Energy Storage Science and Technology ›› 2021, Vol. 10 ›› Issue (1): 111-117.doi: 10.19799/j.cnki.2095-4239.2020.0236

• Energy Storage Materials and Devices • Previous Articles Next Articles

Jixian WANG1,2( ), Sikan PENG1,2, Wenzheng NAN1,2, Xiang CHEN1,2, Chen WANG1,2, Shaojiu YAN1,2(

), Sikan PENG1,2, Wenzheng NAN1,2, Xiang CHEN1,2, Chen WANG1,2, Shaojiu YAN1,2( ), Shenglong DAI1,2

), Shenglong DAI1,2

Received:2020-07-03

Revised:2020-07-17

Online:2021-01-05

Published:2021-01-08

Contact:

Shaojiu YAN

E-mail:wangjixian520@163.com;shaojiuyan@126.com

CLC Number:

Jixian WANG, Sikan PENG, Wenzheng NAN, Xiang CHEN, Chen WANG, Shaojiu YAN, Shenglong DAI. Preparation of graphene-coated Li1.22Mn0.52Ni0.26O2 using a spray drying method for lithium-ion batteries[J]. Energy Storage Science and Technology, 2021, 10(1): 111-117.

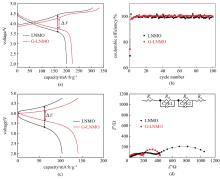

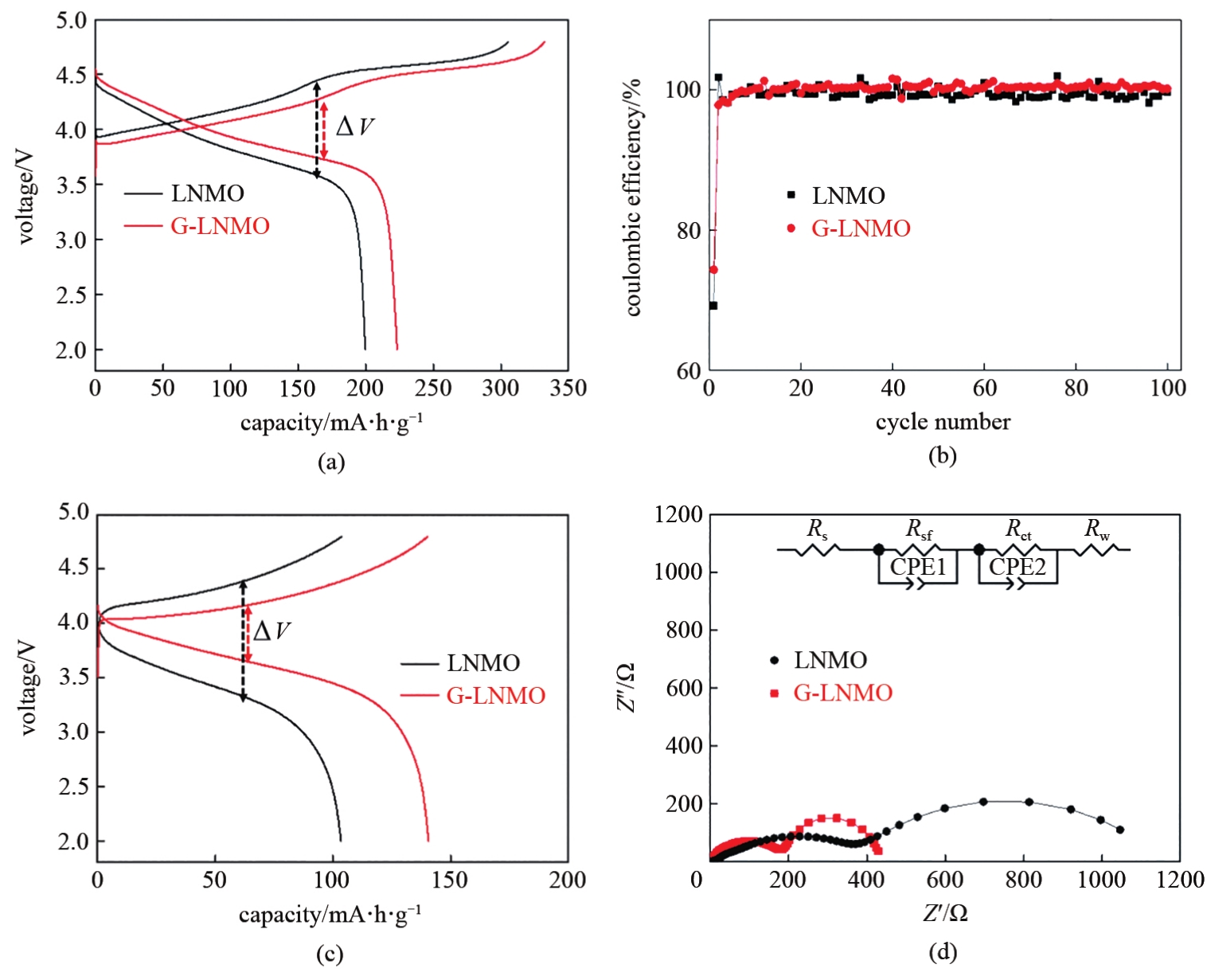

Fig.6

(a) initial charge-discharge curves of LNMO and G-LNMO electrodes at 0.1 C; (b) coulombic efficiency profiles of LNMO and G-LNMO electrodes at 0.5 C; (c) 100th charge-discharge curves of LNMO and G-LNMO electrodes at 0.5 C; (d) Nyquist plots of LNMO and G-LNMO electrodes after 100 cycles at 0.5 C (SOC is 50%)"

| 1 | KANG S H, POL V G, BELHAROUAK I, et al. A comparison of high capacity xLi2MnO3· ( 1 - x ) LiMO2 ( M = Ni , Co , Mn ) cathodes in lithium-ion cells with Li4Ti5O12- and carbon-encapsulated anatase TiO2 anodes[J]. Journal of the Electrochemical Society, 2010, 157(3): A267-A271. |

| 2 | LIU Jinlong, WANG Jie, XIA Yongyao. A new rechargeable lithium-ion battery with a xLi2MnO3·(1-x) LiMn0.4Ni0.4Co0.2O2 cathode and a hard carbon anode[J]. Electrochimica Acta, 2011, 56(21): 7392-7396. |

| 3 | LI J, KLÖPSCH R, STAN M C, et al. Synthesis and electrochemical performance of the high voltage cathode material Li[Li0.2Mn0.56Ni0.16Co0.08]O2 with improved rate capability[J]. Journal of Power Sources, 2011, 196(10): 4821-4825. |

| 4 | THACKERAY M M, KANG S, JOHNSON C S, et al. Li2MnO3-stabilized LiMO2 (M=Mn, Ni, Co) electrodes for lithium-ion batteries[J]. Journal of Materials Chemistry, 2007, 17(30): 3112-3115. |

| 5 | SUN YC, SHIOSAKI Y, XIA YG, et al. The preparation and electrochemical performance of solid solutions LiCoO2-Li2MnO3 as cathode materials for lithium ion batteries[J]. Journal of Power Sources, 2006, 159(2): 1353-1359. |

| 6 | NUMATA K, SAKASI C, YAMANAKA S. Synthesis of solid solutions in a system of LiCoO2-Li2MnO3 for cathode materials of secondary lithium batteries[J]. Chemistry Letters, 1997, 26(8): 725-726. |

| 7 | LU Z H, BEAULIEU L Y, DONABERGER R A, et al. Synthesis, structure, and electrochemical behavior of Li[NixLi1/3-2x/3Mn2/3-x/3]O2[J]. Journal of the Electrochemical Society, 2002, 149(6): A778-A791. |

| 8 | STROBEL P, LAMBERT-ANDRON B. Crystallographic and magnetic structure of Li2MnO3[J]. Journal of Solid State Chemistry, 1988, 75(1): 90-98. |

| 9 | LU Z H, CHEN Z H, DAHN J R. Lack of cation clustering in Li[NixLi1/3-2x/3Mn2/3-x/3]O2 (0<x≤1/2) and Li [CrxLi(1-x)/3Mn(2-2x)/3]O2 (0<x<1)[J]. Chemistry of Materials, 2003, 15(16): 3214-3220. |

| 10 | PAULSEN J M, MUELLER-NEUHAUS J R, DAHN J R. Layered LiCoO2 with a different oxygen stacking (O2 structure) as a cathode material for rechargeable lithium batteries[J]. Journal of the Electrochemical Society, 2000, 147(2): 508 -516. |

| 11 | LIU J, WANG Q Y, REEJA-JAYAN B, et al. Carbon-coated high capacity layered Li[Li0.2Mn0.54Ni0.13Co0.13]O2 cathodes[J]. Electrochemistry Communications, 2010, 12(6): 750-753. |

| 12 | WU Y F, MANTHIRAM A. Effect of surface modifications on the layered solid solution cathodes (1-z)Li[Li1/3Mn2/3]O2-(z)Li[Mn0.5-yNi0.5-yCo2y]O2[J]. Solid State Ionics, 2009, 180(1): 50-56. |

| 13 | LIU J, MANTHIRAM A. Functional surface modifications of a high capacity layered Li[Li0.2Mn0.54Ni0.13Co0.13]O2 cathode[J]. Journal of Materials Chemistry, 2010, 20(19): 3961-3967. |

| 14 | ZHENG Jiangming, LI Juntao, ZHANG Zhongru, et al. The effects of TiO2 coating on the electrochemical performance of Li[Li0.2Mn0.54Ni0.13Co0.13]O2 cathode material for lithium-ion battery[J]. Solid State Ionics, 2008, 179(27/28/29/30/31/32): 1794-1799. |

| 15 | XIN Sen, GUO Yuguo, WAN Lijun. Nanocarbon networks for advanced rechargeable lithium batteries[J]. Accounts of Chemical Research, 2012, 45(10): 1759-1769. |

| 16 | PAN Dengyu, WANG Song, ZHAO Bing, et al. Li storage properties of disordered graphene nanosheets[J]. Chemistry Materials, 2009, 21(14), 3136-3142. |

| 17 | 南文争, 燕绍九, 彭思侃, 等. 磷酸铁锂/石墨烯复合材料的合成及电化学性能[J]. 材料工程, 2018, 46(4): 43-50. |

| NAN Wenzheng, YAN Shaojiu, PENG Sikan, et al. Synthesis and performance of LiFePO4-C/graphene composite[J]. Journal of Materials Engineering, 2018, 46(4): 43-50. | |

| 18 | JIANG Kecheng, XIN Sen, LEE Jongsook, et al. Improved kinetics of LiNi1/3Mn1/3Co1/3O2 cathode material through reduced graphene oxide networks[J]. Physical Chemistry Chemical Physics, 2012, 14(8): 2934-2939. |

| 19 | 侯孟炎, 王珂, 董晓丽, 等. 石墨烯包覆富锂层状材料的制备及其电化学性能电化学[J]. 电化学, 2015, 21(3): 195-200. |

| HOU Mengyan, WANG Ke, DONG Xiaoli, et al. Synthesis of graphene wrapped Li-rich layered metal oxide and its electrochemical performance[J]. Journal of Electrochemistry, 2015, 21(3): 195-200. | |

| 20 | 王晨, 燕绍九, 南文争, 等. 高浓度石墨烯水分散液的制备与表征[J]. 材料工程, 2019, 47(4): 56-63. |

| WANG Chen, YAN Shaojiu, NAN Wenzheng, et al. Preparation and characterization of high concentration graphene aqueous dispersion[J]. Journal of Materials Engineering, 2019, 47(4): 56-63. | |

| 21 | LI Bing, YU Yangyang, ZHAO Jinbao. Facile synthesis of spherical xLi2MnO3·(1-x)Li(Mn0.33Co0.33Ni0.33)O2 as cathode materials for lithium-ion batteries with improved electrochemical performance[J]. Journal of Power Sources, 2015, 275: 64-72. |

| 22 | ZHENG Jianming, SHI Wei, GU Meng, et al. Electrochemical kinetics and performance of layered composite cathode material Li[Li0.2Ni0.2Mn0.6]O2[J]. Journal of the Electrochemical Society, 2013, 160(11): A2212-A2219. |

| 23 | LIN Jing, MU Daobin, JIN Ying, et al. Li-rich layered composite Li[Li0.2Ni0.2Mn0.6]O2 synthesized by a novel approach as cathode material for lithium ion battery[J]. Journal of Power Sources, 2013, 230: 76-80. |

| 24 | JOHNSON C S, LI Naichao, LEFIEF C, et al. Synthesis, Characterization and electrochemistry of lithium battery electrodes: xLi2MnO3·(1-x)LiMn0.333Ni0.333Co0.333O2 (0≤x≤0.7)[J]. Chemistry of Materials, 2008, 20(19): 6095-6106. |

| 25 | ZHENG Jiangming, WU Xiaobiao, YANG Yong. A comparison of preparation method on the electrochemical performance of cathode material Li[Li0.2Mn0.54Ni0.13Co0.13]O2 for lithium ion battery[J]. Electrochimica Acta, 2011, 56(8): 3071-3078. |

| 26 | DENG Z, MANTHIRAM A. Influence of cationic substitutions on the oxygen loss and reversible capacity of lithium-rich layered oxide cathodes[J]. The Journal of Physical Chemistry C, 2011, 115(14): 7097-7103. |

| 27 | XIANG XD, KNIGHT J C, LI Weishan, et al. Understanding the effect of Co3+ substitution on the electrochemical properties of lithium-rich layered oxide cathodes for lithium-ion batteries[J]. The Journal of Physical Chemistry C, 2014, 118(38): 21826-21833. |

| 28 | JIANG Kecheng, WU Xinglong, YIN Yaxia, et al. Superior hybrid cathode material containing lithium-excess layered material and graphene for lithium-ion batteries[J]. ACS Applied Materials & Interfaces, 2012, 4(9): 4858-4863. |

| 29 | SONG B H, LAI M O, LIU Z W, et al. Graphene-based surface modification on layered Li-rich cathode for high-performance Li-ion batteries[J]. Journal of Material Chemistry A, 2013, 1(34): 9954-9965. |

| 30 | LI Xiangjun, XIN Hongxing, QIN Xiaoying, et al. Graphene modified Li-rich cathode material Li[Li0.26Ni0.07Co0.07Mn0.56]O2 for lithium ion battery[J]. Functional Materials Letters, 2014, 7(6): doi: 10.1142/S179360471440013X. |

| 31 | JAN S S, NURGUL S, SHI X Q, et al. Improvement of electrochemical performance of LiNi0.8Co0.1Mn0.1O2 cathode material by graphene nanosheets modification[J]. Electrochimica Acta, 2014, 149: 86-93. |

| [1] | ZHANG Yan, WANG Hai, LIU Zhaomeng, ZHANG Deliu, WANG Jiadong, LI Jianzhong, GAO Xuanwen, LUO Wenbin. Research progress of nickel-rich ternary cathode material ncm for lithium-ion batteries [J]. Energy Storage Science and Technology, 2022, 11(6): 1693-1705. |

| [2] | Chaochao WEI, Chuang YU, Zhongkai WU, Linfeng PENG, Shijie CHENG, Jia XIE. Research progress of Li3PS4 solid electrolyte [J]. Energy Storage Science and Technology, 2022, 11(5): 1368-1382. |

| [3] | Yongli TONG, Xiang WU. Electrochemical performance of Co3O4 electrode materials derived from Co metal-organic framework [J]. Energy Storage Science and Technology, 2022, 11(3): 1035-1043. |

| [4] | Xiaohan FENG, Jie SUN, Jianhao HE, Yihua WEI, Chenggang ZHOU, Ruimin SUN. Research progress in LiFePO4 cathode material modification [J]. Energy Storage Science and Technology, 2022, 11(2): 467-486. |

| [5] | Dangling LIU, Shimin WANG, Zhihui GAO, Lufu XU, Shubiao XIA, Hong GUO. Properties of three-dimensional NZSPO/PAN-[PEO-NATFST] sodium-battery-composite solid electrolyte [J]. Energy Storage Science and Technology, 2021, 10(3): 931-937. |

| [6] | Xinxin ZHU, Wei JIANG, Zhengwei WAN, Shu ZHAO, Zeheng LI, Liguang WANG, Wenbin NI, Min LING, Chengdu LIANG. Research progress in electrolyte and interfacial issues of solid lithium sulfur batteries [J]. Energy Storage Science and Technology, 2021, 10(3): 848-862. |

| [7] | Chunyan YANG, Yunlong MA, Xiaoqiong FENG, Shiying ZHANG, Changsheng AN, Jingfeng LI. Research progress of carbon-based materials in aluminum-ion batteries [J]. Energy Storage Science and Technology, 2021, 10(2): 432-439. |

| [8] | Jin WANG, Jianquan WANG, Dianbo RUAN, Jiao XIE, Bin YANG. Preparation and electrochemical performances of Si/activated carbon composites [J]. Energy Storage Science and Technology, 2021, 10(1): 104-110. |

| [9] | Jiajing ZHU, Yun GAO. Research progress of water-in-salt electrolytes [J]. Energy Storage Science and Technology, 2020, 9(S1): 13-22. |

| [10] | Rixin LAI, Chuanjian JIANG, Lin LIU, Wenfeng ZHANG, Yu XIANG, Hai MING, Hao ZHANG, Gaoping CAO, Yun DU. Research progress of the regulation of nitrogen doping of graphene and the influence mechanism of supercapacitor capacitive performance [J]. Energy Storage Science and Technology, 2020, 9(6): 1657-1667. |

| [11] | Caiwen WU, Lijing HUANG, Chunyang ZOU, Bowen LI, Wenjuan WU. Research progress of the lignin in application energy storage [J]. Energy Storage Science and Technology, 2020, 9(6): 1737-1746. |

| [12] | Mengying MA, Huilin PAN, Yongsheng HU. Progress in electrolyte research for non-aqueous sodium ion batteries [J]. Energy Storage Science and Technology, 2020, 9(5): 1234-1250. |

| [13] | MA Tengfei, MA Chao, SUN Rui, JI Hongmei, YANG Gang. Freeze-drying assisted synthesis of mno/reduced graphene composite and the improved rate cyclic performance for lithium ion batteries [J]. Energy Storage Science and Technology, 2020, 9(4): 1044-1051. |

| [14] | XIONG Xiaolin, YUE Jinming, ZHOU Anxing, SUO Liumin, HU Yongsheng, LI Hong, HUANG Xuejie. Electrochemical performance of spinel LiMn2O4 inWater-in-salt aqueouselectrolyte [J]. Energy Storage Science and Technology, 2020, 9(2): 375-384. |

| [15] | REN Ya, WANG Ying, XU Zhiyu, YAN Xiao, HUANG Bixiong. Graphite modified LiNi1/3Co1/3Mn1/3O2 cathodes with improved performance for lithium-ion battery [J]. Energy Storage Science and Technology, 2019, 8(5): 935-940. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||