Energy Storage Science and Technology ›› 2023, Vol. 12 ›› Issue (2): 398-430.doi: 10.19799/j.cnki.2095-4239.2022.0521

• Energy Storage Materials and Devices • Previous Articles Next Articles

Wei LIU1( ), Zhenming LI1(

), Zhenming LI1( ), Mingyang LIU1, Cenyu YANG1, Chao MEI2, Ying LI2

), Mingyang LIU1, Cenyu YANG1, Chao MEI2, Ying LI2

Received:2022-09-13

Revised:2022-10-21

Online:2023-02-05

Published:2023-02-24

Contact:

Zhenming LI

E-mail:liuwei3@epri.sgcc.com.cn;lizhenming@epri.sgcc.com.cn

CLC Number:

Wei LIU, Zhenming LI, Mingyang LIU, Cenyu YANG, Chao MEI, Ying LI. Review of high-temperature phase change heat storage material preparation and applications[J]. Energy Storage Science and Technology, 2023, 12(2): 398-430.

Table 1

Thermophysical properties of inorganic salts of some high-temperature phase change materials[6-7, 17-21]"

| 化合物 | 熔化温度/℃ | 熔化热/(kJ/kg) | 导热系数/[W/(m·K)] | 比热容/[kJ/(kg·K)] |

|---|---|---|---|---|

| NaNO3 | 306 | 182 | 0.5/—(液固) | —/1.1(液固) |

| KNO3 | 334 | 266 | —/0.5 | —/0.953(液固) |

| NaOH | 323 | 170 | 0.92/—(液固) | 2.09/2.01(液固) |

| KOH | 380 | 149.7 | —/0.5(液固) | — |

| Na2CO3 | 854 | 275.7 | — | —/2(液固) |

| K2CO3 | 897 | 235.8 | — | —/2(液固) |

| 96KNO3-4KCl | 320 | 150 | —/0.5(液固) | —/1.21(液固) |

| 60MgCl2-20.4KCl-19.6NaCl | 380 | 400 | — | —/0.96(液固) |

| 52MgCl2-48NaCl | 450 | 430 | 0.95/—(液固) | 1/0.92(液固) |

| 64MgCl2-36KCl | 470 | 388 | 0.83/—(液固) | 0.96/0.84(液固) |

| 48MgCl2-27CaCl2-25KCl | 487 | 342 | 0.88/—(液固) | 0.92/0.8(液固) |

| 53BaCl2-28KCl-19NaCl | 542 | 221 | 0.86/—(液固) | 0.8/0.63(液固) |

| 44Li2CO3-56Na2CO3 | 496 | 370 | 2.09/—(液固) | 2.09/1.8(液固) |

| 39MgCl2-61NaCl | 435 | 351 | 0.81/—(液固) | 0.96/0.8(液固) |

| 22Li2CO3-16Na2CO3-62K2CO3 | 580 | 288 | 1.95/—(液固) | 2.09/1.80(液固) |

| 67CaCl2-33NaCl | 500 | 281 | 1.02/—(液固) | 1/0.84(液固) |

| 33LiF-67KF | 442 | 618 | 3.98/—(液固) | 1.63/1.34(液固) |

| 12NaF-59KF-29LiF | 454 | 590 | 4.50/—(液固) | 1.55/1.34(液固) |

| 20Li2CO3-60Na2CO3-20K2CO3 | 550 | 283 | 1.83/—(液固) | 1.88/1.59(液固) |

| 54KCl-46ZnCl2 | 432 | 218 | 0.83/—(液固) | 0.88/0.67(液固) |

| 28KCl-19NaCl-53BaCl2 | 542 | 221 | 0.86/—(液固) | 0.80/0.63(液固) |

| 48NaCl-52MgCl2 | 450 | 430 | 0.95/—(液固) | 1.00/0.92(液固) |

| 47BaCl2-24KCl-29CaCl | 551 | 219 | 0.95/—(液固) | 0.84/0.67(液固) |

| 36KCl-64MgCl2 | 470 | 388 | 0.83/—(液固) | 0.96/0.84(液固) |

| 33NaCl-67CaCl2 | 500 | 281 | 1.02/—(液固) | 1.00/0.84(液固) |

| 37MgCl2-63SrCl2 | 535 | 239 | 1.05/—(液固) | 0.80/0.67(液固) |

| 47Li2CO3-53K2CO3 | 488 | 342 | 1.99/—(液固) | 1.34/1.03(液固) |

| 17NaF-21KF-62K2CO3 | 520 | 274 | 1.50/—(液固) | 1.38/1.17(液固) |

| 28Li2CO3-72K2CO3 | 498 | 263 | 1.85/—(液固) | 1.80/1.46(液固) |

| 51K2CO3-49Na2CO3 | 710 | 163 | 1.73/—(液固) | 1.56/1.67(液固) |

| 24KCl-47BaCl2-29CaCl2 | 551 | 219 | 0.95/—(液固) | 0.84/0.67(液固) |

| 32Li2CO3-35K2CO3-Na2CO3 | 397 | 276 | 2.02/—(液固) | 1.63/1.67(液固) |

| 61KCl-39MgCl2 | 435 | 351 | 0.81/—(液固) | 0.96/0.8(液固) |

| 40KCl-23KF-37K2CO3 | 528 | 283 | 1.19/—(液固) | 1.26/1(液固) |

| 35Li2CO3-65K2CO3 | 505 | 344 | 1.89/—(液固) | 1.76/1.34(液固) |

Table 3

Thermophysical properties of metal alloys of some high temperature phase change materials[17]"

| 金属及金属合金 | 熔化温度/℃ | 熔化热/(kJ/kg) |

|---|---|---|

| Zn | 419 | 112 |

| Al | 661 | 388 |

| 96Zn-4Al | 381 | 138 |

| 86.4Al-9.4Si-4.2Sb | 471 | 471 |

| 59Al-33Mg-6Zn | 443 | 310 |

| 65.35Al-34.65Mg | 497 | 285 |

| 60.8Al-33.2Cu-6Mg | 506 | 365 |

| 64.6Al-28Cu-5.2Si-2.2Mg | 507 | 374 |

| 68.5Al-26.5Cu-5Si | 525 | 364 |

| Mg | 648 | 365 |

| 46.3Mg-53.7Zn | 341 | 185 |

| 86Si-12Al | 576 | 560 |

| 56Si-44Mg | 946 | 757 |

| 49Zn-45Cu-6Mg | 703 | 176 |

| 49.1Cu-46.3Al-4.6Si | 571 | 406 |

| 83.14Al-11.7Si-5.16Mg | 555 | 485 |

| 64.1Al-28Mg-5.2Si-2.2Cu | 507 | 374 |

| 66.92Al-33.08Cu | 548 | 372 |

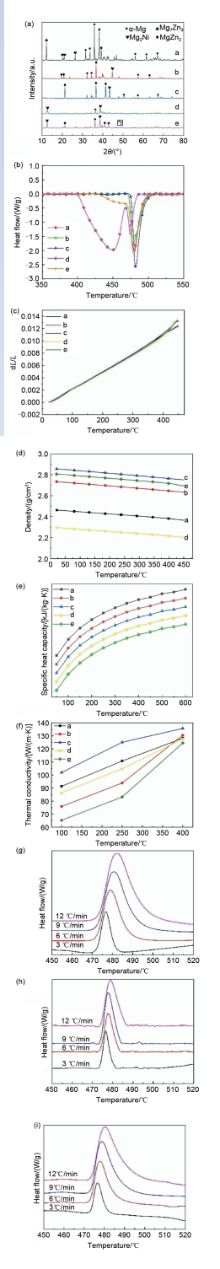

Fig. 1

The DSC dependence of temperature of different compositions (a) 87.8Al-12.2Si, 80Al-20Si, 70Al-30Si, and 60Al-40Si, and (c) 45Al-40Si-15Fe and 17Al-53Si-30Ni with 87.8Al-12.2Si for comparison[26]; (b) The specific heat dependence of temperature of 87.8Al-12.2Si, 80Al-20Si, 70Al-30Si, 60Al-40Si, 45Al-40Si-15Fe, and 17Al-53Si-30Ni[26]; (d) Thermal conductivity of all the compositions: 87.8Al-12.2Si, 80Al-20Si, 70Al-30Si, 60Al-40Si, 45Al-40Si-15Fe, and 17Al-53Si-30Ni[26]"

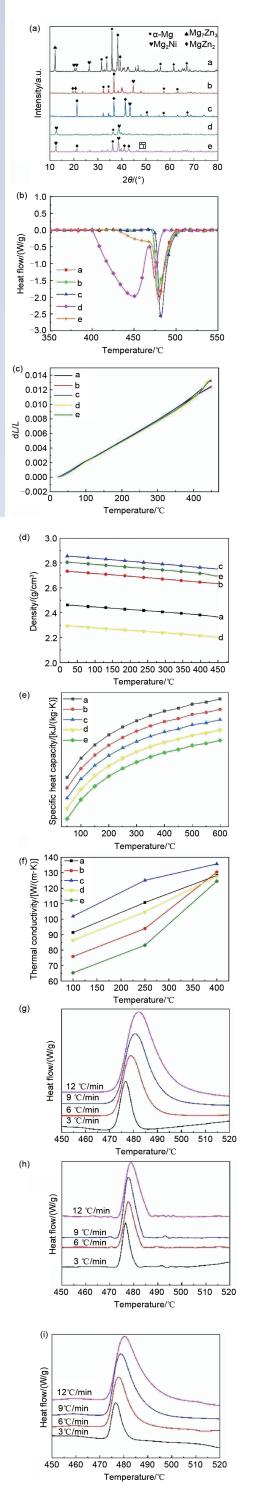

Fig. 2

(a)The XRD patterns of Mg-Ni-Zn alloys[31],(b)DSC curves of Mg-Ni-Zn alloys; (c)Relative elongation of Mg-Ni-Zn alloys[31]; (d)Temperature dependence of density of Mg-Ni-Zn alloys[31]; (e)Temperatures dependence of the specific heat capacity of Mg-Ni-Zn alloys[31]; (f)Temperatures dependence of the thermal conductivity of Mg-Ni-Zn alloys[31]; (g)—(i) DSC curves of Mg-Ni-Zn alloys at different heating rates[(g)Mg-16Ni-24Zn, (h)Mg-15Ni-31Zn, (i)Mg-20.8Ni-22.6Zn][31]"

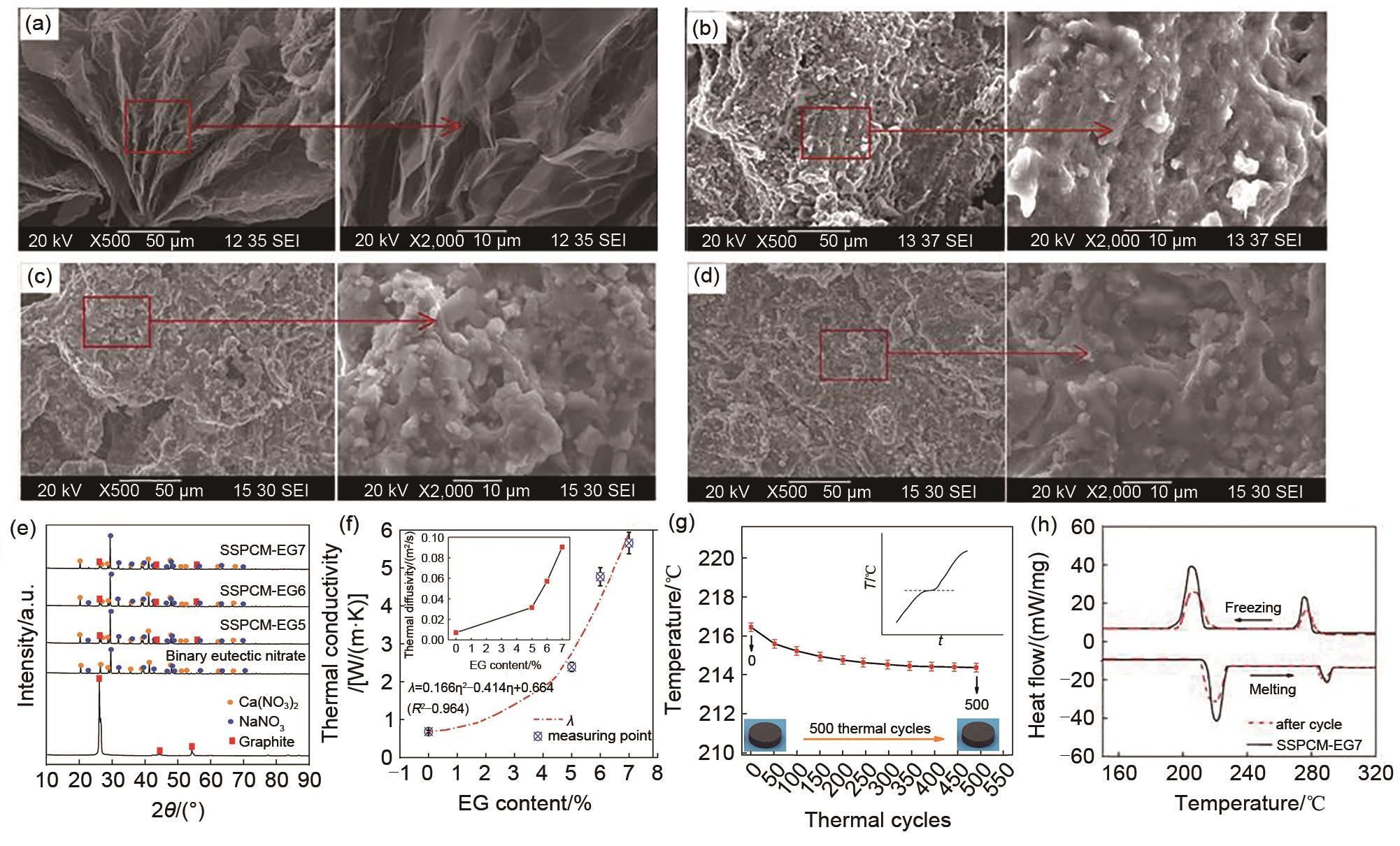

Fig. 3

SEM images of (a) expanded graphite; (b) 5%expanded graphite+Ca(NO3)2-NaNO3; (c) 6%expanded graphite+Ca(NO3)2-NaNO3; (d) 7%expanded graphite+Ca(NO3)2-NaNO3[46]; (e) XRD patterns; (f)Thermal conductivities and of the binary nitrate and composite phase change material[46]; (g)Variation of the phase change temperature of the 7%expanded graphite+Ca(NO3)2-NaNO3[46]; (h)DSC curves of the 7%expanded graphite+Ca(NO3)2-NaNO3 before and after 500 thermal cycles[46]"

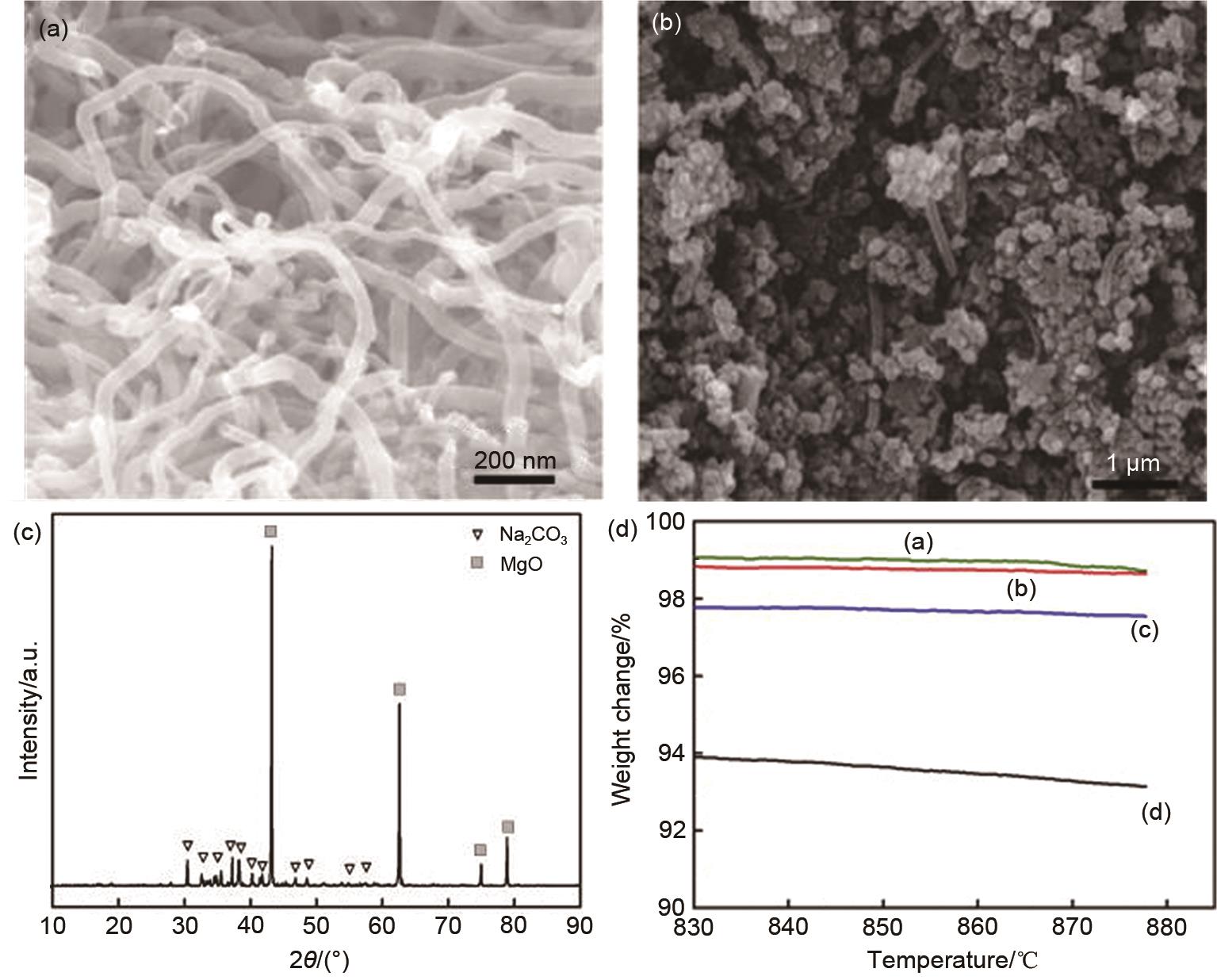

Fig. 5

SEM images of multi-walled carbon nanotubes(a) and Na2CO3/MgO composite phase change material with added MWCNTs sintered at high temperature (b)[53]; (c)X-ray diffraction patterns of Na2CO3/MgO composite phase change material[53]; (d)Thermal gravity analyses of Na2CO3/MgO composite phase change material[53]"

Fig. 12

(a)Schematic of KNO3/ diatomite composite prepared by mixed sintering method[70]; (b) A flow chart of the novel process for fabricating the MgCl2-KCl/expanded graphite composite phase change material[48]; (c)Schematic of the synthesis of Ca(NO3)2-NaNO3/expanded graphite composite phase change material[46]"

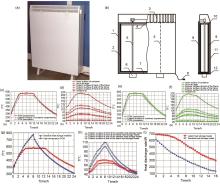

Fig. 15

(a)—(b)Photo of the high temperature phase change storage heater[95]; (c)—(d)Temperature curves with heating power of 1540 W[95]; (e)—(f)Temperature curves with heating power of 1810 W[95]; (g)Temperature curves of heat storage medium[95]; (h)Temperature curves of exterior surfaces of the heaters[95]; (i)Heat discharge rate of the heaters during power off[95]"

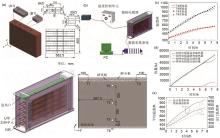

Fig. 16

(a)Scheme of the electrical storage heater[96]; (b)Scheme of the electric heater test process[96]; (c)Comparison between experimental and modelling results[96]; (d)Comparison of electrical storage heater total heat storage capacity[96]; (e)Compare the average temperature in the heater with the temperature at the outlet[96]"

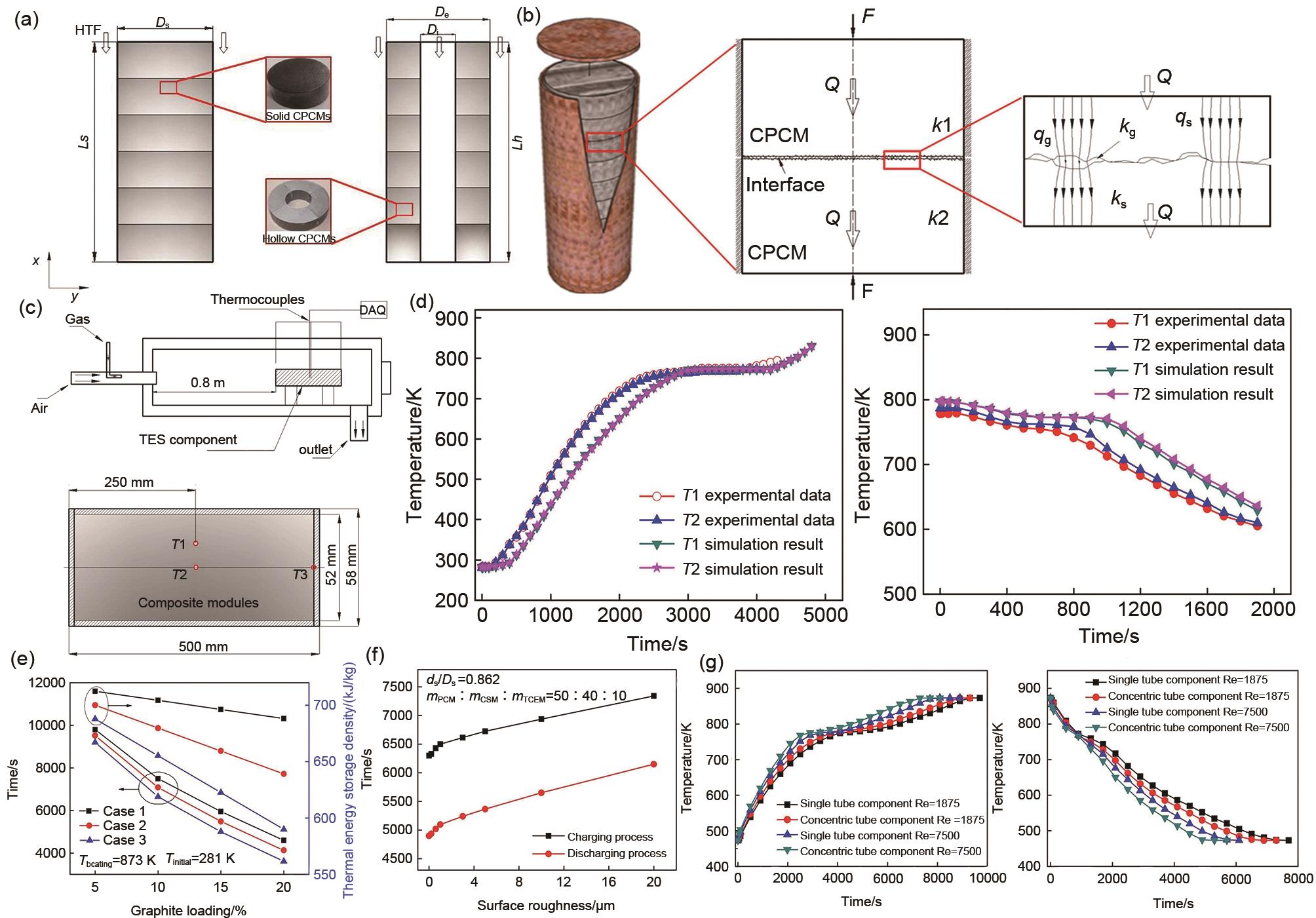

Fig. 17

(a)Single tube based component and Concentric tube based component[97]; (b)Contact of rough surface between CPCMs module with presence of gas[97]; (c)Diagrammatic sketches of the experimental apparatus[97]; (d)Comparison of the experimental data and numerical results[97]; (e)Heat storage time and heat storage element density as a function of graphite loading[97]; (f)Effects of surface roughness of CPCMs module on charging and discharging processes[97]; (g)Comparison of two heat storage components based on phase change materials[97]"

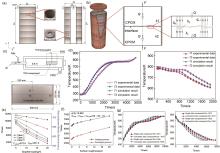

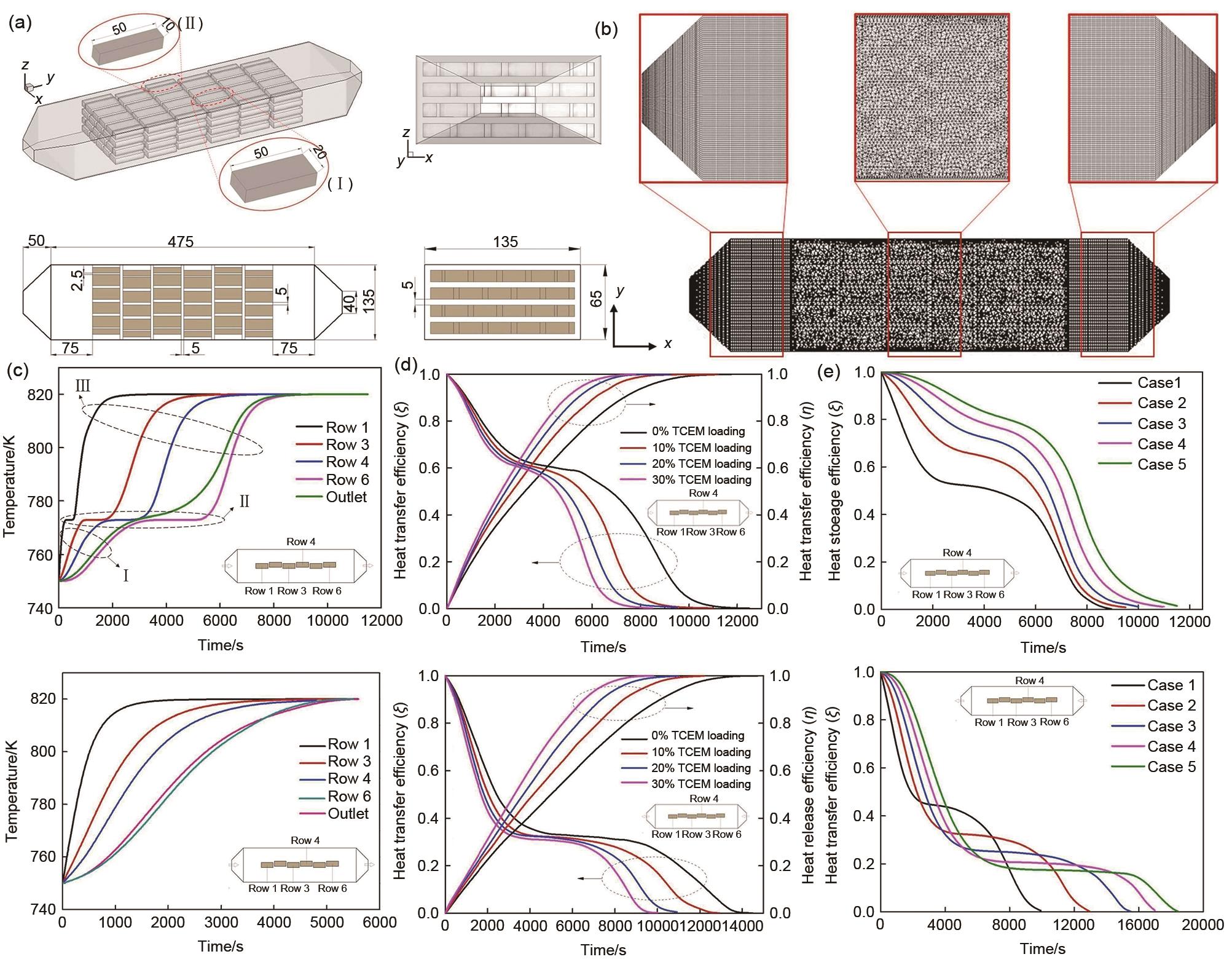

Fig. 19

(a)Schematic illustrations of the CPCMs based packed bed TES system[105]; (b)Meshing of the computational domain of the packed bed containing CPCMs[105]; (c)The time evolution of temperature at different locations of the system containing CPCMs and ferric oxide over the charging process[105]; (d)Time evolution of the heat transfer efficiency and heat storage/release efficiency at different graphite loading in the CPCMs during the charging process and discharging process[105]; (e)Time evolutions of the heat transfer efficiency at different operation conditions during the charging process and discharging proces[105]"

| 1 | 程珊珊. 基于电、煤锅炉联合供暖的弃风消纳策略研究[D]. 沈阳: 沈阳工业大学, 2020. |

| CHENG S S. Research on wind power accommodation strategy of combined heating of electric and coal boilers[D]. Shenyang: Shenyang University of Technology, 2020. | |

| 2 | JACOB R, BELUSKO M, INÉS FERNÁNDEZ A, et al. Embodied energy and cost of high temperature thermal energy storage systems for use with concentrated solar power plants[J]. Applied Energy, 2016, 180: 586-597. |

| 3 | YANG T Y, KING W P, MILJKOVIC N. Phase change material-based thermal energy storage[J]. Cell Reports Physical Science, 2021, 2(8): doi: 10.1016/j.xcrp.2021.100540. |

| 4 | HE F, SONG G P, HE X D, et al. Structural and phase change characteristics of inorganic microencapsulated core/shell Al-Si/Al2O3 micro-particles during thermal cycling[J]. Ceramics International, 2015, 41(9): 10689-10696. |

| 5 | ZHANG G C, LI J Q, CHEN Y F, et al. Encapsulation of copper-based phase change materials for high temperature thermal energy storage[J]. Solar Energy Materials and Solar Cells, 2014, 128: 131-137. |

| 6 | WEI G S, WANG G, XU C, et al. Selection principles and thermophysical properties of high temperature phase change materials for thermal energy storage: A review[J]. Renewable and Sustainable Energy Reviews, 2018, 81: 1771-1786. |

| 7 | KENISARIN M M. High-temperature phase change materials for thermal energy storage[J]. Renewable and Sustainable Energy Reviews, 2010, 14(3): 955-970. |

| 8 | KHARE S, DELL'AMICO M, KNIGHT C, et al. Selection of materials for high temperature latent heat energy storage[J]. Solar Energy Materials and Solar Cells, 2012, 107: 20-27. |

| 9 | LIU M, FERNÁNDEZ A I, SEGARRA M. Materials for phase change material at high temperature[M]//High Temperature Thermal Storage Systems Using Phase Change Materials. Amsterdam: Elsevier, 2018: 195-230. |

| 10 | ANSYS. The 21th anniversary celebration of materials selection software, Cambridge[EB/OL]. (2007-08-15)[2013-05-29].http://www.newmaker.com/. |

| 11 | MISHRA R K, VERMA K, MISHRA V, et al. A review on carbon-based phase change materials for thermal energy storage[J]. Journal of Energy Storage, 2022, 50: doi: 10.1016/j.est.2022.104166. |

| 12 | LIU M, OMARAA E S, QI J, et al. Review and characterisation of high-temperature phase change material candidates between 500 C and 700 ℃[J]. Renewable and Sustainable Energy Reviews, 2021, 150: doi: 10.1016/j.rser.2021.111528. |

| 13 | ZHONG L M, ZHANG X W, LUAN Y, et al. Preparation and thermal properties of porous heterogeneous composite phase change materials based on molten salts/expanded graphite[J]. Solar Energy, 2014, 107: 63-73. |

| 14 | TIAN H Q, WANG W L, DING J, et al. Thermal conductivities and characteristics of ternary eutectic chloride/expanded graphite thermal energy storage composites[J]. Applied Energy, 2015, 148: 87-92. |

| 15 | BAUER T, DRTE L, ULRIKE K, et al. Sodium nitrate for high temperature latent heat storage[C]//The 11 th International Conference on Thermal Energy Storage-Effstock. DLR, 2009. |

| 16 | HEIDENREICH G R, PAREKH M B. Thermal energy storage for organic Rankine cycle solar dynamic space power systems[J]. Proceedings of the Intersociety Energy Conversion Engineering Conference, 1986: 791-797. |

| 17 | CÁRDENAS B, LEÓN N. High temperature latent heat thermal energy storage: Phase change materials, design considerations and performance enhancement techniques[J]. Renewable and Sustainable Energy Reviews, 2013, 27: 724-737. |

| 18 | MARIANOWSKI L G, MARU H C. Latent heat thermal energy storage systems above 450 C[C]//12th Intersociety Energy Conversion Engineering Conference, 1977, 1: 555-566. |

| 19 | DULLES J F, Maru H C. Molten-salt thermal-energy storage systems[R]. CHO (Chicago Operations Office, Argonne, IL (United States)), 1977:1-129. |

| 20 | VERDIEV N N, ARBUKHANOVA P A, ISKENDEROV E G. NaF-NaBr-Na2MoO4 and KF-KCl-KBr ternary systems[J]. Russian Journal of Inorganic Chemistry, 2009, 54(1): 128-133. |

| 21 | PETRI R, ONG E, MARTIN J. High temperature composite thermal energy storage (TES) systems for industrial applications[R]. Institute of Gas Technology, Chicago, IL (USA); Oak Ridge National Lab. TN (USA), 1986 |

| 22 | MISRA A K. Fluoride salts and container materials for thermal energy storage applications in the temperature range 973-1400 K[C]//22nd Intersociety Energy Conversion Engineering Conference. August 10-14, 1987, Philadelphia, Pennsylvania. Reston, Virginia: AIAA, 1987: doi: 10.2514/6.1987-9226. |

| 23 | BIRCHENALL C E, TELKES M. Thermal storage in metals[J]. Sharing the Sun: Solar Technology in the Seventies, 1976, 8(8): 138-154. |

| 24 | RIECHMAN A F. Heat storage in eutectic alloys[J]. Metallurgical Transactions A, 1980, 11(8): 1415-1420. |

| 25 | ACHARD P. Heat Storage at 450 deg C in Aluminum-Magnesium Alloys[J]. Rational Utilization of Energy, 1981: 39-46. |

| 26 | WANG Z Y, WANG H, LI X B, et al. Aluminum and silicon based phase change materials for high capacity thermal energy storage[J]. Applied Thermal Engineering, 2015, 89: 204-208. |

| 27 | HUANG Z G, MEI S H, WU G Z. Prospect of metal phase change thermal energy storage technologies[J]. New Energy 1999(4): 1-5. |

| 28 | SUN J Q, ZHANG R Y, LIU Z P, et al. Thermal reliability test of Al-34%Mg-6%Zn alloy as latent heat storage material and corrosion of metal with respect to thermal cycling[J]. Energy Conversion and Management, 2007, 48(2): 619-624. |

| 29 | RODRÍGUEZ-ASEGUINOLAZA J, BLANCO-RODRÍGUEZ P, RISUEÑO E, et al. Thermodynamic study of the eutectic Mg49-Zn51 alloy used for thermal energy storage[J]. Journal of Thermal Analysis and Calorimetry, 2014, 117(1): 93-99. |

| 30 | BLANCO-RODRÍGUEZ P, RODRÍGUEZ-ASEGUINOLAZA J, RISUEÑO E, et al. Thermophysical characterization of Mg-51%Zn eutectic metal alloy: A phase change material for thermal energy storage in direct steam generation applications[J]. Energy, 2014, 72: 414-420. |

| 31 | CHEN H X, LI J J, LI Y Y, et al. Microstructure and phase transition kinetics of Mg-Ni-Zn alloy phase change thermal storage materials[J]. Journal of Alloys and Compounds, 2020, 829: doi: 10.1016/j.jallcom.2020.154574. |

| 32 | FANG D, CHENG X M, LI Y Y, et al. Microstructure and thermal characteristics of Mg-Sn alloys as phase change materials for thermal energy storage[J]. RSC Advances, 2016, 6(98): 96327-96333. |

| 33 | FANG D, SUN Z, LI Y Y, et al. Preparation, microstructure and thermal properties of MgBi alloys as phase change materials for thermal energy storage[J]. Applied Thermal Engineering, 2016, 92: 187-193. |

| 34 | SUN Z, LI L F, CHENG X M, et al. Thermal properties and the prospects of thermal energy storage of Mg-25%Cu-15%Zn eutectic alloy as phase change material[J]. Materials (Basel, Switzerland), 2021, 14(12): doi: 10.3390/ma14123296. |

| 35 | RISUEÑO E, DOPPIU S, RODRÍGUEZ-ASEGUINOLAZA J, et al. Experimental investigation of Mg-Zn-Al metal alloys for latent heat storage application[J]. Journal of Alloys and Compounds, 2016, 685: 724-732. |

| 36 | SABOL J C, MISIOLEK W Z, OZTEKIN A, et al. Characterization of intermediate phases formed between solid nickel and liquid zinc during use as an encapsulated phase change material in solar thermal energy storage systems[J]. Metallography, Microstructure, and Analysis, 2012, 1(5): 208-216. |

| 37 | ADINBERG R, ZVEGILSKY D, EPSTEIN M. Heat transfer efficient thermal energy storage for steam generation[J]. Energy Conversion and Management, 2010, 51(1): 9-15. |

| 38 | TAO Y B, HE Y L. A review of phase change material and performance enhancement method for latent heat storage system[J]. Renewable and Sustainable Energy Reviews, 2018, 93: 245-259. |

| 39 | ZHAO C Y, WU Z G. Heat transfer enhancement of high temperature thermal energy storage using metal foams and expanded graphite[J]. Solar Energy Materials and Solar Cells, 2011, 95(2): 636-643. |

| 40 | 祁先进. 金属基相变复合蓄热材料的实验研究[D]. 昆明: 昆明理工大学, 2005. |

| QI X J. Experimental study on composite heat storage material with metal and molten[D]. Kunming: Kunming University of Science and Technology, 2005. | |

| 41 | ZHANG P, XIAO X, MENG Z N, et al. Heat transfer characteristics of a molten-salt thermal energy storage unit with and without heat transfer enhancement[J]. Applied Energy, 2015, 137: 758-772. |

| 42 | SINGH D, KIM T, ZHAO W H, et al. Development of graphite foam infiltrated with MgCl2 for a latent heat based thermal energy storage (LHTES) system[J]. Renewable Energy, 2016, 94: 660-667. |

| 43 | LAFDI K, MESALHY O, ELGAFY A. Graphite foams infiltrated with phase change materials as alternative materials for space and terrestrial thermal energy storage applications[J]. Carbon, 2008, 46(1): 159-168. |

| 44 | ZHAO W H, FRANCE D M, YU W H, et al. Phase change material with graphite foam for applications in high-temperature latent heat storage systems of concentrated solar power plants[J]. Renewable Energy, 2014, 69: 134-146. |

| 45 | PY X, OLIVES R, MAURAN S. Paraffin/porous-graphite-matrix composite as a high and constant power thermal storage material[J]. International Journal of Heat and Mass Transfer, 2001, 44(14): 2727-2737. |

| 46 | REN Y X, XU C, YUAN M D, et al. Ca(NO3)2-NaNO3/expanded graphite composite as a novel shape-stable phase change material for mid- to high-temperature thermal energy storage[J]. Energy Conversion and Management, 2018, 163: 50-58. |

| 47 | TIAN H Q, WANG W L, DING J, et al. Preparation of binary eutectic chloride/expanded graphite as high-temperature thermal energy storage materials[J]. Solar Energy Materials and Solar Cells, 2016, 149: 187-194. |

| 48 | LIU J W, WANG Q H, LING Z Y, et al. A novel process for preparing molten salt/expanded graphite composite phase change blocks with good uniformity and small volume expansion[J]. Solar Energy Materials and Solar Cells, 2017, 169: 280-286. |

| 49 | ZHAO Y J, WANG R Z, WANG L W, et al. Development of highly conductive KNO3/NaNO3 composite for TES (thermal energy storage)[J]. Energy, 2014, 70: 272-277. |

| 50 | XU T, LI Y T, CHEN J Y, et al. Preparation and thermal energy storage properties of LiNO3-KCl-NaNO3/expanded graphite composite phase change material[J]. Solar Energy Materials and Solar Cells, 2017, 169: 215-221. |

| 51 | PETRI R, ONG E, MARIANOWSKI L. High temperature composite thermal storage systems for industrial applications[R]. Institute of Gas Technology, Chicago, IL (USA); Oak Ridge National Lab. TN (USA), 1985. |

| 52 | GOKON N, NAKANO D, INUTA S, et al. High-temperature carbonate/MgO composite materials as thermal storage media for double-walled solar reformer tubes[J]. Solar Energy, 2008, 82(12): 1145-1153. |

| 53 | YE F, GE Z W, DING Y L, et al. Multi-walled carbon nanotubes added to Na2CO3/MgO composites for thermal energy storage[J]. Particuology, 2014, 15: 56-60. |

| 54 | GE Z W, YE F, CAO H, et al. Carbonate-salt-based composite materials for medium-and high-temperature thermal energy storage[J]. Particuology, 2014, 15: 77-81. |

| 55 | JIANG Z, JIANG F, LI C, et al. A form stable composite phase change material for thermal energy storage applications over 700 ℃[J]. Applied Sciences, 2019, 9(5): doi: 10.3390/app9050814. |

| 56 | SANG L X, LI F, XU Y W. Form-stable ternary carbonates/MgO composite material for high temperature thermal energy storage[J]. Solar Energy, 2019, 180: 1-7. |

| 57 | JIANG Y F, SUN Y P, LI S A. Performance of novel Na2SO4-NaCl-ceramic composites as high temperature phase change materials for solar power plants (Part II)[J]. Solar Energy Materials and Solar Cells, 2019, 194: 285-294. |

| 58 | JIANG Y F, SUN Y P, JACOB R D, et al. Novel Na2SO4-NaCl-ceramic composites as high temperature phase change materials for solar thermal power plants (Part I)[J]. Solar Energy Materials and Solar Cells, 2018, 178: 74-83. |

| 59 | ZHOU W B, LI R G, ZHOU W, et al. Fabrication of Al2O3-NaCl composite heat storage materials by one-step synthesis method[J]. Journal of Wuhan University of Technology-Mater Sci Ed, 2016, 31(5): 950-954. |

| 60 | QIAN T T, LI J H, MIN X, et al. Radial-like mesoporous silica sphere: A promising new candidate of supporting material for storage of low-, middle-, and high-temperature heat[J]. Energy, 2016, 112: 1074-1083. |

| 61 | NOTTER W, LECHNER T, GROß U, et al. Thermophysical properties of the composite ceramic-salt system (SiO2/Na2SO4)[J]. Thermochimica Acta, 1993, 218: 455-463. |

| 62 | 李爱菊, 王毅. 无机盐/陶瓷基复合蓄热材料高温稳定性的研究[J]. 材料导报, 2011, 25(12): 78-81. |

| LI A J, WANG Y. Study on the high temperature stability of salt/ceramic composite heat storage material[J]. Materials Review, 2011, 25(12): 78-81. | |

| 63 | 吴建锋, 李剑, 徐晓虹, 等. NaCl/SiC泡沫陶瓷高温复合相变蓄热材料[J]. 武汉理工大学学报, 2009, 31(17): 70-73. |

| WU J F, LI J, XU X H, et al. Preparation of molten salts/ceramic-foam composites by melt infiltration method as energy storagy materials at high temperature[J]. Journal of Wuhan University of Technology, 2009, 31(17): 70-73. | |

| 64 | LI Y, GUO B, HUANG G F, et al. Characterization and thermal performance of nitrate mixture/SiC ceramic honeycomb composite phase change materials for thermal energy storage[J]. Applied Thermal Engineering, 2015, 81: 193-197. |

| 65 | XU G Z, LENG G H, YANG C Y, et al. Sodium nitrate - Diatomite composite materials for thermal energy storage[J]. Solar Energy, 2017, 146: 494-502. |

| 66 | DENG Y, LI J H, NIAN HONGEN. Expanded vermiculite: A promising natural encapsulation material of LiNO3, NaNO3, and KNO3 phase change materials for medium-temperature thermal energy storage[J]. Advanced Engineering Materials, 2018, 20(8): doi: 10.1002/adem.201800135. |

| 67 | LENG G H, QIAO G, JIANG Z, et al. Micro encapsulated & form-stable phase change materials for high temperature thermal energy storage[J]. Applied Energy, 2018, 217: 212-220. |

| 68 | QIAN T T, LI J H, MIN X, et al. Diatomite: A promising natural candidate as carrier material for low, middle and high temperature phase change material[J]. Energy Conversion and Management, 2015, 98: 34-45. |

| 69 | QIN Y, LENG G H, YU X, et al. Sodium sulfate-diatomite composite materials for high temperature thermal energy storage[J]. Powder Technology, 2015, 282: 37-42. |

| 70 | DENG Y, LI J H, QIAN T T, et al. Preparation and characterization of KNO3/diatomite shape-stabilized composite phase change material for high temperature thermal energy storage[J]. Journal of Materials Science & Technology, 2017, 33(2): 198-203. |

| 71 | LIU R P, ZHANG F, SU W M, et al. Impregnation of porous mullite with Na2SO4 phase change material for thermal energy storage[J]. Solar Energy Materials and Solar Cells, 2015, 134: 268-274. |

| 72 | LV P Z, LIU C Z, RAO Z H. Review on clay mineral-based form-stable phase change materials: Preparation, characterization and applications[J]. Renewable and Sustainable Energy Reviews, 2017, 68: 707-726. |

| 73 | LI R G, ZHU J Q, ZHOU W B, et al. Thermal compatibility of Sodium Nitrate/Expanded Perlite composite phase change materials[J]. Applied Thermal Engineering, 2016, 103: 452-458. |

| 74 | LI R G, ZHU J Q, ZHOU W B, et al. Thermal properties of sodium nitrate-expanded vermiculite form-stable composite phase change materials[J]. Materials & Design, 2016, 104: 190-196. |

| 75 | 顾华志, 韩藏娟, 张美杰, 等. 高温相变蓄热材料的封装研究及应用展望[J]. 耐火材料, 2021, 55(6): 528-532, 538. |

| GU H Z, HAN C J, ZHANG M J, et al. Package research and application of high-temperature phase change heat storage materials[J]. Refractories, 2021, 55(6): 528-532, 538. | |

| 76 | JIANG F, ZHANG L L, SHE X H, et al. Skeleton materials for shape-stabilization of high temperature salts based phase change materials: A critical review[J]. Renewable and Sustainable Energy Reviews, 2020, 119: doi: 10.1016/j.rser.2019.109539. |

| 77 | PINCEMIN S, OLIVES R, PY X, et al. Highly conductive composites made of phase change materials and graphite for thermal storage[J]. Solar Energy Materials and Solar Cells, 2008, 92(6): 603-613. |

| 78 | SINGH D, YU W H, ZHAO W H, et al. Development and prototype testing of MgCl2/graphite foam latent heat thermal energy storage system[J]. Solar Energy, 2018, 159: 270-282. |

| 79 | WU Z G, ZHAO C Y. Experimental investigations of porous materials in high temperature thermal energy storage systems[J]. Solar Energy, 2011, 85(7): 1371-1380. |

| 80 | 何镐东, 杨林, 曹建新. 黄磷渣与硫酸钠-氯化钠制备高温复合相变储能材料[J/OL]. 无机盐工业. [2022-07-24]. https://doi.org/10.19964/j.issn.1006-4990.2022-0140. |

| HE H D, YANG L, CAO J X. Preparation of high temperature composite phase change energy storage materials by yellow phosphorus slag and Na2SO4-NaCl[J/OL]. Inorganic Chemicals Industry. [2022-07-24]. https://doi.org/10.19964/j.issn.1006-4990. 2022-0140. | |

| 81 | 刘汉昌, 朱桂花, 吕硕, 等. 相变介质组成对粉煤灰基高温定形复合相变材料蓄热性能的影响[J]. 硅酸盐通报, 2022, 41(2): 597-606. |

| LIU H C, ZHU G H, LYU S, et al. Influence of phase change medium composition on heat storage performance of fly ash-based high-temperature shaped composite phase change materials[J]. Bulletin of the Chinese Ceramic Society, 2022, 41(2): 597-606. | |

| 82 | 韩金鹏, 朱桂花, 吕硕, 等. 相变介质粒径对粉煤灰基高温定形复合相变材料蓄热性能的影响[J]. 煤炭转化, 2019, 42(1): 78-86. |

| HAN J P, ZHU G H, LYU S, et al. Effects of particle size of phase change medium on thermal storage performance of fly ash-based high temperature formstable composite phase change material[J]. Coal Conversion, 2019, 42(1): 78-86. | |

| 83 | 焦勇. Al-Si/Al2O3高温复合相变蓄热材料的制备与性能研究[D]. 西安: 西安建筑科技大学, 2012. |

| JIAO Y. Study on preparation and properties of Al-Si/Al2O3 high temperature phase change heat storage materials[D]. Xi'an: Xi'an University of Architecture and Technology, 2012. | |

| 84 | 王建宏. 粉煤灰基高温复合相变蓄热材料的制备与性能研究[D]. 西安: 西安建筑科技大学, 2013. |

| WANG J H. Study on preparation and properties of high temperature fly ash base phase change heat storage composite materials[D]. Xi'an: Xi'an University of Architecture and Technology, 2013. | |

| 85 | HAN C J, GU H Z, ZHANG M J, et al. Preparation and characterization of a heat storage ceramic with Al-12 wt% Si as the phase change material[J]. Ceramics International, 2020, 46(18): 28042-28052. |

| 86 | GUO Q, WANG T. Preparation and characterization of sodium sulfate/silica composite as a shape-stabilized phase change material by Sol-gel method[J]. Chinese Journal of Chemical Engineering, 2014, 22(3): 360-364. |

| 87 | LAI C C, LIN S M, CHU Y D, et al. Tunable endothermic plateau for enhancing thermal energy storage obtained using binary metal alloy particles[J]. Nano Energy, 2016, 25: 218-224. |

| 88 | ORTEGA-FERNÁNDEZ I, RODRÍGUEZ-ASEGUINOLAZA J. Thermal energy storage for waste heat recovery in the steelworks: The case study of the REslag project[J]. Applied Energy, 2019, 237: 708-719. |

| 89 | YU Q H, JIANG Z, CONG L, et al. A novel low-temperature fabrication approach of composite phase change materials for high temperature thermal energy storage[J]. Applied Energy, 2019, 237: 367-377. |

| 90 | DAL MAGRO F, MENEGHETTI A, NARDIN G, et al. Enhancing energy recovery in the steel industry: Matching continuous charge with off-gas variability smoothing[J]. Energy Conversion and Management, 2015, 104: 78-89. |

| 91 | DAL MAGRO F, BENASCIUTTI D, NARDIN G. Thermal stress analysis of PCM containers for temperature smoothing of waste gas[J]. Applied Thermal Engineering, 2016, 106: 1010-1022. |

| 92 | DAL MAGRO F, SAVINO S, MENEGHETTI A, et al. Coupling waste heat extraction by phase change materials with superheated steam generation in the steel industry[J]. Energy, 2017, 137: 1107-1118. |

| 93 | ANDERSSON O, RYDELL L, ALGOTSSON T. Efficient usage of waste heat by applying a seasonal energy storage (BTES) at ITT Water & Wastewater AB, Emmaboda, Sweden[J]. Proceedings of Effstock, 2009: 14-17. |

| 94 | KOIDE H, KURNIAWAN A, TAKAHASHI T, et al. Performance analysis of packed bed latent heat storage system for high-temperature thermal energy storage using pellets composed of micro-encapsulated phase change material[J]. Energy, 2022, 238: doi: 10.1016/j.energy.2021.121746. |

| 95 | WANG X, LIU J, ZHANG Y P, et al. Experimental research on a kind of novel high temperature phase change storage heater[J]. Energy Conversion and Management, 2006, 47(15/16): 2211-2222. |

| 96 | 李传, 司艳阳, 冷光辉, 等. 高温复合相变材料储热电暖器的储热性能[J]. 储能科学与技术, 2017, 6(4): 739-747. |

| LI C, SI Y Y, LENG G H, et al. Charging behavior of an electrical storage heater using a high temperature composite phase change material[J]. Energy Storage Science and Technology, 2017, 6(4): 739-747. | |

| 97 | ZHAO B, LI C, JIN Y, et al. Heat transfer performance of thermal energy storage components containing composite phase change materials[J]. IET Renewable Power Generation, 2016, 10(10): 1515-1522. |

| 98 | JIANG Y F, LIU M, SUN Y P. Review on the development of high temperature phase change material composites for solar thermal energy storage[J]. Solar Energy Materials and Solar Cells, 2019, 203: doi: 10.1016/j.solmat.2019.110164. |

| 99 | ZANGANEH G, COMMERFORD M, HASELBACHER A, et al. Stabilization of the outflow temperature of a packed-bed thermal energy storage by combining rocks with phase change materials[J]. Applied Thermal Engineering, 2014, 70(1): 316-320. |

| 100 | MATHUR A, KASETTY R, OXLEY J, et al. Using encapsulated phase change salts for concentrated solar power plant[J]. Energy Procedia, 2014, 49: 908-915. |

| 101 | STEINMANN W D, TAMME R. Latent heat storage for solar steam systems[J]. Journal of Solar Energy Engineering, 2008, 130(1): doi: 10.1115/1.2804624. |

| 102 | ZHANG H L, BAEYENS J, DEGRÈVE J, et al. Latent heat storage with tubular-encapsulated phase change materials (PCMs)[J]. Energy, 2014, 76: 66-72. |

| 103 | 陈举飞. 铝基高温相变储热材料的储热性能与实际应用研究[D]. 长沙: 中南大学, 2013. |

| CHEN J F. The research on heat storage performance and practical application of aluminum-based high temperature phase change thermal storage material[D]. Changsha: Central South University, 2013. | |

| 104 | MEHRPOOYA M, GHORBANI B, SADEGHZADEH M. Hybrid solar parabolic dish power plant and high-temperature phase change material energy storage system[J]. International Journal of Energy Research, 2019, 43(10): 5405-5420. |

| 105 | LI C, LI Q, DING Y L. Investigation on the thermal performance of a high temperature packed bed thermal energy storage system containing carbonate salt based composite phase change materials[J]. Applied Energy, 2019, 247: 374-388. |

| 106 | 张永学, 王梓熙, 鲁博辉, 等. 雪花型翅片提高相变储热单元储/放热性能[J]. 储能科学与技术, 2022, 11(2): 521-530. |

| ZHANG Y X, WANG Z X, LU B H, et al. Enhancement of charging and discharging performance of a latent-heat thermal-energy storage unit using snowflake-shaped fins[J]. Energy Storage Science and Technology, 2022, 11(2): 521-530. | |

| 107 | 金光, 肖安汝, 刘梦云. 相变储能强化传热技术的研究进展[J]. 储能科学与技术, 2019, 8(6): 1107-1115. |

| JIN G, XIAO A R, LIU M Y. Research progress on heat transfer enhancement technology of phase change energy storage[J]. Energy Storage Science and Technology, 2019, 8(6): 1107-1115. | |

| 108 | 王倩蓉, 李正贵, 卢昌燊, 等. 翅片式相变储能器内赤藻糖醇蓄热性能研究[J]. 热能动力工程, 2021, 36(2): 49-56. |

| WANG Q R, LI Z G, LU C S, et al. Study on the thermal storage performance of erythritol in a fin type phase change energy storage device[J]. Journal of Engineering for Thermal Energy and Power, 2021, 36(2): 49-56. | |

| 109 | 陈东明. 管壳式蓄热器与复合相变材料的强化传热特性研究[D]. 青岛: 青岛科技大学, 2022. |

| CHEN D M. Study on the enhanced heat transfer characteristics of shell-and-tube latent heat exchanger and composite phase change material[D]. Qingdao: Qingdao University of Science & Technology, 2022. | |

| 110 | 李亚强. 热电厂高温相变蓄热装置蓄放热特性的研究[D]. 吉林: 东北电力大学, 2022. |

| LI Y Q. Study on heat storage and release characteristics of high temperature phase change heat storage device in heating and power plent[D]. Jilin: Northeast Dianli University, 2022. | |

| 111 | 陈园园. 新型相变蓄热换热器的设计与传热特性分析[D]. 郑州: 华北水利水电大学, 2020. |

| CHEN Y Y. Design and analysis of heat transfer performance of a new phase change heat storage exchanger(PCHSE)[D]. Zhengzhou: North China University of Water Resources and Electric Power, 2020. | |

| 112 | 侯普民, 茅靳丰, 刘蓉蓉, 等. 环形相变单元的蓄热装置设计及运行特性[J]. 制冷学报, 2018, 39(1): 98-107. |

| HOU P M, MAO J F, LIU R R, et al. Design and operating characteristics of heat storage device for annular unit[J]. Journal of Refrigeration, 2018, 39(1): 98-107. | |

| 113 | SEDDEGH S, WANG X L, HENDERSON A D. A comparative study of thermal behaviour of a horizontal and vertical shell-and-tube energy storage using phase change materials[J]. Applied Thermal Engineering, 2016, 93: 348-358. |

| [1] | Xueqing SHEN, Wei CHEN. Thermal management performance of batteries with embedded tree-like fins for phase transition layers [J]. Energy Storage Science and Technology, 2023, 12(2): 459-467. |

| [2] | Jinmei DONG, Qiyuan LIU, Fang WU, Lirui JIA, Jing WEN, Chenggong CHANG, Weixin ZHENG, Xueying XIAO. Phase change characteristics and proportion adjustment of fatty acid binary energy storage materials [J]. Energy Storage Science and Technology, 2023, 12(2): 349-356. |

| [3] | Qianjun MAO, Yuanyuan ZHU. Study on heat storage performance of novel bifurcated fins to strengthen shell-and-tube energy storage tanks [J]. Energy Storage Science and Technology, 2023, 12(1): 69-78. |

| [4] | Lexian DONG, Qun ZHENG, Yue HUANG, Zhipeng TIAN, Jianping LIU, Chao WANG, Bo LIANG, Libin LEI. Research progress on cutting-edge technology of tubular solid oxide fuel cells [J]. Energy Storage Science and Technology, 2023, 12(1): 131-138. |

| [5] | Junlei WANG, Diling ZHANG, Kun WANG, Dongdong XU, Xianggui XU, Hua YAO, Wenwei LIU, Yun HUANG. Carbonates/blast furnace slag form-stable phase change materials [J]. Energy Storage Science and Technology, 2022, 11(9): 3028-3034. |

| [6] | JIANG Chengyi, ZHONG Zunrui, WU Zide, PENG Hao. Thermodynamic properties of C8H18-C11H24 mixed alkane system phase change materials [J]. Energy Storage Science and Technology, 2022, 11(6): 1957-1967. |

| [7] | Xinyu ZHOU, Daocheng LUAN, Zhihua HU, Junhua LING, Kelin WEN, Lang LIU, Zhiming YIN, Shuheng MI, Zhengyun WANG. Thermal storage performance of carbon-containing binary phase change heat storage materials [J]. Energy Storage Science and Technology, 2022, 11(4): 1175-1183. |

| [8] | Yuying LI, Wenzhen WEI, Qi LI, Yuting WU. Preparation and investigation of quaternary nitrates/halloysites/graphite shape-stable composite phase change material with low melting temperature for thermal energy storage [J]. Energy Storage Science and Technology, 2022, 11(3): 1044-1051. |

| [9] | Jie XUE, Jun ZHANG, Zhao DU, Rukun HU, Xiaohu YANG. A numerical simulation study on the heat-storage performance of a flat-bottom heat storage tank [J]. Energy Storage Science and Technology, 2022, 11(12): 3855-3861. |

| [10] | Qi ZHANG, Yujing WANG, Yinlei LI, Chongyang LIU. A novel composite phase change material with cold storage and insulation and its application [J]. Energy Storage Science and Technology, 2022, 11(10): 3133-3141. |

| [11] | Jin CHAI, Jun WANG, Qiqiang NI. Experiment on heat transfer performance of phase change materials strengthened by nanoparticles and fins [J]. Energy Storage Science and Technology, 2022, 11(10): 3161-3170. |

| [12] | Yanghui CHANG, Zhigao SUN. Preparation and properties of pentadecane microcapsule latent heat functional fluid [J]. Energy Storage Science and Technology, 2022, 11(10): 3123-3132. |

| [13] | Xiaoguang ZHANG, Xiaonan PAN, Jinming LI, Li LIU, Yan HE. Effect of battery arrangement on the phase change thermal management performance of lithium-ion battery packs [J]. Energy Storage Science and Technology, 2022, 11(1): 127-135. |

| [14] | Enda CI, Hui WANG, Xiaoqing LI, Ying ZHANG, Zhenying ZHANG, Jianqiang LI. Preparation and property enhancement of magnesium nitrate hexahydrate-lithium nitrate eutectic/expanded graphite composite phase change materials [J]. Energy Storage Science and Technology, 2022, 11(1): 30-37. |

| [15] | Zhiguo AN, Xian ZHANG, Hui ZHU, Chunjie ZHANG. Heat dissipation performance of honeycomb-like thermal management system combined CPCM with water cooling for lithium batteries [J]. Energy Storage Science and Technology, 2022, 11(1): 211-220. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||