储能科学与技术 ›› 2023, Vol. 12 ›› Issue (5): 1427-1443.doi: 10.19799/j.cnki.2095-4239.2023.0260

• 喜迎东北大学建校百年-储能电池关键材料与循环技术专刊 • 上一篇 下一篇

张奇1,2( ), 李晓东1,2, 王文雯1,2, 刘晓1,2(

), 李晓东1,2, 王文雯1,2, 刘晓1,2( )

)

收稿日期:2023-04-25

修回日期:2023-04-28

出版日期:2023-05-05

发布日期:2023-05-29

通讯作者:

刘晓

E-mail:zhangqi01@tyut.edu.cn;liuxiao@tyut.edu.cn

作者简介:张奇(1988—),男,工学博士,助理研究员,研究方向为新能源材料,E-mail:zhangqi01@tyut.edu.cn;

基金资助:

Qi ZHANG1,2( ), Xiaodong LI1,2, Wenwen WANG1,2, Xiao LIU1,2(

), Xiaodong LI1,2, Wenwen WANG1,2, Xiao LIU1,2( )

)

Received:2023-04-25

Revised:2023-04-28

Online:2023-05-05

Published:2023-05-29

Contact:

Xiao LIU

E-mail:zhangqi01@tyut.edu.cn;liuxiao@tyut.edu.cn

摘要:

生物质材料细胞壁物质的高效分离及功能化直接关系着废弃生物质的高值化应用。作为生物质材料细胞壁的三大组分之一,纤维素纳米纤丝已经被广泛用于构建独特纳米结构和功能的复合材料如三维结构气凝胶、自修复水凝胶、纳米微晶光子膜、光敏感织物等。探索一条生物质纤维素高值化、实用化发展路径显得尤为重要,本文围绕生物质纳米纤维素的分离提取和功能材料的构筑及其在新型能源存储方面的应用进行论述。首先,简要叙述当前纳米纤维素的化学结构及其作为多功能材料结构单元的优势,并从实验条件、环保、经济、纤维得率与质量的角度分析了生物基纳米纤维素分离制备方法的发展历程和优缺点;然后,介绍了纳米纤维素基纤维、薄膜、气凝胶、碳气凝胶的微/纳米结构、化学键、力学性能在热管理器件如建筑制冷器、太阳驱动式水蒸发器中太阳能的散射与吸收、红外发射、水分的吸收与传导和电化学能源储存中柔性电极的设计、亲锂型隔膜及碳基集流体等功能材料的构建过程中所发挥的作用。最后,从生物质材料的特异性结构的利用、组分的提取分离与转化、复合材料构建角度对纳米纤维素的未来研究方向进行了展望。

中图分类号:

张奇, 李晓东, 王文雯, 刘晓. 生物质纤维素基多功能材料构建及其在新型能量存储方面的应用[J]. 储能科学与技术, 2023, 12(5): 1427-1443.

Qi ZHANG, Xiaodong LI, Wenwen WANG, Xiao LIU. Rational design of multifunctional cellulose based materials for their application in emerging energy storage[J]. Energy Storage Science and Technology, 2023, 12(5): 1427-1443.

表1

几种不同材料的力学性能比较[4, 6-9]"

| Material | Density/(kg/m3) | Ultimate tensile strength/GPa | Ultimate tensile modulus/GPa |

|---|---|---|---|

| Cellulose nanofibers | 1500 | 2~6 | 145 |

| Cellulose nanocrystals | 1500 | — | 150 |

| Cellulose nanofiber films | ~1400 | 0.2 | 10 |

| Cellulose nanofiber wet spun fiber | ~1400 | 0.321 | 23.6 |

| Carbon fiber | 1700 | 1~4 | 100~400 |

| Kevlar/polyaramid (high modulus grade) | 1450 | 2.8~3.6 | 120 |

| E-glass fiber | 2600 | 2 | 73 |

| Steel (high carbon) | 7850 | 750~900 | 210 |

| Titanium (Ti 99.5) | 4500 | 250~1.1 | 102~110 |

| Single walled carbon nanotube | — | 300 | 1002 |

图5

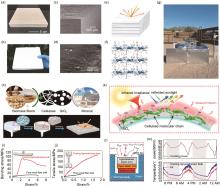

木材基和纤维素基被动辐射制冷材料的构建。原始木材(a) 及制冷木材(b) 的数码照片;制冷木材的轴向(生长方向)导管(c) 和部分与轴向排列的纤维素纳米纤维(d) 扫描电镜图;(e) 木材天然结构散射太阳辐射示意图;(f) 纤维素官能团分子振动发射红外光示意图;(g) 制冷木材制冷效果的实时测量装置[29]。 (h) 由生物质纤维素和二氧化硅构建制冷木质纤维素基块体材料示意图;制冷木质纤维素基块体材料弯曲(i) 和拉伸(j) 力学试验图;(k) 制冷木质纤维素基块体材料发射红外波和散射太阳光示意图;(l) 辐射制冷效果的测量装置示意图;(m) 辐射制冷功率、周围环境温度(黑色)和块体材料表面温度(红色)周期性监测[30]"

图7

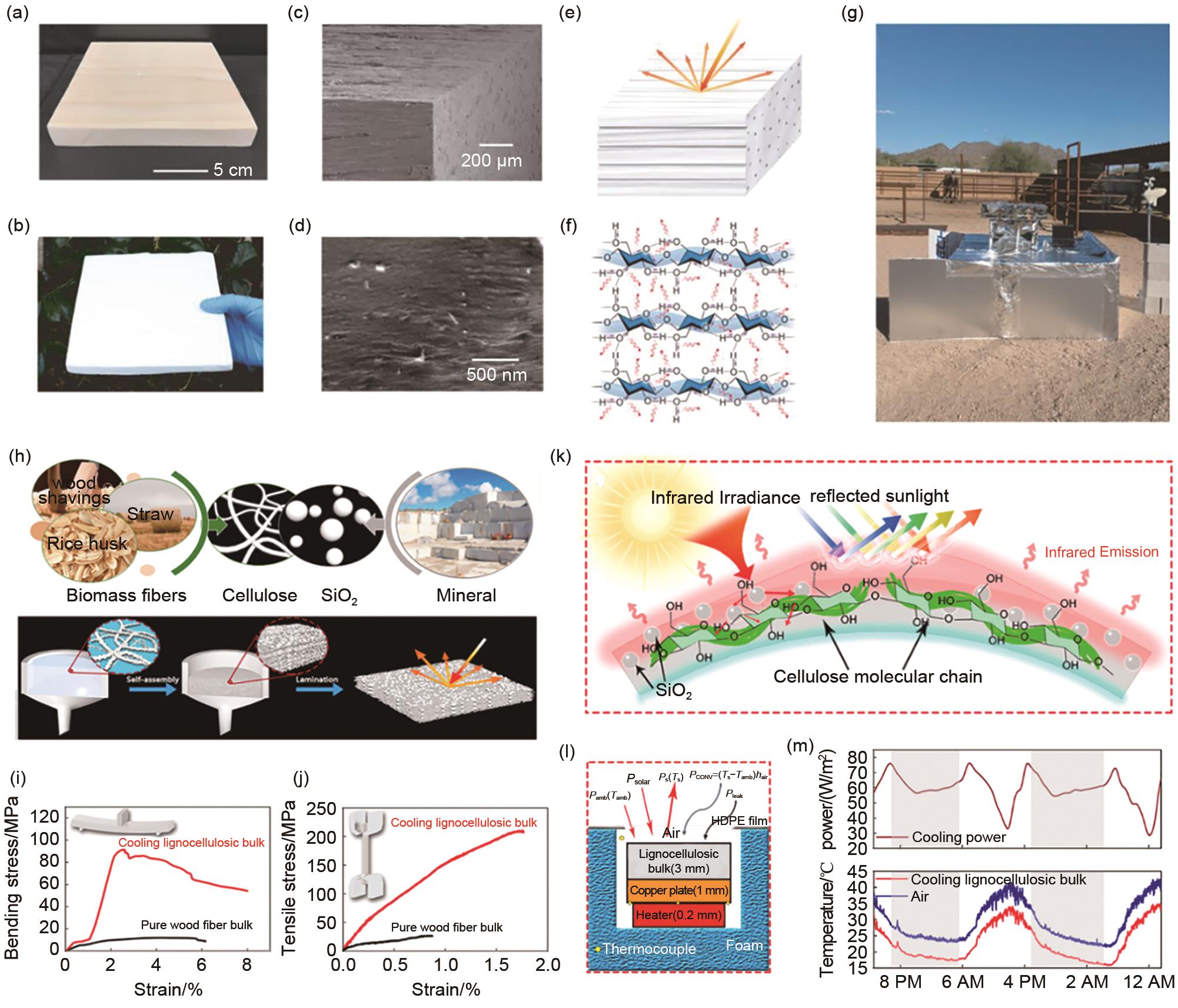

等离子体木材的设计示意图。(a) 木材向上运输水分和进行光合作用;(b) 负载等离子体金属颗粒的天然木材;(c) 等离子木材对光线的调控与吸收示意图;(d) 两个相邻等离子体金属颗粒产生的等离子体效应示意图;(e) 水分在沿着木材内部微孔道传输的示意图;(f) 负载等离子体金属颗粒前后木材对光的吸收能力对比图;(g) 不同强度光线辐射下,等离子体木材顶端的温度变化[38];(h) 石墨-木材复合太阳能驱动水蒸发器的大规模制备流程;(i) 木材轴向多孔结构示意图;(j) 负载石墨木材基太阳能驱动水蒸发器的作用机制示意图;在一个太阳光照强度下,该太阳能水蒸发器的蒸发率(k) 和循环稳定性(l)[39]"

| 1 | 付时雨. 纤维素的研究进展[J]. 中国造纸, 2019, 38(6): 54-64. |

| FU S Y. Progress in cellulose research[J]. China Pulp & Paper, 2019, 38(6): 54-64. | |

| 2 | PINKERT A, MARSH K N, PANG S S, et al. Ionic liquids and their interaction with cellulose[J]. Chemical Reviews, 2009, 109(12): 6712-6728. |

| 3 | CHEN C J, HU L B. Nanocellulose toward advanced energy storage devices: Structure and electrochemistry[J]. Accounts of Chemical Research, 2018, 51(12): 3154-3165. |

| 4 | SAITO T, KURAMAE R, WOHLERT J, et al. An ultrastrong nanofibrillar biomaterial: The strength of single cellulose nanofibrils revealed via sonication-induced fragmentation[J]. Biomacromolecules, 2013, 14(1): 248-253. |

| 5 | LI J, CHEN C, ZHU J Y, et al. In situ wood delignification toward sustainable applications[J]. Accounts of Materials Research, 2021, 2(8): 606-620. |

| 6 | SEHAQUI H, LIU A D, ZHOU Q, et al. Fast preparation procedure for large, flat cellulose and cellulose/inorganic nanopaper structures[J]. Biomacromolecules, 2010, 11(9): 2195-2198. |

| 7 | IWAMOTO S, ISOGAI A, IWATA T. Structure and mechanical properties of wet-spun fibers made from natural cellulose nanofibers[J]. Biomacromolecules, 2011, 12(3): 831-836. |

| 8 | HUANG X S. Fabrication and properties of carbon fibers[J]. Materials, 2009, 2(4): 2369-2403. |

| 9 | YU M F, FILES B S, AREPALLI S, et al. Tensile loading of ropes of single wall carbon nanotubes and their mechanical properties[J]. Physical Review Letters, 2000, 84(24): 5552-5555. |

| 10 | 祁明辉, 易锬, 莫琪, 等. 硫酸水解辅助高压均质法制备小麦秸秆纳米纤维素[J]. 中国造纸学报, 2020, 35(3): 1-8. |

| QI M H, YI T, MO Q, et al. Preparation of wheat straw nanocellulose by acid hydrolysis assisted high pressure homogenization[J]. Transactions of China Pulp and Paper, 2020, 35(3): 1-8. | |

| 11 | BRAUN B, DORGAN J R. Single-step method for the isolation and surface functionalization of cellulosic nanowhiskers[J]. Biomacromolecules, 2009, 10(2): 334-341. |

| 12 | CAI J, ZHANG L N. Rapid dissolution of cellulose in LiOH/urea and NaOH/urea aqueous solutions[J]. Macromolecular Bioscience, 2005, 5(6): 539-548. |

| 13 | HUANG J C, ZHONG Y, ZHANG L N, et al. Distinctive viewpoint on the rapid dissolution mechanism of α-chitin in aqueous potassium hydroxide-urea solution at low temperatures[J]. Macromolecules, 2020, 53(13): 5588-5598. |

| 14 | SWATLOSKI R P, SPEAR S K, HOLBREY J D, et al. Dissolution of cellose with ionic liquids[J]. Journal of the American Chemical Society, 2002, 124(18): 4974-4975. |

| 15 | TARDY B L, MATTOS B D, OTONI C G, et al. Deconstruction and reassembly of renewable polymers and biocolloids into next generation structured materials[J]. Chemical Reviews, 2021, 121(22): 14088-14188. |

| 16 | ABBOTT A P, CAPPER G, DAVIES D L, et al. Novel solvent properties of choline chloride/urea mixtures[J]. Chemical Communications, 2003(1): 70-71. |

| 17 | 胡鹏程, 江伟,钟丽娟, 低共熔溶剂的应用研究进展[J]. 现代化工, 2018, 38(10): 53-57. |

| 18 | CHOI Y H, VAN SPRONSEN J, DAI Y T, et al. Are natural deep eutectic solvents the missing link in understanding cellular metabolism and physiology?[J]. Plant Physiology, 2011, 156(4): 1701-1705. |

| 19 | WU X Y, YUAN Y, HONG S, et al. Controllable preparation of nano-cellulose via natural deep eutectic solvents prepared with lactate and choline chloride[J]. Industrial Crops and Products, 2023, 194: 116259. |

| 20 | LI P P, SIRVIÖ J A, HAAPALA A, et al. Cellulose nanofibrils from nonderivatizing urea-based deep eutectic solvent pretreatments[J]. ACS Applied Materials & Interfaces, 2017, 9(3): 2846-2855. |

| 21 | LIU Y Z, GUO B T, XIA Q Q, et al. Efficient cleavage of strong hydrogen bonds in cotton by deep eutectic solvents and facile fabrication of cellulose nanocrystals in high yields[J]. ACS Sustainable Chemistry & Engineering, 2017, 5(9): 7623-7631. |

| 22 | WU Z T, CHEN S Y, LI J, et al. Insights into hierarchical structure-property-application relationships of advanced bacterial cellulose materials[J]. Advanced Functional Materials, 2023, 33(12): 2214327. |

| 23 | SHEN X P, ZHAO D W, XIE Y J, et al. Cellulose gel mechanoreceptors-principles, applications and prospects[J]. Advanced Functional Materials, 2023: 2214317. |

| 24 | RAHMANIAN V, PIRZADA T, WANG S Y, et al. Cellulose-based hybrid aerogels: Strategies toward design and functionality[J]. Advanced Materials, 2021, 33(51): 2102892. |

| 25 | CHEN Y M, ZHANG L, YANG Y, et al. Recent progress on nanocellulose aerogels: Preparation, modification, composite fabrication, applications[J]. Advanced Materials, 2021, 33(11): 2005569. |

| 26 | ZHAO D W, ZHU Y, CHENG W K, et al. Cellulose-based flexible functional materials for emerging intelligent electronics[J]. Advanced Materials, 2021, 33(28): 2000619. |

| 27 | WANG Z H, LEE Y H, KIM S W, et al. Why cellulose-based electrochemical energy storage devices?[J]. Advanced Materials, 2021, 33(28): 2000892. |

| 28 | TIAN Y P, SHAO H, LIU X J, et al. Superhydrophobic and recyclable cellulose-fiber-based composites for high-efficiency passive radiative cooling[J]. ACS Applied Materials & Interfaces, 2021, 13(19): 22521-22530. |

| 29 | LI T, ZHAI Y, HE S, et al., A radiative cooling structural material[J]. Science, 2019, 364(6442): 760-763. |

| 30 | CHEN Y P, DANG B K, FU J Z, et al. Cellulose-based hybrid structural material for radiative cooling[J]. Nano Letters, 2021, 21(1): 397-404. |

| 31 | CAI C Y, WEI Z C, DING C X, et al. Dynamically tunable all-weather daytime cellulose aerogel radiative supercooler for energy-saving building[J]. Nano Letters, 2022, 22(10): 4106-4114. |

| 32 | GUO Y H, LU H Y, ZHAO F, et al. Biomass-derived hybrid hydrogel evaporators for cost-effective solar water purification[J]. Advanced Materials, 2020, 32(11): 1907061. |

| 33 | LI Y J, GAO T T, YANG Z, et al. 3D-printed, all-in-one evaporator for high-efficiency solar steam generation under 1 Sun illumination[J]. Advanced Materials, 2017, 29(26): 1700981. |

| 34 | QI H S, WEI T Q, ZHAO W, et al. An interfacial solar-driven atmospheric water generator based on a liquid sorbent with simultaneous adsorption-desorption[J]. Advanced Materials, 2019, 31(43): 1903378. |

| 35 | LI R Y, WANG W B, SHI Y F, et al. Advanced material design and engineering for water-based evaporative cooling[J]. Advanced Materials, 2023: https://doi.org/10.1002/adma.2209460. |

| 36 | CHEN Y M, LI S J, LI X L, et al. Liquid transport and real-time dye purification via lotus petiole-inspired long-range-ordered anisotropic cellulose nanofibril aerogels[J]. ACS Nano, 2021, 15(12): 20666-20677. |

| 37 | CHEN G G, LI T, CHEN C J, et al. A highly conductive cationic wood membrane[J]. Advanced Functional Materials, 2019, 29(44): 1902772. |

| 38 | ZHU M W, LI Y J, CHEN F J, et al. Plasmonic wood for high-efficiency solar steam generation[J]. Advanced Energy Materials, 2018, 8(4): 1701028. |

| 39 | LI T, LIU H, ZHAO X P, et al. Scalable and highly efficient mesoporous wood-based solar steam generation device: Localized heat, rapid water transport[J]. Advanced Functional Materials, 2018, 28(16): 1707134. |

| 40 | HAN S B, RUOKO T P, GLADISCH J, et al. Cellulose-conducting polymer aerogels for efficient solar steam generation[J]. Advanced Sustainable Systems, 2020, 4(7): 2000004. |

| 41 | LI N, QIAO L F, HE J T, et al. Solar-driven interfacial evaporation and self-powered water wave detection based on an all-cellulose monolithic design[J]. Advanced Functional Materials, 2021, 31(7): 2008681. |

| 42 | ZHANG Y, ZHU W K, ZHANG C, et al. Atmospheric water harvesting by large-scale radiative cooling cellulose-based fabric[J]. Nano Letters, 2022, 22(7): 2618-2626. |

| 43 | ZHOU S Y, KONG X Y, ZHENG B, et al. Cellulose nanofiber @ conductive metal-organic frameworks for high-performance flexible supercapacitors[J]. ACS Nano, 2019, 13(8): 9578-9586. |

| 44 | KADUMUDI F B, TRIFOL J, JAHANSHAHI M, et al. Flexible and green electronics manufactured by origami folding of nanosilicate-reinforced cellulose paper[J]. ACS Applied Materials & Interfaces, 2020, 12(42): 48027-48039. |

| 45 | LIN C M, HUANG H, ZHAO H H, et al. Acid- and alkali-resistant and high-performance cellulose paper-based triboelectric nanogenerator by controlling the surface hydrophobicity[J]. ACS Sustainable Chemistry & Engineering, 2022, 10(41): 13669-13679. |

| 46 | CHEN C J, XU S M, KUANG Y D, et al. Nature-inspired tri-pathway design enabling high-performance flexible Li-O2 batteries[J]. Advanced Energy Materials, 2019, 9(9): 1802964. |

| 47 | YU B C, PARK K, JANG J H, et al. Cellulose-based porous membrane for suppressing Li dendrite formation in lithium-sulfur battery[J]. ACS Energy Letters, 2016, 1(3): 633-637. |

| 48 | ZHAO D W, CHEN C J, ZHANG Q, et al. High performance, flexible, solid-state supercapacitors based on a renewable and biodegradable mesoporous cellulose membrane[J]. Advanced Energy Materials, 2017, 7(18): 1700739. |

| 49 | PAN R J, XU X X, SUN R, et al. Nanocellulose modified polyethylene separators for lithium metal batteries[J]. Small (Weinheim an Der Bergstrasse, Germany), 2018, 14(21): e1704371. |

| 50 | FU J, ZHANG J, SONG X P, et al. A flexible solid-state electrolyte for wide-scale integration of rechargeable zinc-air batteries[J]. Energy & Environmental Science, 2016, 9(2): 663-670. |

| 51 | ZHANG J, JIANG G P, GOLEDZINOWSKI M, et al. Green solid electrolyte with cofunctionalized nanocellulose/graphene oxide interpenetrating network for electrochemical gas sensors[J]. Small Methods, 2017, 1(11): 1700237. |

| 52 | ZHANG J, FU J, SONG X P, et al. Laminated cross-linked nanocellulose/graphene oxide electrolyte for flexible rechargeable zinc-air batteries[J]. Advanced Energy Materials, 2016, 6(14): 1600476. |

| 53 | SEO J Y, LEE Y H, KIM J H, et al. Electrode-customized separator membranes based on self-assembled chiral nematic liquid crystalline cellulose nanocrystals as a natural material strategy for sustainable Li-metal batteries[J]. Energy Storage Materials, 2022, 50: 783-791. |

| 54 | YANG J L, ZHAO X X, ZHANG W, et al. Inside back cover: “pore-hopping” ion transport in cellulose-based separator towards high-performance sodium-ion batterie[J]. Angewandte Chemie International Edition, 2023, 62(15): https://doi.org/10.1002/anie.202302568. |

| 55 | LIU L M, QIN Y Y, WANG K, et al. Rational design of nanostructured metal/C interface in 3D self-supporting cellulose carbon aerogel facilitating high-performance Li-CO2 batteries[J]. Advanced Energy Materials, 2022, 12(20): https://doi.org/10.1002/aenm.2103681. |

| 56 | CHEN Z M, WANG X F, XUE B C, et al. Self-templating synthesis of 3D hollow tubular porous carbon derived from straw cellulose waste with excellent performance for supercapacitors[J]. ChemSusChem, 2019, 12(7): 1390-1400. |

| 57 | WU Z Y, LIANG H W, CHEN L F, et al. Bacterial cellulose: A robust platform for design of three dimensional carbon-based functional nanomaterials[J]. Accounts of Chemical Research, 2016, 49(1): 96-105. |

| 58 | BOMMIER C, XU R, WANG W, et al. Self-activation of cellulose: A new preparation methodology for activated carbon electrodes in electrochemical capacitors[J]. Nano Energy, 2015, 13: 709-717. |

| 59 | HAO P, ZHAO Z H, TIAN J, et al. Hierarchical porous carbon aerogel derived from bagasse for high performance supercapacitor electrode[J]. Nanoscale, 2014, 6(20): 12120-12129. |

| 60 | JIANG L L, LI L, LUO S, et al. Configuring hierarchical Ni/NiO 3D-network assisted with bamboo cellulose nanofibers for high-performance Ni-Zn aqueous batteries[J]. Nanoscale, 2020, 12(27): 14651-14660. |

| 61 | LIU K, MO R W, DONG W J, et al. Nature-derived, structure and function integrated ultra-thick carbon electrode for high-performance supercapacitors[J]. Journal of Materials Chemistry A, 2020, 8(38): 20072-20081. |

| 62 | WANG F, CHEONG J Y, LEE J, et al. Pyrolysis of enzymolysis-treated wood: Hierarchically assembled porous carbon electrode for advanced energy storage devices[J]. Advanced Functional Materials, 2021, 31(31): 2101077. |

| 63 | XIE F, XU Z, JENSEN A C S, AU H, et al. Hard-soft carbon composite anodes with synergistic sodium storage performance[J]. Advanced Functional Materials, 2019, 29: doi:10.1002/adfm. 201901072. |

| [1] | 李纪伟, 刘睿涵, 吕桃林, 潘隆, 马常军, 李清波, 赵芝芸, 杨文, 解晶莹. 基于局部离群点检测和标准差方法的锂离子电池组早期故障诊断[J]. 储能科学与技术, 2023, (): 1-10. |

| [2] | 王轩臣, 王达, 刘朝孟, 高宣雯, 骆文彬. 钾离子电池电解液的研究进展及展望[J]. 储能科学与技术, 2023, 12(5): 1409-1426. |

| [3] | 周俊龙, 赵鲁康, 刘朝孟, 高宣雯, 骆文彬. 量子点及其复合材料作为碱金属离子电池负极的研究进展[J]. 储能科学与技术, 2023, 12(5): 1392-1408. |

| [4] | 余永诗, 夏先明, 黄弘扬, 姚雨, 芮先宏, 钟国彬, 苏伟, 余彦. 钠金属负极人工界面保护层的研究进展[J]. 储能科学与技术, 2023, 12(5): 1380-1391. |

| [5] | 韩文哲, 赖青松, 高宣雯, 骆文彬. 钾离子电池锰基层状氧化物正极的研究进展[J]. 储能科学与技术, 2023, 12(5): 1364-1379. |

| [6] | 李尚倬, 龙禹彤, 刘朝孟, 高宣雯, 骆文彬. 钾离子电池聚阴离子正极材料的研究进展[J]. 储能科学与技术, 2023, 12(5): 1348-1363. |

| [7] | 赵玉文, 杨欢, 郭俊朋, 张毅, 孙琦, 张志佳. 磁性金属元素在钠离子电池中的应用[J]. 储能科学与技术, 2023, 12(5): 1332-1347. |

| [8] | 李社栋, 宋莹莹, 边煜华, 刘朝孟, 高宣雯, 骆文彬. 室温钠硫电池的发展现状和挑战[J]. 储能科学与技术, 2023, 12(5): 1315-1331. |

| [9] | 李欣雨, 韩雪冰, 卢兰光, 李建秋, 欧阳明高. 基于大倍率电流脉冲的动力锂离子电池阻抗模型优化[J]. 储能科学与技术, 2023, 12(5): 1686-1694. |

| [10] | 胡川, 胡志伟, 李振东, 李帅, 王豪, 王丽平. 调控LiPF6 基电解液溶剂化结构稳定富锂锰基正极界面[J]. 储能科学与技术, 2023, 12(5): 1604-1615. |

| [11] | 边煜华, 刘朝孟, 高宣雯, 李健国, 王达, 李尚倬, 骆文彬. 醚基电解液中CoS2/NC作为钠离子电池高性能阳极的原因分析[J]. 储能科学与技术, 2023, 12(5): 1500-1509. |

| [12] | 郝奕帆, 祝夏雨, 王静, 邱景义, 明海, 方振华. 电池无损检测监测方法分析[J]. 储能科学与技术, 2023, 12(5): 1713-1737. |

| [13] | 时文超, 刘宇, 张博冕, 李琪, 韩春华, 麦立强. 电解液添加剂稳定水系电池锌负极界面的研究进展[J]. 储能科学与技术, 2023, 12(5): 1589-1603. |

| [14] | 朱璟, 申晓宇, 岑官骏, 乔荣涵, 郝峻丰, 季洪祥, 田孟羽, 金周, 詹元杰, 武怿达, 闫勇, 贲留斌, 俞海龙, 刘燕燕, 黄学杰. 锂电池百篇论文点评(2023.2.1—2023.3.31)[J]. 储能科学与技术, 2023, 12(5): 1553-1569. |

| [15] | 雷蕾, 高鹏, 冯娜娜, 蔡坤鹏, 张海, 张扬. 锆酸镧锂固态电解质合成过程多因素影响[J]. 储能科学与技术, 2023, 12(5): 1625-1635. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||