Energy Storage Science and Technology ›› 2022, Vol. 11 ›› Issue (5): 1401-1410.doi: 10.19799/j.cnki.2095-4239.2021.0580

• Energy Storage Materials and Devices • Previous Articles Next Articles

Zhicheng CHEN( ), Zongxu LI, Ling CAI, Yisi LIU(

), Zongxu LI, Ling CAI, Yisi LIU( )

)

Received:2021-11-04

Revised:2022-01-05

Online:2022-05-05

Published:2022-05-07

Contact:

Yisi LIU

E-mail:czc420321@foxmail.com;yliu88@hbnu.edu.cn

CLC Number:

Zhicheng CHEN, Zongxu LI, Ling CAI, Yisi LIU. Development status and future prospects of flexible metal-air batteries[J]. Energy Storage Science and Technology, 2022, 11(5): 1401-1410.

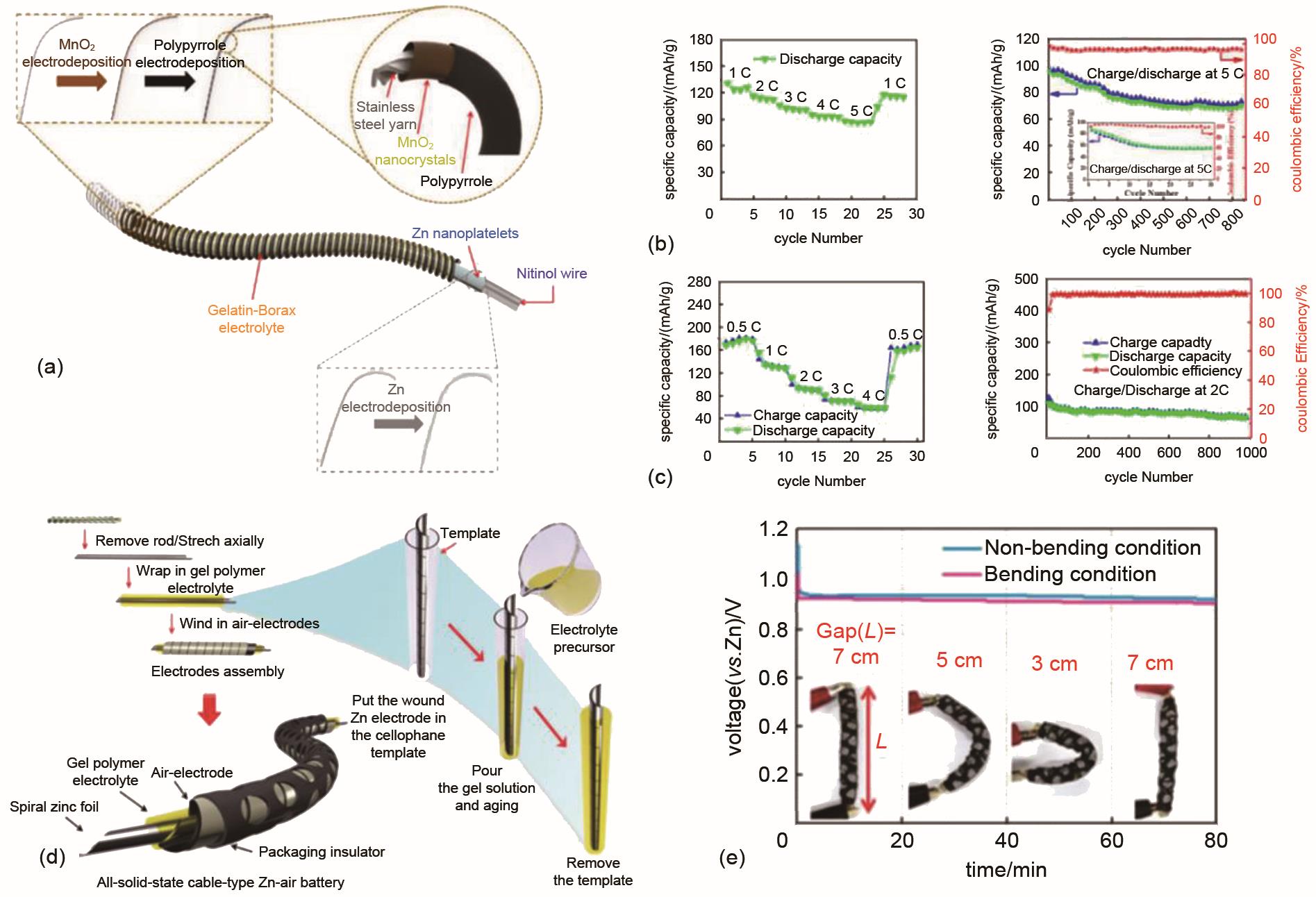

Fig. 1

(a) Ni Ti alloy deposited MnO2 catalyst as air electrode wound into a cable-shaped flexible cell [12]; (b) Ni Ti alloy deposited MnO2 as electrode, assembled into aqueous zinc ion battery 1 C to 5 C discharge diagram. Cyclic stability of the Zn@NT-MnO2/PPy@SS battery in aqueous electrolyte at 5 C, inset shows the comparative study of Zn@NT-MnO2@SS system without PPy coating at 5 C; (c) Rate capability of Zn@NT-MnO2/PPy@SS yarn battery from 0.5 to 4 C in the gelatin-borax electrolyte; Cyclic stability of the yarn battery in the gelatin-borax electrolyte at 2 C. (d) Schematic diagram of a flexible air electrode prepared using silk fibrin as precursor and gelatin as electrolyte to assemble the cell[13]; (e) Cable type battery bending at different angles discharge voltage change graph"

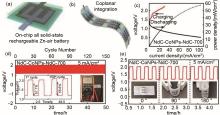

Fig. 2

(a) Single planar-type structure cell; (b) Multiple cells with planar-type structure connected in series[14]; (c) Charge and discharge polarization curves of planar-type structure cell; (d) cycle performance and open circuit voltage; (e) Charge and discharge of planar-type structure cell under bending deformation in different angles"

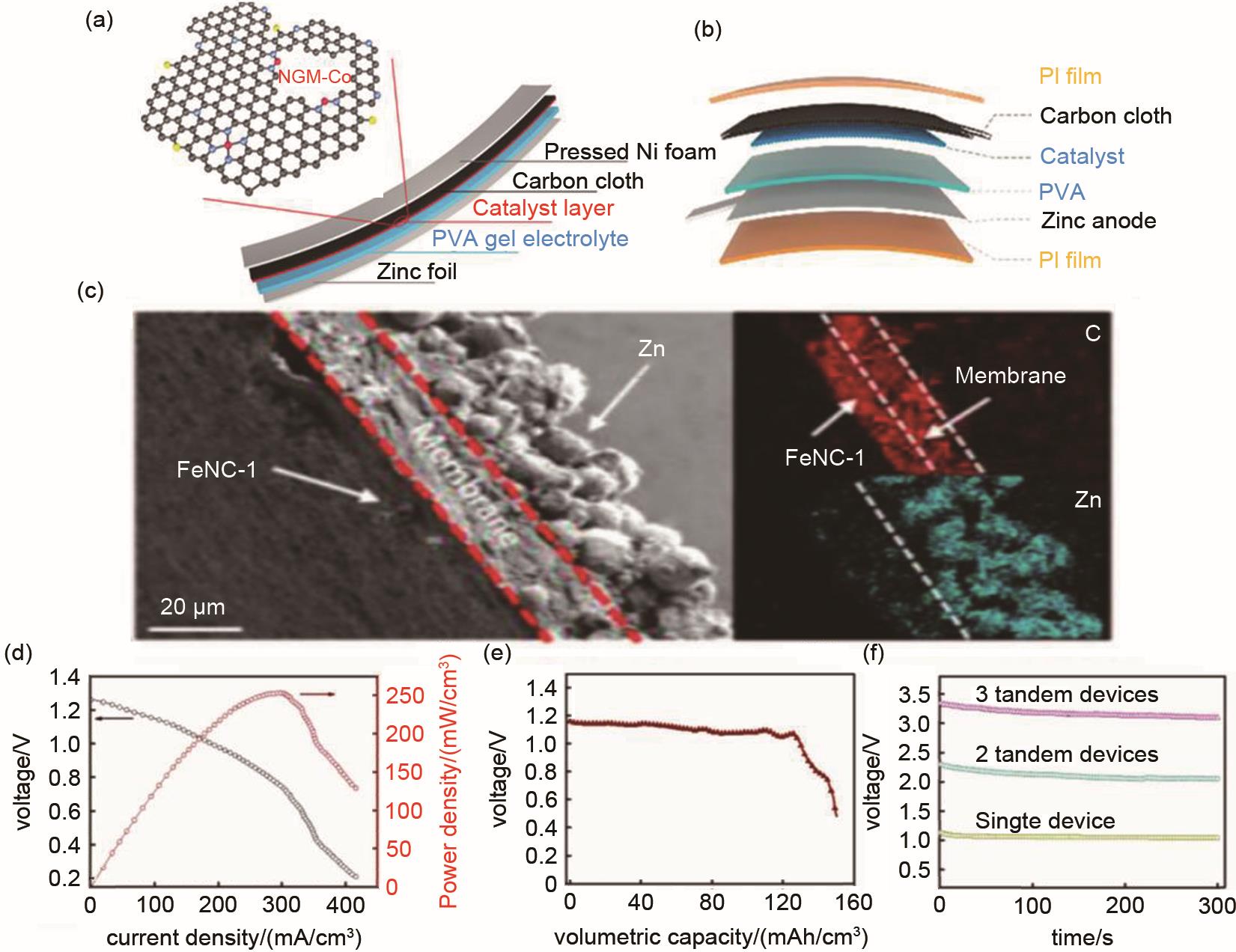

Fig. 3

(a) Schematic diagram of sandwich structure flexible cell[15]; (b) Sandwich layered cell assembled by coating Co-CoO@NSC on carbon cloth[16]; (c) Cross-sectional view of a solid zinc-air cell prepared by depositing catalyst and zinc powder on each side of the solid electrolyte[17]; (d) Polarization and power density curves and (e) discharge curve at 8.3 mA/cm2 of the ZAB; (f) The galvanostatic discharge profile of one, two and three tandem devices at a discharge current of 0.15 mA"

Table 1

Overview of air electrode related problems and solutions"

| 相关问题 | 原因 | 影响 | 解决办法 |

|---|---|---|---|

| 缓慢的反应速率 | 氧还原(ORR)与析氧反应(OER)的过电位太高[ | 能量密度与能量效率受到限制 | 开发高效稳定的电催化剂 |

| 空气电极溢流 | 电解液渗透进空气电极的孔隙 | 减少氧气进入 | 用石蜡处理空气电极;优化气相扩散层(GDL) |

| 碳酸盐沉淀 | 大气中的CO2与碱性电解液反应产生碳酸盐沉淀[ | 降低电解液导电性与空气电极活性 | 用纯氧代替以减少CO2浓度 |

| 电解液渗漏 | 开放体系水分蒸发 | 缩短电池寿命 | 优化气相扩散层(GDL) |

| 电极结构组成复杂、制备繁琐 | 黏结剂等添加物会增加非活性物质组分 | 堵塞孔结构、降低电导率等 | 简化电极结构,采用自支撑式空气电极 |

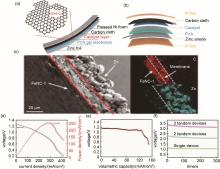

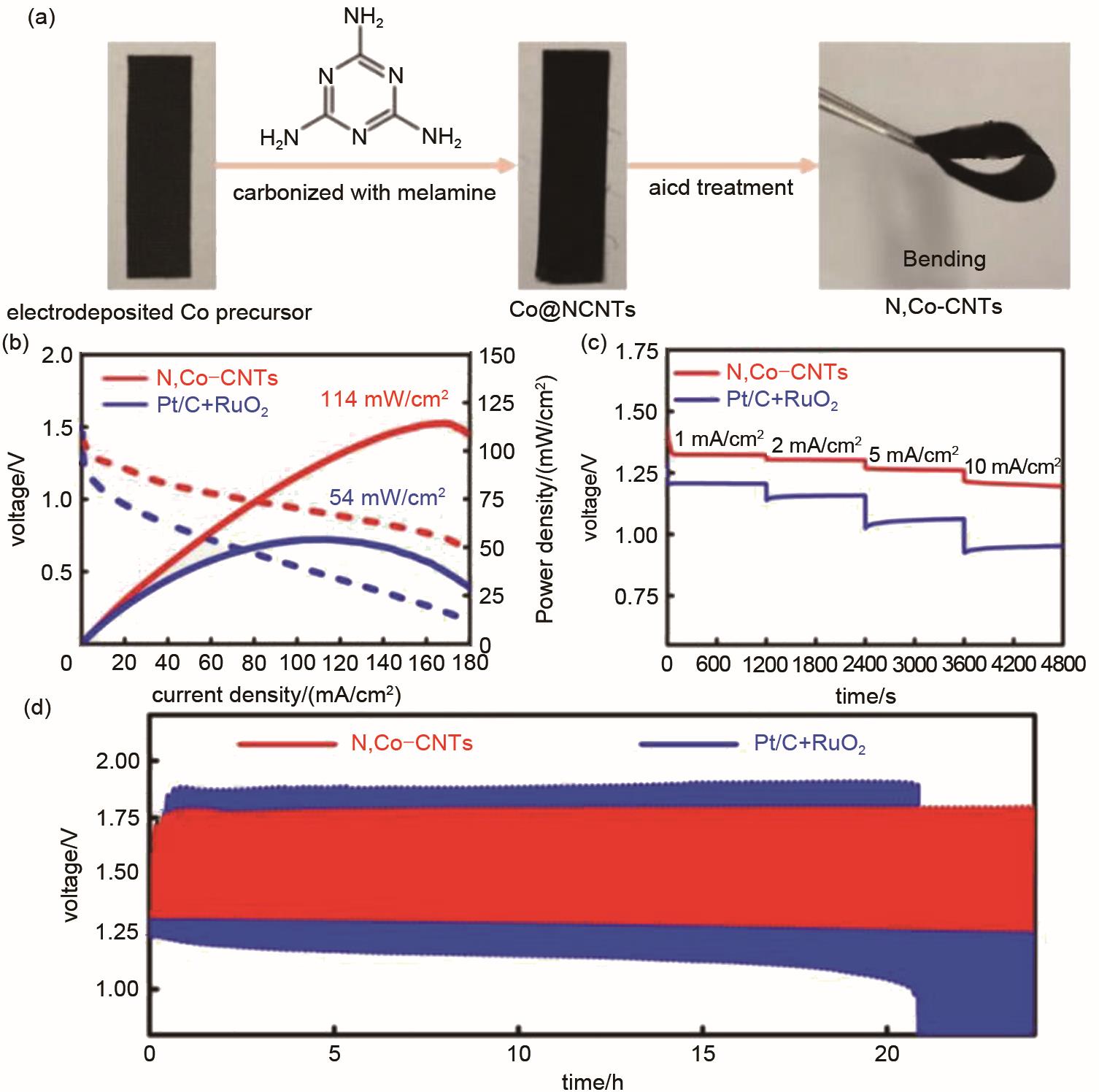

Fig. 4

(a) In situ growth catalyst on carbon cloth as free-standing electrode[23]; (b) Discharge polarization and the corresponding power density curves of N, Co-CNTs ZAB and Pt/C+RuO2 ZAB; (c) Galvanostatic discharge of N, Co-CNTs ZAB and Pt/C+RuO2 ZAB with different current densities; (d) Galvanostatic charge-discharge profile of N, Co-CNTs ZAB and Pt/C+RuO2 ZAB"

Table 2

Ionic conductivity of various polymer gel electrolytes"

| 凝胶类型 | 各种物质比例 | 离子电导率 | 引用 |

|---|---|---|---|

| PVA+PVP+KOH | PVA∶PVP=8∶2 40% KOH | (1.5±1.1)×10 -4 S/cm | [ |

| PVA+AA+KOH | PVA∶AA=7∶3 6 mol/L KOH | 3.5510 -2 S/cm | [ |

| PEO+PVA+glass-fiber-mat | PEO∶PVA=1∶1 | 0.0475 S/cm | [ |

| PVA+PAA+KOH | PVA∶PAA=10∶7.5 | 0.301 S/cm | [ |

| PAM+PVP+H3PO4 | AM∶PVP=1∶0.16 | 0.138 S/cm | [ |

| P(BMA-St)+PEG | P(BMA-St)∶PEG=1.25 g∶0.67 mL | 2.2×10 -3 S/cm | [ |

| 1 | 曹宁, 孟佳欣, 臧晓蓓. 碳基柔性正极制备的综合性实验研究[J]. 实验室研究与探索, 2021, 40(2): 38-42, 53. |

| CAO N, MENG J X, ZANG X B. Comprehensive experimental study on the preparation of carbon-based flexible cathode[J]. Research and Exploration in Laboratory, 2021, 40(2): 38-42, 53. | |

| 2 | 孟锦涛, 周良毅, 钟芸, 等. 柔性钠离子电池研究进展[J]. 材料导报, 2020, 34(1): 1169-1176. |

| MENG J T, ZHOU L Y, ZHONG Y, et al. Research progress on flexible sodium-ion batteries[J]. Materials Reports, 2020, 34(1): 1169-1176. | |

| 3 | 马超. 柔性可充锌—空电池锌电极的电化学制备及电池性能[D]. 天津: 天津大学, 2018. |

| MA C. Electrochemical preparation and cell performance of zinc electrodes for flexible rechargeable zinc-air batteries[D]. Tianjin: Tianjin University, 2018. | |

| 4 | 刘志成, 彭道刚, 赵慧荣, 等. 双碳目标下储能参与电力系统辅助服务发展前景[J]. 储能科学与技术, 2022, 11(2): 704-716. |

| LIU Z C, PENG D G, ZHAO H R, et al. Development prospects of energy storage participating in auxiliary services of power systems under the targets of the dual-carbon goal[J]. Energy Storage Science and Technology, 2022, 11(2): 704-716. | |

| 5 | LI Y B, FU J, ZHONG C, et al. Recent advances in flexible zinc-based rechargeable batteries[J]. Advanced Energy Materials, 2019, 9(1): doi:10.1002/aenm.201802605. |

| 6 | YU H H, LIU D P, FENG X L, et al. Mini review: Recent advances on flexible rechargeable Li-air batteries[J]. Energy & Fuels, 2021, 35(6): 4751-4761. |

| 7 | LIU Y S, SUN Q, LI W Z, et al. A comprehensive review on recent progress in aluminum-air batteries[J]. Green Energy & Environment, 2017, 2(3): 246-277. |

| 8 | 李蕊. 基于材料、集流体与电池结构设计的柔性/可拉伸电池的研究[D]. 北京: 北京科技大学, 2021. |

| LI R. The study of materials, current collector and cell structure design for flexible/stretchable batteries[D]. Beijing: University of Science and Technology Beijing, 2021. | |

| 9 | CAO Z Q, HU H B, WU M Z, et al. Planar all-solid-state rechargeable Zn-air batteries for compact wearable energy storage[J]. Journal of Materials Chemistry A, 2019, 7(29): 17581-17593. |

| 10 | ZHANG Y G, DENG Y P, WANG J Y, et al. Recent progress on flexible Zn-air batteries[J]. Energy Storage Materials, 2021, 35: 538-549. |

| 11 | SONG Z S, DING J, LIU B, et al. A rechargeable Zn-air battery with high energy efficiency and long life enabled by a highly water-retentive gel electrolyte with reaction modifier[J]. Advanced Materials, 2020, 32(22): doi:10.1002/adma.201908127. |

| 12 | ZUO X X, CHANG K, ZHAO J, et al. Bubble-template-assisted synthesis of hollow fullerene-like MoS2 nanocages as a lithium ion battery anode material[J]. Journal of Materials Chemistry A, 2016, 4(1): 51-58. |

| 13 | PARK J, PARK M, NAM G, et al. All-solid-state cable-type flexible zinc-air battery[J]. Advanced Materials, 2015, 27(8): 1396-1401. |

| 14 | SHEN Y T, LIANG L J, ZHANG S Q, et al. Organelle-targeting surface-enhanced Raman scattering (SERS) nanosensors for subcellular pH sensing[J]. Nanoscale, 2018, 10(4): 1622-1630. |

| 15 | TANG C, WANG B, WANG H F, et al. Defect engineering toward atomic Co-Nx-C in hierarchical graphene for rechargeable flexible solid Zn-air batteries[J]. Advanced Materials, 2017, 29(37): doi:10.1002/adma.201703185. |

| 16 | TAN Y Y, ZHANG Z Y, LEI Z, et al. Thiourea-Zeolitic imidazolate Framework-67 assembly derived Co-CoO nanoparticles encapsulated in N, S Codoped open carbon shell as bifunctional oxygen electrocatalyst for rechargeable flexible solid Zn-Air batteries[J]. Journal of Power Sources, 2020, 473: doi:10.1016/j.jpowsour.2020.228570. |

| 17 | WANG W, TANG M H, ZHENG Z Y, et al. Alkaline polymer membrane-based ultrathin, flexible, and high-performance solid-state Zn-air battery[J]. Advanced Energy Materials, 2019, 9(14): doi:10.1002/aenm.201803628. |

| 18 | 陈祥, 雷凯翔, 孙洪明, 等. 尖晶石型氧化物催化剂与金属-空气电池[J]. 储能科学与技术, 2017, 6(5): 904-923. |

| CHEN X, LEI K X, SUN H M, et al. Spinel-type transition metal oxide electrocatalysts for metal-air batteries[J]. Energy Storage Science and Technology, 2017, 6(5): 904-923. | |

| 19 | BIDAULT F, BRETT D J L, MIDDLETON P H, et al. Review of gas diffusion cathodes for alkaline fuel cells[J]. Journal of Power Sources, 2009, 187(1): 39-48. |

| 20 | LIN C, SHINDE S S, WANG Y, et al. Flexible and rechargeable Zn-air batteries based on green feedstocks with 75% round-trip efficiency[J]. Sustainable Energy & Fuels, 2017, 1(9): 1909-1914. |

| 21 | XU N N, CAI Y X, PENG L W, et al. Superior stability of a bifunctional oxygen electrode for primary, rechargeable and flexible Zn-air batteries[J]. Nanoscale, 2018, 10(28): 13626-13637. |

| 22 | WANG Z F, RUAN Z H, LIU Z X, et al. A flexible rechargeable zinc-ion wire-shaped battery with shape memory function[J]. Journal of Materials Chemistry A, 2018, 6(18): 8549-8557. |

| 23 | LU Q, ZOU X H, LIAO K M, et al. Direct growth of ordered N-doped carbon nanotube arrays on carbon fiber cloth as a free-standing and binder-free air electrode for flexible quasi-solid-state rechargeable Zn-Air batteries[J]. Carbon Energy, 2020, 2(3): 461-471. |

| 24 | ZHU C Y, MA Y Y, ZANG W J, et al. Conformal dispersed cobalt nanoparticles in hollow carbon nanotube arrays for flexible Zn-air and Al-air batteries[J]. Chemical Engineering Journal, 2019, 369: 988-995. |

| 25 | JIN Q Y, REN B W, CUI H, et al. Nitrogen and cobalt co-doped carbon nanotube films as binder-free trifunctional electrode for flexible zinc-air battery and self-powered overall water splitting[J]. Applied Catalysis B: Environmental, 2021, 283: doi:10.1016/j.apcatb.2020.119643. |

| 26 | ZHAO X T, ABBAS S C, HUANG Y Y, et al. Robust and highly active FeNi@NCNT nanowire arrays as integrated air electrode for flexible solid-state rechargeable Zn-air batteries[J]. Advanced Materials Interfaces, 2018, 5(9): doi:10.1002/admi.201701448. |

| 27 | WU Y G, RAN F. Vanadium nitride quantum dot/nitrogen-doped microporous carbon nanofibers electrode for high-performance supercapacitors[J]. Journal of Power Sources, 2017, 344: 1-10. |

| 28 | WANG X D, ZHANG Y F, ZHANG X J, et al. A highly stretchable transparent self-powered triboelectric tactile sensor with metallized nanofibers for wearable electronics[J]. Advanced Materials, 2018, 30(12): doi:10.1002/adma.201706738. |

| 29 | WANG P C, WAN L, LIN Y Q, et al. Construction of mass-transfer channel in air electrode with bifunctional catalyst for rechargeable zinc-air battery[J]. Electrochimica Acta, 2019, 320: doi:10.1016/j.electacta.2019.134564. |

| 30 | ZHANG L, HUANG Q A, YAN W, et al. Design and fabrication of non-noble metal catalyst-based air-cathodes for metal-air battery[J]. The Canadian Journal of Chemical Engineering, 2019, 97(12): 2984-2993. |

| 31 | WANG Y M, SONG S F, XU C H, et al. Development of solid-state electrolytes for sodium-ion battery-A short review[J]. Nano Materials Science, 2019, 1(2): 91-100. |

| 32 | WANG Y F, PAN W D, LEONG K W, et al. Solid-state Al-air battery with an ethanol gel electrolyte[J]. Green Energy & Environment, 2021: doi:10.1016/j.gee.2021.05.011. |

| 33 | ZAHID A R M, MASRI M N, HUSSIN M H, et al. The preliminary study on cassava (Manihot Esculenta) as gel polymer electrolyte for zinc-air battery[J]. AIP Conference Proceedings, 2018, 2030(1): doi:10.1063/1.5066919. |

| 34 | ZHANG Z, ZUO C C, LIU Z H, et al. All-solid-state Al-air batteries with polymer alkaline gel electrolyte[J]. Journal of Power Sources, 2014, 251: 470-475. |

| 35 | MIAO H, CHEN B, LI S H, et al. All-solid-state flexible zinc-air battery with polyacrylamide alkaline gel electrolyte[J]. Journal of Power Sources, 2020, 450: doi: 10.1016/j.jpowsour.2019.227653. |

| 36 | DEGHIEDY N M, EL-SAYED S M. Evaluation of the structural and optical characters of PVA/PVP blended films[J]. Optical Materials, 2020, 100: doi:10.1016/j.optmat.2020.109667. |

| 37 | MANO V, RIBEIRO E SILVA M E S, BARBANI N, et al. Binary blends based on poly(N-isopropylacrylamide): Miscibility studies with PVA, PVP, and PAA[J]. Journal of Applied Polymer Science, 2004, 92(2): 743-748. |

| 38 | MIGLIARDINI F, PALMA T M, GAELE M F, et al. Solid and acid electrolytes for Al-air batteries based on xanthan-HCl hydrogels[J]. Journal of Solid State Electrochemistry, 2018, 22(9): 2901-2916. |

| 39 | DI PALMA T M, MIGLIARDINI F, GAELE M F, et al. Aluminum-air batteries with solid hydrogel electrolytes: Effect of pH upon cell performance[J]. Analytical Letters, 2021, 54(1/2): 28-39. |

| 40 | HATTA F F, YAHYA M Z A, ALI A M M, et al. Electrical conductivity studies on PVA/PVP-KOH alkaline solid polymer blend electrolyte[J]. Ionics, 2005, 11(5/6): 418-422. |

| 41 | 陆霞, 吴仁香, 朱云峰, 等. PVA-PAA-KOH碱性聚合物电解质膜的制备及其性能[J]. 功能材料, 2013, 44(4): 590-594. |

| LU X, WU R X, ZHU Y F, et al. Preparation and properties of PVA-PAA-KOH alkaline polymer electrolyte membrane[J]. Journal of Functional Materials, 2013, 44(4): 590-594. | |

| 42 | YANG C C, LIN S J. Alkaline composite PEO-PVA-glass-fibre-mat polymer electrolyte for Zn-air battery[J]. Journal of Power Sources, 2002, 112(2): 497-503. |

| 43 | WU G M, LIN S J, YANG C C. Alkaline Zn-air and Al-air cells based on novel solid PVA/PAA polymer electrolyte membranes[J]. Journal of Membrane Science, 2006, 280(1/2): 802-808. |

| 44 | WANG M X, FAN L D, QIN G, et al. Flexible and low temperature resistant semi-IPN network gel polymer electrolyte membrane and its application in supercapacitor[J]. Journal of Membrane Science, 2020, 597: doi:10.1016/j.memsci.2019.117740. |

| 45 | LIAO Y H, RAO M M, LI W S, et al. Fumed silica-doped poly(butyl methacrylate-styrene)-based gel polymer electrolyte for lithium ion battery[J]. Journal of Membrane Science, 2010, 352(1/2): 95-99. |

| [1] | Xiongwen XU, Yang NIE, Jian TU, Zheng XU, Jian XIE, Xinbing ZHAO. Abuse performance of pouch-type Na-ion batteries based on Prussian blue cathode [J]. Energy Storage Science and Technology, 2022, 11(7): 2030-2039. |

| [2] | Xiaoyu SHEN, Guanjun CEN, Ronghan QIAO, Jing ZHU, Hongxiang JI, Mengyu TIAN, Zhou JIN, Yong YAN, Yida WU, Yuanjie ZHAN, Hailong YU, Liubin BEN, Yanyan LIU, Xuejie HUANG. Reviews of selected 100 recent papers for lithium batteries (Apr. 1, 2022 to May 31, 2022) [J]. Energy Storage Science and Technology, 2022, 11(7): 2007-2022. |

| [3] | ZHANG Yan, WANG Hai, LIU Zhaomeng, ZHANG Deliu, WANG Jiadong, LI Jianzhong, GAO Xuanwen, LUO Wenbin. Research progress of nickel-rich ternary cathode material ncm for lithium-ion batteries [J]. Energy Storage Science and Technology, 2022, 11(6): 1693-1705. |

| [4] | ZHOU Wei, FU Dongju, LIU Weifeng, CHEN Jianjun, HU Zhao, ZENG Xierong. Research progress on recycling technology of waste lithium iron phosphate power battery [J]. Energy Storage Science and Technology, 2022, 11(6): 1854-1864. |

| [5] | Ronghan QIAO, Guanjun CEN, Xiaoyu SHEN, Mengyu TIAN, Hongxiang JI, Feng TIAN, Wenbin QI, Zhou JIN, Yida WU, Yuanjie ZHAN, Yong YAN, Liubin BEN, Hailong YU, Yanyan LIU, Xuejie HUANG. Reviews of selected 100 recent papers for lithium batteries (Feb. 1, 2022 to Mar. 31, 2022) [J]. Energy Storage Science and Technology, 2022, 11(5): 1289-1304. |

| [6] | Chang SUN, Zerong DENG, Ningbo JIANG, Lulu ZHANG, Hui FANG, Xuelin YANG. Recent research progress of sodium vanadium fluorophosphate as cathode material for sodium-ion batteries [J]. Energy Storage Science and Technology, 2022, 11(4): 1184-1200. |

| [7] | Haiyan HU, Shulei CHOU, Yao XIAO. Layered oxide cathode materials based on molecular orbital hybridization for high voltage sodium-ion batteries [J]. Energy Storage Science and Technology, 2022, 11(4): 1093-1102. |

| [8] | Guanjun CEN, Jing ZHU, Ronghan QIAO, Xiaoyu SHEN, Hongxiang JI, Mengyu TIAN, Feng TIAN, Zhou JIN, Yong YAN, Yida WU, Yuanjie ZHAN, Hailong YU, Liubin BEN, Yanyan LIU, Xuejie HUANG. Reviews of selected 100 recent papers for lithium batteries (Dec. 1, 2021 to Jan. 31, 2022) [J]. Energy Storage Science and Technology, 2022, 11(3): 1077-1092. |

| [9] | Suting WENG, Zepeng LIU, Gaojing YANG, Simeng ZHANG, Xiao ZHANG, Qiu FANG, Yejing LI, Zhaoxiang WANG, Xuefeng WANG, Liquan CHEN. Cryogenic electron microscopy (cryo-EM) characterizing beam-sensitive materials in lithium metal batteries [J]. Energy Storage Science and Technology, 2022, 11(3): 760-780. |

| [10] | Zhongmin REN, Bin WANG, Shuaishuai CHEN, Hua LI, Zhenlian CHEN, Deyu WANG. Mechanics-induced degradation on layer-structured cathodes and remedies to address it [J]. Energy Storage Science and Technology, 2022, 11(3): 948-956. |

| [11] | Chunlin YU, Xudong CHEN, Toshio MIYAGAWA, Hui SUN, Xingwang ZHANG, Lige TONG. Precursor with special structure for improving the performance of the ternary cathode material of Li-ion batteries [J]. Energy Storage Science and Technology, 2022, 11(3): 1000-1007. |

| [12] | Miao WU, Guiqing ZHAO, Zhongzhu QIU, Baofeng WANG. Preparation and electrochemical properties of NiCo2O4 as a novel cathode material for aqueous zinc-ion batteries [J]. Energy Storage Science and Technology, 2022, 11(3): 1019-1025. |

| [13] | Linhui JIA, Zejia GAI, Moxi LI, Huagen LIANG. Research progress of MOFs and their derivatives as cathode catalysts for Li-O2 batteries [J]. Energy Storage Science and Technology, 2022, 11(2): 503-510. |

| [14] | Penghui LI, Caiwen WU, Jianpeng REN, Wenjuan WU. Research progress of lignin as electrode materials for lithium-ion batteries [J]. Energy Storage Science and Technology, 2022, 11(1): 66-77. |

| [15] | Mengyu TIAN, Jing ZHU, Guanjun CEN, Ronghan QIAO, Xiaoyu SHEN, Hongxiang JI, Feng TIAN, Zhou JIN, Yong YAN, Yida WU, Yuanjie ZHAN, Hailong YU, Liubin BEN, Yanyan LIU, Xuejie HUANG. Reviews of selected 100 recent papers for lithium batteries(Oct. 1, 2021 to Nov. 30, 2021) [J]. Energy Storage Science and Technology, 2022, 11(1): 297-312. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||