Energy Storage Science and Technology ›› 2025, Vol. 14 ›› Issue (1): 77-89.doi: 10.19799/j.cnki.2095-4239.2024.0767

• Energy Storage Materials and Devices • Previous Articles Next Articles

Yueni MEI( ), Wenjie QU, Guangyu CHENG, Yonggui XIANG, Haiyan LU, Xiaodan SHAO, Yiming ZHANG, Ke WANG

), Wenjie QU, Guangyu CHENG, Yonggui XIANG, Haiyan LU, Xiaodan SHAO, Yiming ZHANG, Ke WANG

Received:2024-08-14

Revised:2024-08-26

Online:2025-01-28

Published:2025-02-25

Contact:

Yueni MEI

E-mail:meiyueni@126.com

CLC Number:

Yueni MEI, Wenjie QU, Guangyu CHENG, Yonggui XIANG, Haiyan LU, Xiaodan SHAO, Yiming ZHANG, Ke WANG. Recent progress of cathode prelithiation strategies for lithium ion batteries[J]. Energy Storage Science and Technology, 2025, 14(1): 77-89.

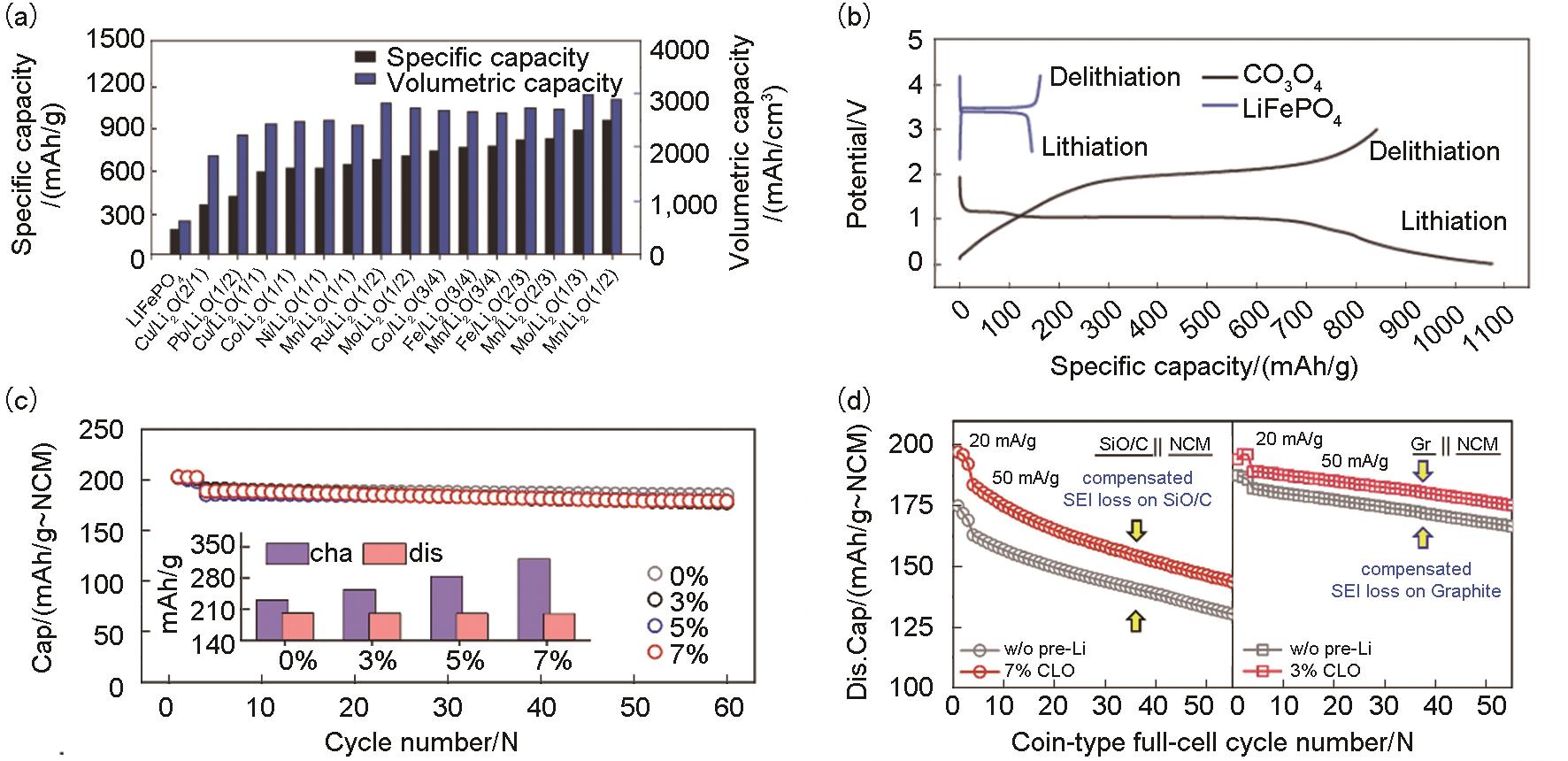

Fig.3

(a) Theoretical specific capacities and volumetric capacities of various M/Li2O composites based on the inverse conversion reaction; (b) Typical potential curves of Co3O4 and existing commercial cathodes LiFePO4[11]; (c) Cycling performance of NCM811 and NCM811 with P% (P%=3%, 5%, and 7%) CLO prelithiation agent; (d) Cycling performance of SiO/C||NCM without/with 7% CLO prelithiation agent (left) and Graphite||NCM without/with 3% CLO prelithiation agent (right) coin-type full-cell[23]"

Table 1

Comparison of different cathode prelithiation strategies"

| 正极补锂策略 | 典型代表材料 | 基本性质 | 补锂优势 | 存在的挑战 | (潜在)应用情况 |

|---|---|---|---|---|---|

| 过锂化正极材料 | 过锂化设计的LiNi x Co y Mn1-x-y O2(NCM),LiNi1-x-y Co x Al y O2(NCA),Li1+x Mn2O4,Li1+x Mn1.5Ni0.5O4等材料 | 通过化学或电化学方法设计制备含有过量锂的“富锂”正极材料,电池总体电化学行为不变 | (1)过锂化正极材料在去锂化后,电化学体系中不残留惰性物质; (2)与NMP溶剂体系兼容性良好 | (1)过锂化设计容量偏低; (2)可进行过锂化设计的正极材料种类有限; (3)过锂化正极材料的制备会额外增加生产步骤 | 仅适用于可进行过锂化设计的正极材料体系,但过锂化正极材料需增加额外的设计制备步骤,在规模化应用中仍存在挑战 |

| 二元含锂化合物补锂剂 | LiN3、Li3N、Li2O、Li2O2、Li2S、Li2Se、LiF、Li3P等 | 理论补锂容量高于1000 mAh/g,金属/二元含锂化合物复合物理论补锂容量可达900 mAh/g | (1)理论补锂容量高; (2)分解产物主要为气体,成分单一 | (1)完全分解电位高,与主流正极材料体系不适配,需结合改性策略降低分解电位; (2)部分材料制备时需使用熔融锂和惰性气氛,不利于规模化工业制备 | 结合表面包覆、基于转化反应方法等制备改性二元含锂补锂材料,同时应考虑补锂剂分解产气排出的工艺方法及引入金属单质后分解残留等问题 |

| 三元含锂化合物补锂剂 | Li2NiO2、Li5FeO4、Li6CoO4、Li2MoO3、Li8ZrO6等 | 由固相反应法制备合成,补锂容量高于300 mAh/g,其中Li5FeO4材料理论补锂容量可达870 mAh/g | (1)制备成本较低,易于规模化生产制备; (2)分解电位区间与当前主流正极材料体系适配; (3)与NMP溶剂兼容性良好 | (1)残碱高,空气稳定性及导电性较差,需结合改性方法进行改善; (2)分解后在电池体系中残留惰性金属氧化物 | 已实现规模化应用的正极补锂方法,综合评估最为经济实惠的补锂技术路线,适用于对于总补锂量需求不高的电化学体系 |

| 有机含锂化合物补锂剂 | Li2C2O4、Li2C4O4、 Li2DHBN等 | 由液相法合成,其中Li2C4O4完全分解容量可达3845 mAh/g,具有“自牺牲”、无残留等特点 | (1)制备方法简单,稳定性好,具有批量制备潜力; (2)分解电位区间与主流正极材料体系兼容 | (1)本征导电性较差,需结合导电剂或催化剂的引入进行改善; (2)完全分解后产气量大,需采取后续排气措施减少产气对电池体系的不良影响 | 具备未来规模化应用的前景,补锂方法更加多样化,但仍面临将分解产气彻底排出电池体系等重要工艺问题 |

| 1 | LI M, LU J, CHEN Z W, et al. 30 years of lithium-ion batteries[J]. Advanced Materials, 2018: e1800561. DOI:10.1002/adma. 201800561. |

| 2 | ARMAND M, AXMANN P, BRESSER D, et al. Lithium-ion batteries–Current state of the art and anticipated developments[J]. Journal of Power Sources, 2020, 479: 228708. DOI:10.1016/j.jpowsour.2020.228708. |

| 3 | HOLTSTIEGE F, WILKEN A, WINTER M, et al. Running out of lithium? A route to differentiate between capacity losses and active lithium losses in lithium-ion batteries[J]. Physical Chemistry Chemical Physics, 2017, 19(38): 25905-25918. DOI:10.1039/C7CP05405J. |

| 4 | JIN L M, SHEN C, WU Q, et al. Pre-lithiation strategies for next-generation practical lithium-ion batteries[J]. Advanced Science, 2021, 8(12): e2005031. DOI:10.1002/advs.202005031. |

| 5 | ZHANG H Q, CHENG J, LIU H B, et al. Prelithiation: A critical strategy towards practical application of high-energy-density batteries[J]. Advanced Energy Materials, 2023, 13(27): 2300466. DOI:10.1002/aenm.202300466. |

| 6 | 田孟羽, 詹元杰, 闫勇, 等. 锂离子电池补锂技术[J]. 储能科学与技术, 2021, 10(3): 800-812. DOI: 10.19799/j.cnki.2095-4239. 2021. 0066. |

| TIAN M Y, ZHAN Y J, YAN Y, et al. Replenishment technology of the lithium ion battery[J]. Energy Storage Science and Technology, 2021, 10(3): 800-812. DOI: 10.19799/j.cnki.2095-4239.2021.0066. | |

| 7 | 詹元杰. 正极补锂材料及其在锂离子电池中的应用[D]. 北京: 中国科学院大学(中国科学院物理研究所), 2018. |

| ZHAN Y J. Lithium-supplementing material for positive electrode and its application in lithium-ion battery[D]. Beijing: University of Chinese Academy of Sciences(Institute of Physics CAS), 2018. | |

| 8 | 李子晨. 锂离子电池正极补锂添加剂的制备及其性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2020. DOI: 10.27061/d.cnki.ghgdu. 2020. 000828. |

| LI Z C. Preparation and properties of lithium supplement additive for positive electrode of lithium ion battery[D]. Harbin: Harbin Institute of Technology, 2020. DOI: 10.27061/d.cnki.ghgdu. 2020. 000828. | |

| 9 | HUANG Z Y, DENG Z, ZHONG Y, et al. Progress and challenges of prelithiation technology for lithium-ion battery[J]. Carbon Energy, 2022, 4(6): 1107-1132. DOI:10.1002/cey2.256. |

| 10 | DOSE W M, BLAUWKAMP J, PIERNAS-MUÑOZ M J, et al. Liquid ammonia chemical lithiation: An approach for high-energy and high-voltage Si-Graphite|Li1+ xNi0.5Mn1.5O4 Li-ion batteries[J]. ACS Applied Energy Materials, 2019, 2(7): 5019-5028. DOI:10.1021/acsaem.9b00695. |

| 11 | SUN Y M, LEE H W, SEH Z W, et al. High-capacity battery cathode prelithiation to offset initial lithium loss[J]. Nature Energy, 2016, 1(1): 15008. DOI:10.1038/nenergy.2015.8. |

| 12 | KANG K, CHEN C H, HWANG B J, et al. Synthesis, electrochemical properties, and phase stability of Li2NiO2 with the Immm structure[J]. Chemistry of Materials, 2004, 16(13): 2685-2690. DOI:10.1021/cm049922h. |

| 13 | JOHNSON C S, KANG S H, VAUGHEY J T, et al. Li2O removal from Li5FeO4: A cathode precursor for lithium-ion batteries[J]. Chemistry of Materials, 2010, 22(3): 1263-1270. DOI:10.1021/cm902713m. |

| 14 | SHEN B L, SARKODIE B, ZHANG L, et al. Self-sacrificing lithium source with high electrochemical activity and water oxygen stability and its application in Si-C//S battery[J]. Energy Storage Materials, 2022, 45: 687-695. DOI:10.1016/j.ensm.2021.12.014. |

| 15 | DOSE W M, KIM S, LIU Q, et al. Dual functionality of over-lithiated NMC for high energy silicon-based lithium-ion batteries[J]. Journal of Materials Chemistry A, 2021, 9(21): 12818-12829. DOI:10.1039/D1TA01290H. |

| 16 | GABRIELLI G, MARINARO M, MANCINI M, et al. A new approach for compensating the irreversible capacity loss of high-energy Si/C|LiNi0.5Mn1.5O4 lithium-ion batteries[J]. Journal of Power Sources, 2017, 351: 35-44. DOI:10.1016/j.jpowsour. 2017. 03.051. |

| 17 | ARAVINDAN V, ARUN N, SHUBHA N, et al. Overlithiated Li1+ x Ni0.5Mn1.5O4 in all one dimensional architecture with conversion type α-Fe2O3: A new approach to eliminate irreversible capacity loss[J]. Electrochimica Acta, 2016, 215: 647-651. DOI:10.1016/j.electacta.2016.08.078. |

| 18 | SHANMUKARAJ D, GRUGEON S, LARUELLE S, et al. Sacrificial salts: Compensating the initial charge irreversibility in lithium batteries[J]. Electrochemistry Communications, 2010, 12(10): 1344-1347. DOI:10.1016/j.elecom.2010.07.016. |

| 19 | PARK K, YU B C, GOODENOUGH J B. Li3N as a cathode additive for high-energy-density lithium-ion batteries[J]. Advanced Energy Materials, 2016, 6(10): 1502534. DOI:10.1002/aenm. 201502534. |

| 20 | SUN Y M, LI Y B, SUN J, et al. Stabilized Li3N for efficient battery cathode prelithiation[J]. Energy Storage Materials, 2017, 6: 119-124. DOI:10.1016/j.ensm.2016.10.004. |

| 21 | BIAN X F, PANG Q, WEI Y J, et al. Dual roles of Li3N as an electrode additive for Li-excess layered cathode materials: A Li-ion sacrificial salt and electrode-stabilizing agent[J]. Chemistry – A European Journal, 2018, 24(52): 13815-13820. DOI:10.1002/chem.201801809. |

| 22 | QIAO Y, YANG H J, CHANG Z, et al. A high-energy-density and long-life initial-anode-free lithium battery enabled by a Li2O sacrificial agent[J]. Nature Energy, 2021, 6: 653-662. DOI:10. 1038/s41560-021-00839-0. |

| 23 | CHEN Y L, ZHU Y L, ZUO W H, et al. Implanting transition metal into Li2 O-based cathode prelithiation agent for high-energy-density and long-life Li-ion batteries[J]. Angewandte Chemie (International Ed), 2024, 63(5): e202316112. DOI:10.1002/anie. 202316112. |

| 24 | BIE Y T, YANG J, WANG J L, et al. Li2O2 as a cathode additive for the initial anode irreversibility compensation in lithium-ion batteries[J]. Chemical Communications, 2017, 53(59): 8324-8327. DOI:10.1039/c7cc04646d. |

| 25 | ZHANG L H, JEONG S, REINSMA N, et al. Decomposition of Li2O2 as the cathode prelithiation additive for lithium-ion batteries without an additional catalyst and the initial performance investigation[J]. Journal of the Electrochemical Society, 2021, 168(12): 120520. DOI:10.1149/1945-7111/ac3e46. |

| 26 | SUN Y M, LEE H W, SEH Z W, et al. Lithium sulfide/metal nanocomposite as a high-capacity cathode prelithiation material[J]. Advanced Energy Materials, 2016, 6(12): 1600154. DOI:10. 1002/aenm.201600154. |

| 27 | ZHAN Y J, YU H L, BEN L B, et al. Using Li2S to compensate for the loss of active lithium in Li-ion batteries[J]. Electrochimica Acta, 2017, 255: 212-219. DOI:10.1016/j.electacta.2017.09.167. |

| 28 | FU Y P, XIE Y, ZENG L Y, et al. Li2Se as cathode additive to prolong the next generation high energy lithium-ion batteries[J]. Surfaces and Interfaces, 2023, 36: 102610. DOI:10.1016/j.surfin. 2022.102610. |

| 29 | PAN Y J, QI X Q, DU H R, et al. Li2Se as a cathode prelithiation additive for lithium-ion batteries[J]. ACS Applied Materials & Interfaces, 2023, 15(15): 18763-18770. DOI:10.1021/acsami. 2c21312. |

| 30 | SUN Y M, LEE H W, ZHENG G Y, et al. In situ chemical synthesis of lithium fluoride/metal nanocomposite for high capacity prelithiation of cathodes[J]. Nano Letters, 2016, 16(2): 1497-1501. DOI:10.1021/acs.nanolett.5b05228. |

| 31 | DU J M, WANG W Y, ENG A Y S, et al. Metal/LiF/Li2O nanocomposite for battery cathode prelithiation: Trade-off between capacity and stability[J]. Nano Letters, 2020, 20(1): 546-552. DOI:10.1021/acs.nanolett.9b04278. |

| 32 | WANG X Y, LIU C, ZHANG S J, et al. Dual-functional cathodic prelithiation reagent of Li3P in lithium-ion battery for compensating initial capacity loss and enhancing safety[J]. ACS Applied Energy Materials, 2021, 4(5): 5246-5254. DOI:10.1021/acsaem.1c00773. |

| 33 | KIM M G, CHO J. Air stable Al2O3-coated Li2NiO2 cathode additive as a surplus current consumer in a Li-ion cell[J]. Journal of Materials Chemistry, 2008, 18(48): 5880-5887. DOI:10.1039/B814161D. |

| 34 | PARK H, YOON T, KIM Y U, et al. Li2NiO2 as a sacrificing positive additive for lithium-ion batteries[J]. Electrochimica Acta, 2013, 108: 591-595. DOI:10.1016/j.electacta.2013.06.117. |

| 35 | SU X, LIN C K, WANG X P, et al. A new strategy to mitigate the initial capacity loss of lithium ion batteries[J]. Journal of Power Sources, 2016, 324: 150-157. DOI:10.1016/j.jpowsour. 2016. 05.063. |

| 36 | LI J, ZHU B, LI S H, et al. Air-stable Li6CoO4@Li5FeO4 pre-lithiation reagent in cathode enabling high performance lithium-ion batteries[J]. Journal of the Electrochemical Society, 2021, 168(8): 080510. DOI:10.1149/1945-7111/ac18e1. |

| 37 | DOSE W M, VILLA C, HU X B, et al. Beneficial effect of Li5FeO4 lithium source for Li-ion batteries with a layered NMC cathode and Si anode[J]. Journal of the Electrochemical Society, 2020, 167(16): 160543. DOI:10.1149/1945-7111/abd1ef. |

| 38 | NOH M, CHO J. Role of Li6CoO4 cathode additive in Li-ion cells containing low coulombic efficiency anode material[J]. Journal of the Electrochemical Society, 2012, 159(8): A1329-A1334. DOI:10.1149/2.085208jes. |

| 39 | PARK M S, LIM Y G, KIM J H, et al. A novel lithium-doping approach for an advanced lithium ion capacitor[J]. Advanced Energy Materials, 2011, 1(6): 1002-1006. DOI:10.1002/aenm. 201100270. |

| 40 | KIM M, SPINDLER B D, DONG L F, et al. Li8ZrO6 as a pre-lithiation additive for lithium-ion batteries[J]. ACS Applied Energy Materials, 2022, 5(11): 14433-14444. DOI:10.1021/acsaem.2c02980. |

| 41 | SOLCHENBACH S, WETJEN M, PRITZL D, et al. Lithium oxalate as capacity and cycle-life enhancer in LNMO/graphite and LNMO/SiG full cells[J]. Journal of the Electrochemical Society, 2018, 165(3): A512-A524. DOI:10.1149/2.0611803jes. |

| 42 | FAN M, MENG Q H, CHANG X, et al. In situ electrochemical regeneration of degraded LiFePO4 electrode with functionalized prelithiation separator[J]. Advanced Energy Materials, 2022, 12(18): 2103630. DOI:10.1002/aenm.202103630. |

| 43 | ARNAIZ M, SHANMUKARAJ D, CARRIAZO D, et al. A transversal low-cost pre-metallation strategy enabling ultrafast and stable metal ion capacitor technologies[J]. Energy & Environmental Science, 2020, 13(8): 2441-2449. DOI:10.1039/D0EE00351D. |

| 44 | LIU G X, WAN W, NIE Q, et al. Controllable long-term lithium replenishment for enhancing energy density and cycle life of lithium-ion batteries[J]. Energy & Environmental Science, 2024, 17(3): 1163-1174. DOI:10.1039/D3EE03740A. |

| 45 | JEŻOWSKI P, CROSNIER O, DEUNF E, et al. Safe and recyclable lithium-ion capacitors using sacrificial organic lithium salt[J]. Nature Materials, 2018, 17(2): 167-173. DOI:10.1038/nmat5029. |

| [1] | Tong LIU, Guiting YANG, Hui BI, Yueni MEI, Shuo LIU, Yongji GONG, Wenlei LUO. Recent progress in high-energy and high-power lithium-ion batteries [J]. Energy Storage Science and Technology, 2025, 14(1): 54-76. |

| [2] | Yuman ZHANG, Lingling FAN, Chongyang YANG. Effects of different anode materials on the cyclic performance of high-power LiFePO4 energy storage devices [J]. Energy Storage Science and Technology, 2024, 13(9): 3245-3253. |

| [3] | Yuelin CHEN, Hongzhong MA, Muyu ZHU, Wenjing XUAN, Sihan WANG. Research on the liquid cooling technology of a lithium iron phosphate battery pack under a peak load regulation in a power grid [J]. Energy Storage Science and Technology, 2024, 13(8): 2704-2712. |

| [4] | Wenhao GONG, Meng LI, Tao ZHANG, Ruotao ZHANG, Yanxia LIU. Development and fabrication of high-energy and long-endurance Li-ion batteries for UAVs [J]. Energy Storage Science and Technology, 2024, 13(8): 2550-2558. |

| [5] | Zheng LI, Zhenzhong YANG, Qiong WANG, Renzong HU. Patent intelligence analysis of the research progress in low-temperature electrolytes for Li-ion batteries [J]. Energy Storage Science and Technology, 2024, 13(7): 2317-2326. |

| [6] | Guangyu CHENG, Xinwei LIU, Shuo LIU, Haitao GU, Ke WANG. Controlling electrolyte solvent components to enhance cycle life of LCO/C low-temperature 18650 batteries [J]. Energy Storage Science and Technology, 2024, 13(7): 2171-2180. |

| [7] | Jianhang YANG, Wenting FENG, Junwei HAN, Xinru WEI, Chenyu MA, Changming MAO, Linjie ZHI, Debin KONG. Recent advances in rechargeable Li/Na-Cl2 batteries: From material construction to performance evaluation [J]. Energy Storage Science and Technology, 2024, 13(6): 1824-1834. |

| [8] | Yuanyuan JIANG, Fangfang TU, Fangping ZHANG, Yinglai WANG, Jiawen CAI, Donghui YANG, Yanhong LI, Jiayuan XIANG, Xinhui XIA, Jipeng FU. Study on technology and mechanism of prelithiation for high-performance lithium iron phosphate battery [J]. Energy Storage Science and Technology, 2024, 13(5): 1435-1442. |

| [9] | Zhaocai LYU, Yuxi WANG, Zhitao WANG, Xiaohui SUN, Jingkang LI. Influence of heated calendering process on cathode film performance of lithium-ion batteries [J]. Energy Storage Science and Technology, 2024, 13(5): 1443-1450. |

| [10] | Xueli ZHANG, Weiqing SUN, Junhua ZHENG. Study on the influence of polyurethane-type solid-solid phase change energy storage materials on the temperature control effect of asphalt [J]. Energy Storage Science and Technology, 2024, 13(3): 841-843. |

| [11] | Binyang ZHANG, Xiaolong REN, Jiangming ZHAO, Shunliang DING. Numerical optimization of a liquid cooling plate with double helix flow channel for lithium-ion battery [J]. Energy Storage Science and Technology, 2024, 13(10): 3545-3555. |

| [12] | Su YAN, Fangfang ZHONG, Junwei LIU, Mei DING, Chuankun JIA. Key materials and advanced characterization of high-energy-density flow battery [J]. Energy Storage Science and Technology, 2024, 13(1): 143-156. |

| [13] | Xin JIN, Jianru ZHANG, Qiyu WANG, Rui ZHANG, Bitong WANG, Zhongyang ZHANG, Hailong YU, Xiqian YU, Hong LI. Study on thermal runaway of hybrid solid-liquid batteries [J]. Energy Storage Science and Technology, 2024, 13(1): 48-56. |

| [14] | Xiaowei HUANG, Shaopeng LI, Xiaogang ZHANG. Research on the impact and mechanism of the lithium replenishment degree of anode prelithiation on the performance of lithium-ion batteries [J]. Energy Storage Science and Technology, 2023, 12(9): 2727-2734. |

| [15] | Yibiao GUAN, Jinran SHEN, Jialiang LIU, Zhanzhan QU, Fei GAO, Shiyang LIU, Cuijing GUO, Shuqin ZHOU, Shanshan FU. Comprehensive performance evaluation standards for energy storage lithium-ion batteries guided by safe and high-quality applications [J]. Energy Storage Science and Technology, 2023, 12(9): 2946-2953. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||