Energy Storage Science and Technology ›› 2024, Vol. 13 ›› Issue (9): 3112-3133.doi: 10.19799/j.cnki.2095-4239.2024.0596

Previous Articles Next Articles

Jinbao FAN1( ), Na LI2, Yikun WU3, Chunwang HE1, Le YANG1, Weili SONG1, Haosen CHEN1(

), Na LI2, Yikun WU3, Chunwang HE1, Le YANG1, Weili SONG1, Haosen CHEN1( )

)

Received:2024-06-10

Revised:2024-07-14

Online:2024-09-28

Published:2024-09-20

Contact:

Haosen CHEN

E-mail:fan_jinbao@foxmail.com;chenhs@bit.edu.cn

CLC Number:

Jinbao FAN, Na LI, Yikun WU, Chunwang HE, Le YANG, Weili SONG, Haosen CHEN. Digital twin technology for energy batteries at the cell level[J]. Energy Storage Science and Technology, 2024, 13(9): 3112-3133.

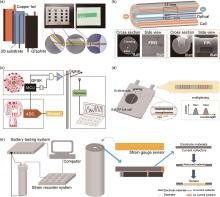

Fig. 2

(a)The schematic and photograph of integrated functional electrode[25]; (b) The configuration of the optical fiber sensor implanted inside a commercial 18650 cell[29]; (c) The schematic illustration of wireless signal transmission[41]; (d) The schematic diagram of a full cell with a single optical fiber[52]; (e) The schematic of the in-situ strain measurement inside a cylindrical Li-ion battery[55]"

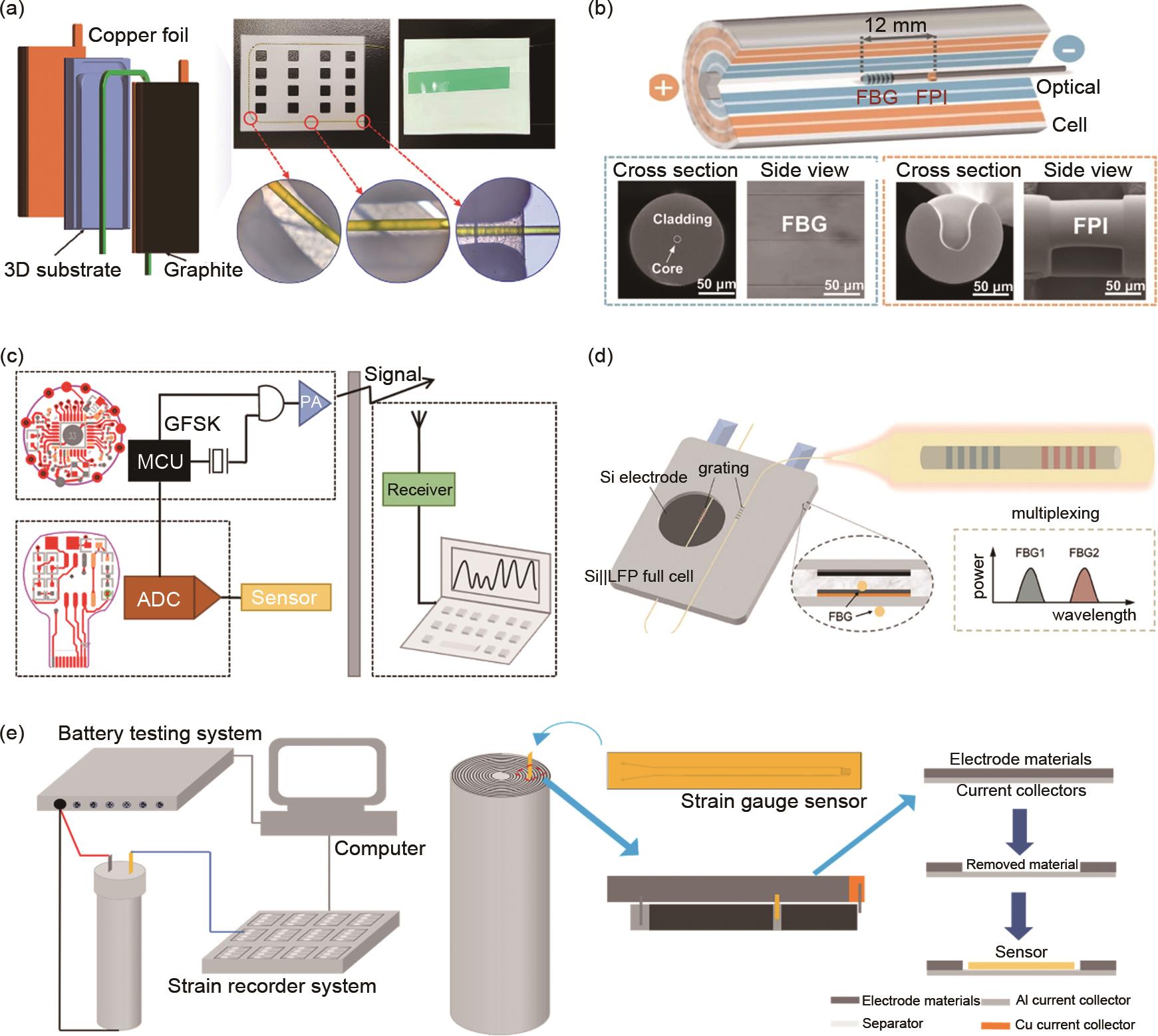

Fig. 3

(a) The gas pressure sensor on the top of the prismatic lithium-ion battery[57]; (b) The relative pressure sensor attached onto the perforated negative electrode of the cylindrical lithium-ion battery[58]; (c) The commercial lithium-ion battery with an implanted MEMS fiber-optic pressure sensor[59]; (d) Rapid measurement of gases inside a lithium-ion battery based on multiple NDIR sensors in a sealed tank[61]"

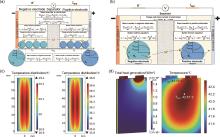

Fig. 4

(a) Schematic illustration of P2D model during discharge[79]; (b) Schematic illustration of SPM model during discharge[79]; (c) 2D simulation of temperature distribution inside a 18650 cell at the end of 1C (left-hand side) and 2C (right-hand side) discharge[71]; (d) 3D simulation of total heat generation (left-hand side) and temperature distribution (right-hand side) of a pouch battery at the end of 3C discharge[76]"

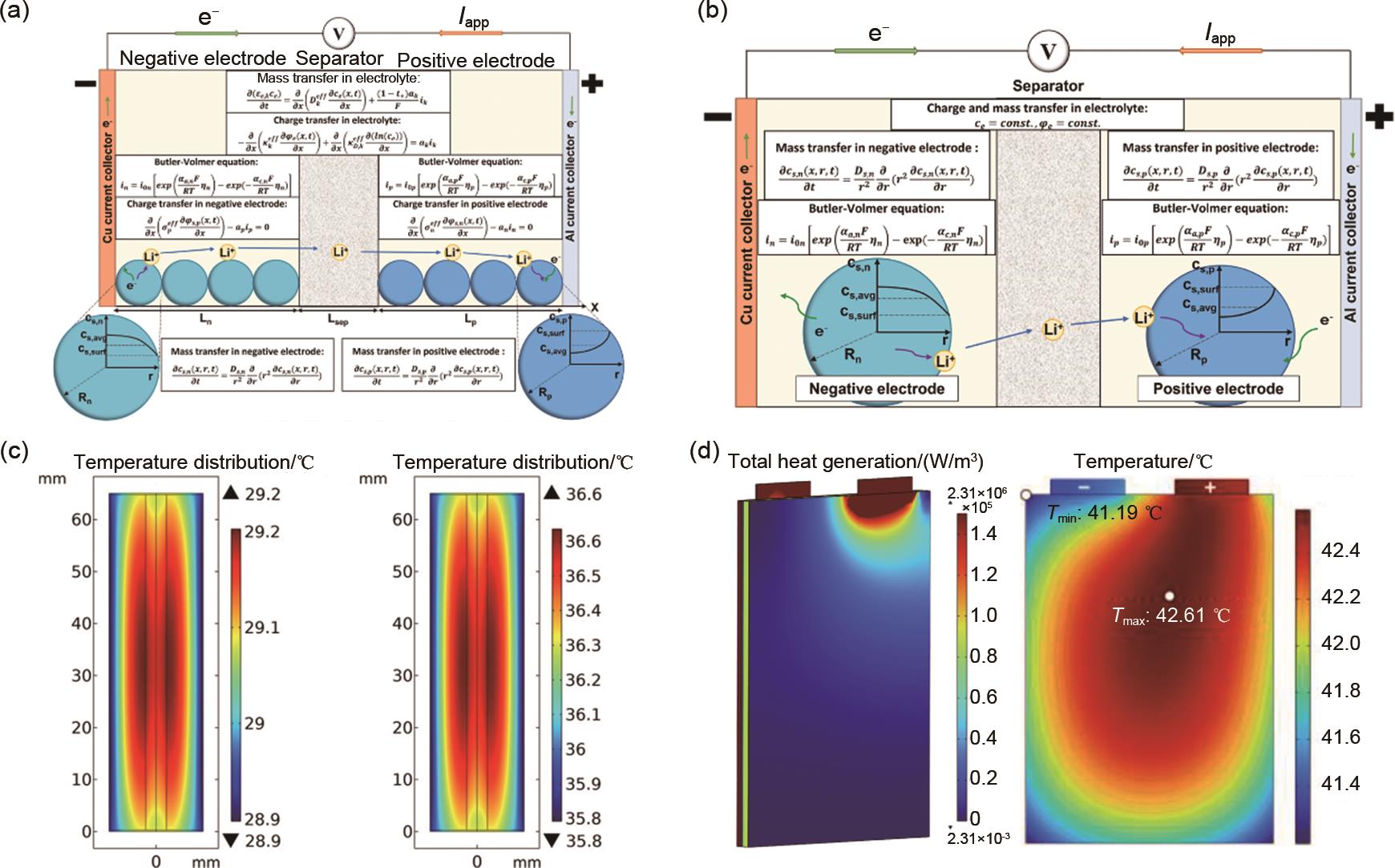

Fig. 5

(a) 2D simulation of von Mises stress in the fully charged state for a cylindrical cell[83]; (b) 3D simulation of displacement distribution of a pouch battery at the end of charge[85]; (c) Displacement distribution (left-hand side) and von Mises stress distribution (right-hand side) of a pouch cell at the end of charge[86]; (d) Temperature (left-hand side) and the projected stress fields (right-hand side) inside the jellyroll at the end of discharge under the forced convection condition[88]; (e) Temperature (left-hand side) and the projected stress fields (right-hand side) in jellyrolls for the nonisothermal case after being charged for 50 min[89]"

| 1 | 陈桂泉, 沙盈吟, 赵威风, 等. 动力电池老化诱发热失控机理仿真[J]. 储能科学与技术, 2022, 11(12): 3987-3998. DOI: 10.19799/j.cnki.2095-4239.2022.0396. |

| CHEN G Q, SHA Y Y, ZHAO W F, et al. Simulation study on the mechanism and process of thermal runaway induced by aging of lithium-ion batteries[J]. Energy Storage Science and Technology, 2022, 11(12): 3987-3998. DOI: 10.19799/j.cnki.2095-4239. 2022.0396. | |

| 2 | ZHAO J Y, FENG X N, PANG Q Q, et al. Battery safety: Machine learning-based prognostics[J]. Progress in Energy and Combustion Science, 2024, 102: 101142. DOI: 10.1016/j.pecs. 2023.101142. |

| 3 | University of Texas at Austin Mechanical Engineering Cockrell School of Engineering. Battery fire and explosion incidents: Database tools[EB/OL]. [2024-07-14]. http://tools.utfireresearch.com/apps/incident_map. |

| 4 | 昝文达, 张睿, 丁飞. 锂离子电池电化学模型发展与应用[J]. 储能科学与技术, 2023, 12(7): 2302-2318. DOI: 10.19799/j.cnki.2095-4239.2023.0296. |

| ZAN W D, ZHANG R, DING F. Development and application of electrochemical models for lithium-ion batteries[J]. Energy Storage Science and Technology, 2023, 12(7): 2302-2318. DOI: 10.19799/j.cnki.2095-4239.2023.0296. | |

| 5 | YU J S, SONG Y, TANG D Y, et al. A Digital Twin approach based on nonparametric Bayesian network for complex system health monitoring[J]. Journal of Manufacturing Systems, 2021, 58: 293-304. DOI: 10.1016/j.jmsy.2020.07.005. |

| 6 | TORZONI M, TEZZELE M, MARIANI S, et al. A digital twin framework for civil engineering structures[J]. Computer Methods in Applied Mechanics and Engineering, 2024, 418: 116584. DOI: 10.1016/j.cma.2023.116584. |

| 7 | YANG C, CAI B P, WU Q B, et al. Digital twin-driven fault diagnosis method for composite faults by combining virtual and real data[J]. Journal of Industrial Information Integration, 2023, 33: 100469. DOI: 10.1016/j.jii.2023.100469. |

| 8 | LIU S Z, QI Y S, GAO X J, et al. Transfer learning-based multiple digital twin-assisted intelligent mechanical fault diagnosi[J]. Measurement Science and Technology, 2024, 35(2): 025133. DOI: 10.1088/1361-6501/ad0683. |

| 9 | WANG M M, FENG S Z, INCECIK A, et al. Structural fatigue life prediction considering model uncertainties through a novel digital twin-driven approach[J]. Computer Methods in Applied Mechanics and Engineering, 2022, 391: 114512. DOI: 10.1016/j.cma.2021.114512. |

| 10 | JANELIUKSTIS R, MCGUGAN M. Control of damage-sensitive features for early failure prediction of wind turbine blades[J]. Structural Control and Health Monitoring, 2022, 29(1). DOI: 10.1002/stc.2852. |

| 11 | LI W H, RENTEMEISTER M, BADEDA J, et al. Digital twin for battery systems: Cloud battery management system with online state-of-charge and state-of-health estimation[J]. Journal of Energy Storage, 2020, 30: 101557. DOI: 10.1016/j.est. 2020.101557. |

| 12 | QU X, SONG Y, LIU D, et al. Lithium-ion battery performance degradation evaluation in dynamic operating conditions based on a digital twin model[J]. Microelectronics Reliability, 2020, 114: 113857. DOI: 10.1016/j.microrel.2020.113857. |

| 13 | MERKLE L, PÖTHIG M, SCHMID F. Estimate e-golf battery state using diagnostic data and a digital twin[J]. Batteries, 2021, 7(1): 15. DOI: 10.3390/batteries7010015. |

| 14 | YANG S C, ZHANG Z J, CAO R, et al. Implementation for a cloud battery management system based on the CHAIN framework[J]. Energy and AI, 2021, 5: 100088. DOI: 10.1016/j.egyai. 2021.100088. |

| 15 | WANG Y J, XU R L, ZHOU C J, et al. Digital twin and cloud-side-end collaboration for intelligent battery management system[J]. Journal of Manufacturing Systems, 2022, 62: 124-134. DOI: 10.1016/j.jmsy.2021.11.006. |

| 16 | TANG H, WU Y C, CAI Y F, et al. Design of power lithium battery management system based on digital twin[J]. Journal of Energy Storage, 2022, 47: 103679. DOI: 10.1016/j.est.2021.103679. |

| 17 | JAFARI S, BYUN Y C. Prediction of the battery state using the digital twin framework based on the battery management system[J]. IEEE Access, 2022, 10: 124685-124696. DOI: 10.1109/ACCESS.2022.3225093. |

| 18 | GLAESSGEN E, STARGEL D. The digital twin paradigm for future NASA and U.S. air force vehicles[C]//53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference<BR>20th AIAA/ASME/AHS Adaptive Structures Conference<BR>14th AIAA. Honolulu, Hawaii. Reston, Virigina: AIAA, 2012: AIAA2012-1818. DOI: 10.2514/6.2012-1818. |

| 19 | PENG Y, ZHANG X L, SONG Y C, et al. A low cost flexible digital twin platform for spacecraft lithium-ion battery pack degradation assessment[C]//2019 IEEE International Instrumentation and Measurement Technology Conference (I2MTC). May 20-23, 2019, Auckland, New Zealand. IEEE, 2019: 1-6. DOI: 10.1109/I2MTC.2019.8827160. |

| 20 | SONG J H, LIM S H, KIM K G, et al. Digital-twin-driven diagnostics of crack propagation in a single LiNi0.7Mn0.15Co0.15O2 secondary particle during lithium intercalation[J]. Advanced Energy Materials, 2023, 13(23): 2204328. DOI: 10.1002/aenm. 202204328. |

| 21 | NGANDJONG A C, LOMBARDO T, PRIMO E N, et al. Investigating electrode calendering and its impact on electrochemical performance by means of a new discrete element method model: Towards a digital twin of Li-Ion battery manufacturing[J]. Journal of Power Sources, 2021, 485: 229320. DOI: 10.1016/j.jpowsour.2020.229320. |

| 22 | ZHANG H M, REN D S, MING H, et al. Digital twin enables rational design of ultrahigh-power lithium-ion batteries[J]. Advanced Energy Materials, 2023, 13(1): 2202660. DOI: 10.1002/aenm.202202660. |

| 23 | 辛耀达, 李娜, 杨乐, 等. 锂离子电池植入传感技术[J]. 储能科学与技术, 2022, 11(6): 1834-1846. DOI: 10.19799/j.cnki.2095-4239. 2022.0183. |

| XIN Y D, LI N, YANG L, et al. Integrated sensing technology for lithium ion battery[J]. Energy Storage Science and Technology, 2022, 11(6): 1834-1846. DOI: 10.19799/j.cnki.2095-4239. 2022.0183. | |

| 24 | TRANTER T G, TIMMS R, SHEARING P R, et al. Communication—Prediction of thermal issues for larger format 4680 cylindrical cells and their mitigation with enhanced current collection[J]. Journal of the Electrochemical Society, 2020, 167(16): 160544. DOI: 10.1149/1945-7111/abd44f. |

| 25 | WANG X W, ZHU J G, WEI X Z, et al. Non-damaged lithium-ion batteries integrated functional electrode for operando temperature sensing[J]. Energy Storage Materials, 2024, 65: 103160. DOI: 10.1016/j.ensm.2023.103160. |

| 26 | GERVILLIÉ-MOURAVIEFF C, ALBERO BLANQUER L, ALPHEN C, et al. Unraveling SEI formation and cycling behavior of commercial Ni-rich NMC Li-ion pouch cells through operando optical characterization[J]. Journal of Power Sources, 2023, 580: 233268. DOI: 10.1016/j.jpowsour.2023.233268. |

| 27 | HUANG J Q, DELACOURT C, DESAI P, et al. Unravelling thermal and enthalpy evolutions of commercial sodium-ion cells upon cycling ageing via fiber optic sensors[J]. Journal of the Electrochemical Society, 2023, 170(9): 090510. DOI: 10.1149/1945-7111/acf625. |

| 28 | WU Y T, LONG X L, LU J Y, et al. Long-life in situ temperature field monitoring using Fiber Bragg grating sensors in electromagnetic launch high-rate hardcase lithium-ion battery[J]. Journal of Energy Storage, 2023, 57: 106207. DOI: 10.1016/j.est.2022.106207. |

| 29 | MEI W X, LIU Z, WANG C D, et al. operando monitoring of thermal runaway in commercial lithium-ion cells via advanced lab-on-fiber technologies[J]. Nature Communications, 2023, 14(1): 5251. DOI: 10.1038/s41467-023-40995-3. |

| 30 | LI P F, WEI Z B, WU K, et al. Embedded sensing-enabled distributed thermal modeling and nondestructive thermal monitoring of lithium-ion battery[J]. IEEE Transactions on Transportation Electrification, 2023, PP(99): 1. DOI: 10.1109/TTE.2023.3340036. |

| 31 | WEI Z B, LI P F, CAO W K, et al. Machine learning-based hybrid thermal modeling and diagnostic for lithium-ion battery enabled by embedded sensing[J]. Applied Thermal Engineering, 2022, 216: 119059. DOI: 10.1016/j.applthermaleng.2022.119059. |

| 32 | YU Y F, VINCENT T, SANSOM J, et al. Distributed internal thermal monitoring of lithium ion batteries with fibre sensors[J]. Journal of Energy Storage, 2022, 50: 104291. DOI: 10.1016/j.est.2022.104291. |

| 33 | YU Y F, VERGORI E, MADDAR F, et al. Real-time monitoring of internal structural deformation and thermal events in lithium-ion cell via embedded distributed optical fibre[J]. Journal of Power Sources, 2022, 521: 230957. DOI: 10.1016/j.jpowsour. 2021. 230957. |

| 34 | HUANG J Q, ALBERO BLANQUER L, BONEFACINO J, et al. operando decoding of chemical and thermal events in commercial Na(Li)-ion cells via optical sensors[J]. Nature Energy, 2020, 5: 674-683. DOI: 10.1038/s41560-020-0665-y. |

| 35 | LING X, ZHANG Q, XIANG Y, et al. A Cu/Ni alloy thin-film sensor integrated with current collector for in situ monitoring of lithium-ion battery internal temperature by high-throughput selecting method[J]. International Journal of Heat and Mass Transfer, 2023, 214: 124383. DOI: 10.1016/j.ijheatmasstransfer.2023.124383. |

| 36 | ZHANG H Y, ZHANG X S, WANG W W, et al. Detection and prediction of the early thermal runaway and control of the Li-ion battery by the embedded temperature sensor array[J]. Sensors, 2023, 23(11): 5049. DOI: 10.3390/s23115049. |

| 37 | PENG X L, HAN J, ZHANG Q, et al. Real-time mechanical and thermal monitoring of lithium batteries with PVDF-TrFE thin films integrated within the battery[J]. Sensors and Actuators A: Physical, 2022, 338: 113484. DOI: 10.1016/j.sna.2022.113484. |

| 38 | ZHU S X, HAN J D, AN H Y, et al. A novel embedded method for in situ measuring internal multi-point temperatures of lithium ion batteries[J]. Journal of Power Sources, 2020, 456: 227981. DOI: 10.1016/j.jpowsour.2020.227981. |

| 39 | MUTYALA M S K, ZHAO J Z, LI J Y, et al. In-situ temperature measurement in lithium ion battery by transferable flexible thin film thermocouples[J]. Journal of Power Sources, 2014, 260: 43-49. DOI: 10.1016/j.jpowsour.2014.03.004. |

| 40 | FORTIER A, TSAO M, WILLIARD N, et al. Preliminary study on integration of fiber optic Bragg grating sensors in Li-ion batteries and in situ strain and temperature monitoring of battery cells[J]. Energies, 2017, 10(7): 838. DOI: 10.3390/en10070838. |

| 41 | YANG L, LI N, HU L K, et al. Internal field study of 21700 battery based on long-life embedded wireless temperature sensor[J]. Acta Mechanica Sinica, 2021, 37(6): 895-901. DOI: 10.1007/s10409-021-01103-0. |

| 42 | MENG D C, XUE Z C, CHEN G K, et al. Multiscale correlative imaging reveals sequential and heterogeneous degradations in fast-charging batteries[J]. Energy & Environmental Science, 2024, 17(13): 4658-4669. DOI: 10.1039/D4EE01497A. |

| 43 | WALDMANN T, GORSE S, SAMTLEBEN T, et al. A mechanical aging mechanism in lithium-ion batteries[J]. Journal of the Electrochemical Society, 2014, 161(10): A1742-A1747. DOI: 10.1149/2.1001410jes. |

| 44 | PFRANG A, KERSYS A, KRISTON A, et al. Geometrical inhomogeneities as cause of mechanical failure in commercial 18650Lithium ion cells[J]. Journal of the Electrochemical Society, 2019, 166(15): A3745-A3752. DOI: 10.1149/2.0551914jes. |

| 45 | WILLENBERG L, DECHENT P, FUCHS G, et al. The development of jelly roll deformation in 18650 lithium-ion batteries at low state of charge[J]. Journal of the Electrochemical Society, 2020, 167(12): 120502. DOI: 10.1149/1945-7111/aba96d. |

| 46 | PFRANG A, KERSYS A, SCURTU R G, et al. Deformation from formation until end of life: Micro X-ray computed tomography of silicon alloy containing 18650 Li-ion cells[J]. Journal of the Electrochemical Society, 2023, 170(3): 030548. DOI: 10.1149/1945-7111/acc6f3. |

| 47 | PENG J, JIA S H, YANG S M, et al. State estimation of lithium-ion batteries based on strain parameter monitored by fiber Bragg grating sensors[J]. Journal of Energy Storage, 2022, 52: 104950. DOI: 10.1016/j.est.2022.104950. |

| 48 | PENG J, ZHOU X, JIA S H, et al. High precision strain monitoring for lithium ion batteries based on fiber Bragg grating sensors[J]. Journal of Power Sources, 2019, 433: 226692. DOI: 10.1016/j.jpowsour.2019.226692. |

| 49 | GANGULI A, SAHA B, RAGHAVAN A, et al. Embedded fiber-optic sensing for accurate internal monitoring of cell state in advanced battery management systems part 2: Internal cell signals and utility for state estimation[J]. Journal of Power Sources, 2017, 341: 474-482. DOI: 10.1016/j.jpowsour. 2016. 11.103. |

| 50 | CHEN S Q, WEI X Z, ZHANG G X, et al. Mechanical strain signal based early warning for failure of different prismatic lithium-ion batteries[J]. Journal of Power Sources, 2023, 580: 233397. DOI: 10.1016/j.jpowsour.2023.233397. |

| 51 | RAGHAVAN A, KIESEL P, SOMMER L W, et al. Embedded fiber-optic sensing for accurate internal monitoring of cell state in advanced battery management systems part 1: Cell embedding method and performance[J]. Journal of Power Sources, 2017, 341: 466-473. DOI: 10.1016/j.jpowsour.2016.11.104. |

| 52 | ZHANG Y, XIAO X P, CHEN W L, et al. In operando monitoring the stress evolution of silicon anode electrodes during battery operation via optical fiber sensors[J]. Small, 2024, 20(29): e2311299. DOI: 10.1002/smll.202311299. |

| 53 | ALBERO BLANQUER L, MARCHINI F, SEITZ J R, et al. Optical sensors for operando stress monitoring in lithium-based batteries containing solid-state or liquid electrolytes[J]. Nature Communications, 2022, 13(1): 1153. DOI: 10.1038/s41467-022-28792-w. |

| 54 | MIAO Z Y, LI Y P, XIAO X P, et al. Direct optical fiber monitor on stress evolution of the sulfur-based cathodes for lithium-sulfur batteries[J]. Energy & Environmental Science, 2022, 15(5): 2029-2038. DOI: 10.1039/D2EE00007E. |

| 55 | ZHU S X, YANG L, WEN J W, et al. In operando measuring circumferential internal strain of 18650 Li-ion batteries by thin film strain gauge sensors[J]. Journal of Power Sources, 2021, 516: 230669. DOI: 10.1016/j.jpowsour.2021.230669. |

| 56 | ZHU S X, YANG L, FAN J B, et al. In-situ obtained internal strain and pressure of the cylindrical Li-ion battery cell with silicon-graphite negative electrodes[J]. Journal of Energy Storage, 2021, 42: 103049. DOI: 10.1016/j.est.2021.103049. |

| 57 | SCHMITT J, KRAFT B, SCHMIDT J P, et al. Measurement of gas pressure inside large-format prismatic lithium-ion cells during operation and cycle aging[J]. Journal of Power Sources, 2020, 478: 228661. DOI: 10.1016/j.jpowsour.2020.228661. |

| 58 | HEMMERLING J, SCHÄFER J, JUNG T, et al. Investigation of internal gas pressure and internal temperature of cylindrical Li-ion cells to study thermodynamical and mechanical properties of hard case battery cells[J]. Journal of Energy Storage, 2023, 59: 106444. DOI: 10.1016/j.est.2022.106444. |

| 59 | TAN K, LI W, LIN Z, et al. operando monitoring of internal gas pressure in commercial lithium-ion batteries via a MEMS-assisted fiber-optic interferometer[J]. Journal of Power Sources, 2023, 580: 233471. DOI: 10.1016/j.jpowsour.2023.233471. |

| 60 | KOCH S, BIRKE K, KUHN R. Fast thermal runaway detection for lithium-ion cells in large scale traction batteries[J]. Batteries, 2018, 4(2): 16. DOI: 10.3390/batteries4020016. |

| 61 | LYU S Q, LI N, SUN L, et al. Rapid operando gas monitor for commercial lithium ion batteries: Gas evolution and relation with electrode materials[J]. Journal of Energy Chemistry, 2022, 72: 14-25. DOI: 10.1016/j.jechem.2022.04.010. |

| 62 | CAI T, VALECHA P, TRAN V, et al. Detection of Li-ion battery failure and venting with Carbon Dioxide sensors[J]. eTransportation, 2021, 7: 100100. DOI: 10.1016/j.etran.2020.100100. |

| 63 | ALLSOP T, NEAL R. A review: Application and implementation of optic fibre sensors for gas detection[J]. Sensors, 2021, 21(20): 6755. DOI: 10.3390/s21206755. |

| 64 | CHEN X R, GAN L, GUO X. Optical fiber-based gas sensing for early warning of thermal runaway in lithium-ion batteries[J]. Advanced Sensor Research, 2023, 2(12). DOI: 10.1002/adsr. 202300055. |

| 65 | FUJIMOTO S, UEMURA S, IMANISHI N, et al. Oxygen concentration measurement in the porous cathode of a lithium-air battery using a fine optical fiber sensor[J]. Mechanical Engineering Letters, 2019, 5: 19-95-19-00095. DOI: 10.1299/mel.19-00095. |

| 66 | DOYLE M, FULLER T F, NEWMAN J. Modeling of galvanostatic charge and discharge of the lithium/polymer/insertion cell[J]. Journal of the Electrochemical Society, 1993, 140(6): 1526. DOI: 10.1149/1.2221597. |

| 67 | FULLER T F, DOYLE M, NEWMAN J. Simulation and optimization of the dual lithium ion insertion cell[J]. Journal of the Electrochemical Society, 1994, 141(1): 1-10. DOI: 10.1149/1.2054684. |

| 68 | ZHANG D, POPOV B N, WHITE R E. Modeling lithium intercalation of a single spinel particle under potentiodynamic control[J]. Journal of the Electrochemical Society, 2000, 147(3): 831. DOI: 10.1149/1.1393279. |

| 69 | GU W B, WANG C Y. Thermal-electrochemical modeling of battery systems[J]. Journal of the Electrochemical Society, 2000, 147(8): 2910. DOI: 10.1149/1.1393625. |

| 70 | LI H H, SAINI A, LIU C Y, et al. Electrochemical and thermal characteristics of prismatic lithium-ion battery based on a three-dimensional electrochemical-thermal coupled model[J]. Journal of Energy Storage, 2021, 42: 102976. DOI: 10.1016/j.est. 2021.102976. |

| 71 | NIE P B, ZHANG S W, RAN A H, et al. Full-cycle electrochemical-thermal coupling analysis for commercial lithium-ion batteries[J]. Applied Thermal Engineering, 2021, 184: 116258. DOI: 10.1016/j.applthermaleng.2020.116258. |

| 72 | XU M, ZHANG Z Q, WANG X, et al. A pseudo three-dimensional electrochemical-thermal model of a prismatic LiFePO4 battery during discharge process[J]. Energy, 2015, 80: 303-317. DOI: 10.1016/j.energy.2014.11.073. |

| 73 | DU S L, LAI Y Q, AI L, et al. An investigation of irreversible heat generation in lithium ion batteries based on a thermo-electrochemical coupling method[J]. Applied Thermal Engineering, 2017, 121: 501-510. DOI: 10.1016/j.applthermaleng.2017.04.077. |

| 74 | GHALKHANI M, BAHIRAEI F, NAZRI G A, et al. Electrochemical-thermal model of pouch-type lithium-ion batteries[J]. Electrochimica Acta, 2017, 247: 569-587. DOI: 10.1016/j.electacta.2017.06.164. |

| 75 | LI C S, ZHANG H Y, ZHANG R J, et al. On the characteristics analysis and tab design of an 18650 type cylindrical LiFePO4 battery[J]. Applied Thermal Engineering, 2021, 182: 116144. DOI: 10.1016/j.applthermaleng.2020.116144. |

| 76 | LIN X W, ZHOU Z F, ZHU X G, et al. Non-uniform thermal characteristics investigation of three-dimensional electrochemical-thermal coupled model for pouch lithium-ion battery[J]. Journal of Cleaner Production, 2023, 417: 137912. DOI: 10.1016/j.jclepro. 2023.137912. |

| 77 | HUANG Y F, LAI X, REN D S, et al. Thermal and stoichiometry inhomogeneity investigation of large-format lithium-ion batteries via a three-dimensional electrochemical-thermal coupling model[J]. Electrochimica Acta, 2023, 468: 143212. DOI: 10.1016/j.electacta.2023.143212. |

| 78 | ÖZDEMIR T, EKICI Ö, KÖKSAL M. Numerical and experimental investigation of the electrical and thermal behaviors of the Li-ion batteries under normal and abuse operating conditions[J]. Journal of Energy Storage, 2024, 77: 109880. DOI: 10.1016/j.est.2023.109880. |

| 79 | AMIRI M N, HÅKANSSON A, BURHEIM O S, et al. Lithium-ion battery digitalization: Combining physics-based models and machine learning[J]. Renewable and Sustainable Energy Reviews, 2024, 200: 114577. DOI: 10.1016/j.rser.2024.114577. |

| 80 | 吴宜琨, 何杰, 杨乐, 等. 锂离子电池多物理场多尺度变形理论模型与计算方法[J]. 储能科学与技术, 2023, 12(7): 2141-2154. DOI: 10.19799/j.cnki.2095-4239.2023.0301. |

| WU Y K, HE J, YANG L, et al. Multiscale and multiphysics theoretical model and computational method for lithium-ion batteries[J]. Energy Storage Science and Technology, 2023, 12(7): 2141-2154. DOI: 10.19799/j.cnki.2095-4239.2023.0301. | |

| 81 | SAUERTEIG D, HANSELMANN N, ARZBERGER A, et al. Electrochemical-mechanical coupled modeling and parameterization of swelling and ionic transport in lithium-ion batteries[J]. Journal of Power Sources, 2018, 378: 235-247. DOI: 10.1016/j.jpowsour.2017.12.044. |

| 82 | LEE Y K, SONG J, PARK J. Multi-scale coupled mechanical-electrochemical modeling for study on stress generation and its impact on multi-layered electrodes in lithium-ion batteries[J]. Electrochimica Acta, 2021, 389: 138682. DOI: 10.1016/j.electacta.2021.138682. |

| 83 | SHIN J, LEE Y K. Multi-scale mechanical-electrochemical coupled modeling of stress generation and its impact on different battery cell geometries[J]. Journal of Power Sources, 2024, 595: 234064. DOI: 10.1016/j.jpowsour.2024.234064. |

| 84 | GUO W D, LI Y Q, SUN Z C, et al. A digital twin to quantitatively understand aging mechanisms coupled effects of NMC battery using dynamic aging profiles[J]. Energy Storage Materials, 2023, 63: 102965. DOI: 10.1016/j.ensm.2023.102965. |

| 85 | YUAN C H, HAHN Y, LU W Q, et al. Quantification of electrochemical-mechanical coupling in lithium-ion batteries[J]. Cell Reports Physical Science, 2022, 3(12): 101158. DOI: 10.1016/j.xcrp.2022.101158. |

| 86 | WANG Y N, NI R K, JIANG X B, et al. An electrochemical-mechanical coupled multi-scale modeling method and full-field stress distribution of lithium-ion battery[J]. Applied Energy, 2023, 347: 121444. DOI: 10.1016/j.apenergy.2023.121444. |

| 87 | DUAN X T, JIANG W J, ZOU Y L, et al. A coupled electrochemical-thermal-mechanical model for spiral-wound Li-ion batteries[J]. Journal of Materials Science, 2018, 53(15): 10987-11001. DOI: 10.1007/s10853-018-2365-6. |

| 88 | ZHANG X X, CHUMAKOV S, LI X B, et al. An electro-chemo-thermo-mechanical coupled three-dimensional computational framework for lithium-ion batteries[J]. Journal of the Electrochemical Society, 2020, 167(16): 160542. DOI: 10.1149/1945-7111/abd1f2. |

| 89 | QIU Y T, ZHANG X X, USUBELLI C, et al. Understanding thermal and mechanical effects on lithium plating in lithium-ion batteries[J]. Journal of Power Sources, 2022, 541: 231632. DOI: 10.1016/j.jpowsour.2022.231632. |

| 90 | YANG S C, HUA Y, QIAO D, et al. A coupled electrochemical-thermal-mechanical degradation modelling approach for lifetime assessment of lithium-ion batteries[J]. Electrochimica Acta, 2019, 326: 134928. DOI: 10.1016/j.electacta.2019.134928. |

| 91 | LUO P F, LI P C, MA D Z, et al. A novel capacity fade model of lithium-ion cells considering the influence of stress[J]. Journal of the Electrochemical Society, 2021, 168(9): 090537. DOI: 10.1149/1945-7111/ac24b5. |

| 92 | LUO P F, LI P C, MA D Z, et al. Coupled electrochemical-thermal-mechanical modeling and simulation of lithium-ion batteries[J]. Journal of the Electrochemical Society, 2022, 169(10): 100535. DOI: 10.1149/1945-7111/ac9a04. |

| 93 | LI Y F, LI K, SHEN W J, et al. Stress-dependent capacity fade behavior and mechanism of lithium-ion batteries[J]. Journal of Energy Storage, 2024, 86: 111165. DOI: 10.1016/j.est. 2024.111165. |

| 94 | ZHAO K, LIU Y, MING W L, et al. Digital twin-driven estimation of state of charge for Li-ion battery[C]//2022 IEEE 7th International Energy Conference (ENERGYCON). May 9-12, 2022, Riga, Latvia. IEEE, 2022: 1-6. DOI: 10.1109/ENERGYCON53164. 2022.9830324. |

| 95 | EATY N D K M, BAGADE P. Electric vehicle battery management using digital twin[C]//2022 IEEE International Conference on Omni-layer Intelligent Systems (COINS). August 1-3, 2022, Barcelona, Spain. IEEE, 2022: 1-5. DOI: 10.1109/COINS54846. 2022.9854955. |

| 96 | LI H, HUANG J X, JI W J, et al. Predicting capacity fading behaviors of lithium ion batteries: An electrochemical protocol-integrated digital-twin solution[J]. Journal of the Electrochemical Society, 2022, 169(10): 100504. DOI: 10.1149/1945-7111/ac95d2. |

| 97 | QIN Y, ARUNAN A, YUEN C. Digital twin for real-time Li-ion battery state of health estimation with partially discharged cycling data[J]. IEEE Transactions on Industrial Informatics, 2023, 19(5): 7247-7257. DOI: 10.1109/TII.2022.3230698. |

| 98 | ALAMIN K S S, CHEN Y K, MACII E, et al. Digital twins for electric vehicle SoX battery modeling: Status and proposed advancements[C]//2023 AEIT International Conference on Electrical and Electronic Technologies for Automotive (AEIT AUTOMOTIVE). July 17-19, 2023. Modena, Italy. IEEE, 2023. DOI: 10.23919/aeitautomotive58986.2023.10217251. |

| 99 | YI Y H, XIA C Y, FENG C, et al. Digital twin-long short-term memory (LSTM) neural network based real-time temperature prediction and degradation model analysis for lithium-ion battery[J]. Journal of Energy Storage, 2023, 64: 107203. DOI: 10.1016/j.est.2023.107203. |

| 100 | EATY N D K M, BAGADE P. Digital twin for electric vehicle battery management with incremental learning[J]. Expert Systems with Applications, 2023, 229: 120444. DOI: 10.1016/j.eswa.2023.120444. |

| 101 | POOYANDEH M, SOHN I. Smart lithium-ion battery monitoring in electric vehicles: An AI-empowered digital twin approach[J]. Mathematics, 2023, 11(23): 4865. DOI: 10.3390/math11234865. |

| 102 | LI W, LI Y S, GARG A, et al. Enhancing real-time degradation prediction of lithium-ion battery: A digital twin framework with CNN-LSTM-attention model[J]. Energy, 2024, 286: 129681. DOI: 10.1016/j.energy.2023.129681. |

| 103 | NAIR P, VAKHARIA V, SHAH M, et al. AI-driven digital twin model for reliable lithium-ion battery discharge capacity predictions[J]. International Journal of Intelligent Systems, 2024, 2024: 8185044. DOI: 10.1155/2024/8185044. |

| 104 | NKECHINYERE NJOKU J, IFEANYI NWAKANMA C, KIM D S. Explainable data-driven digital twins for predicting battery states in electric vehicles[J]. IEEE Access, 2024, 12: 83480-83501. DOI: 10.1109/ACCESS.2024.3413075. |

| 105 | YANG D Z, CUI Y D, XIA Q, et al. A digital twin-driven life prediction method of lithium-ion batteries based on adaptive model evolution[J]. Materials, 2022, 15(9): 3331. DOI: 10.3390/ma15093331. |

| 106 | THELEN A, ZHANG X G, FINK O, et al. A comprehensive review of digital twin: Part 2: Roles of uncertainty quantification and optimization, a battery digital twin, and perspectives[J]. Structural and Multidisciplinary Optimization, 2022, 66(1): 1. DOI: 10.1007/s00158-022-03410-x. |

| 107 | LI H, KALEEM M B, CHIU I J, et al. An intelligent digital twin model for the battery management systems of electric vehicles[J]. International Journal of Green Energy, 2024, 21(3): 461-475. DOI: 10.1080/15435075.2023.2199330. |

| 108 | XIE J H, YANG R F, HUI S Y R, et al. Dual Digital Twin: Cloud-edge collaboration with Lyapunov-based incremental learning in EV batteries[J]. Applied Energy, 2024, 355: 122237. DOI: 10.1016/j.apenergy.2023.122237. |

| 109 | WANG F J, ZHAO Z B, ZHAI Z, et al. Explainability-driven model improvement for SOH estimation of lithium-ion battery[J]. Reliability Engineering & System Safety, 2023, 232: 109046. DOI: 10.1016/j.ress.2022.109046. |

| 110 | FENG F, TENG S L, LIU K L, et al. Co-estimation of lithium-ion battery state of charge and state of temperature based on a hybrid electrochemical-thermal-neural-network model[J]. Journal of Power Sources, 2020, 455: 227935. DOI: 10.1016/j.jpowsour.2020.227935. |

| 111 | DINEVA A, CSOMÓS B, KOCSIS SZ S, et al. Investigation of the performance of direct forecasting strategy using machine learning in State-of-Charge prediction of Li-ion batteries exposed to dynamic loads[J]. Journal of Energy Storage, 2021, 36: 102351. DOI: 10.1016/j.est.2021.102351. |

| 112 | TIAN J P, XIONG R, LU J H, et al. Battery state-of-charge estimation amid dynamic usage with physics-informed deep learning[J]. Energy Storage Materials, 2022, 50: 718-729. DOI: 10.1016/j.ensm.2022.06.007. |

| 113 | SINGH S, EBONGUE Y E, REZAEI S, et al. Hybrid modeling of lithium-ion battery: Physics-informed neural network for battery state estimation[J]. Batteries, 2023, 9(6): 301. DOI: 10.3390/batteries9060301. |

| 114 | YU H Q, ZHANG L S, WANG W T, et al. State of charge estimation method by using a simplified electrochemical model in deep learning framework for lithium-ion batteries[J]. Energy, 2023, 278: 127846. DOI: 10.1016/j.energy.2023.127846. |

| 115 | NASCIMENTO R G, CORBETTA M, KULKARNI C S, et al. Hybrid physics-informed neural networks for lithium-ion battery modeling and prognosis[J]. Journal of Power Sources, 2021, 513: 230526. DOI: 10.1016/j.jpowsour.2021.230526. |

| 116 | KOHTZ S, XU Y W, ZHENG Z Y, et al. Physics-informed machine learning model for battery state of health prognostics using partial charging segments[J]. Mechanical Systems and Signal Processing, 2022, 172: 109002. DOI: 10.1016/j.ymssp.2022.109002. |

| 117 | SUN B, PAN J L, WU Z Y, et al. Adaptive evolution enhanced physics-informed neural networks for time-variant health prognosis of lithium-ion batteries[J]. Journal of Power Sources, 2023, 556: 232432. DOI: 10.1016/j.jpowsour.2022.232432. |

| 118 | HOFMANN T, HAMAR J, ROGGE M, et al. Physics-informed neural networks for state of health estimation in lithium-ion batteries[J]. Journal of the Electrochemical Society, 2023, 170(9): 090524. DOI: 10.1149/1945-7111/acf0ef. |

| 119 | FU H J, LIU Z G, CUI K X, et al. Physics-informed neural network for spacecraft lithium-ion battery modeling and health diagnosis[J]. IEEE/ASME Transactions on Mechatronics, 2024, PP(99): 1-10. DOI: 10.1109/TMECH.2023.3348519. |

| 120 | WEN P F, YE Z S, LI Y, et al. Physics-informed neural networks for prognostics and health management of lithium-ion batteries[J]. IEEE Transactions on Intelligent Vehicles, 2024, 9(1): 2276-2289. DOI: 10.1109/TIV.2023.3315548. |

| 121 | WANG F J, ZHAI Z, ZHAO Z B, et al. Physics-informed neural network for lithium-ion battery degradation stable modeling and prognosis[J]. Nature Communications, 2024, 15(1): 4332. DOI: 10.1038/s41467-024-48779-z. |

| 122 | TANG A H, XU Y C, HU Y Z, et al. Battery state of health estimation under dynamic operations with physics-driven deep learning[J]. Applied Energy, 2024, 370: 123632. DOI: 10.1016/j.apenergy.2024.123632. |

| 123 | SHI J C, RIVERA A, WU D Z. Battery health management using physics-informed machine learning: Online degradation modeling and remaining useful life prediction[J]. Mechanical Systems and Signal Processing, 2022, 179: 109347. DOI: 10.1016/j.ymssp.2022.109347. |

| 124 | NAJERA-FLORES D A, HU Z, CHADHA M, et al. A Physics-Constrained Bayesian neural network for battery remaining useful life prediction[J]. Applied Mathematical Modelling, 2023, 122: 42-59. DOI: 10.1016/j.apm.2023.05.038. |

| 125 | MA L, TIAN J P, ZHANG T L, et al. Accurate and efficient remaining useful life prediction of batteries enabled by physics-informed machine learning[J]. Journal of Energy Chemistry, 2024, 91: 512-521. DOI: 10.1016/j.jechem.2023.12.043. |

| 126 | WANG Y J, TIAN J Q, SUN Z D, et al. A comprehensive review of battery modeling and state estimation approaches for advanced battery management systems[J]. Renewable and Sustainable Energy Reviews, 2020, 131: 110015. DOI: 10.1016/j.rser.2020.110015. |

| 127 | LIN Y H, RUAN S J, CHEN Y X, et al. Physics-informed deep learning for lithium-ion battery diagnostics using electrochemical impedance spectroscopy[J]. Renewable and Sustainable Energy Reviews, 2023, 188: 113807. DOI: 10.1016/j.rser.2023.113807. |

| 128 | CUI B H, WANG H, LI R L, et al. Ultra-early prediction of lithium-ion battery performance using mechanism and data-driven fusion model[J]. Applied Energy, 2024, 353: 122080. DOI: 10.1016/j.apenergy.2023.122080. |

| 129 | THELEN A, LUI Y H, SHEN S, et al. Integrating physics-based modeling and machine learning for degradation diagnostics of lithium-ion batteries[J]. Energy Storage Materials, 2022, 50: 668-695. DOI: 10.1016/j.ensm.2022.05.047. |

| 130 | NAVIDI S, THELEN A, LI T K, et al. Physics-informed machine learning for battery degradation diagnostics: A comparison of state-of-the-art methods[J]. Energy Storage Materials, 2024, 68: 103343. DOI: 10.1016/j.ensm.2024.103343. |

| 131 | SU A Y, MAO S Y, LU L G, et al. Implanted potential sensing separator enables smart battery internal state monitor and safety alert[J]. eTransportation, 2024, 21: 100339. DOI: 10.1016/j.etran.2024.100339. |

| [1] | Zhenwei ZHU, Jiawei MIAO, Xiayu ZHU, Xiaoxu WANG, Jingyi QIU, Hao ZHANG. Research progress in lithium-ion battery remaining useful life prediction based on machine learning [J]. Energy Storage Science and Technology, 2024, 13(9): 3134-3149. |

| [2] | Yingying XIE, Bin DENG, Yuzhi ZHANG, Xiaoxu WANG, Linfeng ZHANG. Intelligent R&D of battery design automation in the era of artificial intelligence [J]. Energy Storage Science and Technology, 2024, 13(9): 3182-3197. |

| [3] | Ziyu LIU, Zekun JIANG, Wei QIU, Quan XU, Yingchun NIU, Chunming XU, Tianhang ZHOU. Application of artificial intelligence in long-duration redox flow batteries storage systems [J]. Energy Storage Science and Technology, 2024, 13(9): 2871-2883. |

| [4] | Congxin LI, Meiling YUE, Xintong LI, Qinghui XIONG, Xiaoyan LIU. Proton exchange membrane fuel cell aging performance prediction based on conditional neural networks [J]. Energy Storage Science and Technology, 2024, 13(9): 3094-3102. |

| [5] | Guobing ZHOU, Shenzhen XU. Progress of theoretical studies on the formation and growth mechanisms of solid electrolyte interphase at lithium metal anodes [J]. Energy Storage Science and Technology, 2024, 13(9): 3150-3160. |

| [6] | Dinghong LIU, Wenkai DONG, Zhaoyang LI, Hongzhu ZHANG, Xin QI. Estimation of real-vehicle battery state of health using the RUN-GRU-attention model [J]. Energy Storage Science and Technology, 2024, 13(9): 3042-3058. |

| [7] | Ruihe XING, Suting WENG, Yejing LI, Jiayi ZHANG, Hao ZHANG, Xuefeng WANG. AI-assisted battery material characterization and data analysis [J]. Energy Storage Science and Technology, 2024, 13(9): 2839-2863. |

| [8] | Yajie LI, Yiping WANG, Bin CHEN, Hailong LIN, Geng ZHANG, Siqi SHI. Machine learning-assisted phase-field simulation for predicting the impact of lithium-ion transport parameters on maximum battery dendrite height and space utilization rate [J]. Energy Storage Science and Technology, 2024, 13(9): 2864-2870. |

| [9] | Zhifeng HE, Yuanzhe TAO, Yonggang HU, Qicong Wang, Yong YANG. Machine learning-enhanced electrochemical impedance spectroscopy for lithium-ion battery research [J]. Energy Storage Science and Technology, 2024, 13(9): 2933-2951. |

| [10] | Long FAN, Yan ZHANG. The whole process digital intelligent manufacturing technology in the energy battery manufacturing process [J]. Energy Storage Science and Technology, 2024, 13(4): 1356-1358. |

| [11] | Bingjin LI, Xiaoxia HAN, Wenjie ZHANG, Weiguo ZENG, Jinde WU. Review of the remaining useful life prediction methods for lithium-ion batteries [J]. Energy Storage Science and Technology, 2024, 13(4): 1266-1276. |

| [12] | Yuhao ZHOU, Luoyun XÜ, Zhongping ZHANG, Lingchong LIU, Bin NAN, Haiqi ZHAO. Construction and simulation analysis of thermoelectric coupling model of lithium battery based on digital twin [J]. Energy Storage Science and Technology, 2023, 12(2): 536-543. |

| [13] | Siqi SHI, Zhangwei TU, Xinxin ZOU, Shiyu SUN, Zhengwei YANG, Yue LIU. Applying data-driven machine learning to studying electrochemical energy storage materials [J]. Energy Storage Science and Technology, 2022, 11(3): 739-759. |

| [14] | Chenkun LI, Shuai WANG, Jun HUANG. Method for solving physical model of electrochemical impedance spectroscopy [J]. Energy Storage Science and Technology, 2022, 11(3): 912-920. |

| [15] | Chong LI, Chenhui WANG, Gao WANG, Zonghu LU, Chengzhi MA. Review on implementation method analysis and performance comparison of lithium battery state of charge estimation [J]. Energy Storage Science and Technology, 2022, 11(10): 3328-3344. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||