Energy Storage Science and Technology ›› 2022, Vol. 11 ›› Issue (7): 2083-2091.doi: 10.19799/j.cnki.2095-4239.2021.0666

• Energy Storage Materials and Devices • Previous Articles Next Articles

Zhen YAO1( ), Qi ZHANG1, Rui WANG1, Qinghua LIU1, Baoguo WANG2, Ping MIAO1(

), Qi ZHANG1, Rui WANG1, Qinghua LIU1, Baoguo WANG2, Ping MIAO1( )

)

Received:2021-12-13

Revised:2021-12-27

Online:2022-07-05

Published:2022-06-29

Contact:

Ping MIAO

E-mail:20074873@chnenergy.com.cn;ping.miao.c@chnenergy.com.cn

CLC Number:

Zhen YAO, Qi ZHANG, Rui WANG, Qinghua LIU, Baoguo WANG, Ping MIAO. Application of biomass derived carbon materials in all vanadium flow battery electrodes[J]. Energy Storage Science and Technology, 2022, 11(7): 2083-2091.

Fig. 2

(a) Schematic diagram of the corn protein-derived electrocatalyst fabrication process[14]; (b) carbon felt incorporated with electrocatalyst[14]; (c) schematic diagrams of the dopamine-derived graphite felt fabrication process[15]; (d) schematic illustration of high-graphitization and porous carbon derived from scaphium scaphigerum[18]"

Fig. 4

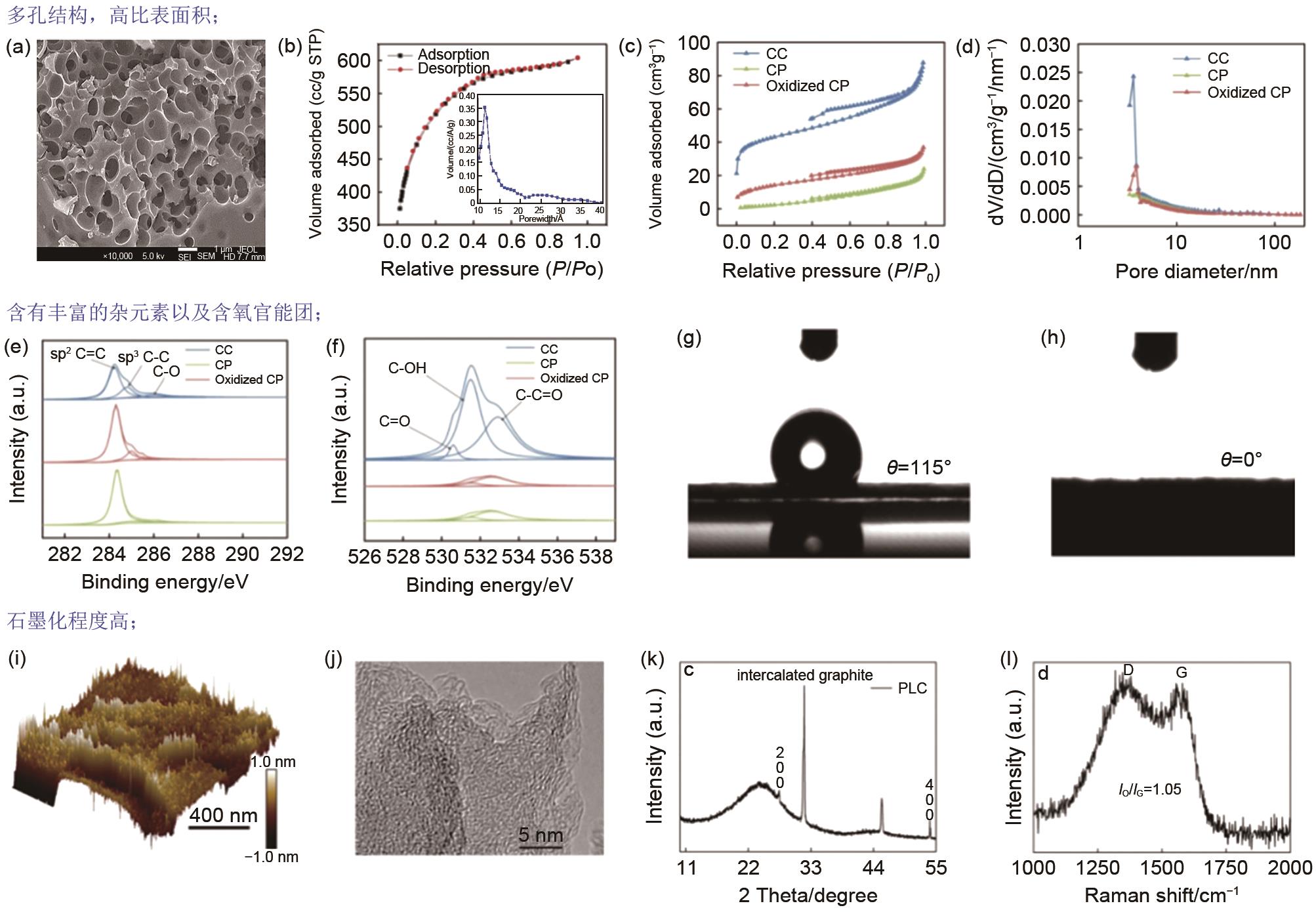

(a)-(b) FE-SEM image, nitrogen adsorption-desorption isotherm and pore size distribution (insert) of graphite felt coated with dopamine-derived nitrogen-doped carbon[21]; (c)-(h) nitrogen adsorption-desorption isotherm, pore size distribution, and XPS carbonized cotton (CC) electrode[29]; (i)-(l) 3D AFM, TEM images, XRD, and Raman of graphite felt coated with Bacillus mycoides derived carbon[17]"

Fig. 5

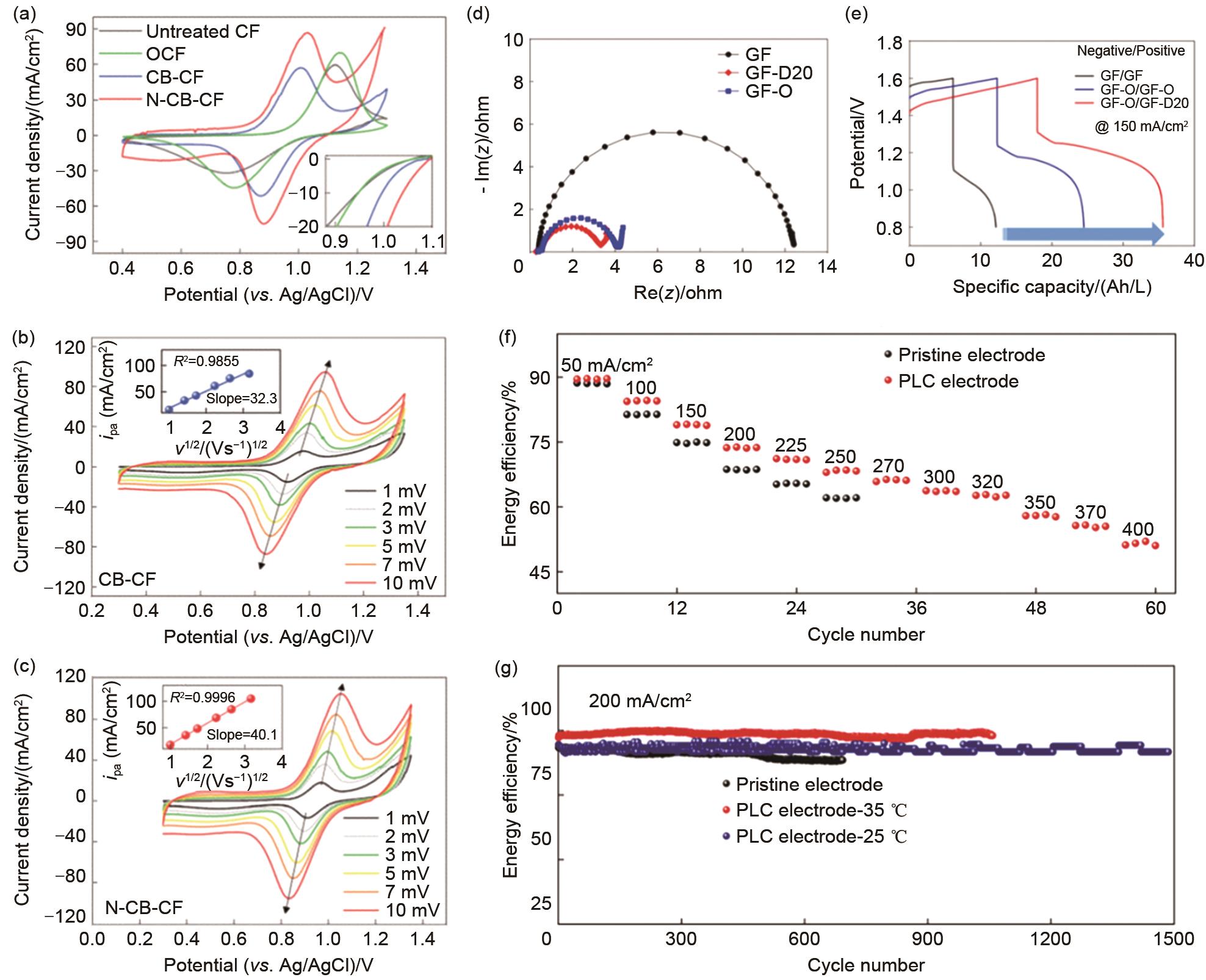

(a) CVs of the N-CB-CF and other electrode[14]; (b)-(c) CVs of the CB-CF and N-CB-CF different scan rate[14]; (d)-(e) Nyquist plots, charge-discharge curves of VRFBs employing of pristine graphite felt, oxidized graphite felt and dopamine-derived graphite felt[15]; (f)-(g) charging and discharging performance of the VRFB employing the pristine and PLC electrodes at different current densities[17]"

| 1 | YANG Z G, ZHANG J L, KINTNER-MEYER M C W, et al. Electrochemical energy storage for green grid[J]. Chemical Reviews, 2011, 111(5): 3577-3613. |

| 2 | 贾志军, 宋士强, 王保国. 液流电池储能技术研究现状与展望[J]. 储能科学与技术, 2012, 1(1): 50-57. |

| JIA Z J, SONG S Q, WANG B G. Acritical review on redox flow batteries for electrical energy storage applications[J]. Energy Storage Science and Technology, 2012, 1(1): 50-57. | |

| 3 | SKYLLAS-KAZACOS M, RYCHCIK M, ROBINS R G, et al. New all-vanadium redox flow cell[J]. Journal of the Electrochemical Society, 1986, 133(5): 1057-1058. |

| 4 | FORNER-CUENCA A, BRUSHETT F R. Engineering porous electrodes for next-generation redox flow batteries: Recent progress and opportunities[J]. Current Opinion in Electrochemistry, 2019, 18: 113-122. |

| 5 | 王新伟, 刘丽梅, 王双印, 等. 聚丙烯腈基炭毡电极改性处理及电化学性能研究[J]. 化工新型材料, 2016, 44(5): 145-147. |

| WANG X W, LIU L M, WANG S Y, et al. Study on the modification and electrochemical property of PAN-carbon felt electrode[J]. New Chemical Materials, 2016, 44(5): 145-147. | |

| 6 | 王刚, 陈金伟, 朱世富, 等. 全钒氧化还原液流电池碳素类电极的活化[J]. 化学进展, 2015, 27(10): 1343-1355. |

| WANG G, CHEN J W, ZHU S F, et al. Activation of carbon electrodes for all-vanadium redox flow battery[J]. Progress in Chemistry, 2015, 27(10): 1343-1355. | |

| 7 | 陈瑞芳, 周科. 全钒液流电池用聚丙烯腈炭毡改性研究[J]. 东方汽轮机, 2018(2): 69-72. |

| CHEN R F, ZHOU K. Study on modification of PAN-graphite felt for all vanadium redox flow battery[J]. Dongfang Turbine, 2018(2): 69-72. | |

| 8 | EIFERT L, BANERJEE R, JUSYS Z, et al. Characterization of carbon felt electrodes for vanadium redox flow batteries: Impact of treatment methods[J]. Journal of the Electrochemical Society, 2018, 165(11): A2577-A2586. |

| 9 | KIM K J, PARK M S, KIM Y J, et al. A technology review of electrodes and reaction mechanisms in vanadium redox flow batteries[J]. Journal of Materials Chemistry A, 2015, 3(33): 16913-16933. |

| 10 | HUONG LE T X, BECHELANY M, CRETIN M. Carbon felt based-electrodes for energy and environmental applications: A review[J]. Carbon, 2017, 122: 564-591. |

| 11 | HE Z X, LV Y R, ZHANG T A, et al. Electrode materials for vanadium redox flow batteries: Intrinsic treatment and introducing catalyst[J]. Chemical Engineering Journal, 2022, 427: doi:10. 1016/j.cej.2021.131680. |

| 12 | ISIKGOR F H, BECER C R. Lignocellulosic biomass: A sustainable platform for the production of bio-based chemicals and polymers[J]. Polymer Chemistry, 2015, 6(25): 4497-4559. |

| 13 | 赵广震. 生物质衍生多孔碳材料的制备及其超级电容储能性能研究[D]. 吉林: 东北电力大学, 2020. |

| ZHAO G Z. Preparation and supercapacitive storage properties of biomass derived porous carbon materials[D]. Jilin: Northeast Dianli University, 2020. | |

| 14 | PARK M, RYU J, KIM Y, et al. Corn protein-derived nitrogen-doped carbon materials with oxygen-rich functional groups: A highly efficient electrocatalyst for all-vanadium redox flow batteries[J]. Energy Environ Sci, 2014, 7(11): 3727-3735. |

| 15 | LEE H J, KIM H. Graphite felt coated with dopamine-derived nitrogen-doped carbon as a positive electrode for a vanadium redox flow battery[J]. Journal of the Electrochemical Society, 2015, 162(8): A1675-A1681. |

| 16 | JEONG K I, SONG S A, KIM S S. Glucose-based carbon-coating layer on carbon felt electrodes of vanadium redox flow batteries[J]. Composites Part B: Engineering, 2019, 175: doi:10.1016/j.compositesb. 2019.107072. |

| 17 | DENG Q, TIAN Y, DING P, et al. Porous lamellar carbon assembled from Bacillus mycoides as high-performance electrode materials for vanadium redox flow batteries[J]. Journal of Power Sources, 2020, 450: doi:10.1016/j.jpowsour.2019.227633. |

| 18 | JIANG Y Q, CHENG G, HE Z X, et al. Biomass-derived porous graphitic carbon with excellent electrocatalytic performances for vanadium redox reactions[J]. Journal of the Electrochemical Society, 2019, 166(16): A3918-A3926. |

| 19 | LIU J, WANG Z A, WU X W, et al. Porous carbon derived from disposable shaddock peel as an excellent catalyst toward VO2 +/VO2 + couple for vanadium redox battery[J]. Journal of Power Sources, 2015, 299: 301-308. |

| 20 | ULAGANATHAN M, JAIN A, ARAVINDAN V, et al. Bio-mass derived mesoporous carbon as superior electrode in all vanadium redox flow battery with multicouple reactions[J]. Journal of Power Sources, 2015, 274: 846-850. |

| 21 | MAHARJAN M, BHATTARAI A, ULAGANATHAN M, et al. High surface area bio-waste based carbon as a superior electrode for vanadium redox flow battery[J]. Journal of Power Sources, 2017, 362: 50-56. |

| 22 | MAHANTA V, RAJA M, KOTHANDARAMAN R. Activated carbon from sugarcane bagasse as a potential positive electrode catalyst for vanadium redox flow battery[J]. Materials Letters, 2019, 247: 63-66. |

| 23 | ABBAS A, ENG X E, EE N, et al. Development of reduced graphene oxide from biowaste as an electrode material for vanadium redox flow battery[J]. Journal of Energy Storage, 2021, 41: doi:10.1016/j.est.2021.102848. |

| 24 | MAHARJAN M, WAI N, VEKSHA A, et al. Sal wood sawdust derived highly mesoporous carbon as prospective electrode material for vanadium redox flow batteries[J]. Journal of Electroanalytical Chemistry, 2019, 834: 94-100. |

| 25 | JIANG Y Q, DU M C, CHENG G, et al. Nanostructured N-doped carbon materials derived from expandable biomass with superior electrocatalytic performance towards V2+/V3+ redox reaction for vanadium redox flow battery[J]. Journal of Energy Chemistry, 2021, 59: 706-714. |

| 26 | LV Y R, LI Y H, HAN C, et al. Application of porous biomass carbon materials in vanadium redox flow battery[J]. Journal of Colloid and Interface Science, 2020, 566: 434-443. |

| 27 | CHENG D X, TIAN M R, WANG B Y, et al. One-step activation of high-graphitization N-doped porous biomass carbon as advanced catalyst for vanadium redox flow battery[J]. Journal of Colloid and Interface Science, 2020, 572: 216-226. |

| 28 | HE Z X, CHENG G, JIANG Y Q, et al. Novel 2D porous carbon nanosheet derived from biomass: Ultrahigh porosity and excellent performances toward V2+/V3+ redox reaction for vanadium redox flow battery[J]. International Journal of Hydrogen Energy, 2020, 45(7): 3959-3970. |

| 29 | ZHANG Z H, ZHAO T S, BAI B F, et al. A highly active biomass-derived electrode for all vanadium redox flow batteries[J]. Electrochimica Acta, 2017, 248: 197-205. |

| 30 | RIBADENEYRA M C, GROGAN L, AU H, et al. Lignin-derived electrospun freestanding carbons as alternative electrodes for redox flow batteries[J]. Carbon, 2020, 157: 847-856. |

| 31 | LEE M E, JANG D, LEE S, et al. Silk protein-derived carbon fabric as an electrode with high electro-catalytic activity for all-vanadium redox flow batteries[J]. Applied Surface Science, 2021, 567: doi:10.1016/j.apsusc.2021.150810. |

| [1] | Xin WU, Wenju SHANG, Zhiyong MA, Wei TENG, Shuang ZHANG, Hairong LUO. Coordinated control method for pumped and flywheel hybrid energy storage system [J]. Energy Storage Science and Technology, 2023, 12(2): 468-476. |

| [2] | Jie SONG, Linxiao GENG, Yongfu SANG, Rongbin WEN, Peng SUN, Linjuan GONG. Study on primary frequency modulation capacity planning of thermal power unit assisted by hybrid energy storage based on EMD decomposition [J]. Energy Storage Science and Technology, 2023, 12(2): 496-503. |

| [3] | Jun SHENG, Yimin FU, Huigen YU. Structure simulation of large soft pack module for energy storage [J]. Energy Storage Science and Technology, 2023, 12(2): 579-584. |

| [4] | Shuili YANG, Xiaokang LAI, Tao DING, Zekai WANG, Jizhong CHEN, Jiahui ZHU, Tingting LI. Application and prospect of new energy storage technologies in resilient power systems [J]. Energy Storage Science and Technology, 2023, 12(2): 515-528. |

| [5] | Haidong CHEN, Fei MENG, Qing WANG, Feng HOU, Yi WANG, Zhihua ZHANG. Influence of installed capacity of energy storage system and renewable energy power generation on power system performance [J]. Energy Storage Science and Technology, 2023, 12(2): 477-485. |

| [6] | Chao ZHANG, Zuoxia XING, Qitong FU, Libing JIANG, Lei CHEN. Design of thermal and energy storage performance test platform for solid electrothermal energy storage device [J]. Energy Storage Science and Technology, 2023, 12(2): 585-592. |

| [7] | Yucheng DAI, Zengpeng WANG, Kaibao LIU, Jiateng ZHAO, Changhui LIU. Research progress of heat storage and heat transfer enhancement based on phase change materials [J]. Energy Storage Science and Technology, 2023, 12(2): 431-458. |

| [8] | Meiqian HOU, Qifan NIU, Jie XING, Yinghao SHAN. Optimal configuration of energy storage system in active distribution network with the consideration of reliability [J]. Energy Storage Science and Technology, 2023, 12(2): 504-514. |

| [9] | Shigang LUO, Wei ZHANG, Weiwu LI, Yongli BAI. A day-ahead optimized operation of integrated energy system and prosumers with flexible economic regulation of electric/thermal storage [J]. Energy Storage Science and Technology, 2023, 12(2): 486-495. |

| [10] | Yang LIU, Weijun TENG, Qingfa GU, Xin SUN, Yuliang TAN, Zhijin FANG, Jianlin LI. Scaled-up diversified electrochemical energy storage LCOE and its economic analysis [J]. Energy Storage Science and Technology, 2023, 12(1): 312-318. |

| [11] | Qianjun MAO, Yuanyuan ZHU. Study on heat storage performance of novel bifurcated fins to strengthen shell-and-tube energy storage tanks [J]. Energy Storage Science and Technology, 2023, 12(1): 69-78. |

| [12] | Limu XIAO, Xin GAO, Shihai ZHANG, Xiankui WEN. Thermodynamic analysis on the liquid air energy storage system with liquid natural gas and organic Rankine cycle [J]. Energy Storage Science and Technology, 2023, 12(1): 155-164. |

| [13] | Juntao CHEN, Yajun WANG, Shunyi SONG, Wenhao QU, Yibing LIU. Simulation of the primary frequency modulation process of wind power with an auxiliary flywheel energy storage [J]. Energy Storage Science and Technology, 2023, 12(1): 172-179. |

| [14] | Fa MAO, Xuelai ZHANG, Weisan HUA. Research progress of aluminum potassium sulfate dodecahydrate phase-change material for thermal energy storage [J]. Energy Storage Science and Technology, 2023, 12(1): 120-130. |

| [15] | Lin LI, Yu WANG, Wenyan QIAN, Dongxu LI. Performance and temperature control effect simulation of fatty acid phase-change energy storage board [J]. Energy Storage Science and Technology, 2023, 12(1): 247-254. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||