure of automotive battery module[J]. Energy Storage Science and Technology, 2022, 11(5): 1608-1616.

Table 1

Thermo-physical properties of materials used in simulation"

| 材料 | 密度/(kg/m3) | 比热容/[J/(kg·K)] | 热导率/[W/(m·K)] | 动力黏度/[kg/(m·s)] |

|---|---|---|---|---|

| 电芯 | 2680 | 1100 | λx =1.8,λy =λz =15.3 | — |

| 正极极柱 | 2719 | 871 | 202 | — |

| 负极极柱 | 8978 | 381 | 387.6 | — |

| 汇流排 | 2719 | 871 | 202 | — |

| 气凝胶 | 200 | 500 | 0.016 | — |

| 灌封胶 | 1600 | 1010 | 0.65 | — |

| 导热套筒 | 2791 | 871 | 155 | — |

| 空气 | 1.225 | 1006.43 | 0.0242 | 1.789×10-5 |

| 水 | 996.95 | 4178.5 | 0.6 | 9.02×10-4 |

Table 2

Battery thermal runaway model parameters and initial values"

| 符号 | 参数值 | 单位 | 名称 |

|---|---|---|---|

| HSEI | 2.57×105 | J/kg | SEI膜放热量 |

| Hne | 1.55×105 | J/kg | 负极与电解液反应放热量 |

| Hpe | 3.14×105 | J/kg | 正极与电解液反应放热量 |

| He | 1.55×105 | J/kg | 电解液分解放热量 |

| WSEI | 6.104×102 | kg/m3 | SEI膜材料密度 |

| Wne | 6.104×102 | kg/m3 | 负极与电解液反应材料密度 |

| Wpe | 1.438×103 | kg/m3 | 正极与电解液反应材料密度 |

| We | 4.069×102 | kg/m3 | 电解液分解材料密度 |

| aSEI | 1.667×1015 | s-1 | SEI膜频率因子 |

| ane | 2.5×1013 | s-1 | 负极与电解液反应频率因子 |

| ape | 6.667×1013 | s-1 | 正极与电解液反应频率因子 |

| ae | 5.14×1025 | s-1 | 电解液分解频率因子 |

| ESEI | 1.3508×105 | J/mol | SEI膜活化能 |

| Ene | 1.3508×105 | J/mol | 负极与电解液反应活化能 |

| Epe | 1.396×105 | J/mol | 正极与电解液反应活化能 |

| Ee | 2.74×105 | J/mol | 电解液分解活化能 |

| CSEI,0 | 0.15 | CSEI的初始值 | |

| Cne,0 | 0.75 | Cne的初始值 | |

| Ce,0 | 1 | Ce的初始值 | |

| z0 | 0.033 | z的初始值 | |

| α0 | 0.04 | α的初始值 |

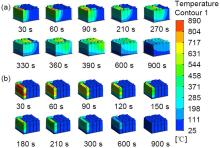

Fig. 3

(a) Evolution process of temperature distribution in case of thermal runaway of battery modules configured without thermal conductivity sleeves; (b) Evolution process of temperature distribution in case of thermal runaway of battery modules configured with thermal conductivity sleeves"

| 1 | 梅文昕, 段强领, 王青山, 等. 大型磷酸铁锂电池高温热失控模拟研究[J]. 储能科学与技术, 2021, 10(1): 202-209. |

| MEI W X, DUAN Q L, WANG Q S, et al. Thermal runaway simulation of large-scale lithium iron phosphate battery at elevated temperatures[J]. Energy Storage Science and Technology, 2021, 10(1): 202-209. | |

| 2 | 王震坡, 袁昌贵, 李晓宇. 新能源汽车动力电池安全管理技术挑战与发展趋势分析[J]. 汽车工程, 2020, 42(12): 1606-1620. |

| WANG Z P, YUAN C G, LI X Y. An analysis on challenge and development trend of safety management technologies for traction battery in new energy vehicles[J]. Automotive Engineering, 2020, 42(12): 1606-1620. | |

| 3 | 常修亮, 郑莉莉, 韦守李, 等. 锂离子电池热失控仿真研究进展[J]. 储能科学与技术, 2021, 10(6): 2191-2199. |

| CHANG X L, ZHENG L L, WEI S L, et al. Progress in thermal runaway simulation of lithium-ion batteries[J]. Energy Storage Science and Technology, 2021, 10(6): 2191-2199. | |

| 4 | 齐创, 邝男男, 张亚军, 等. 高比能锂离子电池模组热扩散行为仿真研究[J]. 高电压技术, 2021, 47(7): 2633-2643. |

| QI C, KUANG N N, ZHANG Y J, et al. Simulation study on the thermal propagation behavior of high energy density lithium-ion battery module[J]. High Voltage Engineering, 2021, 47(7): 2633-2643. | |

| 5 | 陈才星, 牛慧昌, 李钊, 等. 环氧树脂板对锂离子电池热失控扩展的阻隔作用[J]. 储能科学与技术, 2019, 8(3): 532-537. |

| CHEN C X, NIU H C, LI Z, et al. Thermal runaway propagation mitigation of lithium ion battery by epoxy resin board[J]. Energy Storage Science and Technology, 2019, 8(3): 532-537. | |

| 6 | 杨娜, 仝义鑫, 赵立军, 等. 基于相变材料的电池模组热失控传播过程研究[J]. 汽车工程, 2021, 43(8): 1161-1167. |

| YANG N, TONG Y X, ZHAO L J, et al. Study on thermal runaway propagation process of battery module based on phase change materials[J]. Automotive Engineering, 2021, 43(8): 1161-1167. | |

| 7 | WENG J W, OUYANG D X, YANG X Q, et al. Alleviation of thermal runaway propagation in thermal management modules using aerogel felt coupled with flame-retarded phase change material[J]. Energy Conversion and Management, 2019, 200: 112071. |

| 8 | AL-ZAREER M, DINCER I, ROSEN M A. A review of novel thermal management systems for batteries[J]. International Journal of Energy Research, 2018, 42(10): 3182-3205. |

| 9 | COLEMAN B, OSTANEK J, HEINZEL J. Reducing cell-to-cell spacing for large-format lithium ion battery modules with aluminum or PCM heat sinks under failure conditions[J]. Applied Energy, 2016, 180: 14-26. |

| 10 | ZHONG G B, LI H, WANG C, et al. Experimental analysis of thermal runaway propagation risk within 18650 lithium-ion battery modules[J]. Journal of the Electrochemical Society, 2018, 165(9): A1925-A1934. |

| 11 | XU J, LAN C J, QIAO Y, et al. Prevent thermal runaway of lithium-ion batteries with minichannel cooling[J]. Applied Thermal Engineering, 2017, 110: 883-890. |

| 12 | 陈天雨. 大容量锂离子电池热失控蔓延建模与仿真研究[D]. 北京: 清华大学, 2019. |

| CHEN T Y. A study on the modeling and simulation of thermal runaway propagation of large-format lithium-ion batteries[D]. Beijing: Tsinghua University, 2019. | |

| 13 | YANG X L, DUAN Y K, FENG X N, et al. An experimental study on preventing thermal runaway propagation in lithium-ion battery module using aerogel and liquid cooling plate together[J]. Fire Technology, 2020, 56(6): 2579-2602. |

| 14 | MOHAMMED A H, ESMAEELI R, ALINIAGERDROUDBARI H, et al. Dual-purpose cooling plate for thermal management of prismatic lithium-ion batteries during normal operation and thermal runaway[J]. Applied Thermal Engineering, 2019, 160: 114106. |

| 15 | KSHETRIMAYUM K S, YOON Y G, GYE H R, et al. Preventing heat propagation and thermal runaway in electric vehicle battery modules using integrated PCM and micro-channel plate cooling system[J]. Applied Thermal Engineering, 2019, 159: 113797. |

| 16 | PATIL M S, SEO J H, PANCHAL S, et al. Numerical study on sensitivity analysis of factors influencing liquid cooling with double cold-plate for lithium-ion pouch cell[J]. International Journal of Energy Research, 2021, 45(2): 2533-2559. |

| 17 | LIU T, HU J, TAO C F, et al. Effect of parallel connection on 18650-type lithium ion battery thermal runaway propagation and active cooling prevention with water mist[J]. Applied Thermal Engineering, 2021, 184: 116291. |

| 18 | AN Z, SHAH K, JIA L, et al. Modeling and analysis of thermal runaway in Li-ion cell[J]. Applied Thermal Engineering, 2019, 160: 113960. |

| 19 | LAI X, WANG S Y, WANG H B, et al. Investigation of thermal runaway propagation characteristics of lithium-ion battery modules under different trigger modes[J]. International Journal of Heat and Mass Transfer, 2021, 171: 121080. |

| 20 | WANG C J, ZHU Y L, FAN X K, et al. Mathematical model for thermal behavior of lithium-ion battery pack under overheating[J]. Applied Thermal Engineering, 2021, 191: 116894. |

| 21 | HATCHARD T D, MACNEIL D D, BASU A, et al. Thermal model of cylindrical and prismatic lithium-ion cells[J]. Journal of the Electrochemical Society, 2001, 148(7): A755. |

| 22 | PENG P, JIANG F M. Thermal safety of lithium-ion batteries with various cathode materials: A numerical study[J]. International Journal of Heat and Mass Transfer, 2016, 103: 1008-1016. |

| 23 | YE M, XU Y N, HUANGFU Y F. The structure optimization of lithium-ion battery pack based on fluid-solid conjugate thermodynamic analysis[J]. Energy Procedia, 2018, 152: 643-648. |

| 24 | LI Q B, YANG C B, SANTHANAGOPALAN S, et al. Numerical investigation of thermal runaway mitigation through a passive thermal management system[J]. Journal of Power Sources, 2019, 429: 80-88. |

| [1] | DING Yi, YANG Yan, CHEN Kai, ZENG Tao, HUANG Yunhui. Intelligent fire protection of lithium-ion battery and its research method [J]. Energy Storage Science and Technology, 2022, 11(6): 1822-1833. |

| [2] | OU Yu, HOU Wenhui, LIU Kai. Research progress of smart safety electrolytes in lithium-ion batteries [J]. Energy Storage Science and Technology, 2022, 11(6): 1772-1787. |

| [3] | Lei LI, Zhao LI, Dan JI, Huichang NIU. Overcharge induced thermal runaway behaviors of pouch-type lithium-ion batteries with LFP and NCM cathodes: the differences and reasons [J]. Energy Storage Science and Technology, 2022, 11(5): 1419-1427. |

| [4] | Biao MA, Chunjing LIN, Lei LIU, Xiaole MA, Tianyi MA, Shiqiang LIU. Venting characteristics and flammability limit of thermal runaway gas of lithium ion battery [J]. Energy Storage Science and Technology, 2022, 11(5): 1592-1600. |

| [5] | Qiaomin KE, Jian GUO, Yiwei WANG, Wenjiong CAO, Man CHEN, Fangming JIANG. The effect of liquid-cooled thermal management on thermal runaway of power battery [J]. Energy Storage Science and Technology, 2022, 11(5): 1634-1640. |

| [6] | Jun WANG, Zhuangzhuang JIA, Peng QIN, Zheng HUANG, Jingyun WU, Wen QI, Qingsong WANG. Simulation of thermal runaway gas diffusion in LiFePO4 battery module [J]. Energy Storage Science and Technology, 2022, 11(1): 185-192. |

| [7] | Zhihui GUO, Xiaodan CUI, Linshuang ZHAO, Jiawei CHEN. Fire and gas explosion hazards of high-nickel lithium-ion battery [J]. Energy Storage Science and Technology, 2022, 11(1): 193-200. |

| [8] | Xinlong ZHU, Junyi WANG, Jiashuang PAN, Chuanzhi KANG, Yitao ZOU, Kaijie YANG, Hong SHI. Present situation and development of thermal management system for battery energy storage system [J]. Energy Storage Science and Technology, 2022, 11(1): 107-118. |

| [9] | Hongzhang ZHU, Chuanping WU, Tiannian ZHOU, Jie DENG. Thermal runaway characteristics of LiFePO4 and ternary lithium batteries with external overheating [J]. Energy Storage Science and Technology, 2022, 11(1): 201-210. |

| [10] | Xiuliang CHANG, Lili ZHENG, Shouli WEI, Tao ZHANG, Bing CHEN, Zhuo XU, Zuoqiang DAI. Progress in thermal runaway simulation of lithium-ion batteries [J]. Energy Storage Science and Technology, 2021, 10(6): 2191-2199. |

| [11] | Jinlong XU, Jiani SHEN, Qiankun WANG, Yijun HE, Zifeng MA, Wen TAN, Qingheng YANG. Analysis of electrothermal coupling abuse condition based on thermal runaway model of lithium-ion battery [J]. Energy Storage Science and Technology, 2021, 10(4): 1344-1352. |

| [12] | Ke LI, Juyi MU, Yi JIN, Jiajia XU, Pengjie LIU, Qingsong WANG, Huang LI. Fire risk of lithium iron phosphate battery [J]. Energy Storage Science and Technology, 2021, 10(3): 1177-1186. |

| [13] | Zhihong ZHANG, Junyan MOU, Yufa MENG. Thermal runaway propagation characteristics of an air-cooled cylindrical lithium-ion battery system [J]. Energy Storage Science and Technology, 2021, 10(2): 658-663. |

| [14] | Tiannian ZHOU, Chuanping WU, Baohui CHEN. Burning characteristics of the 18650-type lithium-ion ternary battery pack induced by heating [J]. Energy Storage Science and Technology, 2021, 10(2): 558-564. |

| [15] | Li WANG, Leqiong XIE, Guangyu TIAN, Xiangming HE. Safety accidents of Li-ion batteries: Reliability issues or safety issues [J]. Energy Storage Science and Technology, 2021, 10(1): 1-6. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||