Energy Storage Science and Technology ›› 2024, Vol. 13 ›› Issue (2): 643-651.doi: 10.19799/j.cnki.2095-4239.2023.0523

• Energy Storage System and Engineering • Previous Articles Next Articles

Chengzhi XING1,2( ), Ming ZHAO1,2, Chao SHANG1,2, Sijing ZHANG1,2, Zili ZHANG1,2, Yang LIU1,2(

), Ming ZHAO1,2, Chao SHANG1,2, Sijing ZHANG1,2, Zili ZHANG1,2, Yang LIU1,2( )

)

Received:2023-08-04

Revised:2023-09-12

Online:2024-02-28

Published:2024-03-01

Contact:

Yang LIU

E-mail:xchzhi@163.com;angusliu76@163.com

CLC Number:

Chengzhi XING, Ming ZHAO, Chao SHANG, Sijing ZHANG, Zili ZHANG, Yang LIU. Research progress and application scenarios of storage and transportation technology with liquid organic hydrogen carrier[J]. Energy Storage Science and Technology, 2024, 13(2): 643-651.

Table 1

The summery for comprehensive comparison of hydrogen energy storage and transportation technologies[3-9]"

| 指标 | 高压气态 | 液态 | 固态 | ||

|---|---|---|---|---|---|

| 低温液态 | 有机液体 | 金属氢化物 | 碳材料物理吸附 | ||

| 技术原理 | 将氢气压缩于高压容器中,储氢密度与储存压力、储存容器类型相关 | 低温(20 K)条件下对氢液化,并低温保冷储运,实现氢的高密度储运 | 利用可循环有机液体的不饱和共价键作为载体进行加氢、脱氢,实现氢能储运 | 利用合金不同金属组分与氢原子结合形成金属氢化物,实现氢的储存和释放 | 采用高比表面积碳吸附剂(活性炭或纳米碳材料分子筛)通过物理吸附解析,实现氢储运 |

| 体积储氢密度(容器) | 13 g/L(20 MPa) 24 g/L(35 MPa) | 60~71 g/L | 51~62 g/L | 50~55 g/L | 50~55 g/L |

| 质量储氢密度(容器) | 4%(Ⅲ型瓶) 5.5%~6%(Ⅳ型瓶) | 5%~20% | 5.5% | 1%~2% | 2.5%~8.25% |

| 运输工具及经济距离 | 长管拖车 ≤150 km | 液氢槽罐车 ≥200 km | 槽罐车 ≥200 km | 固体货车 ≥200 km | 固体货车 ≥200 km |

| 优点 | 技术成熟、加氢放氢便捷,氢能储运产业链完善 | 液氢体积密度最高,释放氢气纯度高 | 储氢密度高、安全性能高、储运便捷、经济、可实现远距离运输 | 安全性能高,储存压力低,运输方便 | 压力适中,储存容器自重轻,形状多样化,安全性高 |

| 缺点 | 储氢密度低,容器耐压要求高,储运安全性差,运输成本高(1 kg H2 100 km、200 km的运费为7~8元、20~25元),无法完成中运距离运输 | 产业链不完善,液化能耗高(12~17 kWh/kg H2),冷能利用率低,容器绝热性要求高,储运保冷能耗高,汽化及泄压排放损耗大 | 产业链不完善,加氢、脱氢涉及化学可逆反应平衡,技术控制相对复杂,释放的氢气需净化处理,有机液体循环过程存在损耗 | 产业链尚未形成,价格高,寿命短、储存释放条件苛刻 | 产业链尚未形成,价格高,寿命短、储存释放难以控制 |

| 技术进展 | 发展成熟,广泛用于车用氢能领域 | 国外已有多年液氢运输经验,国内氢液化及液氢储运技术仍需进一步提升 | 已完成技术研发,处于工业化推广应用阶段 | 处于研发阶段,距离商业化大规模应用较远 | 处于研发阶段,距离商业化大规模应用较远 |

Table 2

Reaction performance indexes list of LOHC[14-20]"

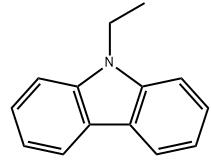

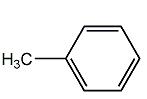

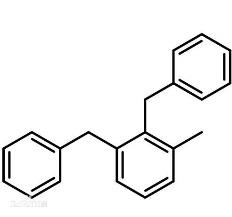

| 储氢介质 | N-乙基咔唑(H0-NEC) | 甲苯(TOL) | 二苄基甲苯(H0-DBT) |

|---|---|---|---|

| 加氢后有机物 | 全氢-乙基咔唑(H12-NEC) | 甲基环己烷(MCH) | 全氢二苄基甲苯(H18-DBT) |

| 反应焓 △H/(kcal/mol H2) | -11.8 | -16.3 | -16.0 |

| 加氢压力 | 8 MPa | 4 MPa | 6.0 MPa |

| 脱氢压力 | 0.3 MPa | 0.4 MPa | 0.3 MPa |

| 加氢方式 | 气(氢气)+液(H0-NEC)两相同时催化反应,加氢反应器流场复杂,需设液体分离器 | 气化温度较低,先将液体(TOL)加热气化,气相反应,加氢反应器流场简单,容易控制 | 气(氢气)+液(H0-DBT)两相同时催化反应,加氢反应器流场复杂,需设液体分离器 |

| 加氢温度 | 140~150 ℃,放热反应,副产140~150 ℃饱和蒸汽 | 130~200 ℃,放热反应,副产130~200 ℃饱和蒸汽 | 130~200 ℃,放热反应,副产130~200 ℃饱和蒸汽 |

| 加氢催化剂 | 镍系催化剂、钯及铂系催化剂、钌系催化剂和铑系催化剂 | ||

| 脱氢方式 | 气(氢气)+液(H12-NEC)两相同时催化反应,加氢反应器流场复杂,需设液体分离器 | 气化温度较低,先将液体(MCH)加热气化,气相反应,加氢反应器流场简单,容易控制 | 气(氢气)+液(H18-DBT)两相同时催化反应,加氢反应器流场复杂,需设液体分离器 |

| 脱氢催化剂 | 微量的贵金属 | 贵金属(Pt/Ir/Pd) | 贵金属(Pt) |

| 脱氢温度/℃ | >200 | >350 | >320 |

| 脱氢速度 | 20 L/(min·kW) | 0.2 L/(min·kW) | 0.7 L/(min·kW) |

Table 3

List of performance indexes of hydrogen carrier[14-20]"

| 储氢介质 | N-乙基咔唑(H0-NEC) | 甲苯(TOL) | 二苄基甲苯(H0-DBT) |

|---|---|---|---|

| 分子结构 |  |  |  |

| 熔点 | H0-NEC 70 ℃ | TOL -95 ℃ | DBT -34 ℃ |

| H12-NEC -85 ℃ | MCH -126 ℃ | H18-DBT -50 ℃ | |

| 沸点 | H0-NEC 220 ℃ | TOL 111 ℃ | H0-DBT 390 ℃ |

| H12-NEC 280 ℃ | MCH 101 ℃ | H18-DBT 371 ℃ | |

| 液态温度范围 | -85~280 ℃ (需加入一定溶剂,乙基咔唑才可在常温常压下保持液态) | -95~101 ℃ (常温常压下稳定液态) | -34~371 ℃ (常温常压下稳定液态) |

| 质量储氢密度/% | 5.8 | 6.12 | 6.23 |

| 体积储氢密度/(g/L) | 58 | 47.4 | 59 |

| 闪点 | 186 ℃ | 闪点(闭杯) 4.4 ℃ | 200 ℃ |

| 火灾危险性 | 丙B 可燃 | 甲 易燃易爆 | 丙B 可燃 |

| 爆炸极限/% | 挥发性弱,无爆炸极限 | 1.2~7.0 | 挥发性弱,无爆炸极限 |

| 毒性 | 无毒 | 低毒 | 无毒 |

| 加氢催化剂 | 镍系催化剂、钯及铂系催化剂、钌系催化剂和铑系催化剂 | ||

| 加氢效率 | >95% | >95% | >95% |

| 脱氢效率 | >95% | >95% | >95% |

| 储氢载体成本 | 50000元/吨,量化生产可降至30000元/吨 | 市场大宗类危险化学品,市场价约8000元/吨 | 市场价格约25000元/吨 |

| 安全性能 | 普通化学品(不在《危险化学品名录(2015 版)》内),储运不受危险化学品限制 | 第三类危险化学品,储运受到危险化学品限制 | 普通化学品(不在《危险化学品名录(2015 版)》内),储运不受危险化学品限制 |

Table 4

Comprehensive cost list of organic liquid hydrogen energy storage and transportation"

| 项目 | N-乙基咔唑装置 | 甲苯装置 | 二苄基甲苯装置 | 备注 |

|---|---|---|---|---|

| 氢气/(元/kg H2) | 8.44 | 8.44 | 8.44 | |

| 加氢/(元/kg H2) | 0.96 | 2.75 | 2.51 | 生产成本,不考虑载体损耗 |

| 储氢载体运输/(元/kg H2) | 4.10 | 4.50 | 4.20 | |

| 脱氢/(元/kg H2)(按导热油加热) | 7.00 | 13.98 | 12.80 | |

| 气氢运输/(元/kg H2) | 7.00 | 7.00 | 7.00 | 城市短途管束车运氢费用 |

| 加氢站到站氢价/(元/kg H2) | 27.54 | 36.27 | 34.95 |

| 1 | 中国氢能联盟. 中国氢能源及燃料电池产业白皮书(2020版)[R]. 2020. |

| 2 | TEICHMANN D, ARLT W, WASSERSCHEID P. Liquid organic hydrogen carriers as an efficient vector for the transport and storage of renewable energy[J]. International Journal of Hydrogen Energy, 2012, 37(23): 18118-18132. |

| 3 | 王尔德, 雷正龙, 于振兴. 镁基储氢材料的研究进展[J]. 粉末冶金技术, 2003, 21(1): 31-36. |

| WANG E D, LEI Z L, YU Z X. A review on the development of Mg-based hydrogen storage materials[J]. Powder Metallurgy Technology, 2003, 21(1): 31-36. | |

| 4 | 李志宝, 孙立贤, 张莹洁, 等. MgH2储氢热力学研究进展[J]. 中国科学: 化学, 2014, 44(6): 964-972. |

| LI Z B, SUN L X, ZHANG Y J, et al. Progress on hydrogen storage thermodynamic of MgH2[J]. Scientia Sinica Chimica), 2014, 44(6: 964-972. | |

| 5 | 李袁庆, 刘志远, 杨松恋. 储氢材料的研究进展[J]. 化工管理, 2013(16): 207. |

| LI Y Q, LIU Z Y, YANG S L. Research progress of hydrogen storage materials[J]. Chemical Enterprise Management, 2013(16): 207. | |

| 6 | 杨明, 王圣平, 张运丰, 等. 储氢材料的研究现状与发展趋势[J]. 硅酸盐学报, 2011, 39(7): 1053-1060. |

| YANG M, WANG S P, ZHANG Y F, et al. Current status and future prospects of research on hydrogen storage materials[J]. Journal of the Chinese Ceramic Society, 2011, 39(7): 1053-1060. | |

| 7 | 龚金明, 刘道平, 谢应明. 储氢材料的研究概况与发展方向[J]. 天然气化工(C1化学与化工), 2010, 35(5): 71-78. |

| GONG J M, LIU D P, XIE Y M. Progress on hydrogen storage materials[J]. Natural Gas Chemical Industry, 2010, 35(5): 71-78. | |

| 8 | SREEDHAR I, KAMANI K M, KAMANI B M, et al. A Bird's Eye view on process and engineering aspects of hydrogen storage[J]. Renewable and Sustainable Energy Reviews, 2018, 91: 838-860. |

| 9 | AZIZ M, ODA T, KASHIWAGI T. Comparison of liquid hydrogen, methylcyclohexane and ammonia on energy efficiency and economy[J]. Energy Procedia, 2019, 158: 4086-4091. |

| 10 | 蔡卫权, 张光旭, 陈进富, 等. 有机氢载体低温高效脱氢催化剂的研究进展[J]. 石油化工, 2007, 36(7): 744-749. |

| CAI W Q, ZHANG G X, CHEN J F, et al. Development of dehydrogenation catalyst for reversible hydrogen storage based on organic hydrides[J]. Petrochemical Technology, 2007, 36(7): 744-749. | |

| 11 | EYPASCH M, SCHIMPE M, KANWAR A, et al. Model-based techno-economic evaluation of an electricity storage system based on liquid organic hydrogen carriers[J]. Applied Energy, 2017, 185: 320-330. |

| 12 | Wulf C, Zapp P. Assessment of system variations for hydrogen transportation by LOHCs[J]. Int J Hydrogen Energy, 2018, 43: 11884-11895. |

| 13 | JIANG Z, PAN Q, XU J, et al. Current situation and prospect of hydrogen storage technology with new organic liquid[J]. International Journal of Hydrogen Energy, 2014, 39(30): 17442-17451. |

| 14 | BINIWALE R B, RAYALU S, DEVOTTA S, et al. Chemical hydrides: A solution to high capacity hydrogen storage and supply[J]. International Journal of Hydrogen Energy, 2008, 33(1): 360-365. |

| 15 | 袁胜楠, 张龙龙, 赵宁, 等. 液态有机物储氢技术发展历程与问题分析[J]. 太阳能, 2022(9): 5-14. |

| YUAN S N, ZHANG L L, ZHAO N, et al. Development history and problem analysis of liquid organic hydrogen carrier technology[J]. Solar Energy, 2022(9): 5-14. | |

| 16 | HE T, PEI Q J, CHEN P. Liquid organic hydrogen carriers[J]. Journal of Energy Chemistry, 2015, 24(5): 587-594. |

| 17 | 姜召, 徐杰, 方涛. 新型有机液体储氢技术现状与展望[J]. 化工进展, 2012, 31(S1): 315-322. |

| JIANG Z, XU J, FANG T. Current situation and prospect for hydrogen storage technology with new organic liquid[J]. Chemical Industry and Engineering Progress, 2012, 31(S1): 315-322. | |

| 18 | 万超, 安越, 孔文静, 等. 十二氢乙基咔唑的催化脱氢性能研究[J]. 太阳能学报, 2014, 35(3): 439-442. |

| WAN C, AN Y, KONG W J, et al. A study of catalytic dehydrogenation from dodecahydro-n-ethylcarbazole over a catalyst[J]. Acta Energiae Solaris Sinica, 2014, 35(3): 439-442. | |

| 19 | 吴富英. 新型有机液体储氢剂乙基咔唑的加氢催化剂研究[D]. 杭州: 浙江大学, 2014. |

| WU F Y. Study on the hydrogenation effect of catalyst on new liquid hydrogen storage material N-ethylcarbazole[D]. Hangzhou: Zhejiang University, 2014. | |

| 20 | 孔文静. 咔唑加脱氢性能研究[D]. 杭州: 浙江大学, 2012. |

| KONG W J. Study on the hydrogen uptake and release performance of carbazole[D]. Hangzhou: Zhejiang University, 2012. | |

| 21 | BP statistical review of world energy 2020[R]. https://www.bp.com/content/dam/bp/country-sites/zh_cn/ china/home/reports/statistical-review-of-world-energy/2019/2019srbook.pdf. |

| 22 | 薛景文, 于鹏飞, 张彦康, 等. 液态有机氢载体储氢系统脱氢反应器研究进展[J]. 热力发电, 2022, 51(11): 1-10. |

| XUE J W, YU P F, ZHANG Y K, et al. Review on advances of dehydrogenation reactor for hydrogen storage system using liquid organic hydrogen carrier[J]. Thermal Power Generation, 2022, 51(11): 1-10. | |

| 23 | NAKAYAMA J, MISONO H, SAKAMOTO J, et al. Simulation-based safety investigation of a hydrogen fueling station with an on-site hydrogen production system involving methylcyclohexane[J]. International Journal of Hydrogen Energy, 2017, 42(15): 10636-10644. |

| [1] | Qili LIN, Hongxun QI, Jingjing HUANG, Bingcheng ZHANG, Zhen CHEN, Zhenkun XIAO. Levelized cost of combined hydrogen production by water electrolysis with alkaline-proton exchange membrane [J]. Energy Storage Science and Technology, 2023, 12(11): 3572-3580. |

| [2] | Jin XU, Xian DING, Yongli GONG, Guangli HE, Ting HU. Economic analysis of hydrogen production plant with water electrolysis [J]. Energy Storage Science and Technology, 2022, 11(7): 2374-2385. |

| [3] | Wei LIU, Yanming WAN, Yalin XIONG, Jian LIU. Outlook of low carbon and clean hydrogen in China under the goal of "carbon peak and neutrality" [J]. Energy Storage Science and Technology, 2022, 11(2): 635-642. |

| [4] | Yalin XIONG, Wei LIU, Pengbo GAO, Binqi DONG, Mingsheng ZHAO. Research on the hydrogen energy demand and carbon-reduction path in China's synthetic ammonia industry to achieve the “carbon peak” and “carbon neutrality” goals [J]. Energy Storage Science and Technology, 2022, 11(12): 4048-4058. |

| [5] | Jiamin LU, Junhui XU, Weidong WANG, Hao WANG, Zijun XU, Liuping CHEN. Development of large-scale underground hydrogen storage technology [J]. Energy Storage Science and Technology, 2022, 11(11): 3699-3707. |

| [6] | Yanming WAN, Yalin XIONG, Xueying WANG. Strategic analysis of hydrogen energy development in major countries [J]. Energy Storage Science and Technology, 2022, 11(10): 3401-3410. |

| [7] | Xiaoyuan WU, Zhelun ZUO, Shiyu GUO, Ru WANG, Jianhui HE. Evaluation on city application readiness of fuel cell logistics vehicles [J]. Energy Storage Science and Technology, 2020, 9(5): 1574-1584. |

| [8] | ZHAO Yuejing, HE Guangli, MIAO Ping, XU Zhuang, YANG Kang, TIAN Zhonghui, DONG Wenping, XIONG Yalin. Study on comprehensive evaluation of 35 MPa/70 MPa hydrogen dispenser refueling performance [J]. Energy Storage Science and Technology, 2020, 9(3): 702-706. |

| [9] | LI Luling, FAN Shuanshi, CHEN Qiuxiong, YANG Guang, WEN Yonggang. Hydrogen storage technology: Current status and prospects [J]. Energy Storage Science and Technology, 2018, 7(4): 586-594. |

| [10] | WANG Shuo1,2, ZHANG Jun3 . Research on patent status and process route of hydrogen production in China [J]. Energy Storage Science and Technology, 2018, 7(2): 353-362. |

| [11] | HUO Xianxu, WANG Jing, JIANG Ling, XU Qingshan. Review on key technologies and applications of hydrogen energy storage system [J]. Energy Storage Science and Technology, 2016, 5(2): 197-203. |

| [12] | CHEN Jun, CHEN Qiuxiong, CHEN Yunwen, FAN Shuanshi, WANG Yanhong, YANG Liang, LANG Xuemei, ZHANG Wenxiang, HUANG Yi, XIONG Wentao, WEN Yonggang. Current status of energy storage using hydrates [J]. Energy Storage Science and Technology, 2015, 4(2): 131-140. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||