Energy Storage Science and Technology ›› 2025, Vol. 14 ›› Issue (1): 54-76.doi: 10.19799/j.cnki.2095-4239.2024.0611

• Energy Storage Materials and Devices • Previous Articles Next Articles

Tong LIU1,3( ), Guiting YANG1, Hui BI4, Yueni MEI1, Shuo LIU1, Yongji GONG3, Wenlei LUO2(

), Guiting YANG1, Hui BI4, Yueni MEI1, Shuo LIU1, Yongji GONG3, Wenlei LUO2( )

)

Received:2024-07-03

Revised:2024-07-18

Online:2025-01-28

Published:2025-02-25

Contact:

Wenlei LUO

E-mail:liutone@126.com;wenleiluo@163.com

CLC Number:

Tong LIU, Guiting YANG, Hui BI, Yueni MEI, Shuo LIU, Yongji GONG, Wenlei LUO. Recent progress in high-energy and high-power lithium-ion batteries[J]. Energy Storage Science and Technology, 2025, 14(1): 54-76.

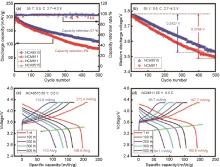

Fig. 4

Long-term cycling performance of NCA8515 and NCM811 in lithium metal half-cells. Evolution of (a) specific discharge capacity and (b) medium charge and discharge voltages over 500 cycles, and (c and d) voltage profiles at the 1st, 100th, 200th, 300th, and 500th cycles at 55 ℃, 0.5 C rate(90 mA/g)[36]"

Table 1

Comparison of main parameters for various cathode materials"

| 晶体 结构 | 正极材料 | 比容量 /(mAh/g) | 电压/V(vs. Li/ Li+) | 扩散系数 /(cm2/s) | 文献 |

|---|---|---|---|---|---|

| 层状 | LCO/ HVLCO | 140~190 | 3.7~3.9 | 约10-8 | [ |

| 层状 | NCA | 170~200 | 3.6 | 约10-9 | [ |

| 层状 | NCM | 150~200 | 3.6~3.9 | 约10-12 | [ |

| 橄榄石 | LFP | 130~150 | 3.4 | 约10-12 | [ |

| LiCoPO4 | 约125 | 4.2 | 约10-14 | [ | |

| 尖晶石 | LNMO | 约130 | 4.7 | 10–11~10–9 | [ |

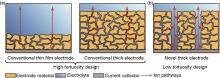

Fig. 12

Schematics illustrating the ion transfer pathways in diverse electrodes. (a) Illustration of the severely elongated ion transport distance arising from the increased electrode thickness in conventional electrodes with the inherent tortuous pore structure; (b) Rapid ion transport in a thick electrode that employs a low-tortuosity pore structure design. The red arrow indicates the shortest ion transfer pathway in this electrode design[143]"

| 1 | LI M Y, LIU T, SHI Z, et al. Dense all-electrochem-active electrodes for all-solid-state lithium batteries[J]. Advanced Materials, 2021, 33(26): 2008723. DOI: 10.1002/adma.202008723. |

| 2 | CHEN G X, SUN X Z, ZHANG X, et al. Progress of high-power lithium-ion batteries [J]. 工程科学学报, 2022, 44(4): 612-624. |

| 3 | 刘通, 朱文豪, 梅悦旎, 等. 小型SAR卫星用双高特性锂离子电池技术[J]. 上海航天(中英文), 2022, 39(3): 138-144, 152. DOI: 10.19328/j.cnki.2096-8655.2022.03.019. |

| LIU T, ZHU W H, MEI Y N, et al. High specific energy and high power lithium-ion battery technologies for small SAR satellites[J]. Aerospace Shanghai (Chinese & English), 2022, 39(3): 138-144, 152. DOI: 10.19328/j.cnki.2096-8655.2022.03.019. | |

| 4 | WANG C Y, YANG C P, ZHENG Z J. Toward practical high-energy and high-power lithium battery anodes: Present and future[J]. Advanced Science, 2022, 9(9): e2105213. DOI: 10.1002/advs.202105213. |

| 5 | GOODENOUGH J B, PARK K S. The Li-ion rechargeable battery: A perspective[J]. Journal of the American Chemical Society, 2013, 135(4): 1167-1176. DOI: 10.1021/ja3091438. |

| 6 | GAO H, WU Q, HU Y X, et al. Revealing the rate-limiting Li-ion diffusion pathway in ultrathick electrodes for Li-ion batteries[J]. The Journal of Physical Chemistry Letters, 2018, 9(17): 5100-5104. DOI: 10.1021/acs.jpclett.8b02229. |

| 7 | WU J Y, JU Z Y, ZHANG X, et al. Gradient design for high-energy and high-power batteries[J]. Advanced Materials, 2022, 34(29): 2202780. DOI: 10.1002/adma.202202780. |

| 8 | ARMAND M, TARASCON J M. Building better batteries[J]. Nature, 2008, 451(7179): 652-657. DOI: 10.1038/451652a. |

| 9 | BARD A J, FAULKNER L R, WHITE H S. Electrochemical methods: Fundamentals and applications[M]. 3rd ed. WILEY, 2022. |

| 10 | 王伟. 智能电池: 能源互联网的关键环节——访中国工程院院士吴锋[J]. 能源评论, 2021(12): 44-47. |

| WANG W. Smart battery: The key link of energy Internet—Interview with wu Feng, academician of China academy of engineering[J]. Energy Review, 2021(12): 44-47. | |

| 11 | SUN Y K, CHEN Z H, NOH H J, et al. Nanostructured high-energy cathode materials for advanced lithium batteries[J]. Nature Materials, 2012, 11(11): 942-947. DOI: 10.1038/nmat3435. |

| 12 | AMICI J, ASINARI P, AYERBE E, et al. A roadmap for transforming research to invent the batteries of the future designed within the European large scale research initiative BATTERY 2030+[J]. Advanced Energy Materials, 2022, 12(17): 2102785. DOI: 10.1002/aenm.202102785. |

| 13 | DECHENT P, EPP A, JÖST D, et al. ENPOLITE: Comparing lithium-ion cells across energy, power, lifetime, and temperature[J]. ACS Energy Letters, 2021, 6(6): 2351-2355. DOI: 10.1021/acsenergylett.1c00743. |

| 14 | XU J J, CAI X Y, CAI S M, et al. High-energy lithium-ion batteries: Recent progress and a promising future in applications[J]. Energy & Environmental Materials, 2023, 6(5): e12450. DOI: 10.1002/eem2.12450. |

| 15 | PADHI A K, NANJUNDASWAMY K S, GOODENOUGH J B. Phospho-olivines as positive-electrode materials for rechargeable lithium batteries[J]. Journal of the Electrochemical Society, 1997, 144(4): 1188. DOI: 10.1149/1.1837571. |

| 16 | ROMMEL S M, SCHALL N, BRÜNIG C, et al. Challenges in the synthesis of high voltage electrode materials for lithium-ion batteries: A review on LiNiPO4[J]. Monatshefte Für Chemie - Chemical Monthly, 2014, 145(3): 385-404. DOI: 10.1007/s00706-013-1134-0. |

| 17 | RAMAR V, BALAYA P. Enhancing the electrochemical kinetics of high voltage olivine LiMnPO4 by isovalent co-doping[J]. Physical Chemistry Chemical Physics, 2013, 15(40): 17240-17249. DOI: 10.1039/c3cp52311j. |

| 18 | WHEATCROFT L, TRAN T D, ÖZKAYA D, et al. Visualization of the delithiation mechanisms in high-voltage battery material LiCoPO4[J]. ACS Applied Energy Materials, 2022, 5(1): 196-206. DOI: 10.1021/acsaem.1c02742. |

| 19 | WU X C, ROHMAN F, MELEDINA M, et al. Analysis of the effects of different carbon coating strategies on structure and electrochemical behavior of LiCoPO4 material as a high-voltage cathode electrode for lithium ion batteries[J]. Electrochimica Acta, 2018, 279: 108-117. DOI: 10.1016/j.electacta.2018.05.067. |

| 20 | ALLEN J L, JOW T R, WOLFENSTINE J. Improved cycle life of Fe-substituted LiCoPO4[J]. Journal of Power Sources, 2011, 196(20): 8656-8661. DOI: 10.1016/j.jpowsour.2011.06.057. |

| 21 | JANG I C, LIM H H, LEE S B, et al. Preparation of LiCoPO4 and LiFePO4 coated LiCoPO4 materials with improved battery performance[J]. Journal of Alloys and Compounds, 2010, 497(1/2): 321-324. DOI: 10.1016/j.jallcom.2010.03.055. |

| 22 | SREEDEEP S, NATARAJAN S, ARAVINDAN V. Recent advancements in LiCoPO4 cathodes using electrolyte additives[J]. Current Opinion in Electrochemistry, 2022, 31: 100868. DOI: 10.1016/j.coelec.2021.100868. |

| 23 | ESHETU G G, ZHANG H, JUDEZ X, et al. Production of high-energy Li-ion batteries comprising silicon-containing anodes and insertion-type cathodes[J]. Nature Communications, 2021, 12(1): 5459. DOI: 10.1038/s41467-021-25334-8. |

| 24 | KIM U H, KUO L Y, KAGHAZCHI P, et al. Quaternary layered Ni-rich NCMA cathode for lithium-ion batteries[J]. ACS Energy Letters, 2019, 4(2): 576-582. DOI: 10.1021/acsenergylett.8b02499. |

| 25 | CHEN Y B, SONG S L, ZHANG X Q, et al. The challenges, solutions and development of high energy Ni-rich NCM/NCA LiB cathode materials[J]. Journal of Physics: Conference Series, 2019, 1347(1): 012012. DOI: 10.1088/1742-6596/1347/1/012012. |

| 26 | SUN Y K, MYUNG S T, PARK B C, et al. High-energy cathode material for long-life and safe lithium batteries[J]. Nature Materials, 2009, 8(4): 320-324. DOI: 10.1038/nmat2418. |

| 27 | NOH H J, YOUN S, YOON C S, et al. Comparison of the structural and electrochemical properties of layered Li[Nix Coy Mnz]O2 (x = 1/3, 0.5, 0.6, 0.7, 0.8 and 0.85) cathode material for lithium-ion batteries[J]. Journal of Power Sources, 2013, 233: 121-130. DOI: 10.1016/j.jpowsour.2013.01.063. |

| 28 | LIU W, OH P, LIU X E, et al. Nickel-rich layered lithium transition-metal oxide for high-energy lithium-ion batteries[J]. Angewandte Chemie (International Ed), 2015, 54(15): 4440-4457. DOI: 10.1002/anie.201409262. |

| 29 | CHENG Y, SUN Y, CHU C T, et al. Stabilizing effects of atomic Ti doping on high-voltage high-nickel layered oxide cathode for lithium-ion rechargeable batteries[J]. Nano Research, 2022, 15(5): 4091-4099. DOI: 10.1007/s12274-021-4035-2. |

| 30 | BINDER J O, CULVER S P, PINEDO R, et al. Investigation of fluorine and nitrogen as anionic dopants in nickel-rich cathode materials for lithium-ion batteries[J]. ACS Applied Materials & Interfaces, 2018, 10(51): 44452-44462. DOI: 10.1021/acsami. 8b16049. |

| 31 | ZHU L, LIU Y, WU W Y, et al. Surface fluorinated LiNi0.8Co0.15Al0.05O2 as a positive electrode material for lithium ion batteries[J]. Journal of Materials Chemistry A, 2015, 3(29): 15156-15162. DOI: 10.1039/C5TA02529J. |

| 32 | ZHAO B, SI J, CAO C H, et al. Enhanced electrochemical performance of LiNi0.8Co0.15Al0.05O2 cathode by reducing lithium residue with low-temperature fluorination treatment[J]. Solid State Ionics, 2019, 339: 114998. DOI: 10.1016/j.ssi.2019.06.006. |

| 33 | LEE S H, YOON C S, AMINE K, et al. Improvement of long-term cycling performance of Li[Ni0.8Co0.15Al0.05]O2 by AlF3 coating[J]. Journal of Power Sources, 2013, 234: 201-207. DOI: 10.1016/j.jpowsour.2013.01.045. |

| 34 | QIU Z P, LIU Z, FU X J, et al. Improving the cycling performance of LiNi0.8Co0.15Al0.05O2 cathode materials via zirconium and fluorine co-substitution[J]. Journal of Alloys and Compounds, 2019, 806: 136-145. DOI: 10.1016/j.jallcom.2019.07.230. |

| 35 | JIN S-J, SEO J-S, NA B-K. Effect of MgF2 surface modification for LiNi0.8Co0.15Al0.05O2 cathode material on Improving electrochemical characteristics [J]. Korean Chemical Engineering Research, 2020, 58(1): 52-58. |

| 36 | WANG B, ZHANG F L, ZHOU X N, et al. Which of the nickel-rich NCM and NCA is structurally superior as a cathode material for lithium-ion batteries?[J]. Journal of Materials Chemistry A, 2021, 9(23): 13540-13551. DOI: 10.1039/D1TA01128F. |

| 37 | KALLURI S, CHA H, KIM J, et al. Building high-rate nickel-rich cathodes by self-organization of structurally stable macrovoid[J]. Advanced Science, 2020, 7(7): 1902844. DOI: 10.1002/advs.201902844. |

| 38 | KIM J, LEE H, CHA H, et al. Prospect and reality of Ni-rich cathode for commercialization[J]. Advanced Energy Materials, 2018, 8(6): 1702028. DOI: 10.1002/aenm.201702028. |

| 39 | THACKERAY M M, KANG S H, JOHNSON C S, et al. Li2MnO3- stabilized LiMO2 (M = Mn, Ni, Co) electrodes for lithium-ion batteries[J]. Journal of Materials Chemistry, 2007, 17(30): 3112-3125. DOI: 10.1039/B702425H. |

| 40 | ZHENG J M, GU M, GENC A, et al. Mitigating voltage fade in cathode materials by improving the atomic level uniformity of elemental distribution[J]. Nano Letters, 2014, 14(5): 2628-2635. DOI: 10.1021/nl500486y. |

| 41 | LI Y, BAI Y, BI X X, et al. An effectively activated hierarchical nano-/ microspherical Li1.2Ni0.2Mn0.6O2 cathode for long-life and high-rate lithium-ion batteries[J]. ChemSusChem, 2016, 9(7): 728-735. DOI: 10.1002/cssc.201501548. |

| 42 | ZUO Y X, LI B, JIANG N, et al. A high-capacity O 2 -type Li-rich cathode material with a single-layer Li2MnO3 superstructure[J]. Advanced Materials, 2018, 30(16): e1707255. DOI: 10.1002/adma.201707255. |

| 43 | SHANG H F, ZUO Y X, SHEN F R, et al. O 2 -type Li0.78[Li0.24Mn0.76]O2 nanowires for high-performance lithium-ion battery cathode[J]. Nano Letters, 2020, 20(8): 5779-5785. DOI: 10.1021/acs.nanolett.0c01640. |

| 44 | CAI M Z, DONG Y H, XIE M, et al. Stalling oxygen evolution in high-voltage cathodes by lanthurization[J]. Nature Energy, 2023, 8: 159-168. DOI: 10.1038/s41560-022-01179-3. |

| 45 | KUNDURACI M, AMATUCCI G G. Synthesis and characterization of nanostructured 4.7 V LixMn1.5Ni0.5O4 spinels for high-power lithium-ion batteries[J]. Journal of the Electrochemical Society, 2006, 153(7): A1345. DOI: 10.1149/1.2198110. |

| 46 | MANTHIRAM A, CHEMELEWSKI K, LEE E S. A perspective on the high-voltage LiMn1.5Ni0.5O4 spinel cathode for lithium-ion batteries[J]. Energy & Environmental Science, 2014, 7(4): 1339-1350. DOI: 10.1039/C3EE42981D. |

| 47 | LIU G Q, WEN L, LIU Y M. Spinel LiNi0.5Mn1.5O4 and its derivatives as cathodes for high-voltage Li-ion batteries[J]. Journal of Solid State Electrochemistry, 2010, 14(12): 2191-2202. DOI: 10.1007/s10008-010-1061-5. |

| 48 | KIM J H, MYUNG S T, YOON C S, et al. Comparative study of LiNi0.5Mn1.5O4-δ and LiNi0.5Mn1.5O4 cathodes having two crystallographic structures: Fd3̄m and P4332[J]. Chemistry of Materials, 2004, 16(5): 906-914. DOI: 10.1021/cm035050s. |

| 49 | HWANG T, LEE J K, MUN J, et al. Surface-modified carbon nanotube coating on high-voltage LiNi0.5Mn1.5O4 cathodes for lithium ion batteries[J]. Journal of Power Sources, 2016, 322: 40-48. DOI: 10.1016/j.jpowsour.2016.04.118. |

| 50 | LU D S, XU M Q, ZHOU L, et al. Failure mechanism of graphite/LiNi0.5Mn1.5O4 cells at high voltage and elevated temperature[J]. Journal of the Electrochemical Society, 2013, 160(5): A3138-A3143. DOI: 10.1149/2.022305jes. |

| 51 | KIM J H, PIECZONKA N P W, LI Z C, et al. Understanding the capacity fading mechanism in LiNi0.5Mn1.5O4/graphite Li-ion batteries[J]. Electrochimica Acta, 2013, 90: 556-562. DOI: 10.1016/j.electacta.2012.12.069. |

| 52 | WU H M, BELHAROUAK I, DENG H, et al. Development of LiNi0.5Mn1.5O4/Li4Ti5O12 system with long cycle life[J]. Journal of the Electrochemical Society, 2009, 156(12): A1047. DOI: 10.1149/1.3240197. |

| 53 | MIZUSHIMA K, JONES P C, WISEMAN P J, et al. LixCoO2 (0<x<-1): A new cathode material for batteries of high energy density[J]. Materials Research Bulletin, 1980, 15(6): 783-789. DOI: 10.1016/0025-5408(80)90012-4. |

| 54 | DU PASQUIER A, PLITZ I, MENOCAL S, et al. A comparative study of Li-ion battery, supercapacitor and nonaqueous asymmetric hybrid devices for automotive applications[J]. Journal of Power Sources, 2003, 115(1): 171-178. DOI: 10.1016/S0378-7753(02)00718-8. |

| 55 | REIMERS J N, DAHN J R. Electrochemical and in situ X-Ray diffraction studies of lithium intercalation in LixCoO2[J]. Journal of the Electrochemical Society, 1992, 139(8): 2091-2097. DOI: 10.1149/1.2221184. |

| 56 | WANG K, WAN J J, XIANG Y X, et al. Recent advances and historical developments of high voltage lithium cobalt oxide materials for rechargeable Li-ion batteries[J]. Journal of Power Sources, 2020, 460: 228062. DOI: 10.1016/j.jpowsour. 2020.228062. |

| 57 | SHEN B, LIU Q Q, WANG L G, et al. Mixed lithium ion and electron conducting LiAlPO3.93F1.07-coated LiCoO2 cathode with improved electrochemical performance[J]. Electrochemistry Communications, 2017, 83: 106-109. DOI: 10.1016/j.elecom. 2017.09.002. |

| 58 | YANO A, SHIKANO M, UEDA A, et al. LiCoO2 degradation behavior in the high-voltage phase transition region and improved reversibility with surface coating[J]. Journal of the Electrochemical Society, 2016, 164(1): A6116-A6122. DOI: 10.1149/2.0181701jes. |

| 59 | CHO J, KIM Y W, KIM B, et al. A breakthrough in the safety of lithium secondary batteries by coating the cathode material with AlPO4 nanoparticles[J]. Angewandte Chemie (International Ed), 2003, 42(14): 1618-1621. DOI: 10.1002/anie.200250452. |

| 60 | YAMADA A, CHUNG S C, HINOKUMA K. Optimized LiFePO4 for lithium battery cathodes[J]. ChemInform, 2001, 32(29): 17. DOI: 10.1002/chin.200129017. |

| 61 | HOU Y, CHANG K, LI B, et al. Highly[010]-oriented self-assembled LiCoPO4/C nanoflakes as high-performance cathode for lithium ion batteries[J]. Nano Research, 2018, 11(5): 2424-2435. DOI: 10.1007/s12274-017-1864-0. |

| 62 | YI T F, LI C Y, ZHU Y R, et al. Electrochemical intercalation kinetics of lithium ions for spinel LiNi0.5Mn1.5O4 cathode material[J]. Russian Journal of Electrochemistry, 2010, 46(2): 227-232. DOI: 10.1134/S1023193510020151. |

| 63 | NITTA N, WU F X, LEE J T, et al. Li-ion battery materials: Present and future[J]. Materials Today, 2015, 18(5): 252-264. DOI: 10.1016/j.mattod.2014.10.040. |

| 64 | 王立超, 张晓虎, 张熊, 等. 高功率锂离子电池负极材料研究进展[J]. 电源技术, 2021, 45(9): 1213-1215. DOI: 10.3969/j.issn.1002-087X.2021.09.031. |

| WANG L C, ZHANG X H, ZHANG X, et al. Review of anode materials for high-power lithium-ion battery[J]. Chinese Journal of Power Sources, 2021, 45(9): 1213-1215. DOI: 10.3969/j.issn.1002-087X.2021.09.031. | |

| 65 | 孙德旺, 蒋必志, 袁涛, 等. 钛铌氧化物用于锂离子电池负极的研究进展[J]. 储能科学与技术, 2021, 10(6): 2127-2143. DOI: 10.19799/j.cnki.2095-4239.2021.0137. |

| SUN D W, JIANG B Z, YUAN T, et al. Research progress of titanium niobium oxide used as anode of lithium-ion batteries[J]. Energy Storage Science and Technology, 2021, 10(6): 2127-2143. DOI: 10.19799/j.cnki.2095-4239.2021.0137. | |

| 66 | 丁晓博, 黄倩晖, 熊训辉. 锂离子电池快充石墨负极研究与应用[J]. 物理化学学报, 2022, 38(11): 95-110. |

| DING X B, HUANG Q H, XIONG X H. Research and application of fast-charging graphite anodes for lithium-ion batteries[J]. Acta Physico-Chimica Sinica, 2022, 38(11): 95-110. | |

| 67 | BAO C G, LIU Z F, YANG Z, et al. Constructing a boron-doped graphite anode with an accelerated Li+ diffusion dynamics for practical high-rate Li-ion batteries[J]. Electrochimica Acta, 2023, 463: 142821. DOI: 10.1016/j.electacta.2023.142821. |

| 68 | HE J H, MENG J K, HUANG Y H. Challenges and recent progress in fast-charging lithium-ion battery materials[J]. Journal of Power Sources, 2023, 570: 232965. DOI: 10.1016/j.jpowsour. 2023.232965. |

| 69 | ZHANG C Y, ZHONG X M, CHEN P, et al. Facile synthesis of porous graphite by calcium carbide and nitrogen gas for lithium-ion batteries[J]. Journal of Energy Storage, 2023, 66: 107386. DOI: 10.1016/j.est.2023.107386. |

| 70 | 廖雅赟, 周峰, 张颖曦, 等. 锂离子电池快充石墨负极材料研究进展[J]. 储能科学与技术, 2024, 13(1): 130-142. DOI: 10.19799/j.cnki.2095-4239.2023.0777. |

| LIAO Y Y, ZHOU F, ZHANG Y X, et al. Research progress on fast-charging graphite anode materials for lithium-ion batteries[J]. Energy Storage Science and Technology, 2024, 13(1): 130-142. DOI: 10.19799/j.cnki.2095-4239.2023.0777. | |

| 71 | PARAKNOWITSCH J P, THOMAS A. Doping carbons beyond nitrogen: An overview of advanced heteroatom doped carbons with boron, sulphur and phosphorus for energy applications[J]. Energy & Environmental Science, 2013, 6(10): 2839-2855. DOI: 10.1039/C3EE41444B. |

| 72 | 孙方静, 韦连梅, 张家玮, 等. 锂离子电池快充石墨负极材料的研究进展及评价方法[J]. 储能科学与技术, 2017, 6(6): 1223-1230. DOI: 10.12028/j.issn.2095-4239.2017.0098. |

| SUN F J, WEI L M, ZHANG J W, et al. Research progress and evaluation methods of lithium-ion battery fast-charge graphite anode material[J]. Energy Storage Science and Technology, 2017, 6(6): 1223-1230. DOI: 10.12028/j.issn.2095-4239. 2017.0098. | |

| 73 | CHENG Q, ZHANG Y. Multi-channel graphite for high-rate lithium ion battery[J]. Journal of the Electrochemical Society, 2018, 165(5): A1104-A1109. DOI: 10.1149/2.1171805jes. |

| 74 | 阳晓霞, 冯辉, 金晶龙, 等. 高比功率锂离子电池设计与性能研究[J]. 电源技术, 2018, 42(2): 195-198. DOI: 10.3969/j.issn.1002-087X.2018.02.010. |

| YANG X X, FENG H, JIN J L, et al. Design and performance research of lithium ion battery with high specific power[J]. Chinese Journal of Power Sources, 2018, 42(2): 195-198. DOI: 10.3969/j.issn.1002-087X.2018.02.010. | |

| 75 | ZOU Z M, JIANG C H. Nitrogen-doped amorphous carbon coated mesocarbon microbeads as excellent high rate Li storage anode materials[J]. Journal of Materials Science & Technology, 2019, 35(4): 644-650. DOI: 10.1016/j.jmst.2018.10.016. |

| 76 | LAI J M, JIANG C H, ZOU Z M. Oxygen-deficient Nb2O5- x decorated MCMB anode with much enhanced rate and cycle performances for Li-ion batteries[J]. Applied Surface Science, 2022, 604: 154564. DOI: 10.1016/j.apsusc.2022.154564. |

| 77 | GONG X, GUO S H, DING Y Y, et al. Preparation of mesocarbon microbeads as anode material for lithium-ion battery by co-carbonization of FCC decant oil and conductive carbon black[J]. Fuel Processing Technology, 2022, 227: 107110. DOI: 10.1016/j.fuproc.2021.107110. |

| 78 | 李圣远, 叶传仁, 王伊哲, 等. 面向快充锂离子电池的氮掺杂多孔硬碳负极[J]. 硅酸盐学报, 2023, 51(9): 2188-2196. DOI: 10.14062/j.issn.0454-5648.20230094. |

| LI S Y, YE C R, WANG Y Z, et al. Nitrogen-doped porous hard carbon as an anode for fast-charging lithium-ion batteries[J]. Journal of the Chinese Ceramic Society, 2023, 51(9): 2188-2196. DOI: 10.14062/j.issn.0454-5648.20230094. | |

| 79 | LI Y Q, VASILEIADIS A, ZHOU Q, et al. Origin of fast charging in hard carbon anodes[J]. Nature Energy, 2024, 9: 134-142. DOI: 10.1038/s41560-023-01414-5. |

| 80 | HU M F, HUANG L P, LI H, et al. Research progress on hard carbon anode for Li/Na-ion batteries[J]. Journal of Inorganic Materials, 2024, 39(1): 32. DOI: 10.15541/jim20230365. |

| 81 | XIE L J, TANG C, BI Z H, et al. Hard carbon anodes for next-generation Li-ion batteries: Review and perspective[J]. Advanced Energy Materials, 2021, 11(38): 2101650. DOI: 10.1002/aenm.202101650. |

| 82 | 苏少鹏, 李进, 张佃平, 等. 红柳基锂电池负极材料的制备及电化学性能[J]. 储能科学与技术, 2021, 10(6): 2082-2089. DOI: 10.19799/j.cnki.2095-4239.2021.0170. |

| SU S P, LI J, ZHANG D P, et al. Preparation and electrochemical properties of negative eletrode materials for tamarium-based lithiumion batteries[J]. Energy Storage Science and Technology, 2021, 10(6): 2082-2089. DOI: 10.19799/j.cnki.2095-4239.2021.0170. | |

| 83 | 赵清江, 张贵锋. 硬碳的预锂化及其电化学性能[J]. 储能科学与技术, 2021, 10(6): 2112-2116. DOI: 10.19799/j.cnki.2095-4239. 2021.0239. |

| ZHAO Q J, ZHANG G F. Prelithiation of hard carbon and its electrochemical performance[J]. Energy Storage Science and Technology, 2021, 10(6): 2112-2116. DOI: 10.19799/j.cnki.2095-4239.2021.0239. | |

| 84 | TANG Y X, ZHANG Y Y, DENG J Y, et al. Mechanical force-driven growth of elongated bending TiO2-based nanotubular materials for ultrafast rechargeable lithium ion batteries[J]. Advanced Materials, 2014, 26(35): 6111-6118. DOI: 10.1002/adma. 201402000. |

| 85 | YANG C F, MA D W, YANG J, et al. Crystallographic insight of reduced lattice volume expansion in mesoporous Cu2+-doped TiNb2O7 microspheres during Li+ insertion[J]. Advanced Functional Materials, 2023, 33(15): 2212854. DOI: 10.1002/adfm. 202212854. |

| 86 | GUO B K, YU X Q, SUN X G, et al. A long-life lithium-ion battery with a highly porous TiNb2O7 anode for large-scale electrical energy storage[J]. Energy & Environmental Science, 2014, 7(7): 2220-2226. DOI: 10.1039/C4EE00508B. |

| 87 | LIANG D W, LU Y, ZHOU N N, et al. Ultrathin carbon-coated porous TiNb2O7 nanosheets as anode materials for enhanced lithium storage[J]. Nanomaterials, 2022, 12(17): 2943. DOI: 10.3390/nano12172943. |

| 88 | CHENG Q S, LIANG J W, LIN N, et al. Porous TiNb2O7 nanospheres as ultra long-life and high-power anodes for lithium-ion batteries[J]. Electrochimica Acta, 2015, 176: 456-462. DOI: 10.1016/j.electacta.2015.07.038. |

| 89 | ZHANG Y, KANG C, ZHAO W, et al. Crystallographic engineering to reduce diffusion barrier for enhanced intercalation pseudocapacitance of TiNb2O7 in fast-charging batteries[J]. Energy Storage Materials, 2022, 47: 178-186. DOI: 10.1016/j.ensm.2022.01.061. |

| 90 | ZHANG Y, HUANG J, SAITO N, et al. Layered perovskite lithium yttrium titanate as a low-potential and ultrahigh-rate anode for lithium-ion batteries[J]. Advanced Energy Materials, 2022, 12(31): 2200922. DOI: 10.1002/aenm.202200922. |

| 91 | BOUKAMP B A, LESH G C, HUGGINS R A. All-solid lithium electrodes with mixed-conductor matrix[J]. Journal of the Electrochemical Society, 1981, 128(4): 725. DOI: 10.1149/1.2127495. |

| 92 | CHAN C K, PENG H L, LIU G, et al. High-performance lithium battery anodes using silicon nanowires[J]. Nature Nanotechnology, 2008, 3(1): 31-35. DOI: 10.1038/nnano. 2007.411. |

| 93 | ZHANG X H, WANG D H, QIU X Y, et al. Stable high-capacity and high-rate silicon-based lithium battery anodes upon two-dimensional covalent encapsulation[J]. Nature Communications, 2020, 11(1): 3826. DOI: 10.1038/s41467-020-17686-4. |

| 94 | FENG K, LI M, LIU W W, et al. Silicon-based anodes for lithium-ion batteries: From fundamentals to practical applications[J]. Small, 2018, 14(8). DOI: 10.1002/smll.201702737. DOI: 10.1002/smll.201702737. |

| 95 | LI J Y, XU Q, LI G, et al. Research progress regarding Si-based anode materials towards practical application in high energy density Li-ion batteries[J]. Materials Chemistry Frontiers, 2017, 1(9): 1691-1708. DOI: 10.1039/C6QM00302H. |

| 96 | CHEN H, LING M, HENCZ L, et al. Exploring chemical, mechanical, and electrical functionalities of binders for advanced energy-storage devices[J]. Chemical Reviews, 2018, 118(18): 8936-8982. DOI: 10.1021/acs.chemrev.8b00241. |

| 97 | ZHANG C Z, WANG F, HAN J, et al. Challenges and recent progress on silicon-based anode materials for next-generation lithium-ion batteries[J]. Small Structures, 2021, 2(6): 2170015. DOI: 10.1002/sstr.202170015. |

| 98 | YANG Y, YUAN W, KANG W Q, et al. A review on silicon nanowire-based anodes for next-generation high-performance lithium-ion batteries from a material-based perspective[J]. Sustainable Energy & Fuels, 2020, 4(4): 1577-1594. DOI: 10.1039/C9SE01165J. |

| 99 | LIM K W, LEE J I, YANG J, et al. Catalyst-free synthesis of Si-SiOx core-shell nanowire anodes for high-rate and high-capacity lithium-ion batteries[J]. ACS Applied Materials & Interfaces, 2014, 6(9): 6340-6345. DOI: 10.1021/am405618m. |

| 100 | HU L, XIA W M, TANG R H, et al. Excellent cyclic and rate performances of SiO/C/graphite composites as Li-ion battery anode[J]. Frontiers in Chemistry, 2020, 8: 388. DOI: 10.3389/fchem.2020.00388. |

| 101 | AL JA'FARAWY M S, HIKMAH D N, RIYADI U, et al. A review: The development of SiO2/C anode materials for lithium-ion batteries[J]. Journal of Electronic Materials, 2021, 50(12): 6667-6687. DOI: 10.1007/s11664-021-09187-x. |

| 102 | GU H T, WANG Y, ZENG Y, et al. Boosting cyclability and rate capability of SiOx via dopamine polymerization-assisted hybrid graphene coating for advanced lithium-ion batteries[J]. ACS Applied Materials & Interfaces, 2022, 14(15): 17388-17395. DOI: 10.1021/acsami.2c01587. |

| 103 | 李文俊, 徐航宇, 杨琪, 等. 高能量密度锂电池开发策略[J]. 储能科学与技术, 2020, 9(2): 448-478. DOI: 10.19799/j.cnki.2095-4239.2020-0050. |

| LI W J, XU H Y, YANG Q, et al. Development of strategies for high-energy-density lithium batteries[J]. Energy Storage Science and Technology, 2020, 9(2): 448-478. DOI: 10.19799/j.cnki.2095-4239.2020-0050. | |

| 104 | CHIU K F, SU S H, LEU H J, et al. Silicon thin film anodes coated on micron carbon-fiber current collectors for lithium ion batteries[J]. Surface and Coatings Technology, 2015, 267: 70-74. DOI: 10.1016/j.surfcoat.2014.10.059. |

| 105 | ZHU X, CHOI S H, TAO R, et al. Building high-rate silicon anodes based on hierarchical Si@C@CNT nanocomposite[J]. Journal of Alloys and Compounds, 2019, 791: 1105-1113. DOI: 10.1016/j.jallcom.2019.03.354. |

| 106 | YUAN X Q, XIN H X, QIN X Y, et al. Self-assembly of SiO/reduced graphene oxide composite as high-performance anode materials for Li-ion batteries[J]. Electrochimica Acta, 2015, 155: 251-256. DOI: 10.1016/j.electacta.2014.12.124. |

| 107 | XU Q, SUN J K, LI G, et al. Facile synthesis of a SiOx/asphalt membrane for high performance lithium-ion battery anodes[J]. Chemical Communications, 2017, 53(89): 12080-12083. DOI: 10.1039/C7CC05816K. |

| 108 | DENG L, ZHENG Y, ZHENG X M, et al. Design criteria for silicon-based anode binders in half and full cells[J]. Advanced Energy Materials, 2022, 12(31): 2200850. DOI: 10.1002/aenm.202200850. |

| 109 | WANG H L, WU B Z, WU X K, et al. Key factors for binders to enhance the electrochemical performance of silicon anodes through molecular design[J]. Small, 2022, 18(1): e2101680. DOI: 10.1002/smll.202101680. |

| 110 | LI Z H, ZHANG Y P, LIU T F, et al. Silicon anode with high initial coulombic efficiency by modulated trifunctional binder for high-areal-capacity lithium-ion batteries[J]. Advanced Energy Materials, 2020, 10(20): 1903110. DOI: 10.1002/aenm. 201903110. |

| 111 | LIU D, ZHAO Y, TAN R, et al. Novel conductive binder for high-performance silicon anodes in lithium ion batteries[J]. Nano Energy, 2017, 36: 206-212. DOI: 10.1016/j.nanoen.2017.04.043. |

| 112 | 武美玲, 牛磊, 李世友, 等. 正极预锂化添加剂用于锂离子电池的研究进展 [J]. 储能科学与技术: 2024, 13(3): 759-769. DOI:10.19799/j.onki.2095-4239.2023.0809. |

| WU M L, NIU L, LI S Y, et al. Research progress on cathode prelithium additives used in lithium-ion batteries [J]. Energy Storage Science and Technology: 2024, 13(3): 759-769. DOI:10.19799/j.onki.2095-4239.2023.0809. | |

| 113 | KASKHEDIKAR N A, MAIER J. Lithium storage in carbon nanostructures[J]. Advanced Materials, 2009, 21(25/26): 2664-2680. DOI: 10.1002/adma.200901079. |

| 114 | LEVI M D, AURBACH D. Diffusion coefficients of lithium ions during intercalation into graphite derived from the simultaneous measurements and modeling of electrochemical impedance and potentiostatic intermittent titration characteristics of thin graphite electrodes[J]. The Journal of Physical Chemistry B, 1997, 101(23): 4641-4647. DOI: 10.1021/jp9701911. |

| 115 | MARKEVICH E, LEVI M D, AURBACH D. Comparison between potentiostatic and galvanostatic intermittent titration techniques for determination of chemical diffusion coefficients in ion-insertion electrodes[J]. Journal of Electroanalytical Chemistry, 2005, 580(2): 231-237. DOI: 10.1016/j.jelechem.2005.03.030. |

| 116 | PERSSON K, SETHURAMAN V A, HARDWICK L J, et al. Lithium diffusion in graphitic carbon[J]. The Journal of Physical Chemistry Letters, 2010, 1(8): 1176-1180. DOI: 10.1021/jz100188d. |

| 117 | TAKAMI N, HOSHINA K, INAGAKI H. Lithium diffusion in Li4/3Ti5/3O4 particles during insertion and extraction[J]. Journal of the Electrochemical Society, 2011, 158(6): A725-A730. DOI: 10.1149/1.3574037. |

| 118 | WUNDE F, BERKEMEIER F, SCHMITZ G. Lithium diffusion in sputter-deposited Li4Ti5O12 thin films[J]. Journal of Power Sources, 2012, 215: 109-115. DOI: 10.1016/j.jpowsour. 2012.04.102. |

| 119 | WAGEMAKER M, SIMON D , KELDER E , et al. A kinetic two-phase and equilibrium solid solution in spinel Li4+ xTi5O12[J]. Advanced Materials, 2006, 18(23): 3169-3173. DOI: 10.1002/adma.200601636. |

| 120 | ZHANG S S, JOW T R, AMINE K, et al. LiPF6-EC-EMC electrolyte for Li-ion battery[J]. Journal of Power Sources, 2002, 107(1): 18-23. DOI: 10.1016/S0378-7753(01)00968-5. |

| 121 | TAN S, JI Y J, ZHANG Z R, et al. Recent progress in research on high-voltage electrolytes for lithium-ion batteries[J]. Chemphyschem, 2014, 15(10): 1956-1969. DOI: 10.1002/cphc.201402175. |

| 122 | LI J L, FLEETWOOD J, HAWLEY W B, et al. From materials to cell: State-of-the-art and prospective technologies for lithium-ion battery electrode processing[J]. Chemical Reviews, 2022, 122(1): 903-956. DOI: 10.1021/acs.chemrev.1c00565. |

| 123 | GUO K L, QI S H, WANG H P, et al. High-voltage electrolyte chemistry for lithium batteries[J]. Small Science, 2022, 2(5): DOI: 10.1002/smsc.202100107. |

| 124 | XU W, CHEN X L, DING F, et al. Reinvestigation on the state-of-the-art nonaqueous carbonate electrolytes for 5 V Li-ion battery applications[J]. Journal of Power Sources, 2012, 213: 304-316. DOI: 10.1016/j.jpowsour.2012.04.031. |

| 125 | CHEBIAM R V, KANNAN A M, PRADO F, et al. Comparison of the chemical stability of the high energy density cathodes of lithium-ion batteries[J]. Electrochemistry Communications, 2001, 3(11): 624-627. DOI: 10.1016/S1388-2481(01)00232-6. |

| 126 | FAN X L, CHEN L, BORODIN O, et al. Non-flammable electrolyte enables Li-metal batteries with aggressive cathode chemistries[J]. Nature Nanotechnology, 2018, 13(8): 715-722. DOI: 10.1038/s41565-018-0183-2. |

| 127 | SU C C, HE M N, SHI J Y, et al. Principle in developing novel fluorinated sulfone electrolyte for high voltage lithium-ion batteries[J]. Energy & Environmental Science, 2021, 14(5): 3029-3034. DOI: 10.1039/D0EE03890C. |

| 128 | ZHAO J T, LIANG Y, ZHANG X, et al. In situ construction of uniform and robust cathode-electrolyte interphase for Li-rich layered oxides[J]. Advanced Functional Materials, 2021, 31(8): 2009192. DOI: 10.1002/adfm.202009192. |

| 129 | FAN X L, WANG C S. High-voltage liquid electrolytes for Li batteries: Progress and perspectives[J]. Chemical Society Reviews, 2021, 50(18): 10486-10566. DOI: 10.1039/d1cs00450f. |

| 130 | NIE M Y, XIA J, DAHN J R. Binary additive blends including pyridine boron trifluoride for Li-ion cells[J]. Journal of the Electrochemical Society, 2015, 162(9): A1693-A1701. DOI: 10.1149/2.0171509jes. |

| 131 | DONG L W, ZHONG S J, YUAN B T, et al. Electrolyte engineering for high-voltage lithium metal batteries[J]. Research, 2022, 2022: 9837586. DOI: 10.34133/2022/9837586. |

| 132 | JIAO S H, REN X D, CAO R G, et al. Stable cycling of high-voltage lithium metal batteries in ether electrolytes[J]. Nature Energy, 2018, 3: 739-746. DOI: 10.1038/s41560-018-0199-8. |

| 133 | KIM H T. Leaching organics from the interphase[J]. Nature Energy, 2023, 8: 911-912. DOI: 10.1038/s41560-023-01281-0. |

| 134 | ZHANG G Z, CHANG J, WANG L G, et al. A monofluoride ether-based electrolyte solution for fast-charging and low-temperature non-aqueous lithium metal batteries[J]. Nature Communications, 2023, 14: 1081. DOI: 10.1038/s41467-023-36793-6. |

| 135 | WANG Q D, ZHAO C L, WANG J L, et al. High entropy liquid electrolytes for lithium batteries[J]. Nature Communications, 2023, 14(1): 440. DOI: 10.1038/s41467-023-36075-1. |

| 136 | CHENG H R, MA Z, KUMAR P, et al. High voltage electrolyte design mediated by advanced solvation chemistry toward high energy density and fast charging lithium-ion batteries[J]. Advanced Energy Materials, 2024, 14(18): 2304321. DOI: 10.1002/aenm.202304321. |

| 137 | LUO F, CHU G, XIA X X, et al. Thick solid electrolyte interphases grown on silicon nanocone anodes during slow cycling and their negative effects on the performance of Li-ion batteries[J]. Nanoscale, 2015, 7(17): 7651-7658. DOI: 10.1039/c5nr00045a. |

| 138 | HAN J G, LEE J B, CHA A M, et al. Unsymmetrical fluorinated malonatoborate as an amphoteric additive for high-energy-density lithium-ion batteries[J]. Energy & Environmental Science, 2018, 11(6): 1552-1562. DOI: 10.1039/C8EE00372F. |

| 139 | CHOI N S, YEW K H, LEE K Y, et al. Effect of fluoroethylene carbonate additive on interfacial properties of silicon thin-film electrode[J]. Journal of Power Sources, 2006, 161(2): 1254-1259. DOI: 10.1016/j.jpowsour.2006.05.049. |

| 140 | KENNEDY T, BRANDON M, LAFFIR F, et al. Understanding the influence of electrolyte additives on the electrochemical performance and morphology evolution of silicon nanowire based lithium-ion battery anodes[J]. Journal of Power Sources, 2017, 359: 601-610. DOI: 10.1016/j.jpowsour.2017.05.093. |

| 141 | 刘通, 吴晓萌, 于红玉, 等. 正极组成对硫系全固态电池电化学性能的影响[J]. 硅酸盐学报, 2019, 47(10): 1415-1422. DOI: 10.14062/j.issn.0454-5648.2019.10.08. |

| LIU T, WU X M, YU H Y, et al. Effect of cathode composition on electrochemical performance of all-solid-state battery with sulfur-based electrolyte[J]. Journal of the Chinese Ceramic Society, 2019, 47(10): 1415-1422. DOI: 10.14062/j.issn.0454-5648.2019.10.08. | |

| 142 | WU F, CHEN N, CHEN R J, et al. "Liquid-in-solid" and "solid-in-liquid" electrolytes with high rate capacity and long cycling life for lithium-ion batteries[J]. Chemistry of Materials, 2016, 28(3): 848-856. DOI: 10.1021/acs.chemmater.5b04278. |

| 143 | KUANG Y D, CHEN C J, KIRSCH D, et al. Thick electrode batteries: Principles, opportunities, and challenges[J]. Advanced Energy Materials, 2019, 9(33): 1901457. DOI: 10.1002/aenm.201901457. |

| 144 | DU Z J, WOOD D L, DANIEL C, et al. Understanding limiting factors in thick electrode performance as applied to high energy density Li-ion batteries[J]. Journal of Applied Electrochemistry, 2017, 47(3): 405-415. DOI: 10.1007/s10800-017-1047-4. |

| 145 | TRAN H Y, GRECO G, TÄUBERT C, et al. Influence of electrode preparation on the electrochemical performance of LiNi0.8Co0.15Al0.05O2 composite electrodes for lithium-ion batteries[J]. Journal of Power Sources, 2012, 210: 276-285. DOI: 10.1016/j.jpowsour.2012.03.017. |

| 146 | ZHENG H H, LI J, SONG X Y, et al. A comprehensive understanding of electrode thickness effects on the electrochemical performances of Li-ion battery cathodes[J]. Electrochimica Acta, 2012, 71: 258-265. DOI: 10.1016/j.electacta.2012.03.161. |

| 147 | EBNER M, WOOD V. Tool for tortuosity estimation in lithium ion battery porous electrodes[J]. Journal of the Electrochemical Society, 2014, 162(2): A3064-A3070. DOI: 10.1149/2.0111502jes. |

| 148 | BILLAUD J, BOUVILLE F, MAGRINI T, et al. Magnetically aligned graphite electrodes for high-rate performance Li-ion batteries[J]. Nature Energy, 2016, 1(8): 16097. DOI: 10.1038/nenergy.2016.97. |

| 149 | WANG J W, SUN Q, GAO X J, et al. Toward high areal energy and power density electrode for Li-ion batteries via optimized 3D printing approach[J]. ACS Applied Materials & Interfaces, 2018, 10(46): 39794-39801. DOI: 10.1021/acsami.8b14797. |

| 150 | ZHANG X, HUI Z Y, KING S T, et al. Gradient architecture design in scalable porous battery electrodes[J]. Nano Letters, 2022, 22(6): 2521-2528. DOI: 10.1021/acs.nanolett.2c00385. |

| 151 | MAJDI H S, LATIPOV Z A, BORISOV V, et al. Nano and battery anode: A review[J]. Nanoscale Research Letters, 2021, 16(1): 177. DOI: 10.1186/s11671-021-03631-x. |

| 152 | CHEN J M, HSU C H, LIN Y R, et al. High-power LiFePO4 cathode materials with a continuous nano carbon network for lithium-ion batteries[J]. Journal of Power Sources, 2008, 184(2): 498-502. DOI: 10.1016/j.jpowsour.2008.04.022. |

| 153 | XIONG Z L, YUN Y S, JIN H J. Applications of carbon nanotubes for lithium ion battery anodes[J]. Materials, 2013, 6(3): 1138-1158. DOI: 10.3390/ma6031138. |

| 154 | DETTLAFF-WEGLIKOWSKA U, YOSHIDA J, SATO N, et al. Effect of single-walled carbon nanotubes as conductive additives on the performance of LiCoO2-based electrodes[J]. Journal of the Electrochemical Society, 2011, 158(2): A174. DOI: 10.1149/1.3526601. |

| 155 | WANG G P, LI H, ZHANG Q T, et al. The study of carbon nanotubes as conductive additives of cathode in lithium ion batteries[J]. Journal of Solid State Electrochemistry, 2011, 15(4): 759-764. DOI: 10.1007/s10008-010-1143-4. |

| 156 | DETTLAFF-WEGLIKOWSKA U, SATO N, YOSHIDA J, et al. Preparation and electrochemical characterization of LiMnPO4/single-walled carbon nanotube composites as cathode material for Li-ion battery[J]. Physica Status Solidi (b), 2009, 246(11/12): 2482-2485. DOI: 10.1002/pssb.200982290. |

| 157 | BAI N B, XIANG K X, ZHOU W, et al. LiFePO4/carbon nanowires with 3D nano-network structure as potential high performance cathode for lithium ion batteries[J]. Electrochimica Acta, 2016, 191: 23-28. DOI: 10.1016/j.electacta.2016.01.019. |

| 158 | LAIN M J, BRANDON J, KENDRICK E. Design strategies for high power vs. high energy lithium ion cells[J]. Batteries, 2019, 5(4): 64. DOI: 10.3390/batteries5040064. |

| 159 | ZHU P C, GASTOL D, MARSHALL J, et al. A review of current collectors for lithium-ion batteries[J]. Journal of Power Sources, 2021, 485: 229321. DOI: 10.1016/j.jpowsour.2020.229321. |

| 160 | 张稚国, 李华清, 王莉, 等. 锂离子电池塑料-金属复合集流体的特性及制备研究进展[J]. 储能科学与技术, 2024, 13(3): 749-758. DOI: 10.19799/j.cnki.2095-4239.2023.0763. |

| ZHANG Z G, LI H Q, WANG L, et al. Characteristics and preparation of metallized plastic current collectors for lithium-ion batteries[J]. Energy Storage Science and Technology, 2024, 13(3): 749-758. DOI: 10.19799/j.cnki.2095-4239.2023.0763. | |

| 161 | ANK M, SOMMER A, ABO GAMRA K, et al. Lithium-ion cells in automotive applications: Tesla 4680 cylindrical cell teardown and characterization[J]. Journal of the Electrochemical Society, 2023, 170(12): 120536. DOI: 10.1149/1945-7111/ad14d0. |

| [1] | Yingying XIE, Bin DENG, Yuzhi ZHANG, Xiaoxu WANG, Linfeng ZHANG. Intelligent R&D of battery design automation in the era of artificial intelligence [J]. Energy Storage Science and Technology, 2024, 13(9): 3182-3197. |

| [2] | Wenhao GONG, Meng LI, Tao ZHANG, Ruotao ZHANG, Yanxia LIU. Development and fabrication of high-energy and long-endurance Li-ion batteries for UAVs [J]. Energy Storage Science and Technology, 2024, 13(8): 2550-2558. |

| [3] | Jianhang YANG, Wenting FENG, Junwei HAN, Xinru WEI, Chenyu MA, Changming MAO, Linjie ZHI, Debin KONG. Recent advances in rechargeable Li/Na-Cl2 batteries: From material construction to performance evaluation [J]. Energy Storage Science and Technology, 2024, 13(6): 1824-1834. |

| [4] | Miao LI, Yongli YU, Jianyang WU, Min LEI, Henghui ZHOU. Design of high-energy-density LiFePO4 cathode materials [J]. Energy Storage Science and Technology, 2023, 12(7): 2045-2058. |

| [5] | Ce ZHANG, Siwu LI, Jia XIE. Research progress on the prelithiation technology of alloy-type anodes [J]. Energy Storage Science and Technology, 2022, 11(5): 1383-1400. |

| [6] | Wenting JIN, Mansheng LIAO, Ji HUANG, Zidong WEI. The technological trend of high energy density Li-ion batteries for vehicles [J]. Energy Storage Science and Technology, 2022, 11(1): 350-358. |

| [7] | Mengdie YAN, Hui LI, Min LING, Huilin PAN, Qiang ZHANG. Brief review of progress in lithium-sulfur batteries based on dissolution-deposition reactions [J]. Energy Storage Science and Technology, 2020, 9(6): 1606-1613. |

| [8] | LI Wenjun, XU Hangyu, YANG Qi, LI Jiuming, ZHANG Zhenyu, WANG Shengbin, PENG Jiayue, ZHANG Bin, CHEN Xianglei, ZHANG Zhen, YANG Meng, ZHAO Yan, GENG Yaoyao, HUANG Wenshi, DING Zepeng, ZHANG Lei, TIAN Qiyou, YU Huigen, LI Hong. Development of strategies for high-energy-density lithium batteries [J]. Energy Storage Science and Technology, 2020, 9(2): 448-478. |

| [9] |

ZOU Jian, WANG Bojun, YANG Jiachao, NIU Xiaobin, WANG Liping.

Electrochemical performance of β-Li0.3V2O5 as a lithium-ion battery cathode material

[J]. Energy Storage Science and Technology, 2020, 9(2): 353-360.

|

| [10] | LIU Qinghua, ZHANG Sai, JIANG Mingzhe, WANG Qiushi, XING Xueqi, YANG Hong, HUANG Feng, LEMMON P John, MIAO Ping. Study on the low-cost flow battery technologies for energy storage [J]. Energy Storage Science and Technology, 2019, 8(S1): 60-64. |

| [11] | ZHANG Yonglong, XIA Huiling, LIN Jiu, CHEN Shaojie, XU Xiaoxiong. Brief analysis the safety of solid-state lithium ion batteries [J]. Energy Storage Science and Technology, 2018, 7(6): 994-1002. |

| [12] | CAO Yong, YAN Changqing, WANG Yifei, LI Daocong, LIN Shaoyong, LIANG Dayu, DAI Beibei, HU Panpan, BIAN Lin, YANG Xulai, XU Xingwu. The technical route exploration of lithium ion battery with high safety and high energy density [J]. Energy Storage Science and Technology, 2018, 7(3): 384-393. |

| [13] | YANG Xulai, CHEN Houmei, GAO Er’ping. Project “development and application of lithium ion batteries with high specific energy density”#br# [J]. Energy Storage Science and Technology, 2017, 6(5): 1145-1147. |

| [14] | XIA Dingguo. Project “ Key technology and basic science problem reach for high energy density lithium batteries” [J]. Energy Storage Science and Technology, 2017, 6(1): 165-168. |

| [15] | LI Hong. Project “High energy density lithium batteries for long range EV” [J]. Energy Storage Science and Technology, 2016, 5(6): 915-918. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||