Energy Storage Science and Technology ›› 2023, Vol. 12 ›› Issue (9): 2735-2745.doi: 10.19799/j.cnki.2095-4239.2023.0318

• Energy Storage Materials and Devices • Previous Articles Next Articles

Wenbiao LI1,2( ), Haitao GENG2, Yibo GAO2, Zhaoshun GAO3(

), Haitao GENG2, Yibo GAO2, Zhaoshun GAO3( ), Bao WANG1,2(

), Bao WANG1,2( )

)

Received:2023-05-06

Revised:2023-05-09

Online:2023-09-05

Published:2023-09-16

Contact:

Zhaoshun GAO, Bao WANG

E-mail:liwenbiao20@mails.ucas.ac.cn;gaozs@mail.iee.ac.cn;baowang@ipe.ac.cn

CLC Number:

Wenbiao LI, Haitao GENG, Yibo GAO, Zhaoshun GAO, Bao WANG. Cu-In/Bi alloys with lithiophilic sites induce uniform lithium nucleation for high-rate lithium-metal batteries[J]. Energy Storage Science and Technology, 2023, 12(9): 2735-2745.

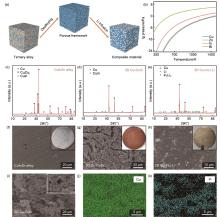

Fig. 1

(a) Schematic diagram of the preparation of lithium metal anodes; (b) Saturated vapor pressure as a function of temperature for copper, zinc, indium, bismuth; XRD patterns of (c) CuInZn, (d) 3D Cu-CuIn, and (e) 3D Cu-InLi-Li; Surface SEM images of (f) CuInZn, (g) 3D Cu-CuIn, and (h) 3D Cu-InLi-Li, and the illustration is the corresponding digital photographs; (i) Cross-sectional SEM image of 3D Cu-CuIn and corresponding spectral images of (j) copper and (k) indium element"

Fig. 2

XRD patterns of (a) CuBiZn, (b) 3D Cu-BiCu, and (c) 3D Cu-LiBi-Li; Surface SEM images of (d) CuBiZn, (e) 3D Cu-BiCu, and (f) 3D Cu-LiBi-Li, and the illustration is the corresponding digital photographs; (g) Cross-sectional SEM image of 3D Cu-BiCu and corresponding spectral images of (h) copper and (i) bismuth element"

Fig. 4

Cyclic voltammetry curves of (a) Bare Li||LFP, (b) 3D Cu-LiBi-Li||LFP, and (c) 3D Cu-InLi-Li||LFP; Galvanostatic charge/discharge of (d) Bare Li||LFP, (e) 3D Cu-LiBi-Li||LFP, and (f) 3D Cu-InLi-Li||LFP at different rates; (g) 1C, (h) 2C, (j) 5C and 10C long cycle performances and (i) impedance diagram for Bare Li||LFP, 3D Cu-LiBi-Li||LFP, and 3D Cu-InLi-Li||LFP"

| 1 | WANG Q Y, LIU B, SHEN Y H, et al. Confronting the challenges in lithium anodes for lithium metal batteries[J]. Advanced Science, 2021, 8(17): e2101111. |

| 2 | GHAZI Z A, SUN Z H, SUN C G, et al. Key aspects of lithium metal anodes for lithium metal batteries[J]. Small, 2019, 15(32): e1900687. |

| 3 | 史冬梅, 邱俊, 王晶. 美国先进电池领域发展态势及启示[J]. 储能科学与技术, 2022, 11(9): 2933-2943. |

| SHI D M, QIU J, WANG J. Development of advanced battery technologies and industries in the United States[J]. Energy Storage Science and Technology, 2022, 11(9): 2933-2943. | |

| 4 | JÄCKLE M, GROß A. Microscopic properties of lithium, sodium, and magnesium battery anode materials related to possible dendrite growth[J]. The Journal of Chemical Physics, 2014, 141(17): 174710. |

| 5 | LIN D C, LIU Y Y, CUI Y. Reviving the lithium metal anode for high-energy batteries[J]. Nature Nanotechnology, 2017, 12(3): 194-206. |

| 6 | 唐亮, 尹小波, 吴候福, 等. 电化学储能产业发展对安全标准的需求[J]. 储能科学与技术, 2022, 11(8): 2645-2652. |

| TANG L, YIN X B, WU H F, et al. Demand for safety standards in the development of the electrochemical energy storage industry[J]. Energy Storage Science and Technology, 2022, 11(8): 2645-2652. | |

| 7 | YANG C P, FU K, ZHANG Y, et al. Protected lithium-metal anodes in batteries: From liquid to solid[J]. Advanced Materials, 2017, 29(36): 1701169. |

| 8 | HAN Y Y, LIU B, XIAO Z, et al. Interface issues of lithium metal anode for high-energy batteries: Challenges, strategies, and perspectives[J]. InfoMat, 2021, 3(2): 155-174. |

| 9 | LUO Z, QIU X J, LIU C, et al. Interfacial challenges towards stable Li metal anode[J]. Nano Energy, 2021, 79: 105507. |

| 10 | LIU Y C, GAO D, XIANG H F, et al. Research progress on copper-based current collector for lithium metal batteries[J]. Energy & Fuels, 2021, 35(16): 12921-12937. |

| 11 | LIU X E, LIU J A, LI G R, et al. Dimensionally stable composite Li electrode with Cu skeleton and lithophilic Li-Mg alloy microstructure[J]. ACS Applied Materials & Interfaces, 2022, 14(51): 56801-56807. |

| 12 | MAO J T, WU K S, NI C K, et al. Enablement of long-lifespan lithium metal battery via building 3D LixGey alloy framework[J]. ElectrochimicaActa, 2021, 382: 138301. |

| 13 | JING W T, ZOU K Y, DAI X, et al. Li-Indium alloy anode for high-performance Li-metal batteries[J]. Journal of Alloys and Compounds, 2022, 924: 166517. |

| 14 | WANG Y Y, WANG M, ZHONG J A, et al. Constructing three-dimensional flexible lithiophilic scaffolds with Bi2O3nanosheets toward stable Li metal anodes[J]. ACS Applied Energy Materials, 2022, 5(10): 12874-12883. |

| 15 | LUO S T, WANG Z Y, LI X L, et al. Growth of lithium-indium dendrites in all-solid-state lithium-based batteries with sulfide electrolytes[J]. Nature Communications, 2021, 12: 6968. |

| 16 | XU Y, ZHENG H Q, YANG H, et al. Thermodynamic regulation of dendrite-free Li plating on Li3Bi for stable lithium metal batteries[J]. Nano Letters, 2021, 21(20): 8664-8670. |

| 17 | 郭凯强, 车海英, 张浩然, 等. B2O3包覆NaNi1/3Fe1/3Mn1/3O2正极材料制备及其电化学性能[J]. 储能科学与技术, 2022, 11(9): 2980-2988. |

| GUO K Q, CHE H Y, ZHANG H R, et al. Preparation and characterization of B2O3-coated NaNi1/3Fe1/3Mn1/3O2 cathode materials for sodium-ion batteries[J]. Energy Storage Science and Technology, 2022, 11(9): 2980-2988. | |

| 18 | WANG S H, YUE J P, DONG W, et al. Tuning wettability of molten lithium via a chemical strategy for lithium metal anodes[J]. Nature Communications, 2019, 10: 4930. |

| 19 | HAN J H, LI C, LU Z, et al. Vapor phase dealloying: A versatile approach for fabricating 3D porous materials[J]. ActaMaterialia, 2019, 163: 161-172. |

| 20 | YAKOVENKO O, SOKOLSKII V, GOLOVATAYA N, et al. Preparation of porous Cu material using vapor phase dealloying[J]. Materials Letters, 2023, 331: 133486. |

| 21 | CAO J Q, QIAN G Y, LU X Y, et al. Advanced composite lithium metal anodes with 3D frameworks: Preloading strategies, interfacial optimization, and perspectives[J]. Small, 2023, 19(10): 2205653. |

| 22 | 申晓宇, 朱璟, 岑官骏, 等. 锂电池百篇论文点评(2022. 12. 1—2023. 1. 31)[J]. 储能科学与技术, 2023, 12(3): 639-653. |

| SHEN X Y, ZHU J, CEN G J, et al. Reviews of selected 100 recent papers for lithium batteries (Dec. 1, 2022 to Jan. 31, 2023)[J]. Energy Storage Science and Technology, 2023, 12(3): 639-653. | |

| 23 | 王其钰, 褚赓, 张杰男, 等. 锂离子扣式电池的组装, 充放电测量和数据分析[J]. 储能科学与技术, 2018, 7(2): 327-344. |

| WANG Q Y, CHU G, ZHANG J N, et al. The assembly, charge-discharge performance measurement and data analysis of lithium-ion button cell[J]. Energy Storage Science and Technology, 2018, 7(2): 327-344. | |

| 24 | 王津, 张少飞, 孙金峰, 等. 纳米多孔合金快速燃烧氧化及高效储能研究[J]. 储能科学与技术, 2023, 12(5): 1480-1489. |

| WANG J, ZHANG S F, SUN J F, et al. Rapid oxidation of nanoporous alloys by self-combustion and their high-efficiency energy storage performance[J]. Energy Storage Science and Technology, 2023, 12(5): 1480-1489. | |

| 25 | ALCOCK C B, ITKIN V P, HORRIGAN M K. Vapour pressure equations for the metallic elements: 298~2500 K[J]. Canadian Metallurgical Quarterly, 1984, 23(3): 309-313. |

| 26 | BAJER J, ZAUNSCHIRM S, PLANK B, et al. Kirkendall effect in twin-roll cast AA 3003 aluminum alloy[J]. Crystals, 2022, 12(5): 607. |

| 27 | PARK J B, CHOI C, YU S, et al. Porous lithiophilic Li-Si alloy-type interfacial framework via self-discharge mechanism for stable lithium metal anode with superior rate[J]. Advanced Energy Materials, 2021, 11(37): 2101544. |

| 28 | CHI S S, WANG Q R, HAN B, et al. Lithiophilic Zn sites in porous CuZn alloy induced uniform Li nucleation and dendrite-free Li metal deposition[J]. Nano Letters, 2020, 20(4): 2724-2732. |

| 29 | YANG C P, YIN Y X, ZHANG S F, et al. Accommodating lithium into 3D current collectors with a submicron skeleton towards long-life lithium metal anodes[J]. Nature Communications, 2015, 6: 8058. |

| 30 | WU J Y, JU Z Y, ZHANG X A, et al. Building efficient ion pathway in highly densified thick electrodes with high gravimetric and volumetric energy densities[J]. Nano Letters, 2021, 21(21): 9339-9346. |

| 31 | FAN Y C, LIAO J P, LUO D X, et al. In situ formation of a lithiophilic surface on 3D current collectors to regulate lithium nucleation and growth for dendrite-free lithium metal anodes[J]. Chemical Engineering Journal, 2023, 453: 139903. |

| 32 | 凌仕刚, 许洁茹, 李泓. 锂电池研究中的EIS实验测量和分析方法[J]. 储能科学与技术, 2018, 7(4): 732-749. |

| LING S G, XU J R, LI H. Experimental measurement and analysis methods of electrochemical impedance spectroscopy for lithium batteries[J]. Energy Storage Science and Technology, 2018, 7(4): 732-749. | |

| 33 | ABDUL AHAD S, ADEGOKE T E, RYAN K M, et al. Cu current collector with binder-free lithiophilic nanowire coating for high energy density lithium metal batteries[J]. Small, 2023, 19(20): 2207902. |

| 34 | FU X L, SHANG C Q, ZHOU G F, et al. Lithiophilic Sb surface modified Cu nanowires grown on Cu foam: A synergistic 1D@3D hierarchical structure for stable lithium metal anodes[J]. Journal of Materials Chemistry A, 2021, 9(44): 24963-24970. |

| 35 | ZHANG L Y, JIN Q, ZHAO K X, et al. 3D hierarchical Cu@Ag nanostructure as a current collector for dendrite-free lithium metal anode[J]. Dalton Transactions, 2022, 51(43): 16565-16573. |

| 36 | 江伟伟, 李俊杰, 叶承舟, 等. 轻质三维多孔泡沫铝用作高性能锂金属负极骨架[J]. 无机化学学报, 2023, 39(2): 291-299. |

| JIANG W W, LI J J, YE C Z, et al. Lightweight three-dimensional porous aluminumfoamusedas high performance lithium metal cathode skeleton[J]. Chinese Journal of Inorganic Chemistry, 2023, 39(2): 291-299. | |

| 37 | WANG J, LIU H W, WU H C, et al. Self-standing carbon nanotube aerogels with amorphous carbon coating as stable host for lithium anodes[J]. Carbon, 2021, 177: 181-188. |

| [1] | Jin LI, Qingsong WANG, Depeng KONG, Xiaodong WANG, Zhenhua YU, Yanfei LE, Xinyan HUANG, Zhenkai HU, Houfu WU, Huabin FANG, Caowei, Shaoyu ZHANG, Ping ZHUO, Ye CHEN, Ziting LI, Wenxin MEI, Yue ZHANG, Lixiang ZHAO, Liang TANG, Zonghou HUANG, Chi CHEN, Yanhu LIU, Yuxi CHU, Xiaoyuan XU, Jin ZHANG, Yikai LI, Rong FENG, Biao YANG, Bo HU, Xiaoying YANG. Research progress on the safety assessment of lithium-ion battery energy storage [J]. Energy Storage Science and Technology, 2023, 12(7): 2282-2301. |

| [2] | Ao TANG, Chuanwei YAN. Modelling and simulation of flow batteries: Recent progress and prospects [J]. Energy Storage Science and Technology, 2022, 11(9): 2866-2878. |

| [3] | Zhizhang YUAN, Zonghao LIU, Xianfeng LI. Research progress of flow battery technologies [J]. Energy Storage Science and Technology, 2022, 11(9): 2944-2958. |

| [4] | Jiajun ZHU, Hengyun ZHANG, Kangdi XU, Shen XU, Peichao LI. Study of structure optimization and thermal spread suppression based on liquid-cooled battery modules [J]. Energy Storage Science and Technology, 2022, 11(8): 2620-2628. |

| [5] | Tian WU, Mincheng LIN, Hao HAI, Haiyu SUN, Zhaoyin WEN, Fuyuan MA. Development of high-power Ni-MH battery system for primary frequency modulation [J]. Energy Storage Science and Technology, 2022, 11(7): 2213-2221. |

| [6] | ZHOU Wei, FU Dongju, LIU Weifeng, CHEN Jianjun, HU Zhao, ZENG Xierong. Research progress on recycling technology of waste lithium iron phosphate power battery [J]. Energy Storage Science and Technology, 2022, 11(6): 1854-1864. |

| [7] | Ying SUN, Qin ZHAO, Bosi YIN, Tianyi MA. Performance of PTCDI//δ-MnO2 aqueous ammonium-ion battery [J]. Energy Storage Science and Technology, 2022, 11(4): 1110-1120. |

| [8] | Jianglong DU, Yiting LIN, Wenqi YANG, Cheng LIAN, Honglai LIU. Application of simulation in thermal safety design of lithium-ion batteries [J]. Energy Storage Science and Technology, 2022, 11(3): 866-877. |

| [9] | Luyu GAN, Rusong CHEN, Hongyi PAN, Siyuan WU, Xiqian YU, Hong LI. Multiscale research strategy of lithium ion battery safety issue: Experimental and simulation methods [J]. Energy Storage Science and Technology, 2022, 11(3): 852-865. |

| [10] | Yongli HENG, Zhenyi GU, Jinzhi GUO, Xinglong WU. Na3V2(PO4)3@C cathode material for aqueous zinc-ion batteries [J]. Energy Storage Science and Technology, 2021, 10(3): 938-944. |

| [11] | Xuejiao NIE, Jinzhi GUO, Meiyi WANG, Zhenyi GU, Xinxin ZHAO, Xu YANG, Haojie LIANG, Xinglong WU. Using spent lithium manganate to prepare Li0.25Na0.6MnO2 as cathode material in sodium-ion batteries [J]. Energy Storage Science and Technology, 2020, 9(5): 1402-1409. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||