Energy Storage Science and Technology ›› 2025, Vol. 14 ›› Issue (7): 2761-2771.doi: 10.19799/j.cnki.2095-4239.2025.0050

• Special Issue on the 13th Energy Storage International Conference and Exhibition • Previous Articles Next Articles

Yuan LI1,2( ), Mingzhi ZHAO3,4(

), Mingzhi ZHAO3,4( ), Yujie XU3,4,5(

), Yujie XU3,4,5( ), Jie CAI1

), Jie CAI1

Received:2025-01-14

Revised:2025-02-27

Online:2025-07-28

Published:2025-07-11

Contact:

Mingzhi ZHAO, Yujie XU

E-mail:jnzmz80@163.com;zhaomingzhi@iet.cn;xuyujie@iet.cn

CLC Number:

Yuan LI, Mingzhi ZHAO, Yujie XU, Jie CAI. Variable-operating-condition operational characteristics of liquid carbon dioxide energy storage systems[J]. Energy Storage Science and Technology, 2025, 14(7): 2761-2771.

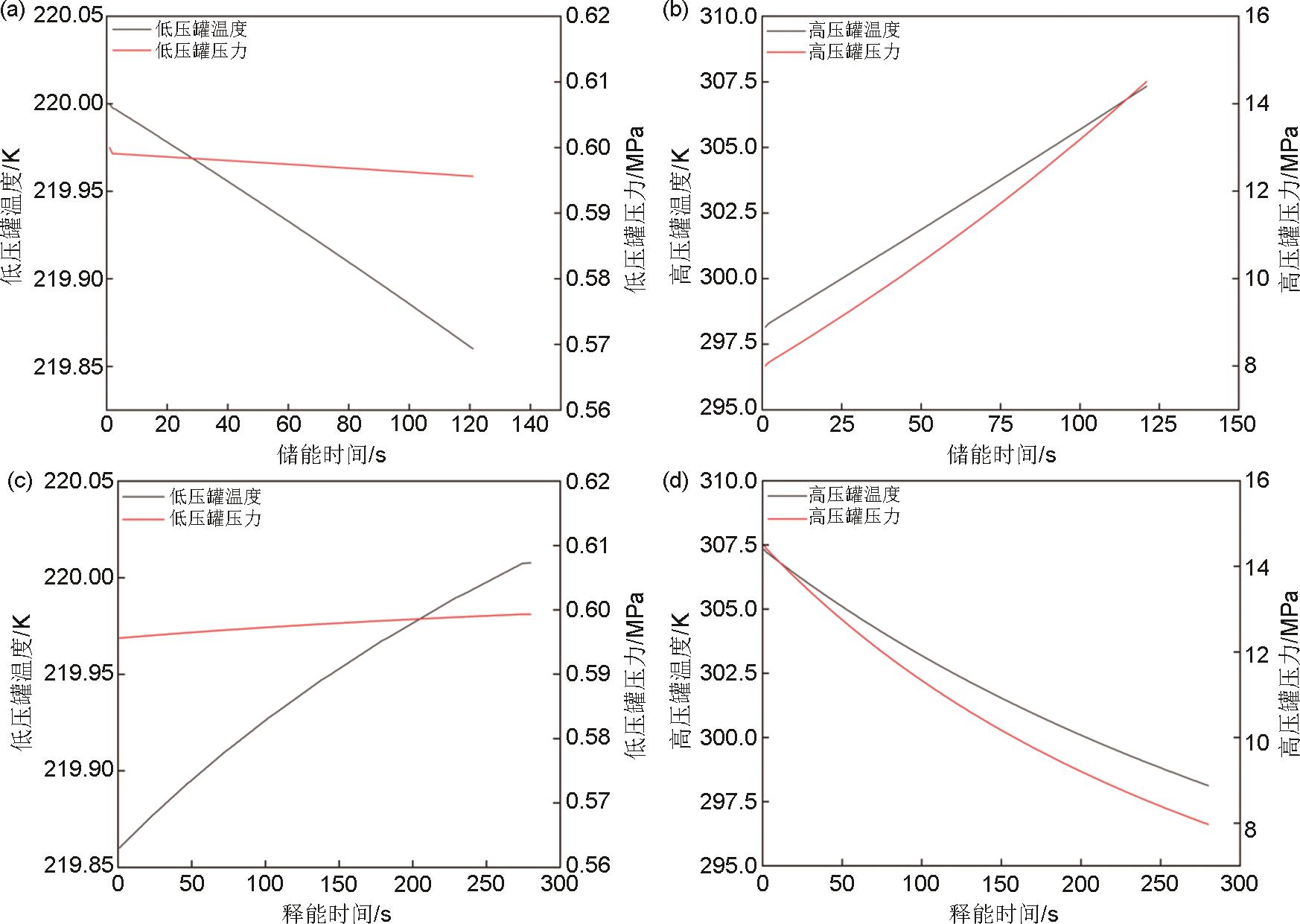

Fig. 5

Change of tank parameters during system variable operating conditions (a) Temperature and pressure variations in low-pressure tank during energy storage, (b) temperature and pressure variations in high-pressure tank during energy storage, (c) temperature and pressure variations in low-pressure tank during energy release, (d) temperature and pressure variations in high-pressure tank during energy release"

Table 3

Thermodynamic parameters of the variable operating condition system"

| 流股 | 工质 | 储能过程初始时刻 | 储能过程终止时刻 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 压力P/MPa | 温度T/K | 焓h/(kJ/kg) | 熵S/[kJ/(kg·K)] | 压力P/MPa | 温度T/K | 焓h/(kJ/kg) | 熵S/[kJ/(kg·K)] | ||

| 1 | CO2 | 0.6 | 220 | 86.72 | 0.551 | 0.59 | 219.8 | 86.45 | 0.550 |

| 2 | CO2 | 0.52 | 216.7 | 86.72 | 0.522 | 0.52 | 216.7 | 86.45 | 0.522 |

| 3 | CO2 | 0.52 | 221.6 | 434.97 | 2.159 | 0.52 | 221.7 | 434.97 | 2.159 |

| 4 | CO2 | 0.52 | 298 | 501.87 | 2.418 | 0.52 | 298 | 501.87 | 2.418 |

| 5 | CO2 | 1.293 | 374.9 | 557.10 | 2.418 | 1.574 | 392.7 | 570.48 | 2.418 |

| 6 | CO2 | 1.293 | 303 | 498.72 | 2.243 | 1.574 | 303 | 495.87 | 2.199 |

| 7 | CO2 | 3.217 | 381.7 | 552.60 | 2.243 | 4.769 | 400.6 | 561.74 | 2.199 |

| 8 | CO2 | 3.217 | 303 | 477.36 | 2.019 | 4.769 | 303 | 455.19 | 1.887 |

| 9 | CO2 | 8 | 383 | 525.09 | 2.019 | 14.5 | 401 | 507.64 | 1.887 |

| 10 | CO2 | 8 | 303 | 283.26 | 1.269 | 14.5 | 303 | 260.55 | 1.167 |

| 11 | CO2 | 14.5 | 307.8 | 271.31 | 1.202 | 8 | 298 | 263.13 | 2.036 |

| 12 | CO2 | 14.5 | 383 | 485.23 | 1.829 | 8 | 383 | 532.92 | 2.039 |

| 13 | CO2 | 5 | 300.3 | 446.33 | 1.829 | 3.37 | 318 | 493.64 | 2.039 |

| 14 | CO2 | 5 | 381.7 | 551.66 | 2.163 | 3.37 | 381.7 | 561.27 | 2.258 |

| 15 | CO2 | 1.726 | 307.8 | 499.53 | 2.163 | 1.421 | 322.9 | 516.38 | 2.258 |

| 16 | CO2 | 1.726 | 374.2 | 563.23 | 2.383 | 1.421 | 374.2 | 565.37 | 2.423 |

| 17 | CO2 | 0.595 | 306.6 | 508.91 | 2.383 | 0.6 | 318.8 | 519.59 | 2.423 |

| 18 | CO2 | 0.595 | 298 | 501.24 | 2.391 | 0.6 | 298 | 501.24 | 2.389 |

| 19 | CO2 | 0.595 | 231.7 | 442.41 | 2.168 | 0.6 | 231.7 | 442.33 | 2.166 |

| 20 | CO2 | 0.595 | 220 | 431.42 | 2.12 | 0.6 | 220 | 86.72 | 2.084 |

| 21 | CH4 | 0.2 | 254.1 | 812.41 | 5.969 | 0.2 | 254.1 | 812.41 | 5.969 |

| 22 | CH4 | 0.2 | 226.7 | 753.47 | 5.725 | 0.2 | 226.7 | 753.47 | 5.725 |

| 23 | H2O | 0.4 | 298 | 104.57 | 0.365 | 0.4 | 298 | 104.57 | 0.365 |

| 24 | H2O | 0.4 | 369.9 | 405.7 | 1.270 | 0.4 | 387.7 | 480.7 | 1.468 |

| 25 | H2O | 0.4 | 298 | 104.57 | 0.365 | 0.4 | 298 | 104.57 | 0.365 |

| 26 | H2O | 0.4 | 376.7 | 434.3 | 1.347 | 0.4 | 395.6 | 514.5 | 1.555 |

| 27 | H2O | 0.4 | 298 | 104.57 | 0.365 | 0.4 | 298 | 104.57 | 0.365 |

| 28 | H2O | 0.4 | 378.6 | 442.5 | 1.368 | 0.4 | 396.4 | 517.8 | 1.563 |

| 29 | H2O | 0.4 | 388.0 | 482 | 1.472 | 0.4 | 388.0 | 482 | 1.472 |

| 30 | H2O | 0.4 | 312.3 | 164.4 | 0.561 | 0.4 | 303.1 | 126.0 | 0.437 |

| 31 | H2O | 0.4 | 386.7 | 476.5 | 1.457 | 0.4 | 386.7 | 476.5 | 1.457 |

| 32 | H2O | 0.4 | 305.2 | 130.6 | 1.352 | 0.4 | 323.8 | 204 | 2.092 |

| 33 | H2O | 0.4 | 379.2 | 444.73 | 1.375 | 0.4 | 379.2 | 444.73 | 1.375 |

| 34 | H2O | 0.4 | 312.9 | 568 | 1.667 | 0.4 | 327.9 | 764 | 2.293 |

| 35 | CH4 | 0.2 | 226.3 | 753.5 | 5.724 | 0.2 | 226.3 | 753.5 | 5.724 |

| 36 | CH4 | 0.2 | 293.2 | 897.8 | 6.28 | 0.2 | 293.2 | 897.8 | 6.28 |

| [1] | SONG C F, LIU Q L, JI N, et al. Alternative pathways for efficient CO2 capture by hybrid processes—A review[J]. Renewable and Sustainable Energy Reviews, 2018, 82: 215-231. DOI: 10.1016/j.rser.2017.09.040. |

| [2] | WEI Y M, WANG J W, CHEN T Q, et al. Frontiers of low-carbon technologies: Results from bibliographic coupling with sliding window[J]. Journal of Cleaner Production, 2018, 190: 422-431. DOI: 10.1016/j.jclepro.2018.04.170. |

| [3] | 李琛, 董诗婕. 聚焦美丽中国建设 减污降碳绿色转型[J]. 中国水泥, 2024(3): 14-17. |

| LI C, DONG S J. Focus on beautiful China and build a green transformation to reduce pollution and carbon[J]. China Cement, 2024(3): 14-17. | |

| [4] | LI H C, DING R C, SU W, et al. A comprehensive performance comparison between compressed air energy storage and compressed carbon dioxide energy storage[J]. Energy Conversion and Management, 2024, 319: 118972. DOI: 10.1016/j.enconman. 2024.118972. |

| [5] | 李玉平. 压缩二氧化碳储能系统的热力学性能分析[D]. 北京: 华北电力大学, 2018. |

| LI Y P. Thermal performance analysis of the compressed carbon dioxide energy storage system[D]. Beijing: North China Electric Power University, 2018. | |

| [6] | WAN Y K, WU C, LIU Y, et al. A technical feasibility study of a liquid carbon dioxide energy storage system: Integrated component design and off-design performance analysis[J]. Applied Energy, 2023, 350: 121797. DOI: 10.1016/j.apenergy. 2023.121797. |

| [7] | ZHAO P, XU W P, ZHANG S Q, et al. Components design and performance analysis of a novel compressed carbon dioxide energy storage system: A pathway towards realizability[J]. Energy Conversion and Management, 2021, 229: 113679. DOI: 10.1016/j.enconman.2020.113679. |

| [8] | XU M J, ZHAO P, HUO Y W, et al. Thermodynamic analysis of a novel liquid carbon dioxide energy storage system and comparison to a liquid air energy storage system[J]. Journal of Cleaner Production, 2020, 242: 118437. DOI: 10.1016/j.jclepro. 2019.118437. |

| [9] | HAO J H, ZHENG P Y, LI Y N, et al. Study on the operational feasibility domain of combined heat and power generation system based on compressed carbon dioxide energy storage[J]. Energy, 2024, 291: 130122. DOI: 10.1016/j.energy.2023.130122. |

| [10] | FU H L, SHI J, YUAN J Q, et al. Thermodynamic analysis of photothermal-assisted liquid compressed CO2 energy storage system hybrid with closed-cycle drying[J]. Journal of Energy Storage, 2023, 66: 107415. DOI: 10.1016/j.est.2023.107415. |

| [11] | TANG D, LI Y, LIU Y J, et al. Factors affecting compressed carbon dioxide energy storage system in deep aquifers[J]. Bulletin of Engineering Geology and the Environment, 2024, 83(10): 407. DOI: 10.1007/s10064-024-03887-4. |

| [12] | LIU Z, LIU X, ZHANG W F, et al. Thermodynamic analysis on the feasibility of a liquid energy storage system using CO2-based mixture as the working fluid[J]. Energy, 2022, 238: 121759. DOI: 10.1016/j.energy.2021.121759. |

| [13] | DENG Y Y, WANG J F, CAO Y, et al. Technical and economic evaluation of a novel liquid CO2 energy storage-based combined cooling, heating, and power system characterized by direct refrigeration with phase change[J]. Applied Thermal Engineering, 2023, 230: 120833. DOI: 10.1016/j.applthermaleng.2023.120833. |

| [14] | MA H Y, LIU Z. Preliminary thermodynamic analysis of a carbon dioxide binary mixture cycled energy storage system with low pressure stores[J]. Energy, 2022, 246: 123346. DOI: 10.1016/j.energy.2022.123346. |

| [15] | XU W P, ZHAO P, WANG J F, et al. Comprehensive thermo-economic analysis of an isobaric compressed CO2 energy storage system: Improvement of the thermodynamic pathway[J]. Energy Conversion and Management, 2024, 322: 119088. DOI: 10.1016/j.enconman.2024.119088. |

| [16] | BARTELA Ł, SKOREK-OSIKOWSKA A, DYKAS S, et al. Thermodynamic and economic assessment of compressed carbon dioxide energy storage systems using a post-mining underground infrastructure[J]. Energy Conversion and Management, 2021, 241: 114297. DOI: 10.1016/j.enconman. 2021.114297. |

| [17] | KIM Y M, SHIN D G, FAVRAT D. Operating characteristics of constant-pressure compressed air energy storage (CAES) system combined with pumped hydro storage based on energy and exergy analysis[J]. Energy, 2011, 36(10): 6220-6233. DOI: 10.1016/j.energy.2011.07.040. |

| [18] | NIELSEN L, LEITHNER R. Dynamic simulation of an innovative compressed air energy storage plant-Detailed modelling of the storage cavern[J]. Wseas Transactions on Power Systems, 2009, 4(7/9): 253-263. |

| [19] | AHMAD M, OSCH M B, BUIT L, et al. Study of the thermohydraulics of CO2 discharge from a high pressure reservoir[J]. International Journal of Greenhouse Gas Control, 2013, 19: 63-73. DOI: 10.1016/j.ijggc.2013.08.004. |

| [20] | 张娜, 林汝谋, 蔡睿贤. 压气机特性通用数学表达式[J]. 工程热物理学报, 1996, 17(1): 21-24. |

| ZHANG N, LIN R M, CAI R X. General formulas for axial compressor performance estimation[J]. Journal of Engineering Thermophysics, 1996, 17(1): 21-24. | |

| [21] | ZHAO M, ZHU Y, HU D, et al. Off-design performance of supercritical compressed carbon dioxide energy storage system[A/OL]. Volume 42: Energy Transitions toward Carbon Neutrality: Part V, 2024[2025-02-26]. https://www.energy-proceedings.org/ p=10997. DOI:10.46855/energy-proceedings-10997. |

| [22] | 卢韶光, 林汝谋. 燃气透平稳态全工况特性通用模型[J]. 工程热物理学报, 1996, 17(4): 404-407. |

| LU S G, LIN R M. Gas turbine steady-state design and off-design characteristic general model[J]. Journal of Engineering Thermophysics, 1996, 17(4): 404-407. |

| [1] | Liyue HU, Wei HUANG, Yun ZHOU, Yingqiang ZHOU, Changzheng SHAO, Ke WANG. Fuzzy reasoning-based evaluation of the thermal diffusion probability of lithium-ion battery modules for energy storage systems [J]. Energy Storage Science and Technology, 2025, 14(7): 2662-2674. |

| [2] | Xiaohui ZHANG, Ruigeng YANG, Songkun JIAO. Research on capacity planning and demand forecasting for energy storage systems based on machine learning [J]. Energy Storage Science and Technology, 2025, 14(7): 2881-2883. |

| [3] | Wenjie ZHANG, Dongsheng REN, Yu WU, Xinyu RUI, Xiang LIU, Xuning FENG, Languang LU. Thermal stability of key materials in Li10GeP12S2-based all-solid-state batteries [J]. Energy Storage Science and Technology, 2025, 14(6): 2193-2199. |

| [4] | Yinchi SHAO, Yu GONG, Meng NIU, Ruohuan YANG, Yating LIU, Ran DING. Grid-forming energy storage system taking phase angle and amplitude jumps into account short-circuit current characteristics and its calculation model [J]. Energy Storage Science and Technology, 2025, 14(6): 2451-2461. |

| [5] | Jiabao TAN, Yufei WANG, Hua XUE. Modeling and performance analysis of piston gravity energy storage system [J]. Energy Storage Science and Technology, 2025, 14(6): 2383-2390. |

| [6] | Xun CHEN. Energy management and optimal scheduling strategies for energy storage systems based on deep reinforcement learning [J]. Energy Storage Science and Technology, 2025, 14(6): 2439-2441. |

| [7] | Junyang XIAO, Jinge LUO, Weizhe MA, Wuping CHENG, Tong ZENG. Energy storage optimization control strategy in distribution system based on improved artificial bee colony algorithm [J]. Energy Storage Science and Technology, 2025, 14(6): 2567-2574. |

| [8] | Liang ZHANG, Xiong ZHOU, Jiukang TENG, Wenjing YANG, Xueming LI. Electrochemical properties of fluorinated Keqin black/graphene composite materials [J]. Energy Storage Science and Technology, 2025, 14(5): 1841-1849. |

| [9] | Qingxiang XU, Wei TENG, Run QIN, Shunyi SONG, Yibing LIU, Shuangyin LIANG. Energy management and control strategy for grid-connected frequency regulation flywheel energy storage systems [J]. Energy Storage Science and Technology, 2025, 14(5): 2013-2022. |

| [10] | Bing YAN, XU Hu, Zhenling LI. Research on intelligent operation and maintenance model of energy storage systems supported by big data [J]. Energy Storage Science and Technology, 2025, 14(5): 2010-2012. |

| [11] | Shiming LI. Application of artificial Intelligence in the fault detection of energy storage system [J]. Energy Storage Science and Technology, 2025, 14(4): 1698-1700. |

| [12] | Daibing SHEN, Jiahao HAO, Yanchang SONG, Junling YANG, Zhentao ZHANG, Yunkai YUE. Centripetal turbine design and structural parameter optimization for hundred-kilowatt-class carbon dioxide energy storage system [J]. Energy Storage Science and Technology, 2025, 14(3): 1270-1285. |

| [13] | Chencheng XU, Zhan WANG, Shuang LI, Jiangmin JIANG, Zhicheng JU. Research progress and engineering application prospects of prelithiation technology for lithium-ion batteries [J]. Energy Storage Science and Technology, 2025, 14(3): 930-946. |

| [14] | Tian GAO, Zufan WANG, Shuyang FANG, Youkang ZHANG, Liancheng ZHANG, Yongzhang HUANG, Haisen ZHAO. Energy efficiency analysis model and experimental verification of gravity energy storage system with gear box and chain transmission mechanisms [J]. Energy Storage Science and Technology, 2025, 14(2): 688-698. |

| [15] | Huaiyu HUANG, Silin HUANG, Rongchao ZHAO, Zhiwen XIAO, Junhui HOU, Liwei YAN. Experimental study on thermal runaway characteristics triggered by insulation failure of aluminum-plastic film shell of lithium iron phosphate battery [J]. Energy Storage Science and Technology, 2025, 14(2): 613-623. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||