Energy Storage Science and Technology ›› 2025, Vol. 14 ›› Issue (5): 1850-1857.doi: 10.19799/j.cnki.2095-4239.2024.1046

• Energy Storage Materials and Devices • Previous Articles Next Articles

Guihong GAO1,2( ), Shenshen LI2, Wei ZHANG1, Shengjie LIANG1, Tian HAN1, Xiangkun WU2,3

), Shenshen LI2, Wei ZHANG1, Shengjie LIANG1, Tian HAN1, Xiangkun WU2,3

Received:2024-11-07

Revised:2024-11-23

Online:2025-05-28

Published:2025-05-21

Contact:

Guihong GAO

E-mail:1019660339@qq.com

CLC Number:

Guihong GAO, Shenshen LI, Wei ZHANG, Shengjie LIANG, Tian HAN, Xiangkun WU. Research on self-supporting membrane technology of high toughness and high conductivity PTFE based dry method[J]. Energy Storage Science and Technology, 2025, 14(5): 1850-1857.

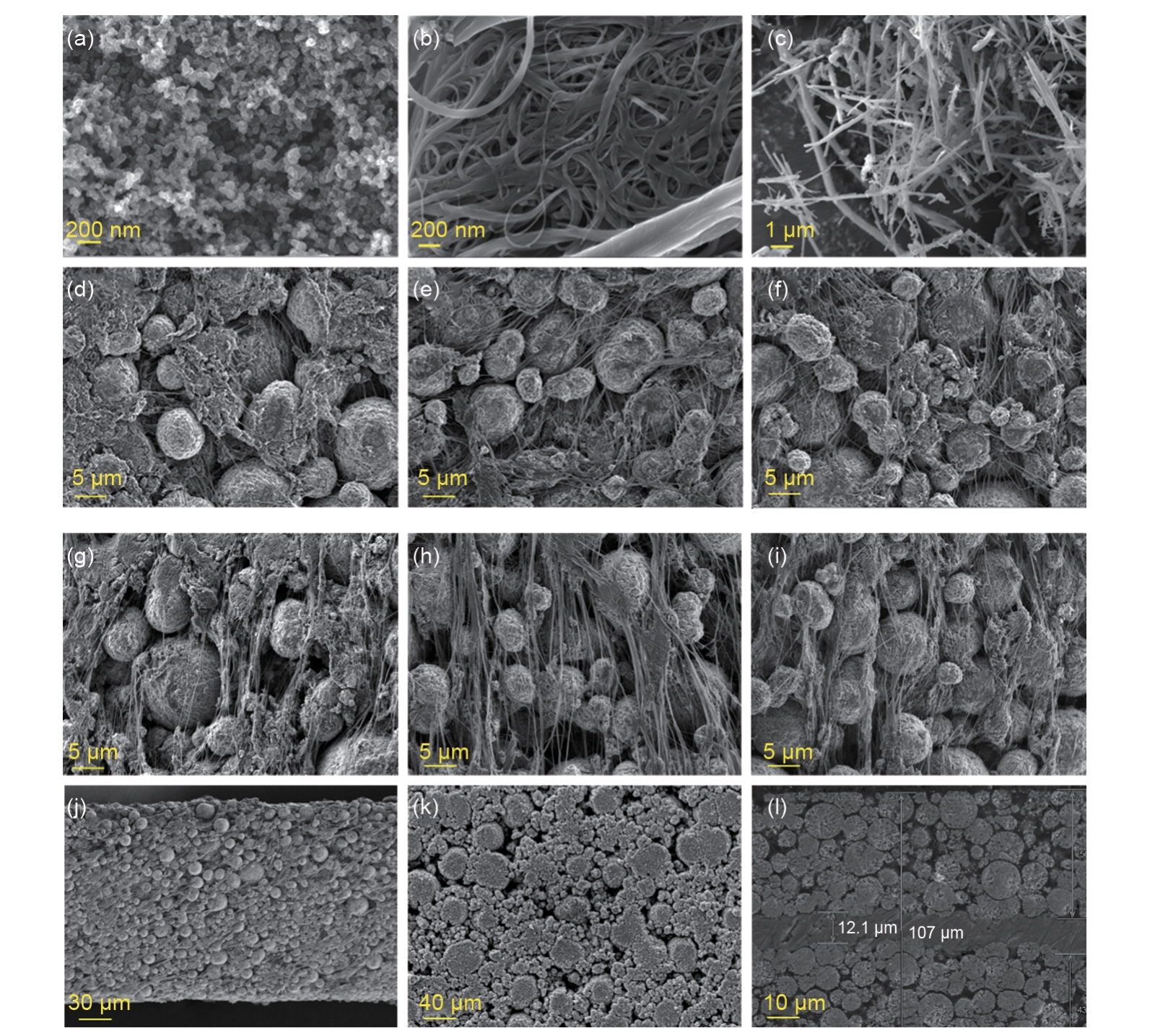

Fig. 2

SEM images of conductive agent, dry membrane and wet membrane (a) KB, (b) SCNTS, (c) VGCF, (d) K-B plane, (e) K-S plane, (f) K-V plane, (g) K-B local cross section, (h) K-S local cross section, (i) K-V local cross section, (j) Complete cross-section of dry diaphragm, (k) Wet diaphragm surface, (l) Wet diaphragm section"

| 1 | ARMAND M, TARASCON J M. Building better batteries[J]. Nature, 2008, 451(7179): 652-657. DOI: 10.1038/451652a. |

| 2 | VAN N R. The rechargeable revolution: A better battery[J]. Nature, 2014, 507(7490): 26-28. DOI: 10.1038/507026a. |

| 3 | DUNN B, KAMATH H, TARASCON J M. Electrical energy storage for the grid: A battery of choices[J]. Science, 2011, 334(6058): 928-935. DOI: 10.1126/science.1212741. |

| 4 | GOODENOUGH J B, KIM Y. Challenges for rechargeable Li batteries[J]. Chemistry of Materials, 2010, 22(3): 587-603. DOI: 10.1021/cm901452z. |

| 5 | GOODENOUGH J B, PARK K S. The Li-ion rechargeable battery: A perspective[J]. Journal of the American Chemical Society, 2013, 135(4): 1167-1176. DOI: 10.1021/ja3091438. |

| 6 | BARRÉ A, DEGUILHEM B, GROLLEAU S, et al. A review on lithium-ion battery ageing mechanisms and estimations for automotive applications[J]. Journal of Power Sources, 2013, 241: 680-689. DOI: 10.1016/j.jpowsour.2013.05.040. |

| 7 | WOOD D L, QUASS J D, LI J L, et al. Technical and economic analysis of solvent-based lithium-ion electrode drying with water and NMP[J]. Drying Technology, 2018, 36(2): 234-244. DOI: 10. 1080/07373937.2017.1319855. |

| 8 | COURTEL F M, NIKETIC S, DUGUAY D, et al. Water-soluble binders for MCMB carbon anodes for lithium-ion batteries[J]. Journal of Power Sources, 2011, 196(4): 2128-2134. DOI: 10. 1016/j.jpowsour.2010.10.025. |

| 9 | HAUFROID V, JAEGER V K, JEGGLI S, et al. Biological monitoring and health effects of low-level exposure to N-methyl-2-pyrrolidone: A cross-sectional study[J]. International Archives of Occupational and Environmental Health, 2014, 87(6): 663-674. DOI: 10.1007/s00420-013-0906-5. |

| 10 | WOOD D L, WOOD M, LI J L, et al. Perspectives on the relationship between materials chemistry and roll-to-roll electrode manufacturing for high-energy lithium-ion batteries[J]. Energy Storage Materials, 2020, 29: 254-265. DOI: 10.1016/j.ensm. 2020. 04.036. |

| 11 | KATO Y, SHIOTANI S, MORITA K, et al. All-solid-state batteries with thick electrode configurations[J]. The Journal of Physical Chemistry Letters, 2018, 9(3): 607-613. DOI: 10.1021/acs.jpclett. 7b02880. |

| 12 | HIPPAUF F, SCHUMM B, DOERFLER S, et al. Overcoming binder limitations of sheet-type solid-state cathodes using a solvent-free dry-film approach[J]. Energy Storage Materials, 2019, 21: 390-398. DOI: 10.1016/j.ensm.2019.05.033. |

| 13 | SCHÄLICKE G, LANDWEHR I, DINTER A, et al. Solvent-free manufacturing of electrodes for lithium-ion batteries via electrostatic coating[J]. Energy Technology, 2020, 8(2): 1900309. DOI: 10.1002/ente.201900309. |

| 14 | WU Q, ZHENG J P, HENDRICKSON M, et al. Dry process for fabricating low cost and high performance electrode for energy storage devices[J]. MRS Advances, 2019, 4(15): 857-863. DOI: 10.1557/adv.2019.29. |

| 15 | 张冬冬, 洪东升, 李婷婷. 干法电极制备技术的研究现状[J]. 电池, 2022, 52(4): 471-474. DOI: 10.19535/j.1001-1579.2022.04.026. |

| ZHANG D D, HONG D S, LI T T. Research status quo of dry electrode preparation technique[J]. Battery Bimonthly, 2022, 52(4): 471-474. DOI: 10.19535/j.1001-1579.2022.04.026. | |

| 16 | YONAGA A, KAWAUCHI S, MORI Y, et al. Effects of dry powder mixing on electrochemical performance of lithium-ion battery electrode using solvent-free dry forming process[J]. Journal of Power Sources, 2023, 581: 233466. DOI: 10.1016/j.jpowsour. 2023. 233466. |

| 17 | WENZEL V, MOELLER R S, NIRSCHL H. Influence of mixing technology and the potential to modify the morphological properties of materials used in the manufacture of lithium-ion batteries[J]. Energy Technology, 2014, 2(2): 176-182. DOI: 10. 1002/ente.201300091. |

| 18 | BOCKHOLT H, HASELRIEDER W, KWADE A. Intensive powder mixing for dry dispersing of carbon black and its relevance for lithium-ion battery cathodes[J]. Powder Technology, 2016, 297: 266-274. DOI: 10.1016/j.powtec.2016.04.011. |

| 19 | WENZEL V, NIRSCHL H, NÖTZEL D. Challenges in lithium-ion-battery slurry preparation and potential of modifying electrode structures by different mixing processes[J]. Energy Technology, 2015, 3(7): 692-698. DOI: 10.1002/ente.201402218. |

| 20 | LI Y X, WU Y J, WANG Z X, et al. Progress in solvent-free dry-film technology for batteries and supercapacitors[J]. Materials Today, 2022, 55: 92-109. DOI: 10.1016/j.mattod.2022.04.008. |

| 21 | HAWLEY W B, LI J L. Electrode manufacturing for lithium-ion batteries—Analysis of current and next generation processing[J]. Journal of Energy Storage, 2019, 25: 100862. DOI: 10.1016/j.est. 2019.100862. |

| 22 | MITCHELL P, XIAOMEI XI, ZHONG L D, et al. Dry-particle based adhesive and dry film and methods of making same: US2015007 2234[P]. 2015-03-12. |

| 23 | 胡文, 李柱, 刘妍娜, 等. 硫化物固态电解质薄膜的室温干法制备和全固态电池性能[J]. 电源技术, 2024, 48(8): 1619-1627. |

| HU W, LI Z, LIU Y N, et al. Preparation and all-solid-state battery performance of sulfide solid electrolyte membranes via a solvent-free approach at room temperature[J]. Chinese Journal of Power Sources, 2024, 48(8): 1619-1627. | |

| 24 | NAM Y J, OH D Y, JUNG S H, et al. Toward practical all-solid-state lithium-ion batteries with high energy density and safety: Comparative study for electrodes fabricated by dry- and slurry-mixing processes[J]. Journal of Power Sources, 2018, 375: 93-101. DOI: 10.1016/j.jpowsour.2017.11.031. |

| 25 | TAO R M, STEINHOFF B, SAWICKI C H, et al. Unraveling the impact of the degree of dry mixing on dry-processed lithium-ion battery electrodes[J]. Journal of Power Sources, 2023, 580: 233379. DOI: 10.1016/j.jpowsour.2023.233379. |

| 26 | 国家市场监督管理总局, 国家标准化管理委员会. 锂离子电池用聚烯烃隔膜: GB/T 36363—2018[S]. 北京: 中国标准出版社, 2018.Standardization Administration of the People's Republic of China. Polyolefin separator for lithium-ion battery: GB/T 36363—2018[S]. Beijing: Standards Press of China, 2018. |

| 27 | KULCSÁR S, ÁGH J, FAZEKAS Á, et al. Microstructure of plastic bonded nickel electrodes[J]. Journal of Power Sources, 1982, 8(1): 55-59. DOI: 10.1016/0378-7753(82)80007-4. |

| 28 | 甄恩萌. 高比能锂离子电池正极极片低成本制备工艺研究[D]. 南京: 南京航空航天大学, 2022. |

| ZHEN E M. Low-cost preparation of cathode electrodes for high specific energy lithium-ion battery[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2022. | |

| 29 | LIU Y T, GONG X T, PODDER C, et al. Roll-to-roll solvent-free manufactured electrodes for fast-charging batteries[J]. Joule, 2023, 7(5): 952-970. DOI: 10.1016/j.joule.2023.04.006. |

| 30 | RYU M, HONG Y K, LEE S Y, et al. Ultrahigh loading dry-process for solvent-free lithium-ion battery electrode fabrication[J]. Nature Communications, 2023, 14: 1316. DOI: 10.1038/s41467-023-37009-7. |

| 31 | LIANG Z M, LI T Y, CHI H, et al. Solvent-free manufacturing of lithium-ion battery electrodes via cold plasma[J]. Energy & Environmental Materials, 2024, 7(1): e12503. DOI: 10.1002/eem 2.12503. |

| 32 | 李静. 高安全性聚酰亚胺基锂离子电池隔膜的制备及其性能研究[D]. 上海: 东华大学, 2023. |

| LI J. Preparation and performance of high safety polyimide based lithium-ion battery separator[D]. Shanghai: Dong hua university, 2023. | |

| 33 | ZHOU H T, LIU M H, GAO H Q, et al. Dense integration of solvent-free electrodes for Li-ion supercabattery with boosted low temperature performance[J]. Journal of Power Sources, 2020, 473: 228553. DOI: 10.1016/j.jpowsour.2020.228553. |

| 34 | 李焱, 于俊荣, 刘兆峰. 聚酰胺酸的合成及其酰亚胺化研究[J]. 合成纤维, 2006, 35(4): 6-9. DOI: 10.3969/j.issn.1001-7054.2006.04.002. |

| LI Y, YU J R, LIU Z F. Study on the synthesis and imidization of poly(amic acid)[J]. Synthetic Fiber in China, 2006, 35(4): 6-9. DOI: 10.3969/j.issn.1001-7054.2006.04.002. | |

| 35 | JIANG F J, NIE Y, YIN L, et al. Core-shell-structured nanofibrous membrane as advanced separator for lithium-ion batteries[J]. Journal of Membrane Science, 2016, 510: 1-9. DOI: 10.1016/j.memsci.2016.02.067. |

| [1] | Honghui WANG, Jiaxin LI, Deren CHU, Yanyi LI, Ting XU. Study on the electrochemical performance failure mechanisms and thermal safety of lithium iron phosphate battery during storage conditions [J]. Energy Storage Science and Technology, 2025, 14(5): 1797-1805. |

| [2] | Zhoulan ZENG, Lei SHANG, Zhijin HU, Zongfan WANG, Xiaochao XIN, Ying LIU. Li5FeO4@C high capacity prelithium cathode materials for lithium-ion batteries [J]. Energy Storage Science and Technology, 2025, 14(5): 1875-1883. |

| [3] | Xiaoru XU, Jianzhen OU, Jiawei LIU, Zhicong CHEN, Hao YE, Yinglong LIU, Yingli LIU, Zeyu LIN, Jingjing LIU, Junhui JIAN, Xu LUO, Jingmin FAN, Chao WANG, Libin LEI, Bo LIANG. Direct ammonia tubular fuel cell with an embedded microchannel ceramic cracking reactor [J]. Energy Storage Science and Technology, 2025, 14(5): 1818-1828. |

| [4] | Zhiqiang LI, Yichun BA, Guangqiang SUN. Research on heat dissipation of cold plates with honeycomb and fork channels of lithium batteries [J]. Energy Storage Science and Technology, 2025, 14(5): 1776-1783. |

| [5] | Congqing TANG, Jingsheng CAI. Recent advances in presodiation strategies for sodium-ion batteries [J]. Energy Storage Science and Technology, 2025, 14(5): 1884-1899. |

| [6] | Shunxin LIU, Haoyang LI, Jianxing ZHANG, Guang ZENG, Lingping XU. A study on the synergistic optimization of flow channel structures and guide plates in a 280 Ah air-cooled battery pack for energy storage [J]. Energy Storage Science and Technology, 2025, 14(5): 1806-1817. |

| [7] | Zhen YAN, Qiang LIU, Huibin LI, Jun ZHANG, Yahui JIANG. Power optimization management method for photovoltaic microgrids based on the state of charge of hybrid energy storage systems [J]. Energy Storage Science and Technology, 2025, 14(5): 2067-2077. |

| [8] | Ping DING, Taotao LI, Linfeng ZHENG, Weixiong WU. SOH estimation of real-world power batteries based on Soft-DTW algorithm and multisource reature fusion [J]. Energy Storage Science and Technology, 2025, 14(5): 2081-2097. |

| [9] | Xiaohu SHI, Yixin HUANG, Tao ZOU, Yiting YUAN. Sulfonated polybenzimidazole membrane crosslinked by a star crosslinker with stable operation of high-performance all-vanadium flow batteries [J]. Energy Storage Science and Technology, 2025, 14(4): 1377-1385. |

| [10] | Jiangwei SHEN, Yixin SHE, Xing SHU, Yonggang LIU, Fuxing WEI, Xuelei XIA, Zheng CHEN. State of health estimation for lithium batteries based on short-term random charging data and optimized convolutional neural network [J]. Energy Storage Science and Technology, 2025, 14(4): 1585-1595. |

| [11] | Bohua WEN, Haijun MENG, Yonglong CHEN, Xiaohui LI, Jiayan LUO, Lin LIN, Lan ZHANG. Research progress on high specific-energy solid-state lithium-sulfur batteries [J]. Energy Storage Science and Technology, 2025, 14(4): 1424-1444. |

| [12] | Yongqi LI, Zhiyuan LI, Youwei WEN, Chengdong WANG, Qiangling DUAN, Qingsong WANG. Experimental study of thermal runaway characteristics of large-capacity sodium-ion batteries [J]. Energy Storage Science and Technology, 2025, 14(4): 1657-1667. |

| [13] | Dequan HUANG, Tao WEI, Guangda YIN, Gang WEN, Jue HOU, Yi LIANG. Research on the application of siloxane solvent in high-voltage lithium metal batteries and electrochemical performance [J]. Energy Storage Science and Technology, 2025, 14(4): 1340-1351. |

| [14] | Shunxin LIU, Lingping XU, Jianxing ZHANG, Guang ZENG, Haoyang LI. Numerical analysis of temperature rise characteristics of lithium battery based on dual-channel parallel series liquid cooling plate [J]. Energy Storage Science and Technology, 2025, 14(4): 1496-1506. |

| [15] | Bowen LI, Guangjin ZHAO, Yamin LI, Xiao YANG, Yunxiao ZHANG, Ruifeng DONG, Yuxia HU. Monitoring the aging process of energy storage lithium-ion batteries: Bilayer GeTe thermoelectric sensors [J]. Energy Storage Science and Technology, 2025, 14(4): 1352-1361. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||