Energy Storage Science and Technology ›› 2025, Vol. 14 ›› Issue (5): 1818-1828.doi: 10.19799/j.cnki.2095-4239.2024.1097

• Energy Storage Materials and Devices • Previous Articles Next Articles

Xiaoru XU1( ), Jianzhen OU3, Jiawei LIU1, Zhicong CHEN1, Hao YE1, Yinglong LIU1, Yingli LIU1, Zeyu LIN1, Jingjing LIU1, Junhui JIAN1, Xu LUO1, Jingmin FAN1, Chao WANG1, Libin LEI1, Bo LIANG1,2(

), Jianzhen OU3, Jiawei LIU1, Zhicong CHEN1, Hao YE1, Yinglong LIU1, Yingli LIU1, Zeyu LIN1, Jingjing LIU1, Junhui JIAN1, Xu LUO1, Jingmin FAN1, Chao WANG1, Libin LEI1, Bo LIANG1,2( )

)

Received:2024-11-25

Revised:2024-12-12

Online:2025-05-28

Published:2025-05-21

Contact:

Bo LIANG

E-mail:1018989193@qq.com;liangbo@gdut.edu.cn

CLC Number:

Xiaoru XU, Jianzhen OU, Jiawei LIU, Zhicong CHEN, Hao YE, Yinglong LIU, Yingli LIU, Zeyu LIN, Jingjing LIU, Junhui JIAN, Xu LUO, Jingmin FAN, Chao WANG, Libin LEI, Bo LIANG. Direct ammonia tubular fuel cell with an embedded microchannel ceramic cracking reactor[J]. Energy Storage Science and Technology, 2025, 14(5): 1818-1828.

Table 1

Input parameters of the numerical model[48]"

| 名称 | 数值[单位] |

|---|---|

| 工作温度 | 973.15 [K] |

| 阳极厚度 | 60 [μm] |

| 电解质厚度 | 220 [μm] |

| 阴极厚度 | 20 [μm] |

| 电池长度 | 80 [mm] |

| 参考压力 | 1 atm |

| 阴极气体成分 | 21%O2, 79%N2 [mol%] |

| 阳极气体成分 | 97 % H2 [mol%] |

| 电解质电导率 | 3.34×104×exp(-10300/T) [S/m] |

| 阴极电导率 | 2.57×107×exp[-80000/(8.314×T)] [S/m] |

| 阳极电导率 | 3.27×106-1065.3×T [S/m] |

| 集流体电导率 | 6.3×107 [S/m] |

| 阳极气体速率 | 150 sccm |

| 阴极气体速率 | 350 sccm |

| 孔隙率 | 0.36 |

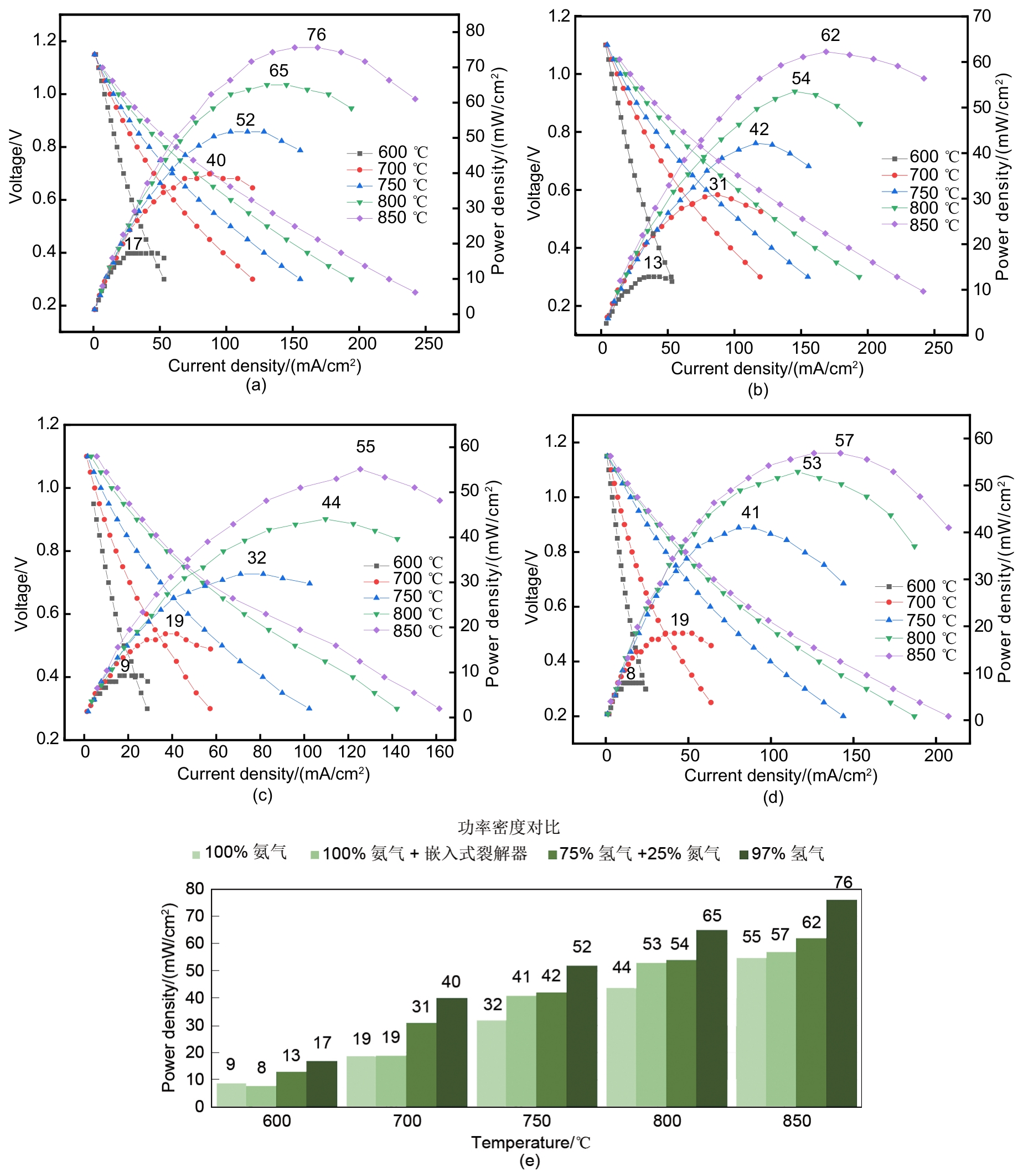

Fig. 5

I-V curves and the corresponding power densities of the micro-tubular SOFC in (a) 97% H2 atmosphere, (b) 75%H2+25%N2, (c) 100%NH3 atmosphere without an embedded honeycomb ceramic catalyst, and (d) 100%NH3 atmosphere with an embedded honeycomb ceramic catalyst; (e) The comparison of peak power density at various operating temperatures"

| 1 | AGYEKUM E B, ODOI-YORKE F, ABBEY A A, et al. A review of the trends, evolution, and future research prospects of hydrogen fuel cells—A focus on vehicles[J]. International Journal of Hydrogen Energy, 2024, 72: 918-939. DOI: 10.1016/j.ijhydene. 2024.05.480. |

| 2 | YANG Z B, GUO M Y, WANG N, et al. A short review of cathode poisoning and corrosion in solid oxide fuel cell[J]. International Journal of Hydrogen Energy, 2017, 42(39): 24948-24959. DOI: 10.1016/j.ijhydene.2017.08.057. |

| 3 | REVANKAR S, MAJUMDAR P. Fuel cells: Principles, design, and analysis[M]. Hoboken: CRC Press, 2014. |

| 4 | HSIEH W S, LIN P, WANG S F. Effects of cathode materials on the characteristics of electrolyte supported micro-tubular solid oxide fuel cells[J]. Journal of Power Sources, 2014, 253: 35-40. DOI: 10.1016/j.jpowsour.2013.11.113. |

| 5 | SINGHAL S C. Advances in solid oxide fuel cell technology[J]. Solid State Ionics, 2000, 135(1/2/3/4): 305-313. DOI: 10.1016/S0167-2738(00)00452-5. |

| 6 | VAN HERLE J, IHRINGER R, SAMMES N M, et al. Concept and technology of SOFC for electric vehicles[J]. Solid State Ionics, 2000, 132(3/4): 333-342. DOI: 10.1016/S0167-2738(00)00649-4. |

| 7 | HOWE K S, THOMPSON G J, KENDALL K. Micro-tubular solid oxide fuel cells and stacks[J]. Journal of Power Sources, 2011, 196(4): 1677-1686. DOI: 10.1016/j.jpowsour.2010.09.043. |

| 8 | SUZUKI T, FUNAHASHI Y, YAMAGUCHI T, et al. Design and fabrication of lightweight, submillimeter tubular solid oxide fuel cells[J]. Electrochemical and Solid-State Letters, 2007, 10(8): A177. DOI: 10.1149/1.2739211. |

| 9 | YAMAGUCHI T, SUZUKI T, SHIMIZU S, et al. Examination of wet coating and co-sintering technologies for micro-SOFCs fabrication[J]. Journal of Membrane Science, 2007, 300(1/2): 45-50. DOI: 10.1016/j.memsci.2007.05.002. |

| 10 | KANAWKA K, GRANDE F D, WU Z T, et al. Microstructure and performance investigation of a solid oxide fuel cells based on highly asymmetric YSZ microtubular electrolytes[J]. Industrial & Engineering Chemistry Research, 2010, 49(13): 6062-6068. DOI: 10.1021/ie1002558. |

| 11 | MORALES M, NAVARRO M E, CAPDEVILA X G, et al. Processing of graded anode-supported micro-tubular SOFCs based on Samaria-doped ceria via gel-casting and spray-coating[J]. Ceramics International, 2012, 38(5): 3713-3722. DOI: 10.1016/j.ceramint.2012.01.015. |

| 12 | ZHANG X Z, LIN B, LING Y H, et al. An anode-supported micro-tubular solid oxide fuel cell with redox stable composite cathode[J]. International Journal of Hydrogen Energy, 2010, 35(16): 8654-8662. DOI: 10.1016/j.ijhydene.2010.05.122. |

| 13 | IRSHAD M, SIRAJ K, RAZA R, et al. A brief description of high temperature solid oxide fuel cell's operation, materials, design, fabrication technologies and performance[J]. Applied Sciences, 2016, 6(3): 75. DOI: 10.3390/app6030075. |

| 14 | BAE J. A novel metal supported SOFC fabrication method developed in KAIST: A sinter-joining method[J]. Journal of the Korean Ceramic Society, 2016, 53(5): 478-482. DOI: 10.4191/kcers.2016.53.5.478. |

| 15 | FAES A, HESSLER-WYSER A, ZRYD A, et al. A review of RedOx cycling of solid oxide fuel cells anode[J]. Membranes, 2012, 2(3): 585-664. DOI: 10.3390/membranes2030585. |

| 16 | FAES A, NAKAJO A, HESSLER-WYSER A, et al. RedOx study of anode-supported solid oxide fuel cell[J]. Journal of Power Sources, 2009, 193(1): 55-64. DOI: 10.1016/j.jpowsour. 2008.12.118. |

| 17 | YOUNG J L, BIRSS V I. Crack severity in relation to non-homogeneous Ni oxidation in anode-supported solid oxide fuel cells[J]. Journal of Power Sources, 2011, 196(17): 7126-7135. DOI: 10.1016/j.jpowsour.2010.09.002. |

| 18 | FAES A, LUND FRANDSEN H, PIHLATIE M, et al. Curvature and strength of Ni-YSZ solid oxide half-cells after redox treatments[J]. Journal of Fuel Cell Science and Technology, 2010, 7(5): 051011. DOI: 10.1115/1.4001019. |

| 19 | MONZÓN H, LAGUNA-BERCERO M A. Redox-cycling studies of anode-supported microtubular solid oxide fuel cells[J]. International Journal of Hydrogen Energy, 2012, 37(8): 7262-7270. DOI: 10.1016/j.ijhydene.2011.10.026. |

| 20 | HEO Y H, LEE J W, LEE S B, et al. Redox-induced performance degradation of anode-supported tubular solid oxide fuel cells[J]. International Journal of Hydrogen Energy, 2011, 36(1): 797-804. DOI: 10.1016/j.ijhydene.2010.10.038. |

| 21 | LAWLOR V, GRIESSER S, BUCHINGER G, et al. Review of the micro-tubular solid oxide fuel cell Part I. Stack design issues and research activities[J]. Journal of Power Sources, 2009, 193(2): 387-399. DOI: 10.1016/j.jpowsour.2009.02.085. |

| 22 | YAMAMOTO O. Solid oxide fuel cells: Fundamental aspects and prospects[J]. Electrochimica Acta, 2000, 45(15/16): 2423-2435. DOI: 10.1016/S0013-4686(00)00330-3. |

| 23 | FLEISCHHAUER F, BERMEJO R, DANZER R, et al. Strength of an electrolyte supported solid oxide fuel cell[J]. Journal of Power Sources, 2015, 297: 158-167. DOI: 10.1016/j.jpowsour. 2015.07.075. |

| 24 | VAFAEENEZHAD S, HANIFI A R, LAGUNA-BERCERO M A, et al. Microstructure and long-term stability of Ni-YSZ anode supported fuel cells: A review[J]. Materials Futures, 2022, 1(4): 042101. DOI: 10.1088/2752-5724/ac88e7. |

| 25 | DROUSHIOTIS N, GRANDE F D, DZARFAN OTHMAN M H, et al. Comparison between anode-supported and electrolyte-supported Ni-CGO-LSCF micro-tubular solid oxide fuel cells[J]. Fuel Cells, 2014, 14(2): 200-211. DOI: 10.1002/fuce.201300024. |

| 26 | MATHUR L, NAMGUNG Y, KIM H, et al. Recent progress in electrolyte-supported solid oxide fuel cells: A review[J]. Journal of the Korean Ceramic Society, 2023, 60(4): 614-636. DOI: 10.1007/s43207-023-00296-3. |

| 27 | AN C H, KANG W, DENG Q B, et al. Pt and Te codoped ultrathin MoS2 nanosheets for enhanced hydrogen evolution reaction with wide pH range[J]. Rare Metals, 2022, 41(2): 378-384. DOI: 10.1007/s12598-021-01791-4. |

| 28 | LIU S S, WANG M F, HE Y Z, et al. Covalent organic frameworks towards photocatalytic applications: Design principles, achievements, and opportunities[J]. Coordination Chemistry Reviews, 2023, 475: 214882. DOI: 10.1016/j.ccr.2022.214882. |

| 29 | SIMBECK D, CHANG E. Hydrogen supply: Cost estimate for hydrogen pathways-Scoping Analysis, January 22, 2002-July 22, 2002 [R]. United States, 2002. |

| 30 | HIBINO T, HASHIMOTO A, INOUE T, et al. A low-operating-temperature solid oxide fuel cell in hydrocarbon-air mixtures[J]. Science, 2000, 288(5473): 2031-2033. DOI: 10.1126/science. 288.5473.2031. |

| 31 | SCHLAPBACH L, ZÜTTEL A. Hydrogen-storage materials for mobile applications. Materials for sustainable energy[M]. Co-Published with Macmillan Publishers Ltd, UK, 2010: 265-270. DOI: 10.1142/9789814317665_0038. |

| 32 | SCHLAPBACH L, ZÜTTEL A. Hydrogen-storage materials for mobile applications[J]. Nature, 2001, 414(6861): 353-358. DOI: 10.1038/35104634. |

| 33 | GAY S, ESHANI M. Fuel cells: Technology alternative fuels and fuel processing [J]. SAE International, Warrendale, 2003: 1. |

| 34 | ROTHSTEIN J. Hydrogen and fossil fuels[J]. International Journal of Hydrogen Energy, 1995, 20(4): 283-286. DOI: 10.1016/0360-3199(93)E0008-9. |

| 35 | TAN W C, IWAI H, KISHIMOTO M, et al. Numerical analysis on effect of aspect ratio of planar solid oxide fuel cell fueled with decomposed ammonia[J]. Journal of Power Sources, 2018, 384: 367-378. DOI: 10.1016/j.jpowsour.2018.03.011. |

| 36 | KISHIMOTO M, MUROYAMA H, SUZUKI S, et al. Development of 1 kW-class ammonia-fueled solid oxide fuel cell stack[J]. Fuel Cells, 2020, 20(1): 80-88. DOI: 10.1002/fuce.201900131. |

| 37 | HACKER V, KORDESCH K. Ammonia crackers [M]. Handbook of Fuel Cells. 2010. |

| 38 | GRASHAM O, DUPONT V, CAMARGO-VALERO M A, et al. Combined ammonia recovery and solid oxide fuel cell use at wastewater treatment plants for energy and greenhouse gas emission improvements[J]. Applied Energy, 2019, 240: 698-708. DOI: 10.1016/j.apenergy.2019.02.029. |

| 39 | WOJCIK A, MIDDLETON H, DAMOPOULOS I, et al. Ammonia as a fuel in solid oxide fuel cells[J]. Journal of Power Sources, 2003, 118(1/2): 342-348. DOI: 10.1016/S0378-7753(03)00083-1. |

| 40 | MA Q L, MA J J, ZHOU S, et al. A high-performance ammonia-fueled SOFC based on a YSZ thin-film electrolyte[J]. Journal of Power Sources, 2007, 164(1): 86-89. DOI: 10.1016/j.jpowsour. 2006.09.093. |

| 41 | PERNA A, MINUTILLO M, JANNELLI E, et al. Design and performance assessment of a combined heat, hydrogen and power (CHHP) system based on ammonia-fueled SOFC[J]. Applied Energy, 2018, 231: 1216-1229. DOI: 10.1016/j.apenergy. 2018.09.138. |

| 42 | STOECKL B, PREININGER M, SUBOTIĆ V, et al. Towards a wastewater energy recovery system: The utilization of humidified ammonia by a solid oxide fuel cell stack[J]. Journal of Power Sources, 2020, 450: 227608. DOI: 10.1016/j.jpowsour. 2019.227608. |

| 43 | ZHANG L M, CONG Y, YANG W S, et al. A direct ammonia tubular solid oxide fuel cell[J]. Chinese Journal of Catalysis, 2007, 28(9): 749-751. DOI: 10.1016/S1872-2067(07)60062-X. |

| 44 | LI Y, PILLAI H S, WANG T, et al. High-performance ammonia oxidation catalysts for anion-exchange membrane direct ammonia fuel cells[J]. Energy & Environmental Science, 2021, 14(3): 1449-1460. DOI: 10.1039/D0EE03351K. |

| 45 | YI Y N, CHEN J M, XU M G, et al. Exsolved nanoparticles decorated double perovskites as high-performance anodes for direct-ammonia solid oxide fuel cells[J]. Catalysts, 2023, 13(6): 996. DOI: 10.3390/catal13060996. |

| 46 | FAN J H, SHI J X, ZHANG R Y, et al. Numerical study of a 20-cell tubular segmented-in-series solid oxide fuel cell[J]. Journal of Power Sources, 2023, 556: 232449. DOI: 10.1016/j.jpowsour. 2022.232449. |

| 47 | LIU X, SUN S D, DAI Y, et al. Numerical study of temperature distribution in tubular segmented-in-series SOFC with co-flow and counter-flow arrangements[J]. International Journal of Hydrogen Energy, 2024, 74: 447-458. DOI: 10.1016/j.ijhydene. 2024.06.145. |

| 48 | CHEN Z C, YAO Y, XU X R, et al. Numerical study of a bamboo-like micro-tubular solid oxide fuel cell[J]. International Journal of Hydrogen Energy, 2024, 87: 1189-1197. DOI: 10.1016/j.ijhydene. 2024.09.037. |

| 49 | LE BARS M, WORSTER M G. Interfacial conditions between a pure fluid and a porous medium: Implications for binary alloy solidification [J]. Journal of Fluid Mechanics, 2006, 550: 149-173. DOI: 10.1017/S0022112005007998. |

| 50 | ZHANG X, ESPINOZA M, LI T, et al. Parametric study for electrode microstructure influence on SOFC performance [J]. International Journal of Hydrogen Energy, 2021, 46(75): 37440-37459. DOI: 10.1016/j.ijhydene.2021.09.057. |

| 51 | ANDERSSON M, YUAN J, SUNDéN B. SOFC modeling considering hydrogen and carbon monoxide as electrochemical reactants [J]. Journal of Power Sources, 2013, 232: 42-54. DOI: 10.1016/j.jpowsour.2012.12.122. |

| 52 | ZHENG K Q, LI L, NI M. Investigation of the electrochemical active thickness of solid oxide fuel cell anode[J]. International Journal of Hydrogen Energy, 2014, 39(24): 12904-12912. DOI: 10.1016/j.ijhydene.2014.06.108. |

| 53 | LIANG B, ZHANG S L, ZHANG Z F, et al. Dimensional analysis of Ni-NiO grains at anode/electrolyte interface for SOFC during redox reaction[J]. International Journal of Applied Ceramic Technology, 2017, 14(4): 543-549. DOI: 10.1111/ijac.12667. |

| 54 | CHEN X, LIN J, SUN L, et al. Improvement of output performance of solid oxide fuel cell by optimizing the active anode functional layer[J]. Electrochimica Acta, 2019, 298: 112-120. DOI: 10.1016/j.electacta.2018.12.078. |

| 55 | MUKHERJEE S, DEVAGUPTAPU S V, SVIRIPA A, et al. Low-temperature ammonia decomposition catalysts for hydrogen generation[J]. Applied Catalysis B: Environmental, 2018, 226: 162-181. DOI: 10.1016/j.apcatb.2017.12.039. |

| [1] | Zhen YAN, Qiang LIU, Huibin LI, Jun ZHANG, Yahui JIANG. Power optimization management method for photovoltaic microgrids based on the state of charge of hybrid energy storage systems [J]. Energy Storage Science and Technology, 2025, 14(5): 2067-2077. |

| [2] | Zhicong CHEN, Yue MA, Huazheng YANG, Chenpeng WANG, Yinglong LIU, Hao YE, Jiawei LIU, Xiaoru XU, Yingli LIU, Jiecheng CHEN, Zhiwei DU, Bo LIANG. Numerical simulation and experimental verification of micro-tubular solid oxide fuel cell with double-convex platform current collector in portable device [J]. Energy Storage Science and Technology, 2024, 13(10): 3523-3533. |

| [3] | Xinyu LIU, Anan ZHANG, Changjiang LIAO. Numerical simulation analysis of solid oxide fuel cells with different support structures [J]. Energy Storage Science and Technology, 2024, 13(5): 1710-1720. |

| [4] | Jing BAI, Huifang FAN, Siqi CUI, Chuang XU, Yi ZHANG, Size GUAN, Hanfei YANG, Yifei JIA, Shuwei GENG, Huifan ZHENG. Experimental study on heat dissipation performance of automotive fuel cells [J]. Energy Storage Science and Technology, 2024, 13(2): 390-395. |

| [5] | Kaifu LUAN, Changkun CAI, Manyi XIE, Chun ZHANG, Kuncan ZHENG, Shengli AN. Research progress of macroscale numerical simulation of fluid and thermal fields of solid oxide fuel cells [J]. Energy Storage Science and Technology, 2023, 12(9): 2985-3002. |

| [6] | Xing WANG, Jun SUN, Ningfang CHEN, Li YAN. Modeling of a proton exchange membrane fuel cell cooling system based on the Simscape temperature control strategy [J]. Energy Storage Science and Technology, 2023, 12(3): 857-869. |

| [7] | Lexian DONG, Qun ZHENG, Yue HUANG, Zhipeng TIAN, Jianping LIU, Chao WANG, Bo LIANG, Libin LEI. Research progress on cutting-edge technology of tubular solid oxide fuel cells [J]. Energy Storage Science and Technology, 2023, 12(1): 131-138. |

| [8] | Xiaohua DENG, Zhu JANG, Chao CHEN, Dai DANG. Recent advances in zeolitic imidazolium-based metal-organic frameworks (ZIFs) and their derivatives as efficient cathode catalysts for zinc-air batteries [J]. Energy Storage Science and Technology, 2022, 11(3): 964-981. |

| [9] | Zhihao LI, Hao PENG, Yaqin CHEN. Neural network prediction model for temperature distribution of proton exchange membrane fuel cell membrane electrode assembly [J]. Energy Storage Science and Technology, 2021, 10(6): 2053-2059. |

| [10] | Mingchang HU, Xueqing ZHOU, Xueyan HUANG, Jianjun XUE. Solvent-free fabrication of zinc-air electrodes and their battery performance [J]. Energy Storage Science and Technology, 2021, 10(6): 2090-2096. |

| [11] | Yuxi WU, Tingting HAN, Ziheng XIE, Lin LI, Yanwen SONG, Jiacang LIANG, Jinjin ZHANG, Fangyong YU, Naitao YANG. Recent progress in direct carbon solid oxide fuel cells: Carbon fuels and reverse Boudouard reaction catalysts [J]. Energy Storage Science and Technology, 2021, 10(6): 1977-1986. |

| [12] | Boya ZHANG, Bohong LIU, Yuanhang LI, Xin LIU, Qianfeng CHEN, Sanying HOU. Binary oxide modified catalyst preparation and self-humidifying performance [J]. Energy Storage Science and Technology, 2021, 10(6): 2013-2019. |

| [13] | Lina ZHENG, Wenzhong WANG, Kaijie JIA, Shaofeng QIU, Haoyuan ZHU, Fangyong YU, Xiuxia MENG, Jinjin ZHANG, Naitao YANG. Three-dimensional printing technologies in the field of solid oxide fuel cells [J]. Energy Storage Science and Technology, 2021, 10(6): 1952-1962. |

| [14] | Wang YU, Chao SUN, QI Ji, Liuzhen BIAN, Jihua PENG, Jun PENG, Shengli AN. Electrochemical performance of Sr2-xFe1.5Mo0.5O6-δ air electrode for solid oxide cell [J]. Energy Storage Science and Technology, 2021, 10(6): 2020-2027. |

| [15] | Junsheng ZHENG, Ningning DAI, Kun ZHAO, Jingnan YU. Performance degradation analysis methods for fuel cell vehicles based on demonstration operations [J]. Energy Storage Science and Technology, 2021, 10(2): 577-585. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||