Energy Storage Science and Technology ›› 2024, Vol. 13 ›› Issue (5): 1443-1450.doi: 10.19799/j.cnki.2095-4239.2023.0946

• Energy Storage Materials and Devices • Previous Articles Next Articles

Zhaocai LYU( ), Yuxi WANG, Zhitao WANG, Xiaohui SUN, Jingkang LI

), Yuxi WANG, Zhitao WANG, Xiaohui SUN, Jingkang LI

Received:2023-12-25

Revised:2024-01-05

Online:2024-05-28

Published:2024-05-28

Contact:

Zhaocai LYU

E-mail:lvzhaocai1993@163.com

CLC Number:

Zhaocai LYU, Yuxi WANG, Zhitao WANG, Xiaohui SUN, Jingkang LI. Influence of heated calendering process on cathode film performance of lithium-ion batteries[J]. Energy Storage Science and Technology, 2024, 13(5): 1443-1450.

Table 2

The specific value of electrochemistry performance test of batteries under the different roll temperature heated calendaring"

| 温度/℃ | 不同电流下的容量/(mAh/g) | 容量保持率/% | ||||||

|---|---|---|---|---|---|---|---|---|

| 0.1C | 0.5C | 1C | 2C | 0.5C/0.1C | 1C/0.1C | 2C/0.1C | ||

| 25 | 154 | 145.2 | 137.9 | 130.4 | 94.3 | 89.5 | 84.7 | |

| 60 | 155 | 147.6 | 142.3 | 135.1 | 95.2 | 91.8 | 87.2 | |

| 80 | 154 | 147.2 | 142.5 | 133.7 | 95.6 | 92.5 | 86.8 | |

| 100 | 157.5 | 150.5 | 145.5 | 137.6 | 95.6 | 92.4 | 87.4 | |

| 120 | 153.8 | 147.2 | 142.2 | 135.4 | 95.7 | 92.5 | 88.0 | |

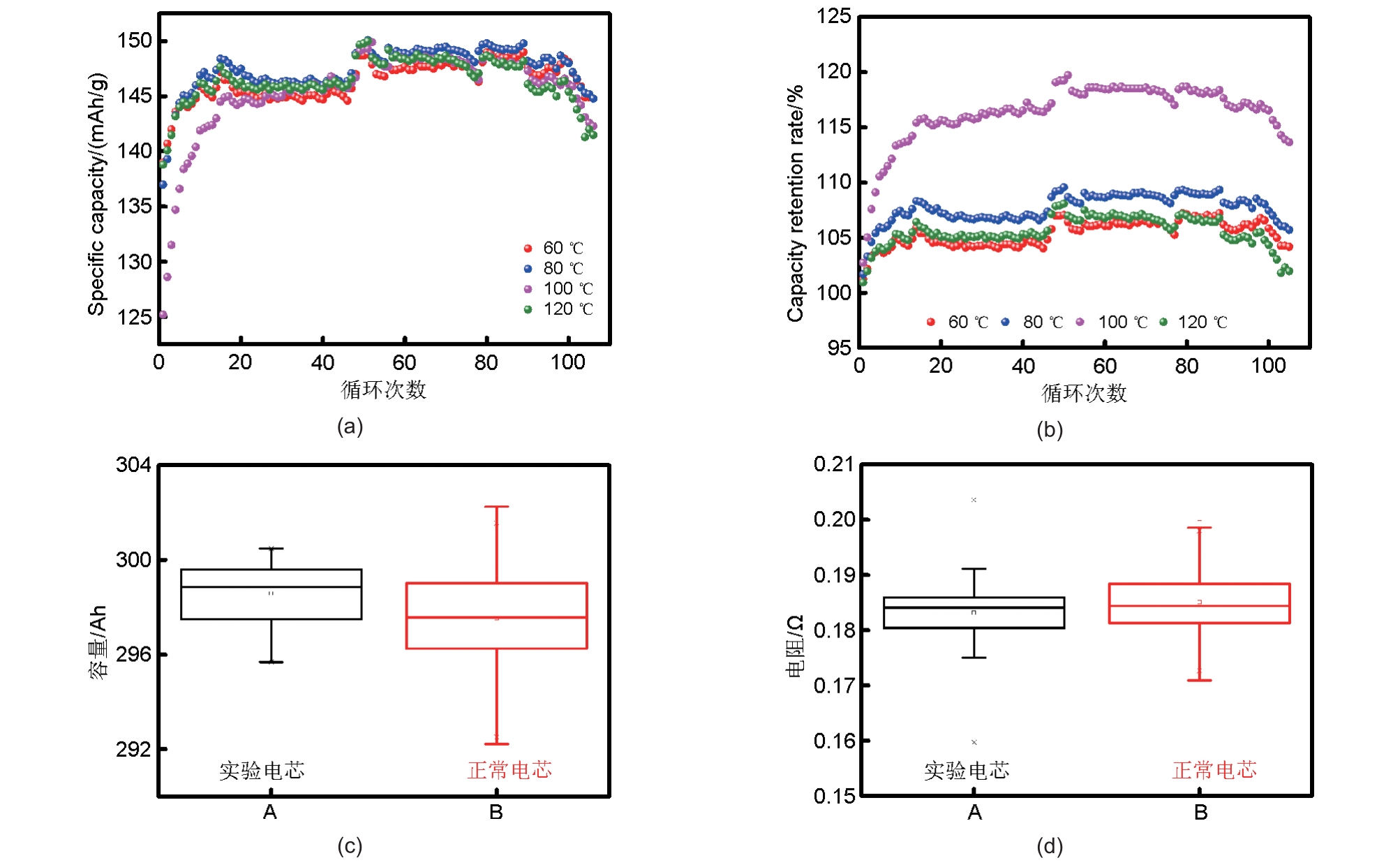

Fig. 8

(a) The cyclic performance test at 1C under the different roll temperature calendaring; (b) The ratio of the discharge specific capacity of different cycles to the discharge specific capacity of the first cycle; Box plots of (c) capacity and (d) resistance comparison between the heated calendaring experiment and normal production of 280 Ah batteries"

| 1 | 丁明, 陈忠, 苏建徽, 等. 可再生能源发电中的电池储能系统综述[J]. 电力系统自动化, 2013, 37(1): 19-25, 102. |

| DING M,CHEN Z, SU J H, et al. An overview of battery energy storage system for renewable energy generation[J]. Automation of Electric Power Systems, 2013, 37(1): 19-25, 102. | |

| 2 | 杨绍斌, 梁正. 锂离子电池制造工艺原理与应用[M]. 北京: 化学工业出版社, 2020. |

| YANG S B, LIANG Z. Fundementals and applications of the manufacturing process of lithium ion batteries[M]. Beijing: Chemical Industry Press, 2020. | |

| 3 | ZHANG J P, HUANG H G, SUN J N. Investigation on mechanical and microstructural evolution of lithium-ion battery electrode during the calendering process[J]. Powder Technology, 2022, 409: 117828. |

| 4 | 张俊鹏, 孙静娜, 黄华贵, 等. 锂离子电池极片辊压异质微结构演化与性能相关性研究进展[J/OL]. 中国有色金属学报, 2023: 1-29. (2023-10-17). https://kns.cnki.net/kcms/detail/43.1238.tg.20231013.1140.005.html. |

| ZHANG J P, SUN J N, HUANG H G, et al. A review of heterogeneous microstructure and performance correlation during calendering process of electrode for LIBs[J/OL]. TheChinese Journal of Nonferrous Metals, 2023: 1-29. (2023-10-17). https://kns.cnki.net/kcms/detail/43.1238.tg.20231013.1140.005.html. | |

| 5 | 韩广欣, 王玉峰, 张向举, 等. 热辊压片对电池性能的影响[J]. 河南化工, 2020, 37(2): 33-35. |

| HAN G X, WANG Y F, ZHANG X J, et al. Effect of hot roller presstr on battery performance[J]. HenanChemical Industry, 2020, 37(2): 33-35. | |

| 6 | PRIMO E N,CHOUCHANE M, TOUZIN M, et al. Understanding the calendering processability of Li(Ni0.33Mn0.33Co0.33)O2-based cathodes[J]. Journal of Power Sources, 2021, 488: 229361. |

| 7 | PRIMO E N, TOUZIN M, FRANCO A A.Calendering of Li(Ni0.33Mn0.33Co0.33)O2-based cathodes: Analyzing the link between process parameters and electrode properties by advanced statistics[J]. Batteries & Supercaps, 2021, 4(5): 834-844. |

| 8 | 冷晓伟, 戴作强, 郑莉莉, 等. 锂离子电池电化学阻抗谱研究综述[J]. 电源技术, 2018, 42(11): 1749-1752. |

| LENG X W, DAI Z Q, ZHENG L L, et al. Review on electrochemical impedance spectroscopy of lithium-ion batteries[J].Chinese Journal of Power Sources, 2018, 42(11): 1749-1752. | |

| 9 | 李敏, 相佳媛, 杨东辉, 等. 涂碳铝箔对磷酸铁锂电池性能的影响[J]. 储能科学与技术, 2020, 9(6): 1714-1719. |

| LI M, XIANG J Y, YANG D H, et al. Effect of carbon-coated Al foil on properties of lithium iron phosphate batteries[J]. Energy Storage Science and Technology, 2020, 9(6): 1714-1719. | |

| 10 | 郑杰允, 李泓. 锂电池基础科学问题(Ⅴ)——电池界面[J]. 储能科学与技术, 2013, 2(5): 503-513. |

| ZHENG J Y, LI H. Fundamental scientific aspects of lithium batteries (Ⅴ)—Interfaces[J]. Energy Storage Science and Technology, 2013, 2(5): 503-513. | |

| 11 | 唐世弟, 万里鹏, 郭密, 等. 涂碳铝箔对两类磷酸铁锂电池性能的影响[J]. 电源技术, 2022, 46(11): 1238-1241. |

| TANG S D, WAN L P, GUO M, et al. Effect of coating carbon aluminum foil on properties of lithium ion battery composed of two types of LiFePO4 cathode[J].Chinese Journal of Power Sources, 2022, 46(11): 1238-1241. |

| [1] | Pengjie ZHU, Wei LI, Chu ZHANG, Hao SONG, Beibei LI, Xiumei LIU, Lili LIU. Study on early warning system for thermal runaway of lithium batteries in energy storage cabinets due to smoke and gas diffusion [J]. Energy Storage Science and Technology, 2025, 14(2): 624-635. |

| [2] | Jinhao YE, Junhui HOU, Zhengguo ZHANG, Ziye LING, Xiaoming FANG, Silin HUANG, Zhiwen XIAO. Thermal runaway characteristics and gas generation behavior of 100 Ah lithium iron phosphate pouch cell [J]. Energy Storage Science and Technology, 2025, 14(2): 636-647. |

| [3] | Huaiyu HUANG, Silin HUANG, Rongchao ZHAO, Zhiwen XIAO, Junhui HOU, Liwei YAN. Experimental study on thermal runaway characteristics triggered by insulation failure of aluminum-plastic film shell of lithium iron phosphate battery [J]. Energy Storage Science and Technology, 2025, 14(2): 613-623. |

| [4] | Yueni MEI, Wenjie QU, Guangyu CHENG, Yonggui XIANG, Haiyan LU, Xiaodan SHAO, Yiming ZHANG, Ke WANG. Recent progress of cathode prelithiation strategies for lithium ion batteries [J]. Energy Storage Science and Technology, 2025, 14(1): 77-89. |

| [5] | Xingguang CHEN, Yifan SHEN, Yuxin SHAO, Yuejiu ZHENG, Tao SUN, Xin LAI, Kai SHEN, Xuebing HAN. Capacity identification method for LiFePO4 batteries with specific optimization in real vehicle applications [J]. Energy Storage Science and Technology, 2024, 13(9): 2963-2971. |

| [6] | Ying LIU, Bingxiang SUN, Xinze ZHAO, Junwei ZHANG. Joint estimation of SOC/SOP for lithium-ion batteries across a wide temperature range using an electro-thermal coupling model [J]. Energy Storage Science and Technology, 2024, 13(9): 3030-3041. |

| [7] | Yuelin CHEN, Hongzhong MA, Muyu ZHU, Wenjing XUAN, Sihan WANG. Research on the liquid cooling technology of a lithium iron phosphate battery pack under a peak load regulation in a power grid [J]. Energy Storage Science and Technology, 2024, 13(8): 2704-2712. |

| [8] | Meilong WANG, Yurui XUE, Wenxi HU, Keyu DU, Ruitao SUN, Bin ZHANG, Ya YOU. Design and research of all-ether high-entropy electrolyte for low-temperature lithium iron phosphate batteries [J]. Energy Storage Science and Technology, 2024, 13(7): 2131-2140. |

| [9] | Zheng LI, Zhenzhong YANG, Qiong WANG, Renzong HU. Patent intelligence analysis of the research progress in low-temperature electrolytes for Li-ion batteries [J]. Energy Storage Science and Technology, 2024, 13(7): 2317-2326. |

| [10] | Yuanyuan JIANG, Fangfang TU, Fangping ZHANG, Yinglai WANG, Jiawen CAI, Donghui YANG, Yanhong LI, Jiayuan XIANG, Xinhui XIA, Jipeng FU. Study on technology and mechanism of prelithiation for high-performance lithium iron phosphate battery [J]. Energy Storage Science and Technology, 2024, 13(5): 1435-1442. |

| [11] | Chunshan HE, Ziyang WANG, Bin YAO. Experimental study of the thermal runaway characteristics of lithium iron phosphate batteries for energy storage under various discharge powers [J]. Energy Storage Science and Technology, 2024, 13(3): 981-989. |

| [12] | Pengjie ZHU, Wei LI, Chu ZHANG, Hao SONG, Beibei LI, Xiumei LIU, Lili LIU. Research on cooling effect of dual-fluid spray on thermal runaway in lithium batteries: An orthogonal experiment study [J]. Energy Storage Science and Technology, 2024, 13(11): 4177-4186. |

| [13] | Binyang ZHANG, Xiaolong REN, Jiangming ZHAO, Shunliang DING. Numerical optimization of a liquid cooling plate with double helix flow channel for lithium-ion battery [J]. Energy Storage Science and Technology, 2024, 13(10): 3545-3555. |

| [14] | Yibiao GUAN, Jinran SHEN, Jialiang LIU, Zhanzhan QU, Fei GAO, Shiyang LIU, Cuijing GUO, Shuqin ZHOU, Shanshan FU. Comprehensive performance evaluation standards for energy storage lithium-ion batteries guided by safe and high-quality applications [J]. Energy Storage Science and Technology, 2023, 12(9): 2946-2953. |

| [15] | Chengbo TANG, Yaohong SUO, Zhaokun HE. Effect of fluid-flow direction on heat dissipation from lithium-ion batteries based on sine-function cooling plate [J]. Energy Storage Science and Technology, 2023, 12(8): 2547-2555. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||