Energy Storage Science and Technology ›› 2024, Vol. 13 ›› Issue (9): 2933-2951.doi: 10.19799/j.cnki.2095-4239.2024.0708

Previous Articles Next Articles

Zhifeng HE1( ), Yuanzhe TAO1, Yonggang HU1,2, Qicong Wang4, Yong YANG1,2,3(

), Yuanzhe TAO1, Yonggang HU1,2, Qicong Wang4, Yong YANG1,2,3( )

)

Received:2024-07-31

Revised:2024-08-22

Online:2024-09-28

Published:2024-09-20

Contact:

Yong YANG

E-mail:hzf13107618190@163.com;yyang@xmu.edu.cn

CLC Number:

Zhifeng HE, Yuanzhe TAO, Yonggang HU, Qicong Wang, Yong YANG. Machine learning-enhanced electrochemical impedance spectroscopy for lithium-ion battery research[J]. Energy Storage Science and Technology, 2024, 13(9): 2933-2951.

Table 1

Comparing methods for obtaining impedance spectra using different machine learning models"

| 输入 | 模型 | 结果 | 预测范围 | 文献 |

|---|---|---|---|---|

| 特征频率 | CNN | 2.4 Ah 18650电池RMSE约1 mΩ 45 mAh LCO max RMSE 约0.11 Ω | 0.1 Hz~10 kHz | [ |

| CC曲线 | CNN | 2.4 Ah 18650电池RMSE <2 mΩ | 0.1 Hz~100 kHz | [ |

| GPR | 2.2 Ah 18650电池RMSE约1.2 mΩ | 10 mHz~6.5 kHz | [ | |

| LR | 2.2 Ah 18650电池RMSE约3.4 mΩ | 10 mHz~6.5 kHz | ||

| RF | 2.2 Ah 18650电池RMSE约1.6 mΩ | 10 mHz~6.5 kHz | ||

| XGBoost | 2.2 Ah 18650电池RMSE约2.1 mΩ | 10 mHz~6.5 kHz | ||

| KNN | 2.2 Ah 18650电池RMSE约1.4 mΩ | 10 mHz~6.5 kHz | ||

| ANN | 2.2 Ah 18650电池RMSE约2.2 mΩ | 10 mHz~6.5 kHz | ||

| CC曲线 | LSTM | 2.4 Ah 18650电池maxRMSE= 1.48 mΩ | 100 mHz~10 kHz | [ |

| CV曲线 | GPR | 2.6 Ah 18650电池max RMSE=0.87 mΩ | 10 mHz~10 kHz | [ |

| LR | 2.6 Ah 18650电池max RMSE=5.18 mΩ | 10 mHz~10 kHz | ||

| RF | 2.6 Ah 18650电池max RMSE=1.04 mΩ | 10 mHz~10 kHz | ||

| XGBoost | 2.6 Ah 18650电池max RMSE=1.01 mΩ | 10 mHz~10 kHz | ||

| KNN | 2.6 Ah 18650电池max RMSE=0.96 mΩ | 10 mHz~10 kHz | ||

| RV曲线 | GPR | 2.6 Ah 18650电池max RMSE=0.72 mΩ | 10 mHz~10 kHz | [ |

| LR | 2.6 Ah 18650电池max RMSE=1.95 mΩ | 10 mHz~10 kHz | ||

| RF | 2.6 Ah 18650电池max RMSE=0.77 mΩ | 10 mHz~10 kHz | ||

| XGBoost | 2.6 Ah 18650电池max RMSE=0.80 mΩ | 10 mHz~10 kHz | ||

| KNN | 2.6 Ah 18650电池max RMSE=0.87 mΩ | 10 mHz~10 kHz | ||

| 99 s脉冲(1 Hz) | LSTM | 2.4 Ah 18650电池 RMSE约1.0 mΩ | 100 mHz~10 kHz | [ |

| 10 s脉冲(10 Hz) | ANN | 2.5 Ah SONY US18650VTC5电池,RMSE为2.1 mΩ | 1.15 Hz~11.5 kHz | [ |

EIS数据 频率、周期电位、温度和SOC | 集成学习 | 30 mAh LIR203预测相角准确率99.9% | 10-2~105 Hz | [ |

| 集成学习 | 实部阻抗98.54%置信区间 虚部阻抗95.35%置信区间 | 20 mHz~100 kHz | [ | |

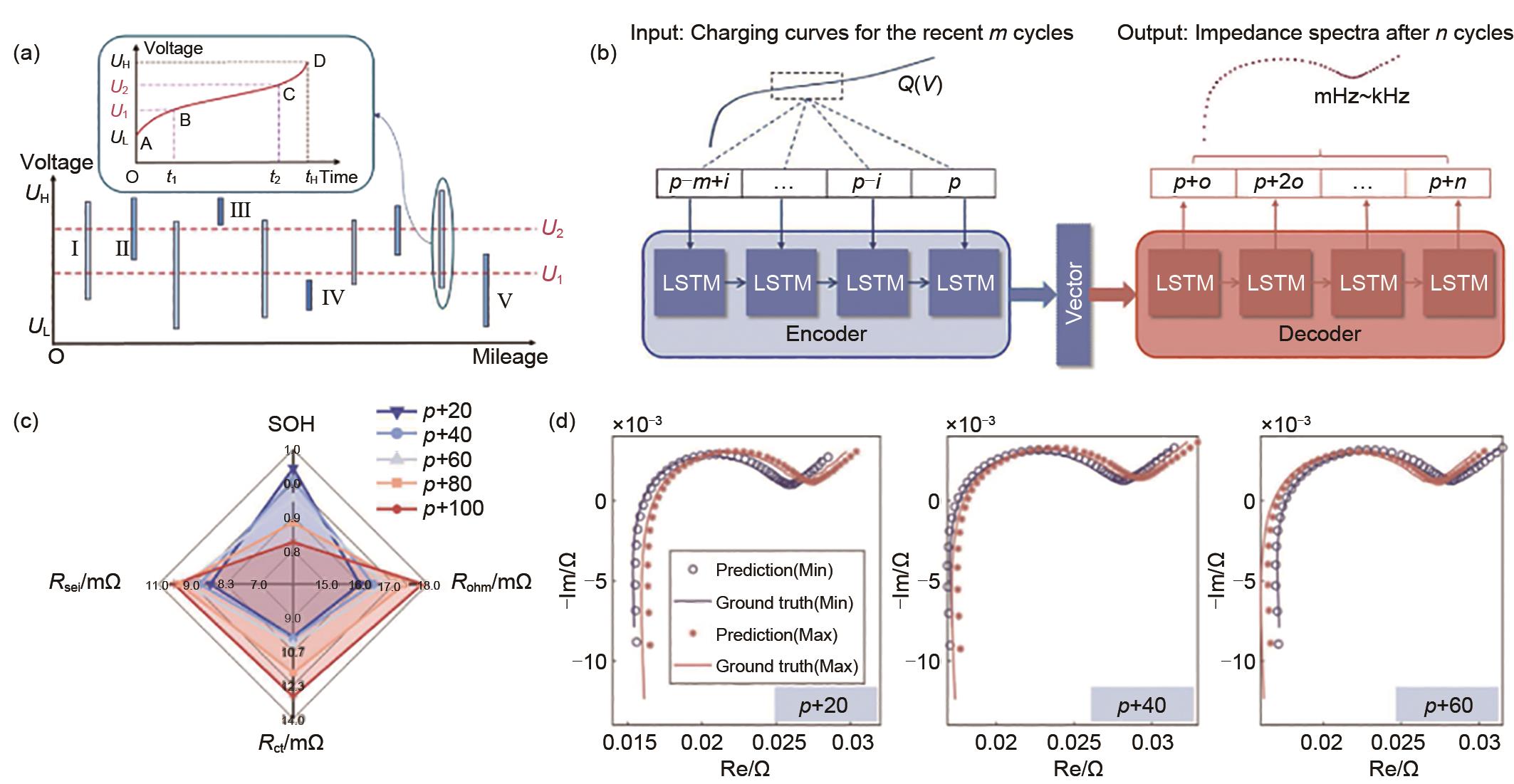

Fig. 4

Framework for predicting short-term EIS variations and lifetime assessment[24]: (a) Selecting the same charging voltage range as input; (b) LSTM neural network for predicting short-term EIS; (c) Realizing predictions of short-term kinetic parameter changes; (d) Predicting the current and future short-term impedance spectra"

Table 2

Research on the application of machine learning in ECM"

| 类型 | 模型 | 内容 | 文献 |

|---|---|---|---|

| ECM的选取和参数识别 | 贝叶斯统计法 | 预测仅含电阻和电容的ECM,超过90%准确率 | [ |

| 支持向量机 | 预测五种典型的ECM,预测准确度为78% | [ | |

| CNN-LSTM | 对最佳电路模型预测,在实验测量的阻抗数据验证其有效性,可用于快速筛选建模大型阻抗谱数据 | [ | |

| DNN | 允许使用生成数据和真实EIS数据训练ECM模型,拟合失败率小于1% | [ | |

| ANN | 引入新的损失函数进行优化识别电池老化EIS产生的变化 | [ | |

| 不同机器学习模型识别ECM准确性比较 | XGboost/RF/CNN | XGboost最佳,CNN可以用于ECM分类,但仍面临挑战 | [ |

| EIS的数据(数量/输入形式/输出标签)对机器学习识别ECM的影响 | ANN | 200条数据足以用于简单的ECM识别,准确率95%,对于复杂场景识别准确率仅为75% | [ |

| Resnet | 讨论EIS的输入情况(Nyquist图/波特图以及三种归一化数据对于预测ECM的影响 | [ | |

| PCA/t-SNE/UMAP | 在无监督条件下在面临复杂条件的EIS可能无法完全揭示EIS谱图的细微差别 | [ | |

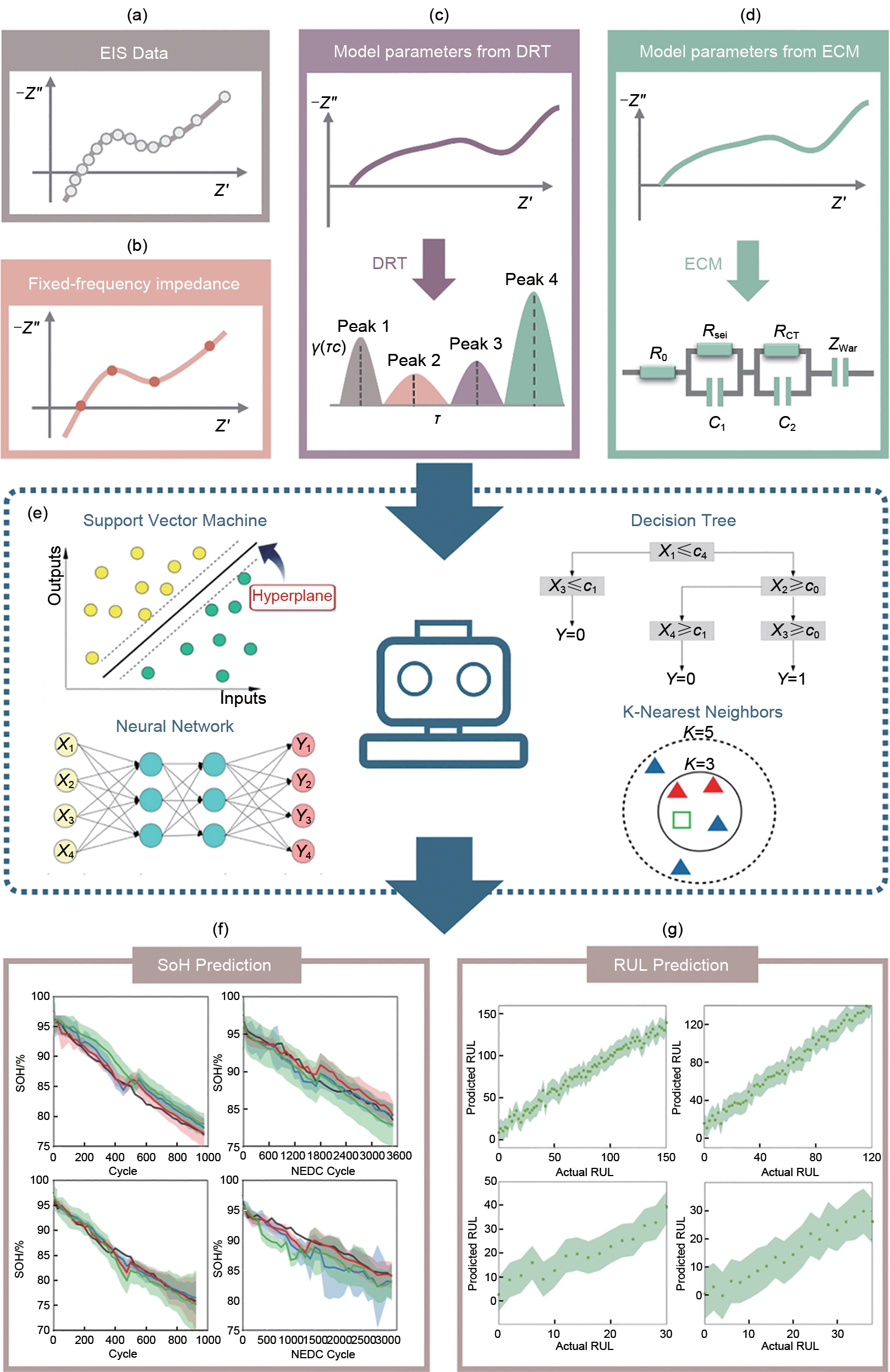

Fig. 8

Flowchart of four different methods for predicting battery lifetime based on EIS: These include (a) broadband input; (b) characteristic frequency input; (c) decoupled parameters input under DRT; (d) ECM model parameter input. (f), (g) Machine learning predictions for battery RUF[61] and SOH[70]"

Table 3

Comparing different machine learning methods for predicting battery life"

| 输入 | 模型 | 预测结果 | 文献 |

|---|---|---|---|

| 宽频输入 | DNN-TL | 在25 ℃和35 ℃训练的DNN模型MSE为0.0266,R2为99.68% | [ |

| CNN | 1C放电下RMSE为9.57% | [ | |

| CNN | RMSE为1.974 SOH%和最大误差为4.935 SOH% | [ | |

| GPR | RMSE为1.1096%, R2为0.9759,MSE为1.0374 | [ | |

| GPR | R2为0.88 | [ | |

| GPR | RMSE为1.168%,MAE为1.016% | [ | |

FL,SVM ANN,RF | R2为0.98,MAE为1.87 | [ | |

| 宽频+IC | SVR-Elman-ELM | R2为0.9957,MAE为0.0065,RMSE为0.109 | [ |

| 特征频率 | SVR | 预测结果相对误差都在2%以内 | [ |

DR, lightGBM XGboost,Catboost | RMSE为3.16,MSE为9.96,R2为0.81 | [ | |

| ELM | 估计误差小于2% | [ | |

| GPR | RMSE为0.932%,MAE为0.750% | [ | |

| 等效电路 | IPSO-CNN-BILSTM | RMSE为1.76% | [ |

| RNN | 容量估计MSE为0.462 | [ | |

| SVM | 准确性可以达到80% | [ | |

| GRU | RMSE, MAE, MAPE均小于 2 %. | [ | |

宽频输入+ 等效电路 | PIDL | RMSE为6.36%,R2为0.95 | [ |

| DRT | ARD-GPR | RMSE为0.6%,MAE为0.4%,R2为0.992 | [ |

| LSBoost | RMSE在不同电池工作状态下可以保持在2.08%以内 | [ | |

| Nyquist图转换为图像后输入 | VGG | RMSE小于2%,与基准模型相比,准确度提高了55.6% | [ |

Table 4

Advantages and disadvantages of different machine learning methods for predicting battery life"

| 方法 | 宽频率范围 | 特征频率 | ECM参数 | DRT参数 |

|---|---|---|---|---|

| 输入方式 | 将阻抗谱的虚部实部作为输入 | 通过手动或自动的方式提取特征频率作为输入 | 通过拟合出的等效电路参数作为输入 | 通过拟合出的DRT参数作为输入 |

| 优点 | 信息完整 并且无需进行预处理,操作简单 | 具有一定可解释性 降低了计算资源的消耗 剔除负面作用数据点提高模型准确性 | 操作简单 具有一定可解释性 | 无人为性 提升模型的解释 可能发现一些额外的特征因子 |

| 缺点 | 计算资源消耗较大 另外有部分数据点对于训练具有负面作用 | 但是由于使用的数据点较少,存在了相应的信息丢失 | 但是等效电路方法具有较强的人为性,在处理的过程中的不确定性较多 | 当杂峰过多时对于训练具有负面作用 |

Fig. 9

(a) Variation of ohmic resistance in EIS under battery operation[97]; (b) Change of charge transfer resistance (Rct) in DRT during lithium plating[98]; (c) Change of solid electrolyte interphase resistance (Rsei) in DRT during lithium plating[99]; (d) Differential voltage (DV) curves related to qualitative and quantitative analysis of lithium plating, as output by deep learning[95]; (e) Machine learning framework for assessing battery aging behavior[57]"

Table 5

Available open-source impedance spectroscopy machine learning datasets"

| 内容 | 开源地址 | 文献 |

|---|---|---|

| 基于EIS和电池寿命数据 | https://github.com/PenelopeJones/battery-forecasting | [ |

| 基于EIS和剩余使用寿命RUF数据 | https://github.com/YunweiZhang/MLidentify-battery-degradation | [ |

| 基于等效电路EIS数据 | https://data.mendeley.com/datasets/mbv3bx847g | [ |

基于不同SOC 不同温度EIS数据 | https://github.com/battery-data-commons/mrs-sp22-tutorial/tree/main/predict_capacity_from_eis. | [ |

基于EIS的 健康状态数据 | EIS Dataset & NN code (figshare.com) | [ |

基于EIS的锂离子电池 电化学诊断数据 | www.github.com/NREL/battery_capacity_from_eis | [ |

基于EIS的电池 容量预测数据 | https://ti.arc.nasa.gov/tech/dash/groups/pcoe/prognostic-data-repository/ | [ |

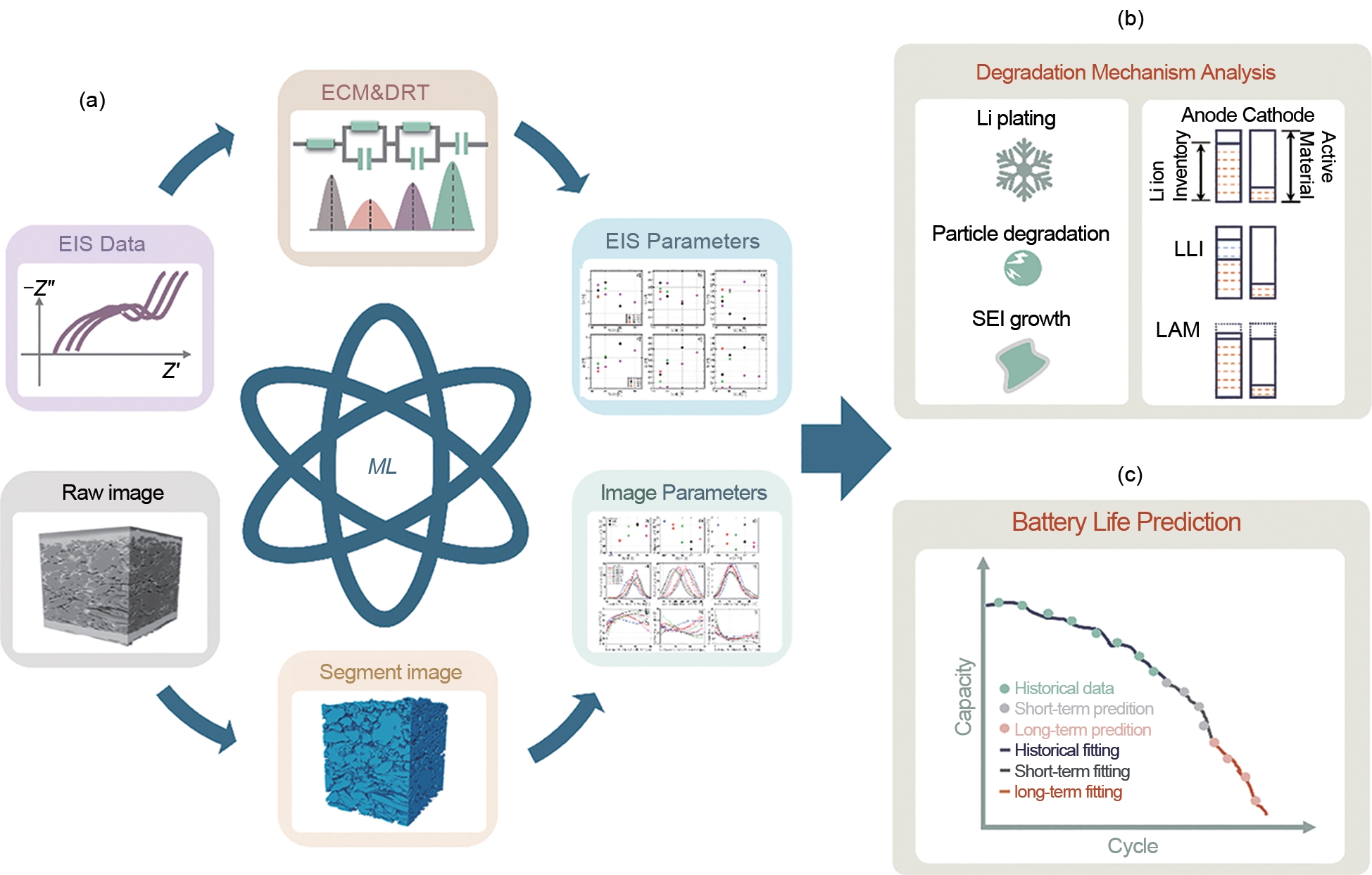

Fig. 10

Framework for data fusion through machine learning:(a) Machine learning for EIS data decoupling analysis [top (a) left), including EIS data, ECM & DRT decoupled EIS, and obtaining EIS parameters under different SOH conditions; Machine learning for quantification of battery image data [bottom (a) left], including raw image data, machine learning for image recognition, and machine learning for quantification of various parameters in the image[105]; (b) Study of battery aging mechanisms; (c) Battery life prediction"

| 1 | GUO R H, WANG F, AKBAR RHAMDHANI M, et al. Managing the surge: A comprehensive review of the entire disposal framework for retired lithium-ion batteries from electric vehicles[J]. Journal of Energy Chemistry, 2024, 92: 648-680. DOI: 10.1016/j.jechem.2024.01.055. |

| 2 | 国际能源署. 2024年全球电动汽车展望:国际能源署报告[R]. 巴黎:国际能源署. https://www.iea.org/reports/global-ev-outlook-2024. |

| International Energy Agency. Global EV Outlook 2024: IEA Report[R]. Paris: International Energy Agency. https://www.iea.org/reports/global-ev-outlook-2024. | |

| 3 | ZHAO J Y, FENG X N, PANG Q Q, et al. Battery safety: Machine learning-based prognostics[J]. Progress in Energy and Combustion Science, 2024, 102: 101142. DOI: 10.1016/j.pecs.2023.101142. |

| 4 | CHEN S Y, GAO Z H, SUN T J. Safety challenges and safety measures of Li-ion batteries[J]. Energy Science & Engineering, 2021, 9(9): 1647-1672. DOI: 10.1002/ese3.895. |

| 5 | SONG K, HU D, TONG Y, et al. Remaining life prediction of lithium-ion batteries based on health management: A review[J]. Journal of Energy Storage, 2023, 57: 106193. DOI: 10.1016/j.est. 2022.106193. |

| 6 | BARAI A, UDDIN K, DUBARRY M, et al. A comparison of methodologies for the non-invasive characterisation of commercial Li-ion cells[J]. Progress in Energy and Combustion Science, 2019, 72: 1-31. DOI: 10.1016/j.pecs.2019.01.001. |

| 7 | WAN X H, XU X J, LI F K, et al. Application of nondestructive testing technology in device-scale for lithium-ion batteries[J]. Small Structures, 2024, 5(3): 2300196. DOI: 10.1002/sstr. 202300196. |

| 8 | 郝奕帆, 祝夏雨, 王静, 等. 电池无损检测监测方法分析[J]. 储能科学与技术, 2023, 12(5): 1713-1737. DOI: 10.19799/j.cnki.2095-4239.2023.0081. |

| HAO Y F, ZHU X Y, WANG J, et al. Analysis of battery nondestructive testing and monitoring methods[J]. Energy Storage Science and Technology, 2023, 12(5): 1713-1737. DOI: 10.19799/j.cnki.2095-4239.2023.0081. | |

| 9 | DAYANI S, MARKÖTTER H, SCHMIDT A, et al. Multi-level X-ray computed tomography (XCT) investigations of commercial lithium-ion batteries from cell to particle level[J]. Journal of Energy Storage, 2023, 66: 107453. DOI: 10.1016/j.est.2023.107453. |

| 10 | LEE M Y, LEE J, SHIN Y, et al. Multiscale imaging techniques for real-time, noninvasive diagnosis of Li-ion battery failures[J]. Small Science, 2023, 3(11): DOI: 10.1002/smsc.202300063. |

| 11 | DU X H, MENG J H, AMIRAT Y, et al. Exploring impedance spectrum for lithium-ion batteries diagnosis and prognosis: A comprehensive review[J]. Journal of Energy Chemistry, 2024, 95: 464-483. DOI: 10.1016/j.jechem.2024.04.005. |

| 12 | WANG S S, ZHANG J B, GHARBI O, et al. Electrochemical impedance spectroscopy[J]. Nature Reviews Methods Primers, 2021, 1: 41. DOI: 10.1038/s43586-021-00039-w. |

| 13 | VIVIER V, ORAZEM M E. Impedance analysis of electrochemical systems[J]. Chemical Reviews, 2022, 122(12): 11131-11168. DOI: 10.1021/acs.chemrev.1c00876. |

| 14 | LU Y, ZHAO C Z, HUANG J Q, et al. The timescale identification decoupling complicated kinetic processes in lithium batteries[J]. Joule, 2022, 6(6): 1172-1198. DOI: 10.1016/j.joule.2022.05.005. |

| 15 | MC CARTHY K, GULLAPALLI H, RYAN K M, et al. Review-use of impedance spectroscopy for the estimation of Li-ion battery state of charge, state of health and internal temperature[J]. Journal of the Electrochemical Society, 2021, 168(8): 080517. DOI: 10.1149/1945-7111/ac1a85. |

| 16 | HU W X, PENG Y F, WEI Y M, et al. Application of electrochemical impedance spectroscopy to degradation and aging research of lithium-ion batteries[J]. The Journal of Physical Chemistry C, 2023, 127(9): 4465-4495. DOI: 10.1021/acs.jpcc.3c00033. |

| 17 | LV C D, ZHOU X, ZHONG L X, et al. Machine learning: An advanced platform for materials development and state prediction in lithium-ion batteries[J]. Advanced Materials, 2022, 34(25): e2101474. DOI: 10.1002/adma.202101474. |

| 18 | SHU X, SHEN S Q, SHEN J W, et al. State of health prediction of lithium-ion batteries based on machine learning: Advances and perspectives[J]. iScience, 2021, 24(11): 103265. DOI: 10.1016/j.isci.2021.103265. |

| 19 | FINEGAN D P, SQUIRES I, DAHARI A, et al. Machine-learning-driven advanced characterization of battery electrodes[J]. ACS Energy Letters, 2022, 7(12): 4368-4378. DOI: 10.1021/acsenergylett.2c01996. |

| 20 | WANG X Y, WEI X Z, ZHU J G, et al. A review of modeling, acquisition, and application of lithium-ion battery impedance for onboard battery management[J]. eTransportation, 2021, 7: 100093. DOI: 10.1016/j.etran.2020.100093. |

| 21 | DUAN Y Z, TIAN J P, LU J H, et al. Deep neural network battery impedance spectra prediction by only using constant-current curve[J]. Energy Storage Materials, 2021, 41: 24-31. DOI: 10. 1016/j.ensm.2021.05.047. |

| 22 | GUO J, CHE Y H, PEDERSEN K, et al. Battery impedance spectrum prediction from partial charging voltage curve by machine learning[J]. Journal of Energy Chemistry, 2023, 79: 211-221. DOI: 10.1016/j.jechem.2023.01.004. |

| 23 | KO C J, CHEN K C. Constructing battery impedance spectroscopy using partial current in constant-voltage charging or partial relaxation voltage[J]. Applied Energy, 2024, 356: 122454. DOI: 10.1016/j.apenergy.2023.122454. |

| 24 | SUN Y, XIONG R, MENG X F, et al. Battery degradation evaluation based on impedance spectra using a limited number of voltage-capacity curves[J]. eTransportation, 2024, 22: 100347. DOI: 10.1016/j.etran.2024.100347. |

| 25 | WU L F, ZHANG Y. Attention-based encoder-decoder networks for state of charge estimation of lithium-ion battery[J]. Energy, 2023, 268: 126665. DOI: 10.1016/j.energy.2023.126665. |

| 26 | CAI L, MENG J H, STROE D I, et al. An evolutionary framework for lithium-ion battery state of health estimation[J]. Journal of Power Sources, 2019, 412: 615-622. DOI: 10.1016/j.jpowsour.2018.12.001. |

| 27 | MENG J H, CAI L, STROE D I, et al. An optimized ensemble learning framework for lithium-ion Battery State of Health estimation in energy storage system[J]. Energy, 2020, 206: 118140. DOI: 10.1016/j.energy.2020.118140. |

| 28 | LI A, WEST A C, PREINDL M. Characterizing degradation in lithium-ion batteries with pulsing[J]. Journal of Power Sources, 2023, 580: 233328. DOI: 10.1016/j.jpowsour.2023.233328. |

| 29 | TIAN J P, XIONG R, CHEN C, et al. Simultaneous prediction of impedance spectra and state for lithium-ion batteries from short-term pulses[J]. Electrochimica Acta, 2023, 449: 142218. DOI: 10.1016/j.electacta.2023.142218. |

| 30 | TANG X P, LAI X, LIU Q, et al. Predicting battery impedance spectra from 10-second pulse tests under 10 Hz sampling rate[J]. iScience, 2023, 26(6): 106821. DOI: 10.1016/j.isci.2023.106821. |

| 31 | TEMIZ S, KURBAN H, EROL S, et al. Regeneration of lithium-ion battery impedance using a novel machine learning framework and minimal empirical data[J]. Journal of Energy Storage, 2022, 52: 105022. DOI: 10.1016/j.est.2022.105022. |

| 32 | TEMIZ S, EROL S, KURBAN H, et al. State of charge and temperature-dependent impedance spectra regeneration of lithium-ion battery by duplex learning modeling[J]. Journal of Energy Storage, 2023, 64: 107085. DOI: 10.1016/j.est.2023.107085. |

| 33 | SUN Y, XIONG R, WANG C X, et al. Deep neural network based battery impedance spectrum prediction using only impedance at characteristic frequencies[J]. Journal of Power Sources, 2023, 580: 233414. DOI: 10.1016/j.jpowsour.2023.233414. |

| 34 | MIYAZAKI Y, NAKAYAMA R, YASUO N, et al. Bayesian statistics-based analysis of AC impedance spectra[J]. AIP Advances, 2020, 10(4): 045231. DOI: 10.1063/1.5143082. |

| 35 | ZHU S, SUN X Y, GAO X Y, et al. Equivalent circuit model recognition of electrochemical impedance spectroscopy via machine learning[J]. Journal of Electroanalytical Chemistry, 2019, 855: 113627. DOI: 10.1016/j.jelechem.2019.113627. |

| 36 | AL-ALI A, MAUNDY B, ALLAGUI A, et al. Optimum impedance spectroscopy circuit model identification using deep learning algorithms[J]. Journal of Electroanalytical Chemistry, 2022, 924: 116854. DOI: 10.1016/j.jelechem.2022.116854. |

| 37 | BUTEAU S, DAHN J R. Analysis of thousands of electrochemical impedance spectra of lithium-ion cells through a machine learning inverse model[J]. Journal of the Electrochemical Society, 2019, 166(8): A1611-A1622. DOI: 10.1149/2.1051908jes. |

| 38 | ZULUETA A, ZULUETA E, OLARTE J, et al. Electrochemical impedance spectrum equivalent circuit parameter identification using a deep learning technique[J]. Electronics, 2023, 12(24): 5038. DOI: 10.3390/electronics12245038. |

| 39 | SCHAEFFER J, GASPER P, GARCIA-TAMAYO E, et al. Machine learning benchmarks for the classification of equivalent circuit models from electrochemical impedance spectra[J]. Journal of the Electrochemical Society, 2023, 170(6): 060512. DOI: 10.1149/1945-7111/acd8fb. |

| 40 | BONGIORNO V, GIBBON S, MICHAILIDOU E, et al. Exploring the use of machine learning for interpreting electrochemical impedance spectroscopy data: Evaluation of the training dataset size[J]. Corrosion Science, 2022, 198: 110119. DOI: 10.1016/j.corsci.2022.110119. |

| 41 | SUN J, ZHANG W, CHEN Y, et al. What is the appropriate data representation of electrochemical impedance spectroscopy in machine-learning analysis?[J/OL]. ChemRxiv, 2024. [2024-04-29]. DOI:10.26434/chemrxiv-2024-mdpw8. |

| 42 | MAKOGON A, KANOUFI F, SHKIRSKIY V. Is unsupervised dimensionality reduction sufficient to decode the complexities of electrochemical impedance spectra?[J]. ChemElectroChem, 2024, 11(7): DOI: 10.1002/celc.202300738. |

| 43 | IURILLI P, BRIVIO C, WOOD V. Detection of lithium-ion cells' degradation through deconvolution of electrochemical impedance spectroscopy with distribution of relaxation time[J]. Energy Technology, 2022, 10(10): 2200547. DOI: 10.1002/ente.202200547. |

| 44 | TUNCER E, GUBANSKI S M. On dielectric data analysis. Using the Monte Carlo method to obtain relaxation time distribution and comparing non-linear spectral function fits[J]. IEEE Transactions on Dielectrics and Electrical Insulation, 2001, 8(3): 310-320. DOI: 10.1109/94.933337. |

| 45 | HERSHKOVITZ S, TOMER S, BALTIANSKI S, et al. ISGP: Impedance spectroscopy analysis using evolutionary programming procedure[J]. ECS Transactions, 2011, 33(40): 67-73. DOI: 10.1149/1.3589186. |

| 46 | BOUKAMP B A. Fourier transform distribution function of relaxation times; application and limitations[J]. Electrochimica Acta, 2015, 154: 35-46. DOI: 10.1016/j.electacta.2014.12.059. |

| 47 | SACCOCCIO M, WAN T H, CHEN C, et al. Optimal regularization in distribution of relaxation times applied to electrochemical impedance spectroscopy: Ridge and lasso regression methods-A theoretical and experimental study[J]. Electrochimica Acta, 2014, 147: 470-482. DOI: 10.1016/j.electacta.2014.09.058. |

| 48 | WAN T H, SACCOCCIO M, CHEN C, et al. Influence of the discretization methods on the distribution of relaxation times deconvolution: Implementing radial basis functions with DRTtools[J]. Electrochimica Acta, 2015, 184: 483-499. DOI: 10.1016/j.electacta.2015.09.097. |

| 49 | LIU J P, CIUCCI F. The deep-prior distribution of relaxation times[J]. Journal of the Electrochemical Society, 2020, 167(2): 026506. DOI: 10.1149/1945-7111/ab631a. |

| 50 | QUATTROCCHI E, WAN T H, BELOTTI A, et al. The deep-DRT: A deep neural network approach to deconvolve the distribution of relaxation times from multidimensional electrochemical impedance spectroscopy data[J]. Electrochimica Acta, 2021, 392: 139010. DOI: 10.1016/j.electacta.2021.139010. |

| 51 | PASTOR-FERNÁNDEZ C, DHAMMIKA WIDANAGE W, MARCO J, et al. Identification and quantification of ageing mechanisms in lithium-ion batteries using the EIS technique[C]//2016 IEEE Transportation Electrification Conference and Expo (ITEC). June 27-29, 2016, Dearborn, MI. IEEE, 2016: 1-6. DOI: 10.1109/ITEC. 2016.7520198. |

| 52 | CHRISTENSEN J, NEWMAN J. Cyclable lithium and capacity loss in Li-ion cells[J]. Journal of the Electrochemical Society, 2005, 152(4): A818. DOI: 10.1149/1.1870752. |

| 53 | DUBARRY M, TRUCHOT C, LIAW B Y. Synthesize battery degradation modes via a diagnostic and prognostic model[J]. Journal of Power Sources, 2012, 219: 204-216. DOI: 10.1016/j.jpowsour.2012.07.016. |

| 54 | DAHN H M, SMITH A J, BURNS J C, et al. User-friendly differential voltage analysis freeware for the analysis of degradation mechanisms in Li-ion batteries[J]. Journal of the Electrochemical Society, 2012, 159(9): A1405-A1409. DOI: 10. 1149/2.013209jes. |

| 55 | RUAN H J, CHEN J Y, AI W L, et al. Generalised diagnostic framework for rapid battery degradation quantification with deep learning[J]. Energy and AI, 2022, 9: 100158. DOI: 10.1016/j.egyai.2022.100158. |

| 56 | COSTA N, SÁNCHEZ L, ANSEÁN D, et al. Li-ion battery degradation modes diagnosis via Convolutional Neural Networks[J]. Journal of Energy Storage, 2022, 55: 105558. DOI: 10.1016/j.est.2022.105558. |

| 57 | CHEN B R, WALKER C M, KIM S, et al. Battery aging mode identification across NMC compositions and designs using machine learning[J]. Joule, 2022, 6(12): 2776-2793. DOI: 10. 1016/j.joule.2022.10.016. |

| 58 | TELIZ E, ZINOLA C F, DÍAZ V. Identification and quantification of ageing mechanisms in Li-ion batteries by Electrochemical impedance spectroscopy[J]. Electrochimica Acta, 2022, 426: 140801. DOI: 10.1016/j.electacta.2022.140801. |

| 59 | SUN H, JIANG B, YOU H Z, et al. Quantitative analysis of degradation modes of lithium-ion battery under different operating conditions[J]. Energies, 2021, 14(2): 350. DOI: 10.3390/en14020350. |

| 60 | HITESH PENJURU N M, REDDY G V, NAIR M R, et al. Machine learning aided predictions for capacity fade of Li-ion batteries[J]. Journal of the Electrochemical Society, 2022, 169(5): 050535. DOI: 10.1149/1945-7111/ac7102. |

| 61 | ZHANG Y W, TANG Q C, ZHANG Y, et al. Identifying degradation patterns of lithium ion batteries from impedance spectroscopy using machine learning[J]. Nature Communications, 2020, 11(1): 1706. DOI: 10.1038/s41467-020-15235-7. |

| 62 | XU T T, PENG Z, LIU D G, et al. A hybrid drive method for capacity prediction of lithium-ion batteries[J]. IEEE Transactions on Transportation Electrification, 2022, 8(1): 1000-1012. DOI: 10.1109/TTE.2021.3118813. |

| 63 | LI Y C, MALEKI M, BANITAAN S. State of health estimation of lithium-ion batteries using EIS measurement and transfer learning[J]. Journal of Energy Storage, 2023, 73: 109185. DOI: 10.1016/j.est.2023.109185. |

| 64 | PRADYUMNA T K, CHO K, KIM M, et al. Capacity estimation of lithium-ion batteries using convolutional neural network and impedance spectra[J]. Journal of Power Electronics, 2022, 22(5): 850-858. DOI: 10.1007/s43236-022-00410-4. |

| 65 | LI Y C, MALEKI M, BANITAAN S, et al. State of health estimation of lithium-ion batteries using convolutional neural network with impedance nyquist plots[C]//Proceedings of the 12th International Conference on Pattern Recognition Applications and Methods. February 22-24, 2023. Lisbon, Portugal. SCITEPRESS-Science and Technology Publications, 2023: 842–849[2024-04-29]. DOI: 10.5220/0011672300003411. |

| 66 | EDDAHECH A, BRIAT O, BERTRAND N, et al. Behavior and state-of-health monitoring of Li-ion batteries using impedance spectroscopy and recurrent neural networks[J]. International Journal of Electrical Power & Energy Systems, 2012, 42(1): 487-494. DOI: 10.1016/j.ijepes.2012.04.050. |

| 67 | KIM S, CHOI Y Y, CHOI J I. Impedance-based capacity estimation for lithium-ion batteries using generative adversarial network[J]. Applied Energy, 2022, 308: 118317. DOI: 10.1016/j.apenergy.2021.118317. |

| 68 | BABAEIYAZDI I, REZAEI-ZARE A, SHOKRZADEH S. Transfer learning with deep neural network for capacity prediction of Li-ion batteries using EIS measurement[J]. IEEE Transactions on Transportation Electrification, 2023, 9(1): 886-895. DOI: 10.1109/TTE.2022.3170230. |

| 69 | XIONG R, TIAN J P, SHEN W X, et al. Semi-supervised estimation of capacity degradation for lithium ion batteries with electrochemical impedance spectroscopy[J]. Journal of Energy Chemistry, 2023, 76: 404-413. DOI: 10.1016/j.jechem.2022.09.045. |

| 70 | JIANG B, ZHU J G, WANG X Y, et al. A comparative study of different features extracted from electrochemical impedance spectroscopy in state of health estimation for lithium-ion batteries[J]. Applied Energy, 2022, 322: 119502. DOI: 10.1016/j.apenergy. 2022.119502. |

| 71 | FU Y M, XU J, SHI M J, et al. A fast impedance calculation-based battery state-of-health estimation method[J]. IEEE Transactions on Industrial Electronics, 2022, 69(7): 7019-7028. DOI: 10.1109/TIE.2021.3097668. |

| 72 | FARAJI-NIRI M, RASHID M, SANSOM J, et al. Accelerated state of health estimation of second life lithium-ion batteries via electrochemical impedance spectroscopy tests and machine learning techniques[J]. Journal of Energy Storage, 2023, 58: 106295. DOI: 10.1016/j.est.2022.106295. |

| 73 | XIA B Z, QIN Z P, FU H Y. Rapid estimation of battery state of health using partial electrochemical impedance spectra and interpretable machine learning[J]. Journal of Power Sources, 2024, 603: 234413. DOI: 10.1016/j.jpowsour.2024.234413. |

| 74 | MESSING M, SHOA T, HABIBI S. Estimating battery state of health using electrochemical impedance spectroscopy and the relaxation effect[J]. Journal of Energy Storage, 2021, 43: 103210. DOI: 10.1016/j.est.2021.103210. |

| 75 | LIN Y H, RUAN S J, CHEN Y X, et al. Physics-informed deep learning for lithium-ion battery diagnostics using electrochemical impedance spectroscopy[J]. Renewable and Sustainable Energy Reviews, 2023, 188: 113807. DOI: 10.1016/j.rser.2023.113807. |

| 76 | LUO W, SYED A U, NICHOLLS J R, et al. An SVM-based health classifier for offline Li-ion batteries by using EIS technology[J]. Journal of the Electrochemical Society, 2023, 170(3): 030532. DOI: 10.1149/1945-7111/acc09f. |

| 77 | ZHANG W C, LI T T, WU W X, et al. Data-driven state of health estimation in retired battery based on low and medium-frequency electrochemical impedance spectroscopy[J]. Measurement, 2023, 211: 112597. DOI: 10.1016/j.measurement.2023.112597. |

| 78 | SU X J, SUN B X, WANG J J, et al. Fast capacity estimation for lithium-ion battery based on online identification of low-frequency electrochemical impedance spectroscopy and Gaussian process regression[J]. Applied Energy, 2022, 322: 119516. DOI: 10.1016/j.apenergy.2022.119516. |

| 79 | ZHU Y L, JIANG B, ZHU J G, et al. Adaptive state of health estimation for lithium-ion batteries using impedance-based timescale information and ensemble learning[J]. Energy, 2023, 284: 129283. DOI: 10.1016/j.energy.2023.129283. |

| 80 | WANG J, ZHAO R, HUANG Q A, et al. High-efficient prediction of state of health for lithium-ion battery based on AC impedance feature tuned with Gaussian process regression[J]. Journal of Power Sources, 2023, 561: 232737. DOI: 10.1016/j.jpowsour.2023.232737. |

| 81 | GASPER P, SCHIEK A, SMITH K, et al. Predicting battery capacity from impedance at varying temperature and state of charge using machine learning[J]. Cell Reports Physical Science, 2022, 3(12): 101184. DOI: 10.1016/j.xcrp.2022.101184. |

| 82 | RASTEGARPANAH A, HATHAWAY J, STOLKIN R. Rapid model-free state of health estimation for end-of-first-life electric vehicle batteries using impedance spectroscopy[J]. Energies, 2021, 14(9): 2597. DOI: 10.3390/en14092597. |

| 83 | ALOISIO D, CAMPOBELLO G, LEONARDI S G, et al. Comparison of machine learning techniques for SoC and SoH evaluation from impedance data of an aged lithium ion battery[J]. Acta Imeko, 2021, 10(2): 80. DOI: 10.21014/acta_imeko.v10i2.1043. |

| 84 | FAN M S, GENG M M, YANG K, et al. State of health estimation of lithium-ion battery based on electrochemical impedance spectroscopy[J]. Energies, 2023, 16(8): 3393. DOI: 10.3390/en16083393. |

| 85 | LI D Z, YANG D F, LI L W, et al. Electrochemical impedance spectroscopy based on the state of health estimation for lithium-ion batteries[J]. Energies, 2022, 15(18): 6665. DOI: 10.3390/en15186665. |

| 86 | GUO F, HUANG G S, ZHANG W C, et al. State of Health estimation method for lithium batteries based on electrochemical impedance spectroscopy and pseudo-image feature extraction[J]. Measurement, 2023, 220: 113412. DOI: 10.1016/j.measurement.2023.113412. |

| 87 | GE H, AOKI T, IKEDA N, et al. Investigating lithium plating in lithium-ion batteries at low temperatures using electrochemical model with NMR assisted parameterization[J]. Journal of the Electrochemical Society, 2017, 164(6): A1050-A1060. DOI: 10. 1149/2.0461706jes. |

| 88 | LIU X S, LIANG Z T, XIANG Y X, et al. Solid-state NMR and MRI spectroscopy for Li/Na batteries: Materials, interface, and in situ characterization[J]. Advanced Materials, 2021, 33(50): 2005878. DOI: 10.1002/adma.202005878. |

| 89 | LI B, CAO B B, ZHOU X X, et al. Pre-constructed SEI on graphite-based interface enables long cycle stability for dual ion sodium batteries[J]. Chinese Chemical Letters, 2023, 34(7): 107832. DOI: 10.1016/j.cclet.2022.107832. |

| 90 | DAWKINS J I G, MARTENS I, DANIS A, et al. Mapping the total lithium inventory of Li-ion batteries[J]. Joule, 2023, 7(12): 2783-2797. DOI: 10.1016/j.joule.2023.11.003. |

| 91 | KOLETI U R, DINH T Q, MARCO J. A new on-line method for lithium plating detection in lithium-ion batteries[J]. Journal of Power Sources, 2020, 451: 227798. DOI: 10.1016/j.jpowsour. 2020.227798. |

| 92 | SCHINDLER S, BAUER M, PETZL M, et al. Voltage relaxation and impedance spectroscopy as in-operando methods for the detection of lithium plating on graphitic anodes in commercial lithium-ion cells[J]. Journal of Power Sources, 2016, 304: 170-180. DOI: 10.1016/j.jpowsour.2015.11.044. |

| 93 | CHEN Y X, TORRES-CASTRO L, CHEN K H, et al. operando detection of Li plating during fast charging of Li-ion batteries using incremental capacity analysis[J]. Journal of Power Sources, 2022, 539: 231601. DOI: 10.1016/j.jpowsour.2022.231601. |

| 94 | BURNS J C, STEVENS D A, DAHN J R. In-situ detection of lithium plating using high precision coulometry[J]. Journal of the Electrochemical Society, 2015, 162(6): A959-A964. DOI: 10.1149/2.0621506jes. |

| 95 | TIAN Y, LIN C, LI H L, et al. Deep neural network-driven in situ detection and quantification of lithium plating on anodes in commercial lithium-ion batteries[J]. EcoMat, 2023, 5(1): e12280. DOI: 10.1002/eom2.12280. |

| 96 | LIN Y, HU W X, DING M F, et al. Unveiling the three stages of Li plating and dynamic evolution processes in pouch C/LiFePO4 batteries[J]. Advanced Energy Materials, 2024: 2400894. DOI: 10.1002/aenm.202400894. |

| 97 | PETZL M, KASPER M, DANZER M A. Lithium plating in a commercial lithium-ion battery–A low-temperature aging study[J]. Journal of Power Sources, 2015, 275: 799-807. DOI: 10.1016/j.jpowsour.2014.11.065. |

| 98 | CHEN X, LI L Y, LIU M M, et al. Detection of lithium plating in lithium-ion batteries by distribution of relaxation times[J]. Journal of Power Sources, 2021, 496: 229867. DOI: 10.1016/j.jpowsour.2021.229867. |

| 99 | BROWN D E, MCSHANE E J, KONZ Z M, et al. Detecting onset of lithium plating during fast charging of Li-ion batteries using operando electrochemical impedance spectroscopy[J]. Cell Reports Physical Science, 2021, 2(10): 100589. DOI: 10.1016/j.xcrp.2021.100589. |

| 100 | FENG J R, ZHOU W H, CHEN Z, et al. Probing degradation of layered lithium oxide cathodes via multilength scaled X-ray imaging techniques[J]. Nano Energy, 2024, 119: 109028. DOI: 10.1016/j.nanoen.2023.109028. |

| 101 | MILLER D J, ZAPOTOK D, ANZALONE P, et al. Exploring Li distribution in Li-ion batteries with FIB-SEM and TOF-SIMS[J]. Microscopy and Microanalysis, 2018, 24(S1): 370-371. DOI: 10.1017/s1431927618002349. |

| 102 | YUSUF M, LAMANNA J M, PAUL P P, et al. Simultaneous neutron and X-ray tomography for visualization of graphite electrode degradation in fast-charged lithium-ion batteries[J]. Cell Reports Physical Science, 2022, 3(11): 101145. DOI: 10.1016/j.xcrp.2022.101145. |

| 103 | YANG Y Z, LI N, WANG B, et al. Microstructure evolution of lithium-ion battery electrodes at different states of charge: Deep learning-based segmentation[J]. Electrochemistry Communications, 2022, 136: 107224. DOI: 10.1016/j.elecom.2022.107224. |

| 104 | BALLAI G, SŐRÉS M A, VÁSÁRHELYI L, et al. Exploration of Li-ion batteries during a long-term heat endurance test using 3D temporal microcomputed tomography investigation[J]. Energy Technology, 2023, 11(8): 2370083. DOI: 10.1002/ente.202370083. |

| 105 | RIDDER A, PRIFLING B, HILGER A, et al. Quantitative analysis of cyclic aging of lithium-ion batteries using synchrotron tomography and electrochemical impedance spectroscopy[J]. Electrochimica Acta, 2023, 444: 142003. DOI: 10.1016/j.electacta.2023.142003. |

| 106 | JONES P K, STIMMING U, LEE A A. Impedance-based forecasting of lithium-ion battery performance amid uneven usage[J]. Nature Communications, 2022, 13(1): 4806. DOI: 10.1038/s41467-022-32422-w. |

| 107 | BUCHICCHIO E, DE ANGELIS A, SANTONI F, et al. Battery SOC estimation from EIS data based on machine learning and equivalent circuit model[J]. Energy, 2023, 283: 128461. DOI: 10.1016/j.energy.2023.128461. |

| 108 | GASPER P, SCHIEK A, SHIMONISHI Y, et al. Lithium-ion battery diagnostics using electrochemical impedance via machine-learning[J]. ECS Meeting Abstracts, 2023, 1(1): DOI: 10.1149/MA2023-011397mtgabs. |

| [1] | Jinbao FAN, Na LI, Yikun WU, Chunwang HE, Le YANG, Weili SONG, Haosen CHEN. Digital twin technology for energy batteries at the cell level [J]. Energy Storage Science and Technology, 2024, 13(9): 3112-3133. |

| [2] | Yajie LI, Yiping WANG, Bin CHEN, Hailong LIN, Geng ZHANG, Siqi SHI. Machine learning-assisted phase-field simulation for predicting the impact of lithium-ion transport parameters on maximum battery dendrite height and space utilization rate [J]. Energy Storage Science and Technology, 2024, 13(9): 2864-2870. |

| [3] | Ruihe XING, Suting WENG, Yejing LI, Jiayi ZHANG, Hao ZHANG, Xuefeng WANG. AI-assisted battery material characterization and data analysis [J]. Energy Storage Science and Technology, 2024, 13(9): 2839-2863. |

| [4] | Ning HE, Fangfang YANG. Early prediction of battery lifetime based on energy and temperature features [J]. Energy Storage Science and Technology, 2024, 13(9): 3016-3029. |

| [5] | Dinghong LIU, Wenkai DONG, Zhaoyang LI, Hongzhu ZHANG, Xin QI. Estimation of real-vehicle battery state of health using the RUN-GRU-attention model [J]. Energy Storage Science and Technology, 2024, 13(9): 3042-3058. |

| [6] | Guobing ZHOU, Shenzhen XU. Progress of theoretical studies on the formation and growth mechanisms of solid electrolyte interphase at lithium metal anodes [J]. Energy Storage Science and Technology, 2024, 13(9): 3150-3160. |

| [7] | Congxin LI, Meiling YUE, Xintong LI, Qinghui XIONG, Xiaoyan LIU. Proton exchange membrane fuel cell aging performance prediction based on conditional neural networks [J]. Energy Storage Science and Technology, 2024, 13(9): 3094-3102. |

| [8] | Ziyu LIU, Zekun JIANG, Wei QIU, Quan XU, Yingchun NIU, Chunming XU, Tianhang ZHOU. Application of artificial intelligence in long-duration redox flow batteries storage systems [J]. Energy Storage Science and Technology, 2024, 13(9): 2871-2883. |

| [9] | Yingying XIE, Bin DENG, Yuzhi ZHANG, Xiaoxu WANG, Linfeng ZHANG. Intelligent R&D of battery design automation in the era of artificial intelligence [J]. Energy Storage Science and Technology, 2024, 13(9): 3182-3197. |

| [10] | Zhenwei ZHU, Jiawei MIAO, Xiayu ZHU, Xiaoxu WANG, Jingyi QIU, Hao ZHANG. Research progress in lithium-ion battery remaining useful life prediction based on machine learning [J]. Energy Storage Science and Technology, 2024, 13(9): 3134-3149. |

| [11] | Jingjing LEI, Zehao LI, Binbin CHEN, Denggao HUANG. Estimation of internal battery temperature based on electrochemical impedance spectroscopy [J]. Energy Storage Science and Technology, 2024, 13(8): 2823-2834. |

| [12] | Junhong LIU. Application of data-driven technology in voiceprint recognition and monitoring diagnosis of power energy storage equipment [J]. Energy Storage Science and Technology, 2024, 13(8): 2835-2838. |

| [13] | Changhao LI, Shuping WANG, Xiankun YANG, Ziqi ZENG, Xinyue ZHOU, Jia XIE. Nonaqueous electrolyte in low-temperature lithium-ion battery [J]. Energy Storage Science and Technology, 2024, 13(7): 2286-2299. |

| [14] | Yang LU, Shuaishuai YAN, Xiao MA, Zhi LIU, Weili ZHANG, Kai LIU. Low-temperature electrolytes and their application in lithium batteries [J]. Energy Storage Science and Technology, 2024, 13(7): 2224-2242. |

| [15] | Meilong WANG, Yurui XUE, Wenxi HU, Keyu DU, Ruitao SUN, Bin ZHANG, Ya YOU. Design and research of all-ether high-entropy electrolyte for low-temperature lithium iron phosphate batteries [J]. Energy Storage Science and Technology, 2024, 13(7): 2131-2140. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||