Energy Storage Science and Technology ›› 2025, Vol. 14 ›› Issue (3): 1010-1025.doi: 10.19799/j.cnki.2095-4239.2024.1159

• Emerging Investigator Issue of Energy Storage • Previous Articles Next Articles

Ruixing QUAN1( ), Wenjing MIAO1, Changshun YUAN1, Guanggui CHNEG1, Yanqi ZHAO1,2(

), Wenjing MIAO1, Changshun YUAN1, Guanggui CHNEG1, Yanqi ZHAO1,2( )

)

Received:2024-12-06

Revised:2024-12-26

Online:2025-03-28

Published:2025-04-28

Contact:

Yanqi ZHAO

E-mail:2222203067@stmail.ujs.edu.cn;y.zhao@njtech.edu.cn

CLC Number:

Ruixing QUAN, Wenjing MIAO, Changshun YUAN, Guanggui CHNEG, Yanqi ZHAO. Advancements in polyethylene glycol-based form-stable composite phase change materials[J]. Energy Storage Science and Technology, 2025, 14(3): 1010-1025.

Table 1

Comparison of properties of medium temperature phase change materials[12]"

| 相变材料 | 分类 | 熔化温度/℃ | 相变潜热/(J/g) | 热导率/[W/(m⋅K)] |

|---|---|---|---|---|

| 聚乙二醇(PEG) | 醇类有机相变材料 | 37.1~67.0 | 161.18~197.2 | 0.29~0.33 |

| 月桂酸(LA) | 脂肪酸类有机相变材料 | 44 | 212 | 0.22 |

| 癸酸 | 脂肪酸类有机相变材料 | 32 | 163 | 0.15 |

| 硬脂酸(SA) | 脂肪酸类有机相变材料 | 70 | 199 | 0.17 |

| 正十八烷 | 石蜡类有机相变材料 | 28 | 244 | 0.36 |

| 正二十烷 | 石蜡类有机相变材料 | 40 | 213 | 0.21 |

| 六水氯化钙(CaCl2·6H2O) | 水合盐类无机相变材料 | 29.6 | 191 | 1.09 |

| 十水硫酸钠(Na2SO4·10H2O) | 水合盐类无机相变材料 | 32 | 180 | 0.56 |

| 三水乙酸钠[Na2(CH3COO)3H2O] | 水合盐类无机相变材料 | 58 | 266 | 0.43 |

Table 2

A summary of properties of PEG-based composite phase change materials with porous materials as supporting skeleton"

| 聚乙二醇 | 多孔材料 | 制备方法 | 负载量/% | 熔融温度/℃ | 熔融焓值/(J/g) |

|---|---|---|---|---|---|

| PEG-2000 | 膨胀蛭石(PAL)[ | 真空浸渍 | 66.16 | 35.81/41.63 | 55.25 |

| PEG-6000 | 膨胀珍珠岩(EP)[ | 真空浸渍 | 72.61 | 59.6 | 142.8 |

| PEG-800 | 脱木素高粱秸秆(DSS)[ | 真空浸渍 | — | 28.21 | 98.71 |

| PEG-6000 | 硅藻土[ | 浸渍和真空蒸发 | 60 | 56.8 | 107.4 |

| PEG | 多孔碳(CF)[ | 熔融浸渍 | 75 | 50.45 | 81.76 |

| PEG-4000 | 三聚氰胺泡沫(MF)[ | 真空浸渍 | 98.3 | 54.5 | 186.2±4.4 |

| PEG-1500 | 泡沫铜(CF)[ | 熔融浸渍 | — | 46 | 155.74 |

| PEG-4000 | 多孔马铃薯[ | 真空浸渍 | 82.1 | 51.26 | 139.88 |

Table 3

Properties of polyurethane solid-solid phase change materials based on isocyanate and polyethylene glycol"

| 聚乙二醇类型 | 异氰酸酯类型 | 其他填料 | 熔融温度/℃ | 熔融焓值/(J/g) |

|---|---|---|---|---|

| PEG-4000, 6000,8000,10000, 12000 | TDI[ | 三聚氰胺,石墨烯纳米片(GNP) | 36.7~59.8 | 最大118.7 |

| PEG-4000 | MDI[ | 有机蒙脱石(OMMT) | 54.97 | 106.8 |

| PEG-10000 | MDI[ | 氧化石墨烯(GO) | 61.81 | 138.12 |

| PEG-8000 | MDI[ | 氧化石墨烯(GO) | 65.3 | 158.2 |

| PEG-8000 | MDI[ | 石墨纳米片(GNP) | 54.6 | 164.4 |

| PEG-8000 | MDI[ | 多壁碳纳米管(MWCNT) | 58.7 | 113.5 |

| PEG-4000 | MDI[ | 聚乙烯醇(PVOH) | 51.11 | 144.14 |

| PEG-6000 | IPDI[ | 铁离子 | — | 97.6 |

| PEG-2000,4000 | IPDI[ | 丁二醇(BDO) | — | 56.93/79.23 |

| PEG-6000 | HMDI[ | 多壁碳纳米管(MWCNT) | 24.91 | 64.81 |

| PEG-8000 | H12MDI[4,4'-亚甲基双(环己基异氰酸酯)][ | 三苯乙烯基苯酚聚乙二醇醚(Emulsogen TS200) | 59.08 | 129.59 |

| PEG-6000 | HDI[ | 泡沫石墨(GF) | 43.8 | 60.3 |

| PEG-10000 | HDI[ | 木粉(WF) | 63.5 | 134.2 |

| PEG-3000 | HDI[ | 碳纳米管(CNT) | 42 | 85.9 |

| PEG-6000 | HDIT[ | — | 64.8 | 136.8 |

| PEG | HDIT[ | MXene | — | 132.82 |

| PEG-4000 | HDIB(六亚甲基二异氰酸酯缩二脲)[ | 网状石墨纳米片(RGNPs) | 46.5 | 163.5 |

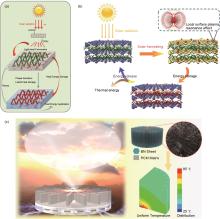

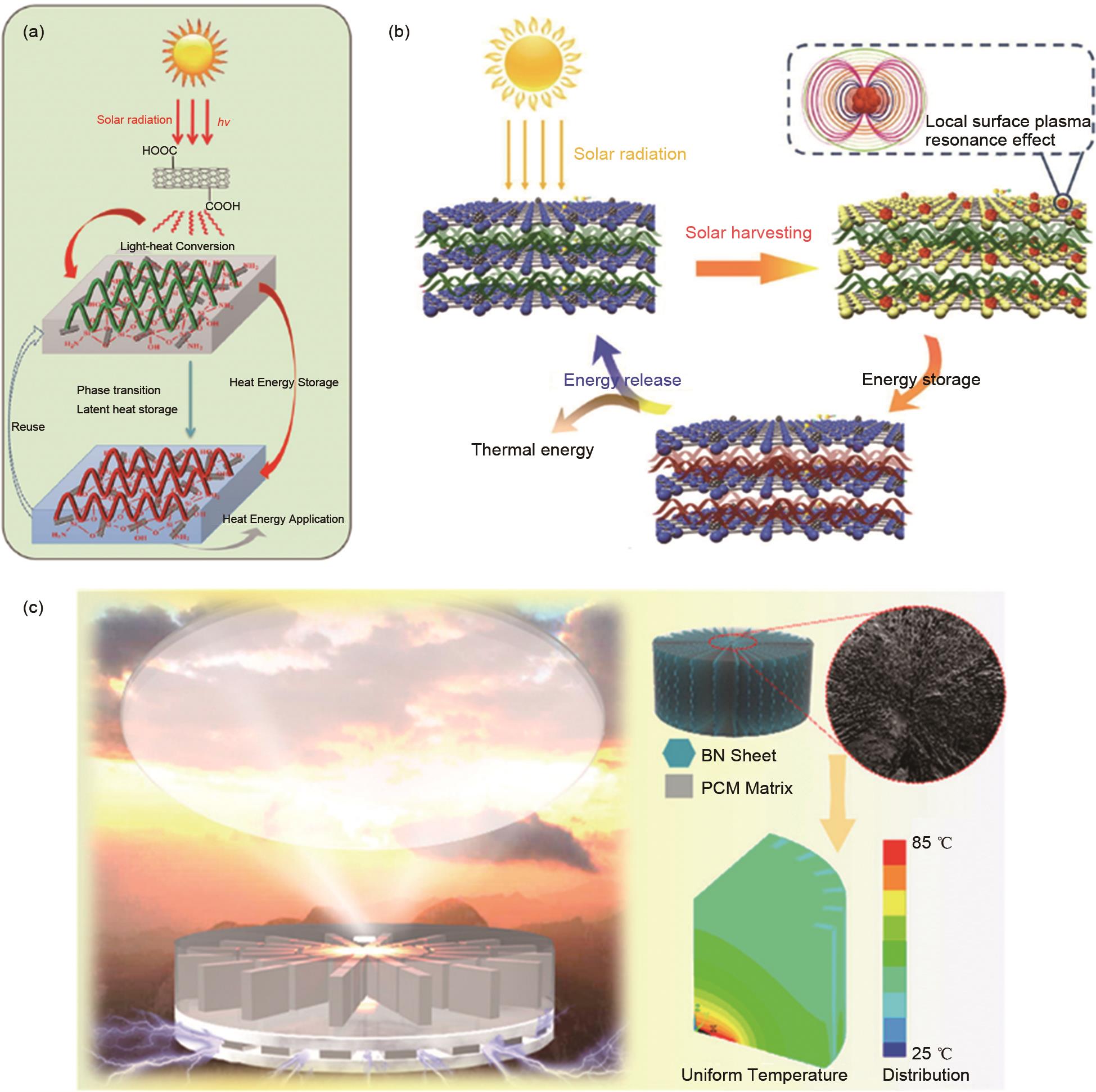

Fig. 4

(a) Principle of photothermal conversion of novel photoinduced phase change materials [93]; (b) Principle of photothermal energy conversion and storage of phase change materials based on polyethylene glycol and silver nanoparticle functionalized graphene nanosheets[95]; (c) Polyethylene glycol/boron nitride composite phase change materials for solar thermoelectric generators[96]"

| 1 | REDDY K S, MUDGAL V, MALLICK T K. Review of latent heat thermal energy storage for improved material stability and effective load management[J]. Journal of Energy Storage, 2018, 15: 205-227. DOI:10.1016/j.est.2017.11.005. |

| 2 | HUA W S, LV X, ZHANG X L, et al. Research progress of seasonal thermal energy storage technology based on supercooled phase change materials[J]. Journal of Energy Storage, 2023, 67: 107378. DOI:10.1016/j.est.2023.107378. |

| 3 | ARIDI R, YEHYA A. Review on the sustainability of phase-change materials used in buildings[J]. Energy Conversion and Management: X, 2022, 15: 100237. DOI:10.1016/j.ecmx.2022. 100237. |

| 4 | FU T W, WANG W Z, FANG G Y. Thermal properties and applications of form-stable phase change materials for thermal energy storage and thermal management: A review[J]. Energy Storage, 2024, 6(1): e533. DOI:10.1002/est2.533. |

| 5 | SINGH S P, BHAT V. Applications of organic phase change materials for thermal comfort in buildings[J]. Reviews in Chemical Engineering, 30(5): 521-538. DOI:10.1515/revce-2014-0015 |

| 6 | KOU Y, WANG S Y, LUO J P, et al. Thermal analysis and heat capacity study of polyethylene glycol (PEG) phase change materials for thermal energy storage applications[J]. The Journal of Chemical Thermodynamics, 2019, 128: 259-274. DOI:10.1016/j. jct.2018.08.031. |

| 7 | KIM A, WERT N A, GOWD E B, et al. Recent progress in PEG-based composite phase change materials[J]. Polymer Reviews, 2023, 63(4): 1078-1129. DOI:10.1080/15583724.2023.2220041. |

| 8 | LIU L K, SU D, TANG Y J, et al. Thermal conductivity enhancement of phase change materials for thermal energy storage: A review[J]. Renewable and Sustainable Energy Reviews, 2016, 62: 305-317. DOI:10.1016/j.rser.2016.04.057. |

| 9 | WU S F, YAN T, KUAI Z H, et al. Thermal conductivity enhancement on phase change materials for thermal energy storage: A review[J]. Energy Storage Materials, 2020, 25: 251-295. DOI:10.1016/j.ensm.2019.10.010. |

| 10 | PRAJAPATI D G, KANDASUBRAMANIAN B. Biodegradable polymeric solid framework-based organic phase-change materials for thermal energy storage[J]. Industrial & Engineering Chemistry Research, 2019, 58(25): 10652-10677. DOI:10.1021/acs.iecr.9b01693. |

| 11 | CHENG P, TANG Z D, GAO Y, et al. Flexible engineering of advanced phase change materials[J]. iScience, 2022, 25(5): 104226. DOI:10.1016/j.isci.2022.104226. |

| 12 | GHADIM H B, GODIN A, VEILLERE A, et al. Review of thermal management of electronics and phase change materials[J]. Renewable and Sustainable Energy Reviews, 2025, 208: 115039. DOI:10.1016/j.rser.2024.115039. |

| 13 | CHEN Y, DING H, WANG B F, et al. Dopamine functionalization for improving crystallization behaviour of polyethylene glycol in shape-stable phase change material with silica fume as the matrix[J]. Journal of Cleaner Production, 2019, 208: 951-959. DOI:10.1016/j.jclepro.2018.10.207. |

| 14 | SARı A, OUIKHALFAN M, CHEHOUANI H, et al. Form-stabilized polyethylene glycol/palygorskite composite phase change material: Thermal energy storage properties, cycling stability, and thermal durability[J]. Polymer Engineering & Science, 2020, 60(5): 909-916. DOI:10.1002/pen.25346. |

| 15 | TAS C E, UNAL H. Thermally buffering polyethylene/halloysite/phase change material nanocomposite packaging films for cold storage of foods[J]. Journal of Food Engineering, 2021, 292: 110351. DOI:10.1016/j.jfoodeng.2020.110351. |

| 16 | 鄢冬茂, 蔡文蓉, 殷国强, 等. PEG/APS-SiO2/O-CNTs导热增强相变材料的制备及性能[J]. 精细化工, 2021, 38(4): 729-735. DOI: 10.13550/j.jxhg.20200877. |

| YAN D M, CAI W R, YIN G Q, et al. Preparation and properties of PEG/APS-SiO2/O-CNTs phase change materials with enhanced thermal conductivity[J]. Fine Chemicals, 2021, 38(4): 729-735. DOI: 10.13550/j.jxhg.20200877. | |

| 17 | LEI C X, WU K, WU L Y, et al. Phase change material with anisotropically high thermal conductivity and excellent shape stability due to its robust cellulose/BNNSs skeleton[J]. Journal of Materials Chemistry A, 2019, 7(33): 19364-19373. DOI:10.1039/C9TA05067A. |

| 18 | XIANG H X, ZHOU J L, ZHANG Y K, et al. Polyethylene glycol infused acid-etched halloysite nanotubes for melt-spun polyamide-based composite phase change fibers[J]. Applied Clay Science, 2019, 182: 105249. DOI:10.1016/j.clay.2019.105249. |

| 19 | SONG S K, QIU F, ZHU W T, et al. Polyethylene glycol/halloysite@Ag nanocomposite PCM for thermal energy storage: Simultaneously high latent heat and enhanced thermal conductivity[J]. Solar Energy Materials and Solar Cells, 2019, 193: 237-245. DOI:10.1016/j.solmat.2019.01.023. |

| 20 | LIANG B, LU X, LI R P, et al. Solvent-free preparation of bio-based polyethylene glycol/wood flour composites as novel shape-stabilized phase change materials for solar thermal energy storage[J]. Solar Energy Materials and Solar Cells, 2019, 200: 110037. DOI:10.1016/j.solmat.2019.110037. |

| 21 | WANG C M, CHEN K, HUANG J, et al. Thermal behavior of polyethylene glycol based phase change materials for thermal energy storage with multiwall carbon nanotubes additives[J]. Energy, 2019, 180: 873-880. DOI:10.1016/j.energy.2019.05.163. |

| 22 | AL-BERMANY E, CHEN B Q. Preparation and characterisation of poly(ethylene glycol)-adsorbed graphene oxide nanosheets[J]. Polymer International, 2021, 70(3): 341-351. DOI:10.1002/pi. 6140. |

| 23 | LI Y, LI Y Q, HUANG X B, et al. Graphene-CoO/PEG composite phase change materials with enhanced solar-to-thermal energy conversion and storage capacity[J]. Composites Science and Technology, 2020, 195: 108197. DOI:10.1016/j.compscitech. 2020.108197. |

| 24 | YUAN P, ZHANG P, LIANG T, et al. Effects of surface functionalization on thermal and mechanical properties of graphene/polyethylene glycol composite phase change materials[J]. Applied Surface Science, 2019, 485: 402-412. DOI:10.1016/j.apsusc.2019.04.011. |

| 25 | HE Y F, LI H Z, LUO F B, et al. Bio-based flexible phase change composite film with high thermal conductivity for thermal energy storage[J]. Composites Part A: Applied Science and Manufacturing, 2021, 151: 106638. DOI:10.1016/j.compositesa. 2021.106638. |

| 26 | SARI A, ALKAN C, KARAIPEKLI A, et al. Poly(ethylene glycol)/poly(methyl methacrylate) blends as novel form-stable phase-change materials for thermal energy storage[J]. Journal of Applied Polymer Science, 2010, 116(2): 929-933. DOI:10.1002/app.31623. |

| 27 | ZHANG L, ZHU J Q, ZHOU W B, et al. Characterization of polymethyl methacrylate/polyethylene glycol/aluminum nitride composite as form-stable phase change material prepared by in situ polymerization method[J]. Thermochimica Acta, 2011, 524(1/2): 128-134. DOI:10.1016/j.tca.2011.07.003. |

| 28 | BING N C, YANG J, GAO H, et al. Unsaturated polyester resin supported form-stable phase change materials with enhanced thermal conductivity for solar energy storage and conversion[J]. Renewable Energy, 2021, 173: 926-933. DOI:10.1016/j.renene. 2021.04.033. |

| 29 | YUAN H M, LIU S T, LI T H, et al. Review on thermal properties with influence factors of solid-liquid organic phase-change micro/nanocapsules[J]. Energies, 2024, 17(3): 604. DOI:10.3390/en17030604. |

| 30 | ALVA G, LIN Y X, LIU L K, et al. Synthesis, characterization and applications of microencapsulated phase change materials in thermal energy storage: A review[J]. Energy and Buildings, 2017, 144: 276-294. DOI:10.1016/j.enbuild.2017.03.063. |

| 31 | JAFARPOUR M, FATHI M, SOLTANIZADEH N. Encapsulation of polyethylene glycol as a phase change material using alginate microbeads to prevent temperature fluctuation- Case study: Fish packaging[J]. Food Hydrocolloids, 2023, 134: 108029. DOI:10.1016/j.foodhyd.2022.108029. |

| 32 | LI J W, MENG L N, CHEN J X, et al. Encapsulation of polyethylene glycol in cellulose-based porous capsules for latent heat storage and light-to-thermal conversion[J]. Frontiers of Chemical Science and Engineering, 2023, 17(8): 1038-1050. DOI:10.1007/s11705-022-2279-3. |

| 33 | SUN Z, SUN K, ZHANG H Z, et al. Development of poly(ethylene glycol)/silica phase-change microcapsules with well-defined core-shell structure for reliable and durable heat energy storage[J]. Solar Energy Materials and Solar Cells, 2021, 225: 111069. DOI:10.1016/j.solmat.2021.111069. |

| 34 | KUMAR A, JAIN H, TRIPATHI B P. Synthesis and nanoencapsulation of poly(ethylene glycol)-distearates phase change materials for latent heat storage and release[J]. ACS Applied Energy Materials, 2020, 3(6): 5965-5976. DOI:10.1021/acsaem.0c00895. |

| 35 | 唐茜. 适用于储油罐控温的聚乙二醇定形相变材料的研发与性能研究[D]. 舟山: 浙江海洋大学, 2020. DOI:10.27747/d.cnki.gzjhy.2020.000043. |

| TANG X. The study on preparation and properties of composite phase change material for temperature control of oil storage tank[D]. Zhoushan: Zhejiang Ocean University, 2020. DOI:10.27747/d.cnki.gzjhy.2020.000043. | |

| 36 | WANG R, KANG Y J, LEI T X, et al. Microcapsules composed of stearic acid core and polyethylene glycol-based shell as a microcapsule phase change material[J]. International Journal of Energy Research, 2021, 45(6): 9677-9684. DOI:10.1002/er.6431. |

| 37 | 陈家东, 佘静, 李发兵, 等. 相变纤维制备及其应用研究进展[J]. 化工新型材料, 2023, 51(4): 51-57, 65. DOI: 10.19817/j.cnki.issn1006-3536.2023.04.009. |

| CHEN J D, SHE J, LI F B, et al. Research progress on preparation and application of phase change fiber[J]. New Chemical Materials, 2023, 51(4): 51-57, 65. DOI: 10.19817/j.cnki.issn1006-3536.2023.04.009. | |

| 38 | YANG Y, WANG H Y, DAI T L, et al. Review on the preparation methods and the research hot spots and development of phase change fibers based on thermoregulation[J]. Journal of Materials Science, 2024, 59(35): 16355-16382. DOI:10.1007/s10853-024-10148-y. |

| 39 | FENG W, ZHANG Y S, SHAO Y W, et al. Coaxial electrospun membranes with thermal energy storage and shape memory functions for simultaneous thermal/moisture management in personal cooling textiles[J]. European Polymer Journal, 2021, 145: 110245. DOI:10.1016/j.eurpolymj.2020.110245. |

| 40 | BABAPOOR A, KARIMI G, GOLESTANEH S I, et al. Coaxial electro-spun PEG/PA6 composite fibers: Fabrication and characterization[J]. Applied Thermal Engineering, 2017, 118: 398-407. DOI:10.1016/j.applthermaleng.2017.02.119. |

| 41 | 徐瑾, 陈龙, 王金玉, 等. 聚乙二醇@聚乙烯醇同轴相变纤维的储热特性[J]. 高分子材料科学与工程, 2024, 40(5): 134-143. DOI: 10.16865/j.cnki.1000-7555.2024.0092. |

| XU J, CHEN L, WANG J Y, et al. Thermal storage properties of poly(ethylene glycol)@poly(vinyl alcohol)coaxial phase change fibers[J]. Polymer Materials Science & Engineering, 2024, 40(5): 134-143. DOI: 10.16865/j.cnki.1000-7555.2024.0092. | |

| 42 | JI R, ZHANG Q F, ZHOU F X, et al. Electrospinning fabricated novel poly (ethylene glycol)/graphene oxide composite phase-change nano-fibers with good shape stability for thermal regulation[J]. Journal of Energy Storage, 2021, 40: 102687. DOI:10.1016/j.est.2021.102687. |

| 43 | ZHANG X G, WU B G, CHEN G, et al. Preparation and characterization of flexible smart glycol/polyvinylpyrrolidone/nano-Al2O3 phase change fibers[J]. Energy & Fuels, 2021, 35(1): 877-882. DOI:10.1021/acs.energyfuels.0c03370. |

| 44 | CHEN G, SHI T T, ZHANG X G, et al. Polyacrylonitrile/polyethylene glycol phase-change material fibres prepared with hybrid polymer blends and nano-SiC fillers via centrifugal spinning[J]. Polymer, 2020, 186: 122012. DOI:10.1016/j.polymer.2019.122012. |

| 45 | CHEN Z Y, ZHOU J L, JIANG Y, et al. Preparation of form-stable silica/polyethylene glycol composites using flash-drying for large-scale melt-spun fibers with thermal management property[J]. Polymer Engineering & Science, 2023, 63(2): 454-466. DOI:10. 1002/pen.26220. |

| 46 | FANG H, LIN J L, ZHANG L J, et al. Fibrous form-stable phase change materials with high thermal conductivity fabricated by interfacial polyelectrolyte complex spinning[J]. Carbohydrate Polymers, 2020, 249: 116836. DOI:10.1016/j.carbpol.2020. 116836. |

| 47 | WANG H, LEI J, WU T F, et al. Effect of boron nitride on the heat transfer and heat storage of poly(ethylene glycol)/expanded vermiculite composite phase-change materials[J]. ACS Omega, 2022, 7(2): 2438-2443. DOI:10.1021/acsomega.1c06502. |

| 48 | 徐山木. 膨胀珍珠岩/PEG相变储热材料及在粉煤灰蓄热砖应用研究[D]. 北京: 中国地质大学(北京), 2019. DOI:10.27493/d.cnki.gzdzy.2019.001376. |

| XU S M. The preparation and characterization of thermal conductivity enhanced expanded perlite/PEG phase change materials and its application in fly ash thermal storage brick[D]. Beijing: China University of Geosciences (Beijing), 2019. DOI:10.27493/d.cnki.gzdzy.2019.001376. | |

| 49 | REN J C, JIANG X Y, HAN X S, et al. Delignified sorghum straw/PEG/EP phase change composites: Combining biomass source, form-stabilities, and high performances[J]. Materials Letters, 2023, 349: 134799. DOI:10.1016/j.matlet.2023.134799. |

| 50 | QIAN T T, ZHU S K, WANG H L, et al. Comparative study of carbon nanoparticles and single-walled carbon nanotube for light-heat conversion and thermal conductivity enhancement of the multifunctional PEG/diatomite composite phase change material[J]. ACS Applied Materials & Interfaces, 2019, 11(33): 29698-29707. DOI:10.1021/acsami.9b04349. |

| 51 | MALEKI M, KARIMIAN H, SHOKOUHIMEHR M, et al. Development of graphitic domains in carbon foams for high efficient electro/photo-to-thermal energy conversion phase change composites[J]. Chemical Engineering Journal, 2019, 362: 469-481. DOI:10.1016/j.cej.2019.01.032. |

| 52 | LI Y Q, HUANG X B, LV J J, et al. Enzymolysis-treated wood-derived hierarchical porous carbon for fluorescence-functionalized phase change materials[J]. Composites Part B: Engineering, 2022, 234: 109735. DOI:10.1016/j.compositesb. 2022.109735. |

| 53 | FENG D L, LI P, FENG Y H, et al. Using mesoporous carbon to pack polyethylene glycol as a shape-stabilized phase change material with excellent energy storage capacity and thermal conductivity[J]. Microporous and Mesoporous Materials, 2021, 310: 110631. DOI:10.1016/j.micromeso.2020.110631. |

| 54 | YANG J, TANG L S, BAO R Y, et al. An ice-templated assembly strategy to construct graphene oxide/boron nitride hybrid porous scaffolds in phase change materials with enhanced thermal conductivity and shape stability for light-thermal-electric energy conversion[J]. Journal of Materials Chemistry A, 2016, 4(48): 18841-18851. DOI:10.1039/C6TA08454K. |

| 55 | YANG G Q, ZHAO L Y, SHEN C F, et al. Boron nitride microsheets bridged with reduced graphene oxide as scaffolds for multifunctional shape stabilized phase change materials[J]. Solar Energy Materials and Solar Cells, 2020, 209: 110441. DOI:10.1016/j.solmat.2020.110441. |

| 56 | LU X, HUANG H W, ZHANG X Y, et al. Novel light-driven and electro-driven polyethylene glycol/two-dimensional MXene form-stable phase change material with enhanced thermal conductivity and electrical conductivity for thermal energy storage[J]. Composites Part B: Engineering, 2019, 177: 107372. DOI:10. 1016/j.compositesb.2019.107372. |

| 57 | DU Y, HUANG H W, HU X P, et al. Melamine foam/polyethylene glycol composite phase change material synergistically modified by polydopamine/MXene with enhanced solar-to-thermal conversion[J]. Renewable Energy, 2021, 171: 1-10. DOI:10.1016/j.renene.2021.02.077. |

| 58 | XIA Z G, LI C E, YU H, et al. Experimental study of a passive thermal management system using expanded graphite/polyethylene glycol composite for lithium-ion batteries[J]. Energies, 2023, 16(23): 7786. DOI:10.3390/en16237786. |

| 59 | FANG Y, LIU S, LI X L, et al. Biomass porous potatoes/MXene encapsulated PEG-based PCMs with improved photo-to-thermal conversion capability[J]. Solar Energy Materials and Solar Cells, 2022, 237: 111559. DOI:10.1016/j.solmat.2021.111559. |

| 60 | LIAO H H, CHEN W H, LIU Y, et al. A phase change material encapsulated in a mechanically strong graphene aerogel with high thermal conductivity and excellent shape stability[J]. Composites Science and Technology, 2020, 189: 108010. DOI:10.1016/j.compscitech.2020.108010. |

| 61 | SHEN J, ZHANG P, SONG L X, et al. Polyethylene glycol supported by phosphorylated polyvinyl alcohol/graphene aerogel as a high thermal stability phase change material[J]. Composites Part B: Engineering, 2019, 179: 107545. DOI:10.1016/j.compositesb.2019.107545. |

| 62 | WANG M M, ZHANG T, MAO D S, et al. Highly compressive boron nitride nanotube aerogels reinforced with reduced graphene oxide[J]. ACS Nano, 2019, 13(7): 7402-7409. DOI:10.1021/acsnano.9b03225. |

| 63 | HU W W, SHI X Y, GAO M H, et al. Light-actuated shape memory and self-healing phase change composites supported by MXene/waterborne polyurethane aerogel for superior solar-thermal energy storage[J]. Composites Communications, 2021, 28: 100980. DOI:10.1016/j.coco.2021.100980. |

| 64 | LIU Z L, TANG B T, ZHANG S F. Novel network structural PEG/PAA/SiO2 composite phase change materials with strong shape stability for storing thermal energy[J]. Solar Energy Materials and Solar Cells, 2020, 216: 110678. DOI:10.1016/j.solmat.2020.1 10678. |

| 65 | CHEN Y H, PEI Y L, YANG X. Synthesis and performance analysis of a novel phase change hydrogel polyethylene glycol/polyacrylamide/silicon dioxide for thermal energy storage[J]. Materials Science, 2023, 29(3): 316-322. DOI:10.5755/j02.ms. 32914. |

| 66 | ZHOU L, TANG L S, TAO X F, et al. Facile fabrication of shape-stabilized polyethylene glycol/cellulose nanocrystal phase change materials based on thiol-ene click chemistry and solvent exchange[J]. Chemical Engineering Journal, 2020, 396: 125206. DOI:10.1016/j.cej.2020.125206. |

| 67 | WANG R, LI Q Y, DU G T, et al. A hydrogel-like form-stable phase change material with high loading efficiency supported by a three dimensional metal-organic network[J]. Chemical Engineering Journal, 2021, 420: 129898. DOI:10.1016/j.cej.2021.129898. |

| 68 | ATINAFU D G, DONG W J, BERARDI U, et al. Phase change materials stabilized by porous metal supramolecular gels: Gelation effect on loading capacity and thermal performance[J]. Chemical Engineering Journal, 2020, 394: 124806. DOI:10.1016/j.cej.2020.124806. |

| 69 | ALKAN C, GÜNTHER E, HIEBLER S, et al. Polyurethanes as solid-solid phase change materials for thermal energy storage[J]. Solar Energy, 2012, 86(6): 1761-1769. DOI:10.1016/j.solener. 2012.03.012. |

| 70 | KOU Y, SUN K Y, LUO J P, et al. An intrinsically flexible phase change film for wearable thermal managements[J]. Energy Storage Materials, 2021, 34: 508-514. DOI:10.1016/j.ensm. 2020.10.014. |

| 71 | GAO N, TANG T, XIANG H X, et al. Preparation and structure-properties of crosslinking organic montmorillonite/polyurethane as solid-solid phase change materials for thermal energy storage[J]. Solar Energy Materials and Solar Cells, 2022, 244: 111831. DOI:10.1016/j.solmat.2022.111831. |

| 72 | WANG J W, WU Z H, XIE H Q, et al. Effect of different soft segment contents on the energy storage capacity and photo–thermal performance of polyurethane-based/graphene oxide composite solid-solid phase change materials[J]. Polymers, 2022, 14(23): 5161. DOI:10.3390/polym14235161. |

| 73 | XIA Y P, ZHANG H Z, HUANG P R, et al. Graphene-oxide-induced lamellar structures used to fabricate novel composite solid-solid phase change materials for thermal energy storage[J]. Chemical Engineering Journal, 2019, 362: 909-920. DOI:10.1016/j.cej.2019.01.097. |

| 74 | PIELICHOWSKA K, BIEDA J, SZATKOWSKI P. Polyurethane/graphite nano-platelet composites for thermal energy storage[J]. Renewable Energy, 2016, 91: 456-465. DOI:10.1016/j.renene. 2016.01.076. |

| 75 | XIA Y P, LI Q T, JI R, et al. Multielement synergetic effect of boron nitride and multiwalled carbon nanotubes for the fabrication of novel shape-stabilized phase-change composites with enhanced thermal conductivity[J]. ACS Applied Materials & Interfaces, 2020, 12(37): 41398-41409. DOI:10.1021/acsami. 0c11002. |

| 76 | ALVA G, LIN Y X, FANG G Y. Synthesis and characterization of chain-extended and branched polyurethane copolymers as form stable phase change materials for solar thermal conversion storage[J]. Solar Energy Materials and Solar Cells, 2018, 186: 14-28. DOI:10.1016/j.solmat.2018.06.023. |

| 77 | WANG R, XIAO Y, LEI J X. A solid-solid phase change material based on dynamic ion cross-linking with reprocessability at room temperature[J]. Chemical Engineering Journal, 2020, 390: 124586. DOI:10.1016/j.cej.2020.124586. |

| 78 | REUBEN RAJ C, SURESH S, VASUDEVAN S, et al. Thermal performance of nano-enriched form-stable PCM implanted in a pin finned wall-less heat sink for thermal management application[J]. Energy Conversion and Management, 2020, 226: 113466. DOI:10.1016/j.enconman.2020.113466. |

| 79 | WU W H, HUANG X Y, LI K, et al. A functional form-stable phase change composite with high efficiency electro-to-thermal energy conversion[J]. Applied Energy, 2017, 190: 474-480. DOI:10.1016/j.apenergy.2016.12.159. |

| 80 | LU X, HUANG J T, WONG W Y, et al. A novel bio-based polyurethane/wood powder composite as shape-stable phase change material with high relative enthalpy efficiency for solar thermal energy storage[J]. Solar Energy Materials and Solar Cells, 2019, 200: 109987. DOI:10.1016/j.solmat.2019.109987. |

| 81 | SHI J M, AFTAB W, LIANG Z B, et al. Tuning the flexibility and thermal storage capacity of solid-solid phase change materials towards wearable applications[J]. Journal of Materials Chemistry A, 2020, 8(38): 20133-20140. DOI:10.1039/C9TA13925G. |

| 82 | LU X, FANG C, SHENG X X, et al. One-step and solvent-free synthesis of polyethylene glycol-based polyurethane As solid–solid phase change materials for solar thermal energy storage[J]. Industrial & Engineering Chemistry Research, 2019, 58(8): 3024-3032. DOI:10.1021/acs.iecr.8b05903. |

| 83 | GONG S, DING Y, LI X L, et al. Novel flexible polyurethane/MXene composites with sensitive solar thermal energy storage behavior[J]. Composites Part A: Applied Science and Manufacturing, 2021, 149: 106505. DOI:10.1016/j.compositesa. 2021.106505. |

| 84 | LIAO Y N, LI J, LI S W, et al. Super-elastic and shape-stable solid-solid phase change materials for thermal management of electronics[J]. Journal of Energy Storage, 2022, 52: 104751. DOI:10.1016/j.est.2022.104751. |

| 85 | FAN X, PU Z A, ZHU M, et al. Solvent-free synthesis of PEG modified polyurethane solid-solid phase change materials with different MW for thermal energy storage[J]. Colloid and Polymer Science, 2021, 299(5): 835-843. DOI:10.1007/s00396-020-04804-3. |

| 86 | WU M Q, LI T X, WANG P F, et al. Dual-encapsulated highly conductive and liquid-free phase change composites enabled by polyurethane/graphite nanoplatelets hybrid networks for efficient energy storage and thermal management[J]. Small, 2022, 18(9): e2105647. DOI:10.1002/smll.202105647. |

| 87 | WEI X, JIN X Z, ZHANG N, et al. Constructing cellulose nanocrystal/graphene nanoplatelet networks in phase change materials toward intelligent thermal management[J]. Carbohydrate Polymers, 2021, 253: 117290. DOI:10.1016/j.carbpol.2020.117290. |

| 88 | XIAO Y Y, HE Y J, WANG R Q, et al. Mussel-inspired strategy to construct 3D silver nanoparticle network in flexible phase change composites with excellent thermal energy management and electromagnetic interference shielding capabilities[J]. Composites Part B: Engineering, 2022, 239: 109962. DOI:10.1016/j.compositesb.2022.109962. |

| 89 | VENKATAKRISHNAN P, PALANISAMY P. A state-of-the-art review on advancements in phase change material encapsulation techniques for electronics cooling[J]. Physica Scripta, 2023, 98(11): 112001. DOI:10.1088/1402-4896/ad0000. |

| 90 | YE G H, ZHANG G Q, JIANG L Q, et al. Temperature control of battery modules through composite phase change materials with dual operating temperature regions[J]. Chemical Engineering Journal, 2022, 449: 137733. DOI:10.1016/j.cej.2022.137733. |

| 91 | XU Z P, CHEN W H, WU T T, et al. Thermal management system study of flame retardant solid-solid phase change material battery[J]. Surfaces and Interfaces, 2023, 36: 102558. DOI:10.1016/j.surfin.2022.102558. |

| 92 | ZHANG Y A, UMAIR M M, ZHANG S F, et al. Phase change materials for electron-triggered energy conversion and storage: A review[J]. Journal of Materials Chemistry A, 2019, 7(39): 22218-22228. DOI:10.1039/C9TA06678K. |

| 93 | YAN D M, MING W X, LIU S, et al. Polyethylene glycol (PEG)/silicon dioxide grafted aminopropyl group and carboxylic multi-walled carbon nanotubes (SAM) composite as phase change material for light-to-heat energy conversion and storage[J]. Journal of Energy Storage, 2021, 36: 102428. DOI:10.1016/j.est. 2021.102428. |

| 94 | ZHENG Z H, SHI T, LIU H, et al. Polyimide/phosphorene hybrid aerogel-based composite phase change materials for high-efficient solar energy capture and photothermal conversion[J]. Applied Thermal Engineering, 2022, 207: 118173. DOI:10.1016/j.applthermaleng.2022.118173. |

| 95 | ZHANG Y A, WANG J S, QIU J J, et al. Ag-graphene/PEG composite phase change materials for enhancing solar-thermal energy conversion and storage capacity[J]. Applied Energy, 2019, 237: 83-90. DOI:10.1016/j.apenergy.2018.12.075. |

| 96 | LIU D Y, LEI C X, WU K, et al. A multidirectionally thermoconductive phase change material enables high and durable electricity via real-environment solar-thermal-electric conversion[J]. ACS Nano, 2020, 14(11): 15738-15747. DOI:10. 1021/acsnano.0c06680. |

| 97 | ZHENG Z H, LIU H, WU D Z, et al. Polyimide/MXene hybrid aerogel-based phase-change composites for solar-driven seawater desalination[J]. Chemical Engineering Journal, 2022, 440: 135862. DOI:10.1016/j.cej.2022.135862. |

| 98 | XIAO S K, HU X W, JIANG L, et al. Nano-Ag modified bio-based loofah foam/polyethylene glycol composite phase change materials with higher photo-thermal conversion efficiency and thermal conductivity[J]. Journal of Energy Storage, 2022, 54: 105238. DOI:10.1016/j.est.2022.105238. |

| 99 | XIE Y H, LI W J, HUANG H W, et al. Bio-based Radish@PDA/PEG sandwich composite with high efficiency solar thermal energy storage[J]. ACS Sustainable Chemistry & Engineering, 2020, 8(22): 8448-8457. DOI:10.1021/acssuschemeng.0c02959. |

| 100 | JIAO K, LU L, WEN T, et al. Endowing photothermal materials with latent heat storage: A state-of-art review on photothermal PCMs[J]. Chemical Engineering Journal, 2024, 500: 156498. DOI:10.1016/j.cej.2024.156498. |

| 101 | RATHORE P K S, SHUKLA S K. Enhanced thermophysical properties of organic PCM through shape stabilization for thermal energy storage in buildings: A state of the art review[J]. Energy and Buildings, 2021, 236: 110799. DOI:10.1016/j.enbuild. 2021.110799. |

| 102 | SHI J B, LI M. Synthesis and characterization of polyethylene glycol/modified attapulgite form-stable composite phase change material for thermal energy storage[J]. Solar Energy, 2020, 205: 62-73. DOI:10.1016/j.solener.2020.05.064. |

| 103 | SUKONTASUKKUL P, UTHAICHOTIRAT P, SANGPET T, et al. Thermal properties of lightweight concrete incorporating high contents of phase change materials[J]. Construction and Building Materials, 2019, 207: 431-439. DOI:10.1016/j.conbuildmat. 2019. 02.152. |

| 104 | XU J Q, YANG T T, XU X, et al. Processing solid wood into a composite phase change material for thermal energy storage by introducing silica-stabilized polyethylene glycol[J]. Composites Part A: Applied Science and Manufacturing, 2020, 139: 106098. DOI:10.1016/j.compositesa.2020.106098. |

| 105 | SUN J M, ZHAO J Q, ZHANG W Y, et al. Composites with a novel core-shell structural expanded perlite/polyethylene glycol composite PCM as novel green energy storage composites for building energy conservation[J]. Applied Energy, 2023, 330: 120363. DOI:10.1016/j.apenergy.2022.120363. |

| 106 | MONTANARI C, LI Y Y, CHEN H, et al. Transparent wood for thermal energy storage and reversible optical transmittance[J]. ACS Applied Materials & Interfaces, 2019, 11(22): 20465-20472. DOI:10.1021/acsami.9b05525. |

| 107 | XIA R Q, ZHANG W Y, YANG Y N, et al. Transparent wood with phase change heat storage as novel green energy storage composites for building energy conservation[J]. Journal of Cleaner Production, 2021, 296: 126598. DOI:10.1016/j.jclepro. 2021.126598. |

| 108 | CHEN Y, WANG H N, YOU Z P, et al. Application of phase change material in asphalt mixture—A review[J]. Construction and Building Materials, 2020, 263: 120219. DOI:10.1016/j.conbuildmat.2020.120219. |

| 109 | WEI K, MA B, DUAN S Y. Preparation and properties of bitumen-modified polyurethane solid-solid phase change materials[J]. Journal of Materials in Civil Engineering, 2019, 31(8): DOI:10.1061/(asce)mt.1943-5533.0002795 |

| 110 | CHENG P, GAO H Y, CHEN X, et al. Flexible monolithic phase change material based on carbon nanotubes/chitosan/poly(vinyl alcohol)[J]. Chemical Engineering Journal, 2020, 397: 125330. DOI:10.1016/j.cej.2020.125330. |

| 111 | CHEN X, GAO H Y, HAI G T, et al. Carbon nanotube bundles assembled flexible hierarchical framework based phase change material composites for thermal energy harvesting and thermotherapy[J]. Energy Storage Materials, 2020, 26: 129-137. DOI:10.1016/j.ensm.2019.12.029. |

| 112 | DONG J K, SHI W Z, LIU J S, et al. Flexibility and thermal storage properties of polyurethane adhesive supported phase change composites based on polyurethane phase change materials[J]. Fibers and Polymers, 2023, 24(9): 3061-3074. DOI:10.1007/s12221-023-00300-x. |

| [1] | Yixuan LIU, Xiaofen REN, Shanhu TONG, Zhiguo SHI, Xiaohui SHE. Cooling performance of air-cooled evaporator based on phase-change cold storage [J]. Energy Storage Science and Technology, 2025, 14(2): 505-514. |

| [2] | Yan CHEN, Ziqi LI, Nanhao CHEN, Yichi ZHANG, Xiaohong WU, Dazhu CHEN. Advances in polymeric solid-solid phase change materials based on polyethylene glycol [J]. Energy Storage Science and Technology, 2025, 14(1): 124-139. |

| [3] | Yunhan LIU, Liang WANG, Shuang ZHANG, Xipeng LIN, Zhiwei GE, Yakai BAI, Lin LIN, Yifei WANG, Haisheng CHEN. Experimental study on heat storage and discharge characteristics of packed bed based on hydrated salt using cylindrical encapsulation units [J]. Energy Storage Science and Technology, 2024, 13(8): 2623-2633. |

| [4] | Qun GE, Tao LIANG, Bin HOU, Wanhong WANG, Long ZHANG, Liangyu WU, Chengbin ZHANG, Xiangdong LIU. Performance enhancement of thermal energy storage units for plant factories [J]. Energy Storage Science and Technology, 2024, 13(8): 2687-2695. |

| [5] | Songyan LIU, Weiliang WANG, Shiliang PENG, Junfu LYU. Thermal management system for power battery in high/low-temperature environments [J]. Energy Storage Science and Technology, 2024, 13(7): 2181-2191. |

| [6] | Chenyang ZHAO, Xiaokun YU, Yubing TAO. Preparation and characterization of modified CuO nanoparticles/n-octadecane phase change material [J]. Energy Storage Science and Technology, 2024, 13(6): 1786-1793. |

| [7] | Yunfeng ZHANG, Xuewen ZHANG, Wei ZHONG, Duwei JIANG, Zewei CHEN, Jie ZHANG. Numerical simulation of heat transfer performance of plate-fin radiator reinforced with double cascade phase change material of paraffin and low melting point alloy [J]. Energy Storage Science and Technology, 2024, 13(5): 1460-1470. |

| [8] | Hongbing CHEN, Yuhang LIU, Congcong WANG, Men LI, Yan ZHANG, Haoyang LU, Chunyang LI. Properties of composite shape-stabilized phase change materials incorporating docosane and dodecyl alcohol with added expanded graphite [J]. Energy Storage Science and Technology, 2024, 13(2): 396-404. |

| [9] | Mengqiong SONG, Yu PENG, Ziqiang LIAO. Research on battery thermal management based on electrochemical model [J]. Energy Storage Science and Technology, 2024, 13(2): 578-585. |

| [10] | Peng NI, Shihao CAO. Melting heat storage properties of metal honeycomb/paraffin composite phase change materials [J]. Energy Storage Science and Technology, 2024, 13(2): 425-435. |

| [11] | Jianlong DAI, Guo LI, Yitong CAO, Zihan YANG, Zhiyuan XIA, Gongshuo ZHANG, Rui CHEN, Nan SHENG, Chunyu ZHU. Enhancing phase change heat storage performance of paraffin using porous metal foam [J]. Energy Storage Science and Technology, 2024, 13(11): 3764-3771. |

| [12] | Bokang YAN, Linfeng LI, Yuanyuan LI, Xiaomin CHENG. Preparation and thermal properties of SSD/PAM-SA dual-network composite phase change hydrogels [J]. Energy Storage Science and Technology, 2024, 13(10): 3369-3375. |

| [13] | Hailan WANG, Xiaoyu ZHANG, Jianhong GUO, Yong ZHAO, Zhuo CHEN, Yibo WANG. Numerical analysis of heat transfer performance in a shell-and-tube heat storage unit based using medium-low temperature phase change material [J]. Energy Storage Science and Technology, 2024, 13(10): 3376-3387. |

| [14] | Jiangtian ZHU, Yuan ZHANG, Yibin LUO, Huiting YANG, Jie LI, Xiaoqin SUN. Optimization of 5G communication base station cabinet based on heat storage of phase change material [J]. Energy Storage Science and Technology, 2023, 12(9): 2789-2798. |

| [15] | Min ZHAO, Yang LI, Jie CAI, Weibin KANG, Lei LIU. Experimental study on the performance of capillary phase-change energy storage tank for civil building [J]. Energy Storage Science and Technology, 2023, 12(8): 2626-2637. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||