储能科学与技术 ›› 2023, Vol. 12 ›› Issue (2): 431-458.doi: 10.19799/j.cnki.2095-4239.2022.0605

戴宇成1( ), 王增鹏2, 刘凯豹1, 赵佳腾1(

), 王增鹏2, 刘凯豹1, 赵佳腾1( ), 刘昌会1(

), 刘昌会1( )

)

收稿日期:2022-10-19

修回日期:2022-11-26

出版日期:2023-02-05

发布日期:2023-02-24

通讯作者:

赵佳腾,刘昌会

E-mail:TS21130008A31@cumt.edu.cn;zhaojiateng@cumt.edu.cn;liuch915@cumt.edu.cn

作者简介:戴宇成(1998—),男,硕士研究生,研究方向为热管和相变储热,E-mail: TS21130008A31@cumt.edu.cn;基金资助:

Yucheng DAI1( ), Zengpeng WANG2, Kaibao LIU1, Jiateng ZHAO1(

), Zengpeng WANG2, Kaibao LIU1, Jiateng ZHAO1( ), Changhui LIU1(

), Changhui LIU1( )

)

Received:2022-10-19

Revised:2022-11-26

Online:2023-02-05

Published:2023-02-24

Contact:

Jiateng ZHAO, Changhui LIU

E-mail:TS21130008A31@cumt.edu.cn;zhaojiateng@cumt.edu.cn;liuch915@cumt.edu.cn

摘要:

相变储热是具有广阔应用前景的储能技术之一,具有储热密度大、相变温度稳定等优点,但相变材料的热导率低制约了相变储热技术的发展。提升相变材料的热导率和储热器件的传热速率是有效的解决途径。针对相变材料热导率强化研究进展有大量综述,而对于储热器件层面的传热强化的总结较少,本文回顾了近10年国内外在储热器及其传热强化研究方面的进展。为适应不同应用需求,不同类型的相变储热器应运而生,根据储热器的工作模式和结构可以分为管壳式、填充床式、板式、热管式4类,本文系统地介绍了4类储热器的工作原理、优缺点以及强化传热研究,主要比较了结构优化后的储热器与传统储热器的传热速率和储/放热性能,结果指出对储热器的内部结构进行改进及拓展外部结构等方法能有效增加储热容量和储/放热速率,对于提高系统相变储热能力具有积极作用,分析表明后续的研究应该明晰储热器内部多相耦合传热机制,增强储热器对动态工况适应能力,拓宽应用范围。

中图分类号:

戴宇成, 王增鹏, 刘凯豹, 赵佳腾, 刘昌会. 基于相变材料的储热器及其传热强化研究进展[J]. 储能科学与技术, 2023, 12(2): 431-458.

Yucheng DAI, Zengpeng WANG, Kaibao LIU, Jiateng ZHAO, Changhui LIU. Research progress of heat storage and heat transfer enhancement based on phase change materials[J]. Energy Storage Science and Technology, 2023, 12(2): 431-458.

表2

添加翅片提高SHTS性能的总结"

| 文献 | 翅片类型 | 翅片材料 | PCM | 结论 |

|---|---|---|---|---|

| Shen等[ | 纵向翅片 | 铝 | 硝酸钠 | 翅片长度和翅片数的增加减弱了热辐射的作用 |

| Li等[ | 纵向翅片 | 铜 | 石蜡 | 添加纵向翅片后石蜡熔化时间减少54.1% |

| Khan等[ | 纵向翅片 | 铜 | 石蜡 | 石蜡的低热传导率对STHS的影响显著降低 |

| Mahdi等[ | 纵向翅片 | 铝,带金属泡沫条 | RT82 | 带有泡沫条的纵向翅片使PCM熔化速度提高58%,凝固速度提高了42% |

| Pizzolato等[ | 纵向翅片 | 铜 | 高导电材料 | 使用设计良好的翅片可以显著增强PCM熔化和凝固过程,并且减少储热时间 |

| Deng等[ | 径向翅片 | 铜 | 月桂酸 | 采用局部双翅片能够加快熔化速度,翅片布置最佳角度时的PCM完全熔化时间可节省66.7% |

| Paria等[ | 径向翅片 | 铜 | 石蜡 | 翅片密度的增加提升了PCM熔化和凝固过程中的储热速率 |

| Pu等[ | 径向翅片 | 铝 | RT35 | 径向翅片使PCM熔化时间减少了44.0% |

| Li等[ | 径向翅片 | 铜 | 石蜡 | 最佳的穿孔翅片结构使PCM熔化时间缩短了5.49%,装置储热效率提高了0.21% |

| Wang等[ | 径向翅片 | 玻璃、不锈钢、锡、铝基碳化硅、铝和铜 | 棕榈酸甲酯、CaCl2·6H2O、石蜡、正十八烷、聚乙二醇和镓 | 翅片间距较小时,采用较大的翅片高度和厚度对储热性能起到很好效果 |

| Wołoszyn等[ | 螺旋翅片 | 铜 | RT50 | 带螺旋翅片的STHS储热效率提高至77% |

| Rozenfeld等[ | 螺旋翅片 | 铝 | 96%C20H42 | PCM熔化时间减少了了30% |

| Mehta等[ | 螺旋翅片 | 铝 | 硬脂酸 | 螺旋翅片的安装使得储/放热时间分别缩短了41.28%和22.16% |

| Duan等[ | 螺旋翅片 | 铜 | RT82 | 螺旋翅片起到的综合作用较优 |

| Li等[ | 纵向+径向+ 螺旋翅片 | 铝合金 | NePCMs(金属/氧化物纳米颗粒、碳纳米管和石墨烯复合材料) | PCM熔化前期,纵向翅片装置性能较优;而后期螺旋翅片装置的储热效果最好 |

表3

重力热管式储热器总结"

| 参考文献 | 研究设计 | 图片 | PCM | 结论 |

|---|---|---|---|---|

| Ladekar等[ | GHP长度比和直径 |  | 石蜡 | 当HPLR为0.9,直径为18 mm时,系统储热时间增加了近186% |

| 白烨[ | 管径、冷热端高度差等 |  , , | 赤藻糖醇 | 大管径和较大高度差促进HPHS系统实现高效稳定储热过程 |

| Sharifi等[ | GHP蒸发段和冷凝段长度比 |  | 石蜡(正十八烷) | GHP蒸发段与冷凝段长度比对系统温度均匀性的影响较大 |

| Zhao等[ | 新型嵌入式GHP |  | 石蜡 | 新型嵌入式GHP具有良好的传热性能和温度均匀性 |

| Mahdavi等[ | 一级和二级GHP组成热管网络 |  | 镓 | 一级和二级GHP的配置使系统热量输入功率达到了3000 W |

| Motahar等[ | 嵌入式GHP |  | 石蜡(正十八烷) | 嵌入式GHP使PCM熔化时间缩短了53%,凝固时间缩短了49% |

| Tiari等[ | 添加翅片 |  | 硝酸钾 | 增加翅片数量和减小热管间距可以提高系统内部传热速率 |

| Zhang等[ | 翅片和泡沫铜组合 |  | 硝酸钾 | 翅片和泡沫铜的组合大大增强了HPHS的储热性能 |

| Zhang等[ | 添加翅片 |  | 镓 | 随着翅片数从38增加到150,温度均匀性提高了31.7% |

| Liu等[ | 复合颗粒PCM |  | 硝酸盐、硝酸钠、硝酸钾和膨润土 | 系统具有优异的储/放热性能,内部温度均匀性十分良好 |

| Hu等[ | 复合颗粒PCM |  | 硝酸盐、硝酸钠、硝酸钾和膨润土 | 系统在70 ℃以上接近恒温,PCM传热性能优良 |

表4

毛细力热管式储热器总结"

| 文献 | 热管类型 | 图片 | PCM | 结论 |

|---|---|---|---|---|

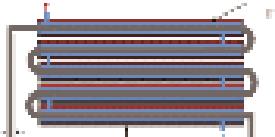

| Wang等[ | 平板热管 |  | 月桂酸 | 新设计的FHP具有很高的传热效率, 并在大风量下减少了系统的热损失 |

| Wang等[ | 平板热管 |  | 石蜡 | 新型HPHS具有热收集效率高和储/放热能量高的优点 |

| Wang等[ | 平板热管 |  | 月桂酸 | 平均热阻从0.084 K/W减小至0.071 K/W, FHP有效热导率随着倾角的增大先减小后增大 |

| Liu等[ | 平板热管 |  | 月桂酸 | 加热和冷却段的长度为160 mm时, 此时HPHS具有最佳的储/放热性能 |

| Diao等[ | 平板热管 |  | 月桂酸 | 增加翅片高度可以有效增加HPHS的储热容量 |

| 蒋俊峰[ | 平板热管 |  | 石蜡 | FHP有效改善了系统的温度均匀性 |

| 钦斌[ | 平板热管 |  | 癸酸 | 冷凝段长度越小,蓄热过程中自然对流现象越明显, PCM整体熔化所需时间越短 |

| Diallo等[ | 环路热管 |  | 石蜡 | 更高的质量流量和更多热管数量可以增强系统的储热效率 |

| Tesfay等[ | 环路热管 |  | 硝酸盐 | HPHS可以有效实现远距离供热 |

| 1 | MAHDI J M, LOHRASBI S, NSOFOR E C. Hybrid heat transfer enhancement for latent-heat thermal energy storage systems: A review[J]. International Journal of Heat and Mass Transfer, 2019, 137: 630-649. |

| 2 | 林文珠, 凌子夜, 方晓明, 等. 相变储热的传热强化技术研究进展[J]. 化工进展, 2021, 40(9): 5166-5179. |

| LIN W Z, LING Z Y, FANG X M, et al. Research progress on heat transfer of phase change material heat storage technology[J]. Chemical Industry and Engineering Progress, 2021, 40(9): 5166-5179. | |

| 3 | 林浩楠. 相变储热材料的研究进展[J]. 冶金与材料, 2021, 41(6): 41-42. |

| LIN H N. Research progress of phase change materials[J]. Metallurgy and Materials, 2021, 41(6): 41-42. | |

| 4 | TAO Y B, HE Y L. A review of phase change material and performance enhancement method for latent heat storage system[J]. Renewable and Sustainable Energy Reviews, 2018, 93: 245-259. |

| 5 | ZAYED M E, ZHAO J, LI W J, et al. Recent progress in phase change materials storage containers: Geometries, design considerations and heat transfer improvement methods[J]. Journal of Energy Storage, 2020, 30: doi: 10.1016/j.est.2020.101341. |

| 6 | 姜竹, 邹博杨, 丛琳, 等. 储热技术研究进展与展望[J]. 储能科学与技术, 2022, 11(9): 2746-2771. |

| JIANG Z, ZOU B Y, CONG L, et al. Recent progress and outlook of thermal energy storage technologies[J]. Energy Storage Science and Technology, 2022, 11(9): 2746-2771. | |

| 7 | JOSHI V, RATHOD M K. Constructal enhancement of thermal transport in latent heat storage systems assisted with fins[J]. International Journal of Thermal Sciences, 2019, 145: doi: 10.1016/j.ijthermalsci.2019.105984. |

| 8 | 吕明璐, 杨鑫, 张瑶, 等. 换热器的现状分析及分类应用[J]. 当代化工, 2018, 47(3): 582-584. |

| LÜ M L, YANG X, ZHANG Y, et al. Current situation analysis and classified application of heat exchangers[J]. Contemporary Chemical Industry, 2018, 47(3): 582-584. | |

| 9 | CALDERÓN-VÁSQUEZ I, CORTÉS E, GARCÍA J, et al. Review on modeling approaches for packed-bed thermal storage systems[J]. Renewable and Sustainable Energy Reviews, 2021, 143: doi: 10.1016/j.rser.2021.110902. |

| 10 | LIU J. The classification of the heat exchangers and theory research[C]// AIP Conference Proceedings. Hangzhou, China, 2017: doi: 10.1063/1.4982393. |

| 11 | 丁祥, 林文贤, 许玲, 等. 热管式真空集热管及其太阳集热器的研究与应用[J]. 云南师范大学学报(自然科学版), 2011, 31(4): 41-49. |

| DING X, LIN W X, XU L, et al. The research and applications of heat-pipe-type evacuated tubes and solar collectors[J]. Journal of Yunnan Normal University (Natural Sciences Edition), 2011, 31(4): 41-49. | |

| 12 | LI Q, LI C, DU Z, et al. A review of performance investigation and enhancement of shell and tube thermal energy storage device containing molten salt based phase change materials for medium and high temperature applications[J]. Applied Energy, 2019, 255: doi: 10.1016/j.apenergy.2019.113806. |

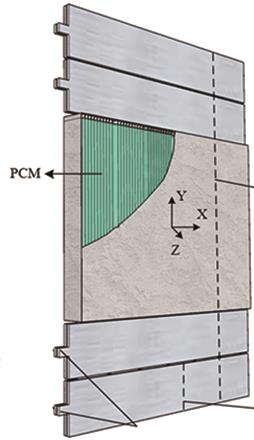

| 13 | SURESH C, SAINI R P. Review on solar thermal energy storage technologies and their geometrical configurations[J]. International Journal of Energy Research, 2020, 44(6): 4163-4195. |

| 14 | KALAPALA L, DEVANURI J K. Influence of operational and design parameters on the performance of a PCM based heat exchanger for thermal energy storage-A review[J]. Journal of Energy Storage, 2018, 20: 497-519. |

| 15 | SHEN Z G, CHEN S, CHEN B. Heat transfer performance of a finned shell-and-tube latent heat thermal energy storage unit in the presence of thermal radiation[J]. Journal of Energy Storage, 2022, 45: doi: 10.1016/j.est.2021.103724. |

| 16 | LI H Y, HU C Z, HE Y C, et al. Influence of fin parameters on the melting behavior in a horizontal shell-and-tube latent heat storage unit with longitudinal fins[J]. Journal of Energy Storage, 2021, 34: doi: 10.1016/j.est.2020.102230. |

| 17 | KHAN Z, AHMAD KHAN Z. An experimental investigation of discharge/solidification cycle of paraffin in novel shell and tube with longitudinal fins based latent heat storage system[J]. Energy Conversion and Management, 2017, 154: 157-167. |

| 18 | MAHDI J M, NAJIM F T, ALJUBURY I M A, et al. Intensifying the thermal response of PCM via fin-assisted foam strips in the shell-and-tube heat storage system[J]. Journal of Energy Storage, 2022, 45: doi: 10.1016/j.est.2021.103733. |

| 19 | PIZZOLATO A, SHARMA A, MAUTE K, et al. Design of effective fins for fast PCM melting and solidification in shell-and-tube latent heat thermal energy storage through topology optimization[J]. Applied Energy, 2017, 208: 210-227. |

| 20 | DENG S X, NIE C D, WEI G Y, et al. Improving the melting performance of a horizontal shell-tube latent-heat thermal energy storage unit using local enhanced finned tube[J]. Energy and Buildings, 2019, 183: 161-173. |

| 21 | PARIA S, BARADARAN S, AMIRI A, et al. Performance evaluation of latent heat energy storage in horizontal shell-and-finned tube for solar application[J]. Journal of Thermal Analysis and Calorimetry, 2016, 123(2): 1371-1381. |

| 22 | PU L, ZHANG S Q, XU L L, et al. Thermal performance optimization and evaluation of a radial finned shell-and-tube latent heat thermal energy storage unit[J]. Applied Thermal Engineering, 2020, 166: doi: 10.1016/j.applthermaleng.2019.114753. |

| 23 | LI H Y, HU C Z, HE Y C, et al. Effect of perforated fins on the heat-transfer performance of vertical shell-and-tube latent heat energy storage unit[J]. Journal of Energy Storage, 2021, 39: doi: 10.1016/j.est.2021.102647. |

| 24 | WANG W W, WANG L B, HE Y L. Parameter effect of a phase change thermal energy storage unit with one shell and one finned tube on its energy efficiency ratio and heat storage rate[J]. Applied Thermal Engineering, 2016, 93: 50-60. |

| 25 | WOŁOSZYN J, SZOPA K, CZERWIŃSKI G. Enhanced heat transfer in a PCM shell-and-tube thermal energy storage system[J]. Applied Thermal Engineering, 2021, 196: doi: 10.1016/j.applthermaleng.2021.117332. |

| 26 | ROZENFELD A, KOZAK Y, ROZENFELD T, et al. Experimental demonstration, modeling and analysis of a novel latent-heat thermal energy storage unit with a helical fin[J]. International Journal of Heat and Mass Transfer, 2017, 110: 692-709. |

| 27 | MEHTA D S, VAGHELA B, RATHOD M K, et al. Thermal performance augmentation in latent heat storage unit using spiral fin: An experimental analysis[J]. Journal of Energy Storage, 2020, 31: doi: 10.1016/j.est.2020.101776. |

| 28 | DUAN J, XIONG Y L, YANG D. Study on the effect of multiple spiral fins for improved phase change process[J]. Applied Thermal Engineering, 2020, 169: doi: 10.1016/j.applthermaleng.2020.114966. |

| 29 | LI Z R, FU G T, FAN L W. Synergistic effects of nano-enhanced phase change material (NePCM) and fin shape on heat storage performance of a finned shell-and-tube unit: An experimental study[J]. Journal of Energy Storage, 2022, 45: doi: 10.1016/j.est.2021.103772. |

| 30 | TAO Y B, LI M J, HE Y L, et al. Effects of parameters on performance of high temperature molten salt latent heat storage unit[J]. Applied Thermal Engineering, 2014, 72(1): 48-55. |

| 31 | SEDDEGH S, WANG X L, JOYBARI M M, et al. Investigation of the effect of geometric and operating parameters on thermal behavior of vertical shell-and-tube latent heat energy storage systems[J]. Energy, 2017, 137: 69-82. |

| 32 | XU Y, ZHENG Z J, LI M J. A half-analytical correlation of total melting time for shell-and-tube latent-heat thermal energy storage unit[J]. Applied Thermal Engineering, 2019, 161: doi: 10.1016/j.applthermaleng.2019.114176. |

| 33 | HU Z P, LI A G, GAO R, et al. Enhanced heat transfer for PCM melting in the frustum-shaped unit with multiple PCMs[J]. Journal of Thermal Analysis and Calorimetry, 2015, 120(2): 1407-1416. |

| 34 | SEDDEGH S, TEHRANI S S M, WANG X L, et al. Comparison of heat transfer between cylindrical and conical vertical shell-and-tube latent heat thermal energy storage systems[J]. Applied Thermal Engineering, 2018, 130: 1349-1362. |

| 35 | SODHI G S, JAISWAL A K, VIGNESHWARAN K, et al. Investigation of charging and discharging characteristics of a horizontal conical shell and tube latent thermal energy storage device[J]. Energy Conversion and Management, 2019, 188: 381-397. |

| 36 | LIN W Z, WANG Q H, FANG X M, et al. Experimental and numerical investigation on the novel latent heat exchanger with paraffin/expanded graphite composite[J]. Applied Thermal Engineering, 2018, 144: 836-844. |

| 37 | LIN W Z, HUANG R, FANG X M, et al. Improvement of thermal performance of novel heat exchanger with latent heat storage[J]. International Journal of Heat and Mass Transfer, 2019, 140: 877-885. |

| 38 | WANG Y, YU K X, LING X. Experimental study on thermal performance of a mobilized thermal energy storage system: A case study of hydrated salt latent heat storage[J]. Energy and Buildings, 2020, 210: doi: 10.1016/j.enbuild.2019.109744. |

| 39 | DAS N, TAKATA Y, KOHNO M, et al. Effect of carbon nano inclusion dimensionality on the melting of phase change nanocomposites in vertical shell-tube thermal energy storage unit[J]. International Journal of Heat and Mass Transfer, 2017, 113: 423-431. |

| 40 | DAS N, KOHNO M, TAKATA Y, et al. Enhanced melting behavior of carbon based phase change nanocomposites in horizontally oriented latent heat thermal energy storage system[J]. Applied Thermal Engineering, 2017, 125: 880-890. |

| 41 | SINGH D, YU W H, ZHAO W H, et al. Development and prototype testing of MgCl2/graphite foam latent heat thermal energy storage system[J]. Solar Energy, 2018, 159: 270-282. |

| 42 | ESAPOUR M, HAMZEHNEZHAD A, ALI RABIENATAJ DARZI A, et al. Melting and solidification of PCM embedded in porous metal foam in horizontal multi-tube heat storage system[J]. Energy Conversion and Management, 2018, 171: 398-410. |

| 43 | TANG B T, WANG L J, XU Y J, et al. Hexadecanol/phase change polyurethane composite as form-stable phase change material for thermal energy storage[J]. Solar Energy Materials and Solar Cells, 2016, 144: 1-6. |

| 44 | TANG B T, WEI H P, ZHAO D F, et al. Light-heat conversion and thermal conductivity enhancement of PEG/SiO2 composite PCM by in situ Ti4O7 doping[J]. Solar Energy Materials and Solar Cells, 2017, 161: 183-189. |

| 45 | HE X B, QIU J, WANG W, et al. A review on numerical simulation, optimization design and applications of packed-bed latent thermal energy storage system with spherical capsules[J]. Journal of Energy Storage, 2022, 51: doi: 10.1016/j.est.2022.104555. |

| 46 | GAUTAM A, SAINI R P. A review on sensible heat based packed bed solar thermal energy storage system for low temperature applications[J]. Solar Energy, 2020, 207: 937-956. |

| 47 | GAUTAM A, SAINI R P. A review on technical, applications and economic aspect of packed bed solar thermal energy storage system[J]. Journal of Energy Storage, 2020, 27: doi: 10.1016/j.est.2019.101046. |

| 48 | BAYÓN R, ROJAS E. Simulation of thermocline storage for solar thermal power plants: From dimensionless results to prototypes and real-size tanks[J]. International Journal of Heat and Mass Transfer, 2013, 60: 713-721. |

| 49 | ZAVATTONI S A, BARBATO M C, PEDRETTI A, et al. Evaluation of thermal stratification of an air-based thermocline TES with low-cost filler material[J]. Energy Procedia, 2015, 73: 289-296. |

| 50 | YANG L, ZHANG X S, XU G Y. Thermal performance of a solar storage packed bed using spherical capsules filled with PCM having different melting points[J]. Energy and Buildings, 2014, 68: 639-646. |

| 51 | 金波, 李明佳, 徐阳, 等. 双层填充床储热器储热性能实验研究[J]. 西安交通大学学报, 2018, 52(7): 80-86. |

| JIN B, LI M J, XU Y, et al. Experimental study on the thermal performance of a thermal storage with double-layered packed bed[J]. Journal of Xi'an Jiaotong University, 2018, 52(7): 80-86. | |

| 52 | ALPTEKIN E, EZAN M A. A systematic assessment on a solar collector integrated packed-bed single/multi-layered latent heat thermal energy storage system[J]. Journal of Energy Storage, 2021, 37: doi: 10.1016/j.est.2021.102410. |

| 53 | SAHA S K, DAS R B. Exergetic and performance analyses of two-layered packed bed latent heat thermal energy storage system[J]. International Journal of Energy Research, 2020, 44(3): 2208-2225. |

| 54 | YIN H B, DING J, JIANG R H, et al. Thermocline characteristics of molten-salt thermal energy storage in porous packed-bed tank[J]. Applied Thermal Engineering, 2017, 110: 855-863. |

| 55 | CÁRDENAS B, DAVENNE T R, ROUSE J P, et al. Effect of design parameters on the exergy efficiency of a utility-scale packed bed[J]. Journal of Energy Storage, 2018, 18: 267-284. |

| 56 | ZANGANEH G, PEDRETTI A, HASELBACHER A, et al. Design of packed bed thermal energy storage systems for high-temperature industrial process heat[J]. Applied Energy, 2015, 137: 812-822. |

| 57 | KLEIN P, ROOS T H, SHEER T J. Parametric analysis of a high temperature packed bed thermal storage design for a solar gas turbine[J]. Solar Energy, 2015, 118: 59-73. |

| 58 | MARTI J, GEISSBÜHLER L, BECATTINI V, et al. Constrained multi-objective optimization of thermocline packed-bed thermal-energy storage[J]. Applied Energy, 2018, 216: 694-708. |

| 59 | WHITE A J, MCTIGUE J D, MARKIDES C N. Analysis and optimisation of packed-bed thermal reservoirs for electricity storage applications[J]. Proceedings of the Institution of Mechanical Engineers, Part A: Journal of Power and Energy, 2016, 230(7): 739-754. |

| 60 | LIU H B, ZHAO Y. The effect of radial porosity oscillation on the heat transfer performance in packed bed latent heat storage system[C]// Proceedings of the ISES Solar World Congress 2019. International Solar Energy Society, 2019: 1218-1229. |

| 61 | XU C, WANG Z F, HE Y L, et al. Parametric study and standby behavior of a packed-bed molten salt thermocline thermal storage system[J]. Renewable Energy, 2012, 48: 1-9. |

| 62 | MERTENS N, ALOBAID F, FRIGGE L, et al. Dynamic simulation of integrated rock-bed thermocline storage for concentrated solar power[J]. Solar Energy, 2014, 110: 830-842. |

| 63 | LIN L, WANG L, LIN X P, et al. Experimental investigation on the distribution uniformity and pressure drop of perforated plate distributors for the innovative spray-type packed bed thermal storage[J]. Particuology, 2022, 61: 60-73. |

| 64 | WEISS J, ORTEGA-FERNÁNDEZ I, MÜLLER R, et al. Improved thermocline initialization through optimized inlet design for single-tank thermal energy storage systems[J]. Journal of Energy Storage, 2021, 42: doi: 10.1016/j.est.2021.103088. |

| 65 | GAJBHIYE P, SALUNKHE N, KEDARE S, et al. Experimental investigation of single media thermocline storage with eccentrically mounted vertical porous flow distributor[J]. Solar Energy, 2018, 162: 28-35. |

| 66 | LOU W R, FAN Y L, LUO L G. Single-tank thermal energy storage systems for concentrated solar power: Flow distribution optimization for thermocline evolution management[J]. Journal of Energy Storage, 2020, 32: doi: 10.1016/j.est.2020.101749. |

| 67 | YU Q H, ROMAGNOLI A, AL-DURI B, et al. Heat storage performance analysis and parameter design for encapsulated phase change materials[J]. Energy Conversion and Management, 2018, 157: 619-630. |

| 68 | LI C, LI Q, DING Y L. Investigation on the thermal performance of a high temperature packed bed thermal energy storage system containing carbonate salt based composite phase change materials[J]. Applied Energy, 2019, 247: 374-388. |

| 69 | LI C, LI Q, DING Y L. Carbonate salt based composite phase change materials for medium and high temperature thermal energy storage: From component to device level performance through modelling[J]. Renewable Energy, 2019, 140: 140-151. |

| 70 | LI M J, JIN B, MA Z, et al. Experimental and numerical study on the performance of a new high-temperature packed-bed thermal energy storage system with macroencapsulation of molten salt phase change material[J]. Applied Energy, 2018, 221: 1-15. |

| 71 | WEI J J, KAWAGUCHI Y, HIRANO S, et al. Study on a PCM heat storage system for rapid heat supply[J]. Applied Thermal Engineering, 2005, 25(17/18): 2903-2920. |

| 72 | KUMAR A, SAHA S K. Performance analysis of a packed bed latent heat thermal energy storage withcylindrical-shaped encapsulation[J]. International Journal of Energy Research, 2021, 45(9): 13130-13148. |

| 73 | CHENG X W, ZHAI X Q. Thermal performance analysis of a novel PCM capsule in red blood cell shape[J]. Applied Thermal Engineering, 2017, 120: 130-137. |

| 74 | DONG Y, WANG F Q, ZHANG Y Q, et al. Experimental and numerical study on flow characteristic and thermal performance of macro-capsules phase change material with biomimetic oval structure[J]. Energy, 2022, 238: doi: 10.1016/j.energy.2021.121830. |

| 75 | 李传, 孙泽, 丁玉龙. 高温填充床相变储热球的储热特性[J]. 储能科学与技术, 2013, 2(5): 480-485. |

| LI C, SUN Z, DING Y L. A numerical investigation into the charge behaviour of a spherical phase change material particle for high temperature thermal energy storage in packed beds[J]. Energy Storage Science and Technology, 2013, 2(5): 480-485. | |

| 76 | MAO Q J, ZHANG Y M. Thermal energy storage performance of a three-PCM cascade tank in a high-temperature packed bed system[J]. Renewable Energy, 2020, 152: 110-119. |

| 77 | KARTHIKEYAN S, RAVIKUMAR SOLOMON G, KUMARESAN V, et al. Parametric studies on packed bed storage unit filled with PCM encapsulated spherical containers for low temperature solar air heating applications[J]. Energy Conversion and Management, 2014, 78: 74-80. |

| 78 | WU M, XU C, HE Y L. Dynamic thermal performance analysis of a molten-salt packed-bed thermal energy storage system using PCM capsules[J]. Applied Energy, 2014, 121: 184-195. |

| 79 | JACOB R, BRUNO F. Review on shell materials used in the encapsulation of phase change materials for high temperature thermal energy storage[J]. Renewable and Sustainable Energy Reviews, 2015, 48: 79-87. |

| 80 | ALAM T E, DHAU J S, GOSWAMI D Y, et al. Macroencapsulation and characterization of phase change materials for latent heat thermal energy storage systems[J]. Applied Energy, 2015, 154: 92-101. |

| 81 | ZHANG F, ZHONG Y J, YANG X, et al. Encapsulation of metal-based phase change materials using ceramic shells prepared by spouted bed CVD method[J]. Solar Energy Materials and Solar Cells, 2017, 170: 137-142. |

| 82 | FUKAHORI R, NOMURA T, ZHU C Y, et al. Macro-encapsulation of metallic phase change material using cylindrical-type ceramic containers for high-temperature thermal energy storage[J]. Applied Energy, 2016, 170: 324-328. |

| 83 | TREVISAN S, WANG W J, ZHAO X Y, et al. A study of metallic coatings on ceramic particles for thermal emissivity control and effective thermal conductivity enhancement in packed bed thermal energy storage[J]. Solar Energy Materials and Solar Cells, 2022, 234: doi: 10.1016/j.solmat.2021.111458. |

| 84 | 何坤雲, 尹华伟, 李向钊, 等. 板式换热器的强化换热方法[J]. 化学工程与装备, 2021(12): 5-6. |

| HE K Y, YIN H W, LI X Z, et al. Heat exchange enhancement method of plate heat exchanger[J]. Chemical Engineering & Equipment, 2021(12): 5-6. | |

| 85 | ABOU ELMAATY T M, KABEEL A E, MAHGOUB M. Corrugated plate heat exchanger review[J]. Renewable and Sustainable Energy Reviews, 2017, 70: 852-860. |

| 86 | KUMAR S, SINGH S K, SHARMA D. A comprehensive review on thermal performance enhancement of plate heat exchanger[J]. International Journal of Thermophysics, 2022, 43(7): doi: 10.1007/s10765-022-03036-7. |

| 87 | ZHANG J, ZHU X W, MONDEJAR M E, et al. A review of heat transfer enhancement techniques in plate heat exchangers[J]. Renewable and Sustainable Energy Reviews, 2019, 101: 305-328. |

| 88 | 钟佳毅. 新型波纹板式相变蓄热器换热特性研究[D]. 济南: 山东大学, 2020.ZHONG J Y. Heat transfer characteristic research on a new corrugated plate latent heat ThermalEnergy storage system[D]. Jinan: Shandong University, 2020. |

| 89 | CEREZO J, LARA F, ROMERO R J, et al. Numerical analysis of a latent heat storage using plate heat exchanger for absorption system conditions[J]. Processes, 2022, 10(5): doi: 10.3390/pr10050815. |

| 90 | GÜREL B. A numerical investigation of the melting heat transfer characteristics of phase change materials in different plate heat exchanger (latent heat thermal energy storage) systems[J]. International Journal of Heat and Mass Transfer, 2020, 148: doi: 10.1016/j.ijheatmasstransfer.2019.119117. |

| 91 | KABEEL A E, KHALIL A, SHALABY S M, et al. Experimental investigation of thermal performance of flat and v-corrugated plate solar air heaters with and without PCM as thermal energy storage[J]. Energy Conversion and Management, 2016, 113: 264-272. |

| 92 | MAHANI R B, MOHAMMED H I, MAHDI J M, et al. Phase change process in a zigzag plate latent heat storage system during melting and solidification[J]. Molecules (Basel, Switzerland), 2020, 25(20): doi: 10.3390/molecules25204643. |

| 93 | WANG P L, WANG X, HUANG Y, et al. Thermal energy charging behaviour of a heat exchange device with a zigzag plate configuration containing multi-phase-change-materials (m-PCMs)[J]. Applied Energy, 2015, 142: 328-336. |

| 94 | WANG P L, LI D C, HUANG Y, et al. Numerical study of solidification in a plate heat exchange device with a zigzag configuration containing multiple phase-change-materials[J]. Energies, 2016, 9(6): doi: 10.3390/en9060394. |

| 95 | JOHNSON M, FIß M, KLEMM T. Experimental testing of various heat transfer structures in a flat plate thermal energy storage unit[J]. AIP Conference Proceedings, 2016, 1734(1): doi: 10.1063/1.4949120. |

| 96 | 徐桂芝, 胡晓, 金翼, 等. 高温相变储热换热装置仿真建模及分析[J]. 储能科学与技术, 2019, 8(2): 338-346. |

| XU G Z, HU X, JIN Y, et al. Simulation modeling and analysis of a high temperature phase change heat storage and exchange device[J]. Energy Storage Science and Technology, 2019, 8(2): 338-346. | |

| 97 | BECHIRI M, MANSOURI K. Exact solution of thermal energy storage system using PCM flat slabs configuration[J]. Energy Conversion and Management, 2013, 76: 588-598. |

| 98 | LIAO Z R, XU C, XU C, et al. Cyclic performance analysis of a high temperature flat plate thermal energy storage unit with phase change material[J]. Applied Thermal Engineering, 2018, 144: 1126-1136. |

| 99 | LIU M, BRUNO F, SAMAN W. Thermal performance analysis of a flat slab phase change thermal storage unit with liquid-based heat transfer fluid for cooling applications[J]. Solar Energy, 2011, 85(11): 3017-3027. |

| 100 | DARZI A A R, MOOSANIA S M, TAN F L, et al. Numerical investigation of free-cooling system using plate type PCM storage[J]. International Communications in Heat and Mass Transfer, 2013, 48: 155-163. |

| 101 | VOGEL J, FELBINGER J, JOHNSON M. Natural convection in high temperature flat plate latent heat thermal energy storage systems[J]. Applied Energy, 2016, 184: 184-196. |

| 102 | 刘丽辉, 莫雅菁, 孙小琴, 等. 板式相变储能单元的蓄热特性及其优化[J]. 储能科学与技术, 2020, 9(6): 1784-1789. |

| LIU L H, MO Y J, SUN X Q, et al. Thermal storage characteristics and optimization of plate-type phase change energy storage unit[J]. Energy Storage Science and Technology, 2020, 9(6): 1784-1789. | |

| 103 | SAEED R M, SCHLEGEL J P, SAWAFTA R, et al. Plate type heat exchanger for thermal energy storage and load shifting using phase change material[J]. Energy Conversion and Management, 2019, 181: 120-132. |

| 104 | LIN W Y, MA Z J, REN H S, et al. Multi-objective optimisation of thermal energy storage using phase change materials for solar air systems[J]. Renewable Energy, 2019, 130: 1116-1129. |

| 105 | KUMIRAI T, DIRKER J, MEYER J. Experimental analysis for thermal storage performance of three types of plate encapsulated phase change materials in air heat exchangers for ventilation applications[J]. Journal of Building Engineering, 2019, 22: 75-89. |

| 106 | CHARVÁT P, KLIMEŠ L, OSTRÝ M. Numerical and experimental investigation of a PCM-based thermal storage unit for solar air systems[J]. Energy and Buildings, 2014, 68: 488-497. |

| 107 | GÜREL B. Thermal performance evaluation for solidification process of latent heat thermal energy storage in a corrugated plate heat exchanger[J]. Applied Thermal Engineering, 2020, 174: doi: 10.1016/j.applthermaleng.2020.115312. |

| 108 | PRIETO M M, SUÁREZ I, GONZÁLEZ B. Analysis of the thermal performance of flat plate PCM heat exchangers for heating systems[J]. Applied Thermal Engineering, 2017, 116: 11-23. |

| 109 | SUN X Q, MO Y J, LI J, et al. Study on the energy charging process of a plate-type latent heat thermal energy storage unit and optimization using Taguchi method[J]. Applied Thermal Engineering, 2020, 164: doi: 10.1016/j.applthermaleng.2019.114528. |

| 110 | BASHAR M, SIDDIQUI K. Experimental investigation of transient melting and heat transfer behavior of nanoparticle-enriched PCM in a rectangular enclosure[J]. Journal of Energy Storage, 2018, 18: 485-497. |

| 111 | ELBAHJAOUI R, EL QARNIA H. Thermal analysis of nanoparticle-enhanced phase change material solidification in a rectangular latent heat storage unit including natural convection[J]. Energy and Buildings, 2017, 153: 1-17. |

| 112 | 李昭, 李宝让, 陈豪志, 等. 相变储热技术研究进展[J]. 化工进展, 2020, 39(12): 5066-5085. |

| LI Z, LI B R, CHEN H Z, et al. State of the art review on phase change thermal energy storage technology[J]. Chemical Industry and Engineering Progress, 2020, 39(12): 5066-5085. | |

| 113 | IBRAHIM N I, AL-SULAIMAN F A, RAHMAN S, et al. Heat transfer enhancement of phase change materials for thermal energy storage applications: A critical review[J]. Renewable and Sustainable Energy Reviews, 2017, 74: 26-50. |

| 114 | JEGADHEESWARAN S, POHEKAR S D. Performance enhancement in latent heat thermal storage system: A review[J]. Renewable and Sustainable Energy Reviews, 2009, 13(9): 2225-2244. |

| 115 | LADEKAR C, CHOUDHARY S K, KHANDARE S S. Experimental investigation for the optimization of heat pipe performance in latent heat thermal storage[J]. Journal of Mechanical Science and Technology, 2017, 31(6): 2627-2634. |

| 116 | 白烨. 两相热虹吸回路耦合相变储热的研究[D]. 北京: 中国科学院大学(中国科学院工程热物理研究所), 2020.BAI Y. Study on coupled phase change heat storage of two-phase thermosyphon loop[D]. Beijing: Institute of Engineering Thermophysics, Chinese Academy of Sciences, 2020. |

| 117 | SHARIFI N, BERGMAN T L, ALLEN M J, et al. Melting and solidification enhancement using a combined heat pipe, foil approach[J]. International Journal of Heat and Mass Transfer, 2014, 78: 930-941. |

| 118 | ZHAO J T, DAI Y C, WANG Z P, et al. Study on the thermal performance of thermal energy storage and heating module based on a novel embedded heat pipe[J]. Journal of Energy Storage, 2022, 52: doi: 10.1016/j.est.2022.104743. |

| 119 | MAHDAVI M, QIU S G, TIARI S. Improvement of a novel heat pipe network designed for latent heat thermal energy storage systems[J]. Applied Thermal Engineering, 2016, 108: 878-892. |

| 120 | MOTAHAR S, KHODABANDEH R. Experimental study on the melting and solidification of a phase change material enhanced by heat pipe[J]. International Communications in Heat and Mass Transfer, 2016, 73: 1-6. |

| 121 | TIARI S, QIU S G, MAHDAVI M. Discharging process of a finned heat pipe-assisted thermal energy storage system with high temperature phase change material[J]. Energy Conversion and Management, 2016, 118: 426-437. |

| 122 | ZHANG C W, FAN Y B, YU M, et al. Performance evaluation and analysis of a vertical heat pipe latent thermal energy storage system with fins-copper foam combination[J]. Applied Thermal Engineering, 2020, 165: doi: 10.1016/j.applthermaleng.2019.114541. |

| 123 | ZHANG X, WU S C, ZHANG C B, et al. Dynamic heat transfer characteristics of gravity heat pipe with heat storage[J]. Journal of Energy Storage, 2022, 53: doi: 10.1016/j.est.2022.105134. |

| 124 | LIU Z H, ZHENG B C, WANG Q, et al. Study on the thermal storage performance of a gravity-assisted heat-pipe thermal storage unit with granular high-temperature phase-change materials[J]. Energy, 2015, 81: 754-765. |

| 125 | HU B W, WANG Q, LIU Z H. Fundamental research on the gravity assisted heat pipe thermal storage unit (GAHP-TSU) with porous phase change materials (PCMs) for medium temperature applications[J]. Energy Conversion and Management, 2015, 89: 376-386. |

| 126 | WANG T Y, DIAO Y H, ZHU T T, et al. Thermal performance of solar air collection-storage system with phase change material based on flat micro-heat pipe arrays[J]. Energy Conversion and Management, 2017, 142: 230-243. |

| 127 | WANG T Y, ZHAO Y H, DIAO Y H, et al. Experimental investigation of a novel thermal storage solar air heater (TSSAH) based on flat micro-heat pipe arrays[J]. Renewable Energy, 2021, 173: 639-651. |

| 128 | WANG Z Y, DIAO Y H, ZHAO Y H, et al. Effect of inclination angle on the charging process of flat heat pipe-assisted latent heat storage unit[J]. Journal of Energy Storage, 2022, 51: doi: 10.1016/j.est.2022.104402. |

| 129 | LIU J, DIAO Y H, ZHAO Y H, et al. Heat transfer properties of a latent thermal storage unit with flat microheat pipe arrays[J]. Journal of Energy Engineering, 2017, 143(5): doi: 10.1061/(asce)ey.1943-7897.0000481. |

| 130 | DIAO Y H, LIANG L, ZHAO Y H, et al. Numerical investigation of the thermal performance enhancement of latent heat thermal energy storage using longitudinal rectangular fins and flat micro-heat pipe arrays[J]. Applied Energy, 2019, 233/234: 894-905. |

| 131 | 蒋俊峰. 平板热管型太阳能光伏光热复合集热器的基础性实验研究[D]. 上海: 上海交通大学, 2020.JIANG J F. Fundamental research of a photovoltaic and solar thermal composite collector with flat heat pipe[D]. Shanghai: Shanghai Jiao Tong University, 2020. |

| 132 | 钦斌. 平板微热管阵列在不同介质中的传热特性研究[D]. 扬州: 扬州大学, 2022.QIN B. Study on heat transfer characteristics of flat micro-heat pipe arrays in different mediums[D]. Yangzhou: Yangzhou University, 2022. |

| 133 | DIALLO T M O, YU M, ZHOU J Z, et al. Energy performance analysis of a novel solar PVT loop heat pipe employing a microchannel heat pipe evaporator and a PCM triple heat exchanger[J]. Energy, 2019, 167: 866-888. |

| 134 | TESFAY A H, KAHSAY M B, NYDAL O J. Steam based charging-discharging of a PCM heat storage[C]//Proceedings of the ISES Solar World Congress 2015. November 8-12, 2015. Daegu, Korea. Freiburg, Germany: International Solar Energy Society, 2016: doi: 10.1061/(asce)ey.1943-7897.0000481. |

| 135 | 赵佳腾, 吴晨辉, 戴宇成, 等. 脉动热管强化传热及其应用研究进展[J]. 化工学报, 2022, 73(2): 535-565. |

| ZHAO J T, WU C H, DAI Y C, et al. Research progress on heat transfer enhancement and application of oscillating heat pipe[J]. CIESC Journal, 2022, 73(2): 535-565. | |

| 136 | 罗孝学, 章学来, 华维三, 等. 一种脉动热管相变蓄放热试验装置的设计[J]. 流体机械, 2017, 45(4): 63-67. |

| LUO X X, ZHANG X L, HUA W S, et al. Design of pulsating heat pipe type phase change thermal storage experimental device[J]. Fluid Machinery, 2017, 45(4): 63-67. | |

| 137 | XU R J, ZHANG X H, WANG R X, et al. Experimental investigation of a solar collector integrated with a pulsating heat pipe and a compound parabolic concentrator[J]. Energy Conversion and Management, 2017, 148: 68-77. |

| 138 | LING Y Z, ZHANG X S, WANG F, et al. Performance study of phase change materials coupled with three-dimensional oscillating heat pipes with different structures for electronic cooling[J]. Renewable Energy, 2020, 154: 636-649. |

| 139 | ZHAO J T, RAO Z H, LIU C Z, et al. Experimental investigation on thermal performance of phase change material coupled with closed-loop oscillating heat pipe (PCM/CLOHP) used in thermal management[J]. Applied Thermal Engineering, 2016, 93: 90-100. |

| 140 | 陈洋. "花"型脉动热管太阳能集热器热性能的实验研究[D]. 昆明: 昆明理工大学, 2020.CHEN Y. Experimental study on thermal performance of "Hua" pulsating heat pipe solar collector[D]. Kunming: Kunming University of Science and Technology, 2020. |

| [1] | 姜竹, 邹博杨, 丛琳, 谢春萍, 李传, 谯耕, 赵彦琦, 聂彬剑, 张童童, 葛志伟, 马鸿坤, 金翼, 李永亮, 丁玉龙. 储热技术研究进展与展望[J]. 储能科学与技术, 2022, 11(9): 2746-2771. |

| [2] | 尹浩, 唐志伟, 王昊, 金翼, 丁玉龙. 基于高密度复合相变储热材料电热锅炉的分时配比供热系统[J]. 储能科学与技术, 2022, 11(9): 3003-3010. |

| [3] | 周新宇, 栾道成, 胡志华, 凌俊华, 文科林, 刘浪, 阴志铭, 米书恒, 王正云. 含碳二元系相变储热材料储热性能分析选择[J]. 储能科学与技术, 2022, 11(4): 1175-1183. |

| [4] | 王辉祥, 熊亚选, 任静, 药晨华, 宋超宇, 吴玉庭, 丁玉龙. Na2CO3/电石渣复合相变储热材料制备与性能[J]. 储能科学与技术, 2022, 11(12): 3819-3827. |

| [5] | 沈永亮, 张朋威, 刘淑丽. 肋片增强式梯级相变储热系统放热特性的三维数值[J]. 储能科学与技术, 2022, 11(11): 3558-3565. |

| [6] | 赵兰, 王国珍. 相变蓄热复合传热强化技术综述[J]. 储能科学与技术, 2022, 11(11): 3534-3547. |

| [7] | 詹世英, 于东旭, 陈楠, 杜菲. 非金属阳离子水系二次电池研究进展[J]. 储能科学与技术, 2021, 10(6): 2144-2155. |

| [8] | 鲁博辉, 师志成, 张永学, 赵泓宇, 王梓熙. 石蜡/Fe3O4纳米颗粒复合相变材料在管壳式储热单元中的储/放热性能研究[J]. 储能科学与技术, 2021, 10(5): 1709-1719. |

| [9] | 孙守斌, 姚华, 刘常鹏, 黄云, 马光宇, 张天赋, 王向锋. 钢铁行业中低温烟气余热相变储热装置特性分析[J]. 储能科学与技术, 2020, 9(3): 730-734. |

| [10] | 马美秀, 李振东, 康伟, 曾洪涛, 苏铁山, 胡荣辉, 胡晓. 高温相变蓄热电暖器的数值模拟及验证[J]. 储能科学与技术, 2020, 9(1): 88-93. |

| [11] | 杨智舜, 陈丽华, 夏振华. 固液相变材料储能过程传热机制的数值模拟[J]. 储能科学与技术, 2019, 8(6): 1217-1223. |

| [12] | 杨岑玉, 胡晓, 李雅文, 邢作霞, 高运兴, 董佳仪, 徐桂芝. 流固耦合固体相变蓄热建模与分析方法[J]. 储能科学与技术, 2019, 8(3): 538-543. |

| [13] | 何峰, 李廷贤, 姚金煜, 王如竹. 基于相变储热的太阳能多模式采暖系统及应用[J]. 储能科学与技术, 2019, 8(2): 311-318. |

| [14] | 李洋, 王彩霞, 宗军, 杨智舜, 陈丽华, 韩雨辰, 张玮. 不同形式相变储热换热器的对比分析[J]. 储能科学与技术, 2019, 8(2): 347-356. |

| [15] | 张佳利, 丁宇, 曲丽洁, 何正斌, 伊松林. 石蜡/膨胀石墨复合相变储热单元的放热性能[J]. 储能科学与技术, 2019, 8(1): 108-115. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||