Energy Storage Science and Technology ›› 2024, Vol. 13 ›› Issue (2): 436-461.doi: 10.19799/j.cnki.2095-4239.2023.0501

• Energy Storage Materials and Devices • Previous Articles Next Articles

Ke LI1( ), Yifan HAO1, Zhenhua FANG2, Jing WANG1(

), Yifan HAO1, Zhenhua FANG2, Jing WANG1( ), Songtong ZHANG3, Xiayu ZHU3, Jingyi QIU3, Hai MING3(

), Songtong ZHANG3, Xiayu ZHU3, Jingyi QIU3, Hai MING3( )

)

Received:2023-07-24

Revised:2023-09-22

Online:2024-02-28

Published:2024-03-01

Contact:

Jing WANG, Hai MING

E-mail:15518814937@163.com;jwang6027@ysu.edu.cn;hai.mingenergy@hotmail.com

CLC Number:

Ke LI, Yifan HAO, Zhenhua FANG, Jing WANG, Songtong ZHANG, Xiayu ZHU, Jingyi QIU, Hai MING. Development and military application analysis of high-power chemical power supply system[J]. Energy Storage Science and Technology, 2024, 13(2): 436-461.

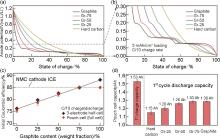

Fig. 2

(a), and (b)Three-electrode measurements showing the anode potential(V vs. Li/Li+)as a function of state-of-charge for graphite, Gr-75, Gr-50, Gr-25, and hard carbon; (c)Initial coulombic efficiency (ICE) versus a graphite content plot of the hybrid anodes in three-electrode cell (black) and pouch cell (red) configurations. The ICE of NMC-532 cathode is also labeled in the plot. The charge/discharge rate was fixed at C/10; (d)Cell capacity plot showing the first-cycle charge and discharge capacity of the pouch cells(Advanced Energy Materials has image copyright)[6]"

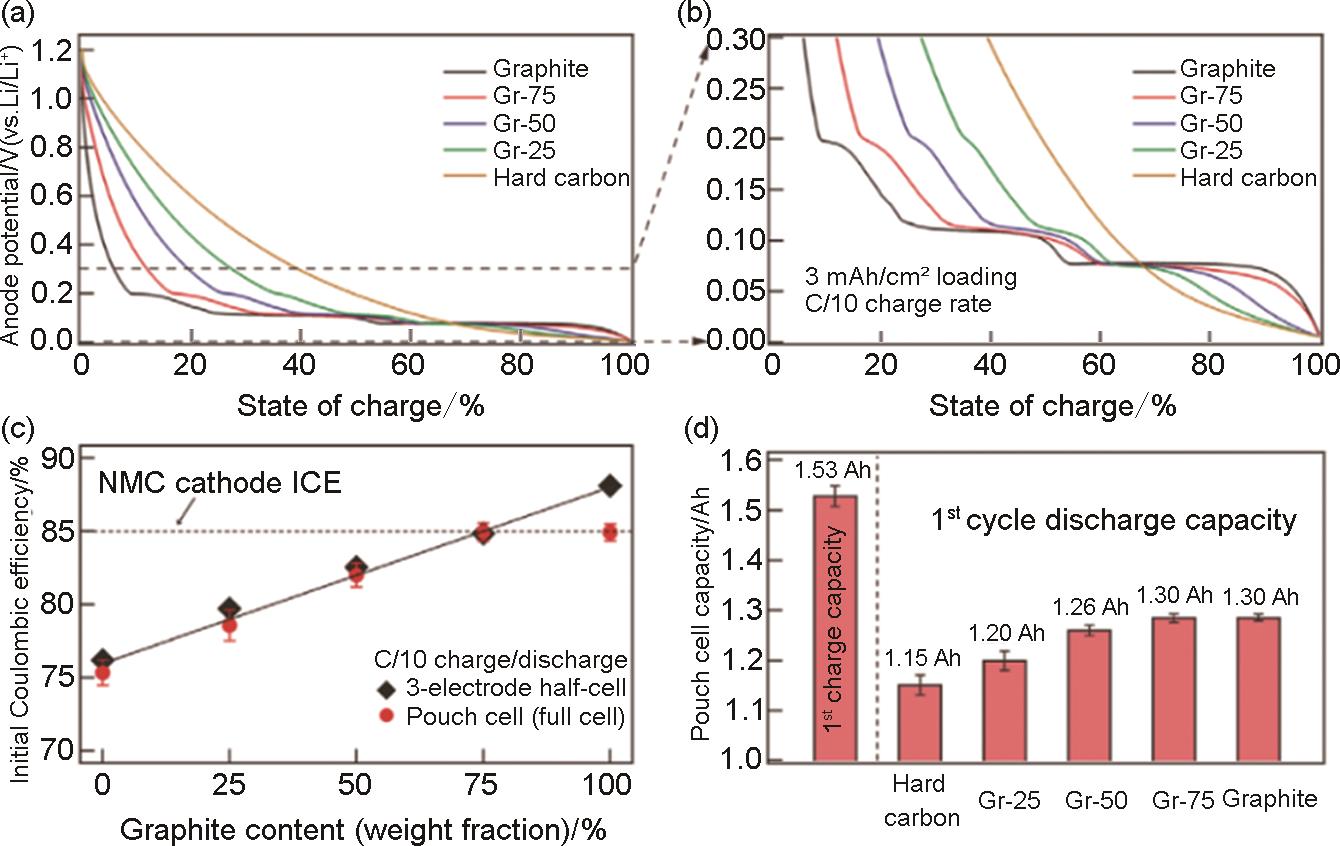

Fig. 4

Predicted conductivity (a) diffusivity (b) and maximum velocity of penetrance (c) of selected AEM-guided electrolyte systems at 30 ℃, compared to the Gen2 BL. Viscosity of B26 versus Gen2 is given in panel (d). Diffusivity values are based on the Nernst-type stoichiometric average between cation and anion diffusivity values. Panel (c) is the ratio of predicted surface tension to viscosity, an important parameter for liquid permeation into porous media (note the log scale basis)(Energy Storage Materialshas image copyright)[9]"

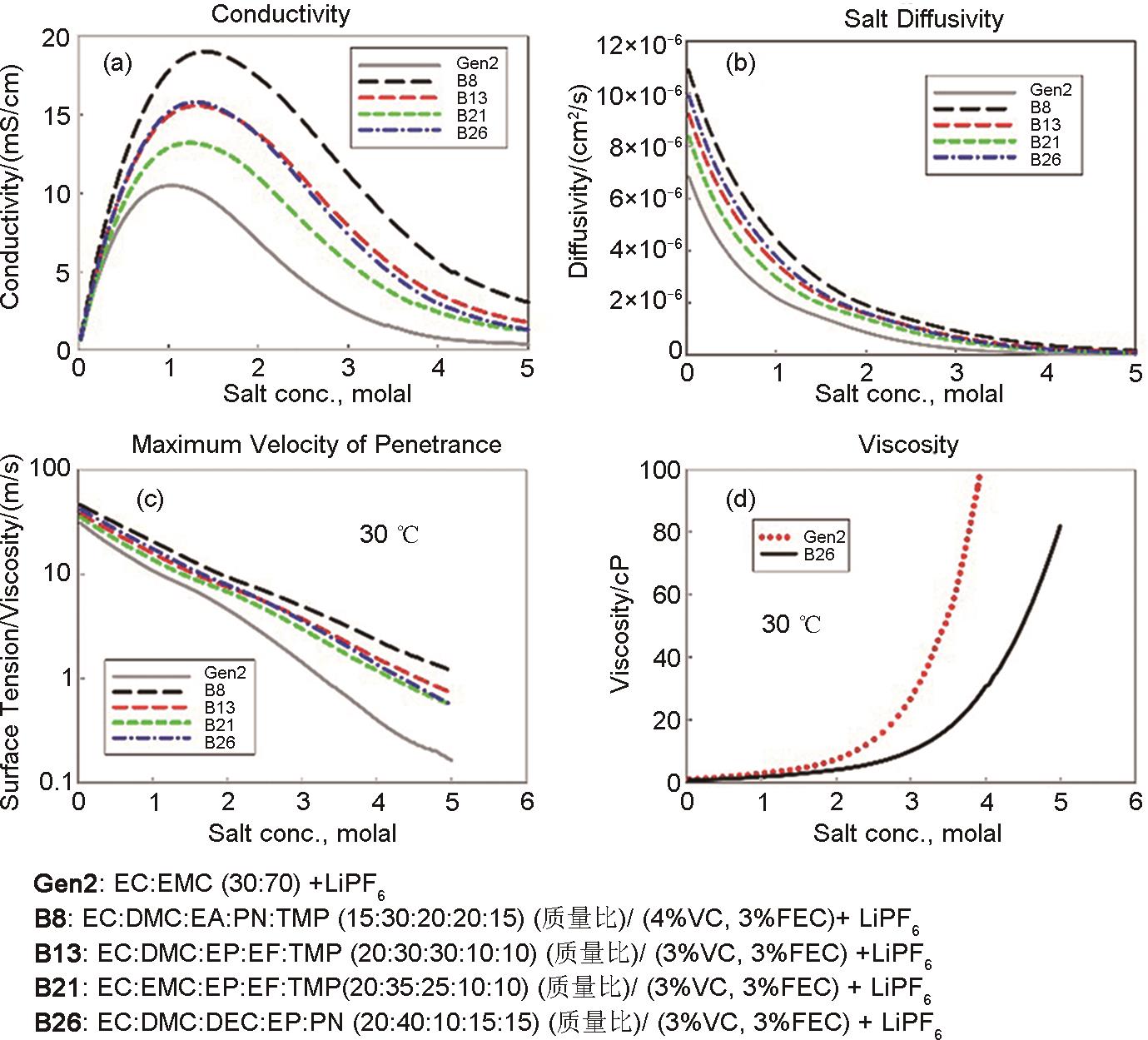

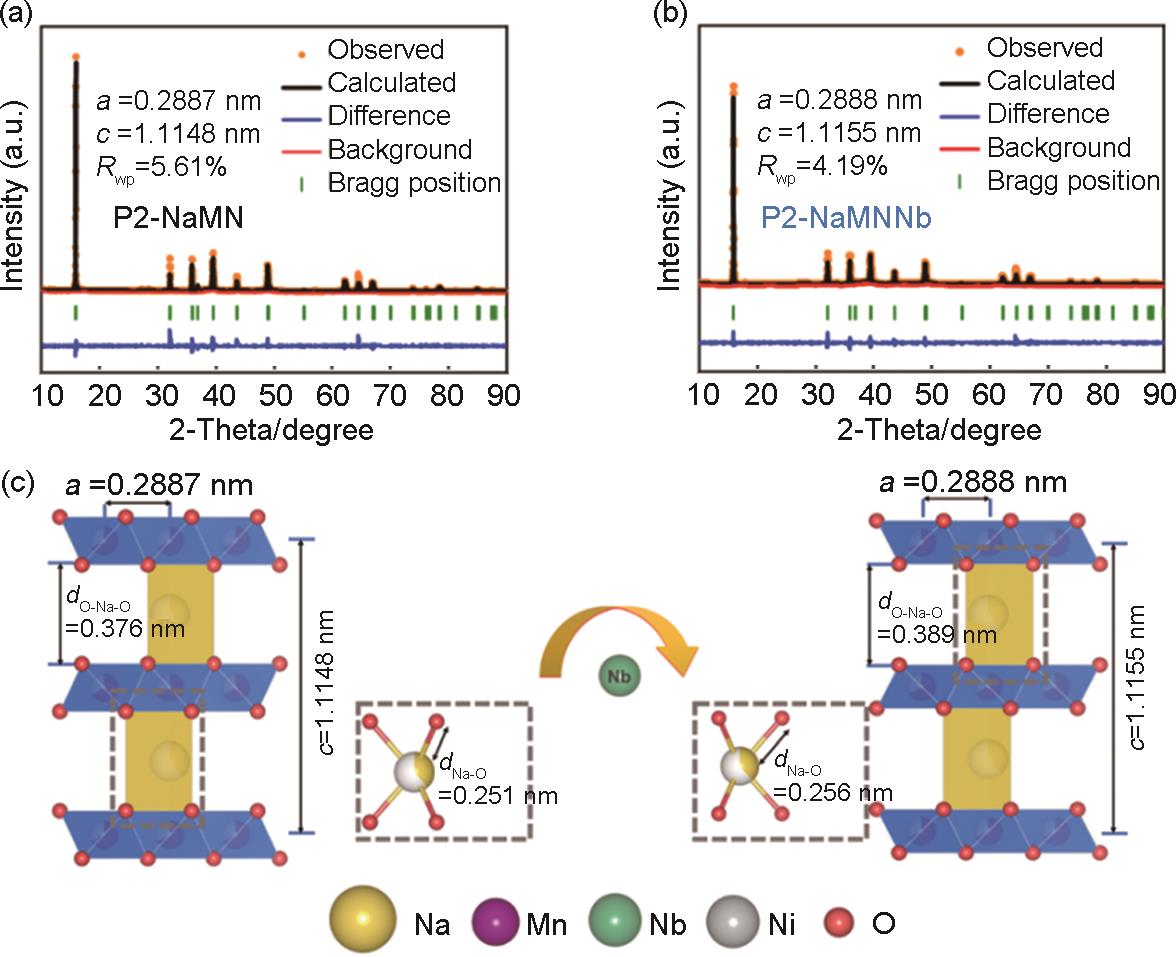

Fig. 6

Structural characterization of the P2-NaMNNb and P2-NaMN cathode material: (a), (b)Rietveld refinements of X-ray diffraction measurements of P2-NaMN and P2-NaMNNb compounds; (c)Schematic diagram of the effect of Nb doping on crystal structure (Nature Communicationshas image copyright)[15]"

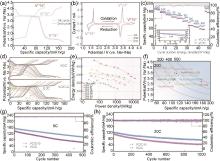

Fig. 7

Fast-charging performances: (a) Charge-discharge curves of VC/C-G at different charging rates with a fixed discharging rate of 1 C; SOC-time plots of (b) VC/C-G and (c) VC/C; dQ/dV plots of (d) VC/C-G; (e) Fast-charging cycling performances at 5—1 C; (f) Summary of capacity retentions at different charging rates; (g) Ex situ XRD results of VC/C-G at the charging rate of 5 C and (h) corresponding enlarged patterns(Advanced Energy Materials has image copyright)[18]"

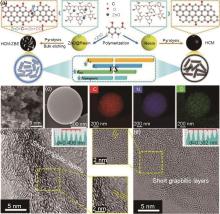

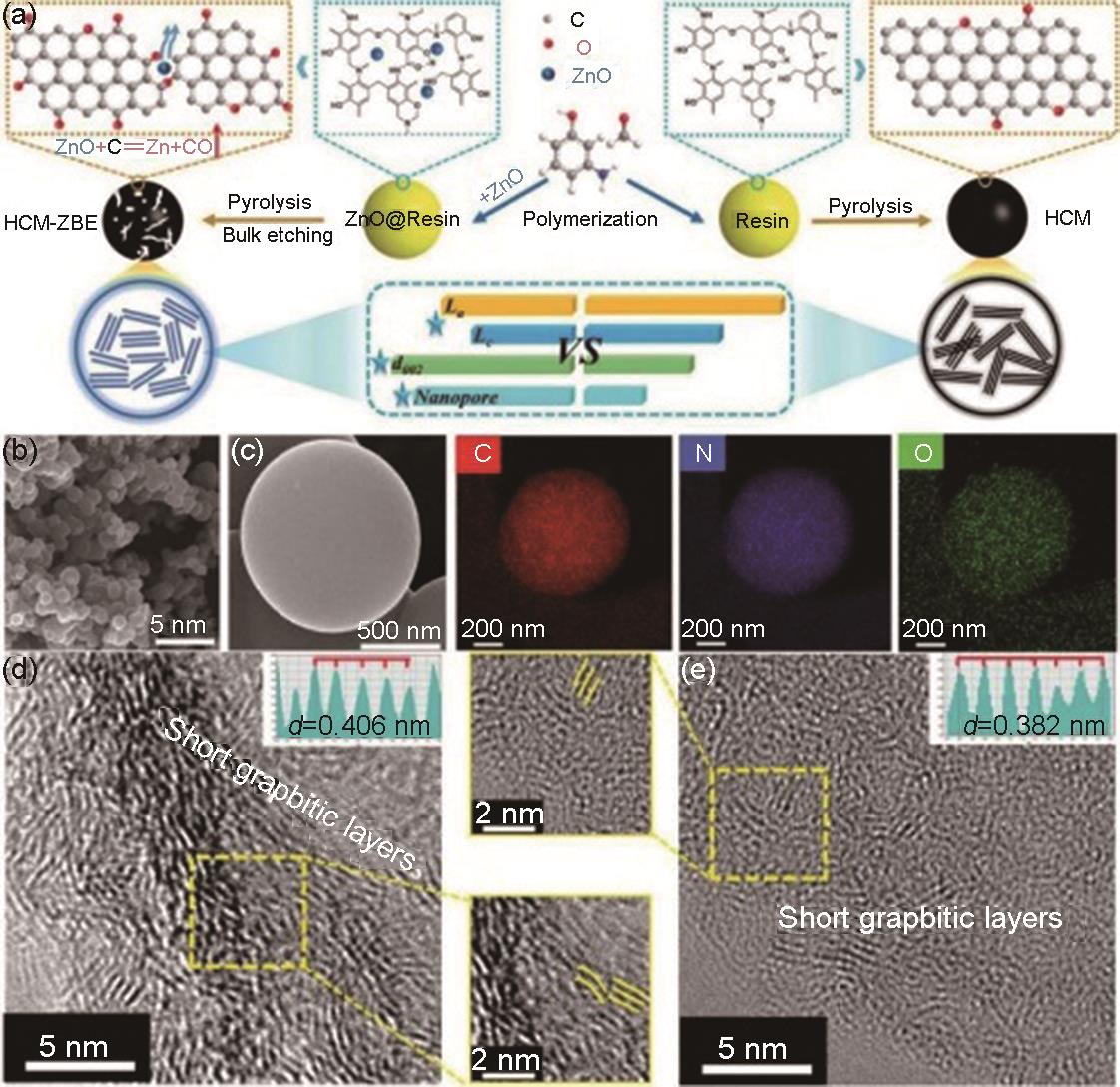

Fig. 8

Schematic illustration and morphological structure characterizations: (a) Schematic diagram illustrating the synthesis route of the samples; (b) SEM images and (c) mapping of HCM-1300-ZBE; (d), (e) HRTEM images of HCM-1300-ZBE (d) and HCM-1300 (e)(The inset shows the corresponding FFT patterns) (Advanced Materials has image copyright)[20]"

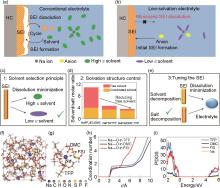

Fig. 10

Electrolyte design principles to suppress the SEI dissolution for highly stable high-voltage sodium-ion batteries: (a), (b) In the conventional electrolyte (a) , SEI dissolution leads to continuous side reactions of SEI formation and electrolyte decomposition, low CEs and irreversible capacity loss. In the low-solvation electrolyte (b), SEI dissolution is suppressed for stable sodium salt anion (FSI-)-derived SEI to stabilize cell long cycling performance; (c)—(e) three main electrolyte design principles to suppress the SEI dissolution: solvent selection by choosing a low dielectric constant (ε) solvent (c), reduced amount of free solvent by manipulating solvation structures (d) and salt-derived SEI with insoluble components (e); (f)—(i) Ab initio molecular dynamics (AIMD) simulation of the NaFSI/DMC: TFP electrolyte: a snapshot of the electrolyte molecular system from the AIMD simulation (f) and a representative Na+ solvation structure extracted from the AIMD simulations (g), coordination number (h) and projected density of states (PDOS) (with an arbitrary unit) (i) of the NaFSI/DMC: TFP electrolyte. the Fermi level is set to 0 eV in the PDOS analysis(Nat Energy has image copyright)[26]"

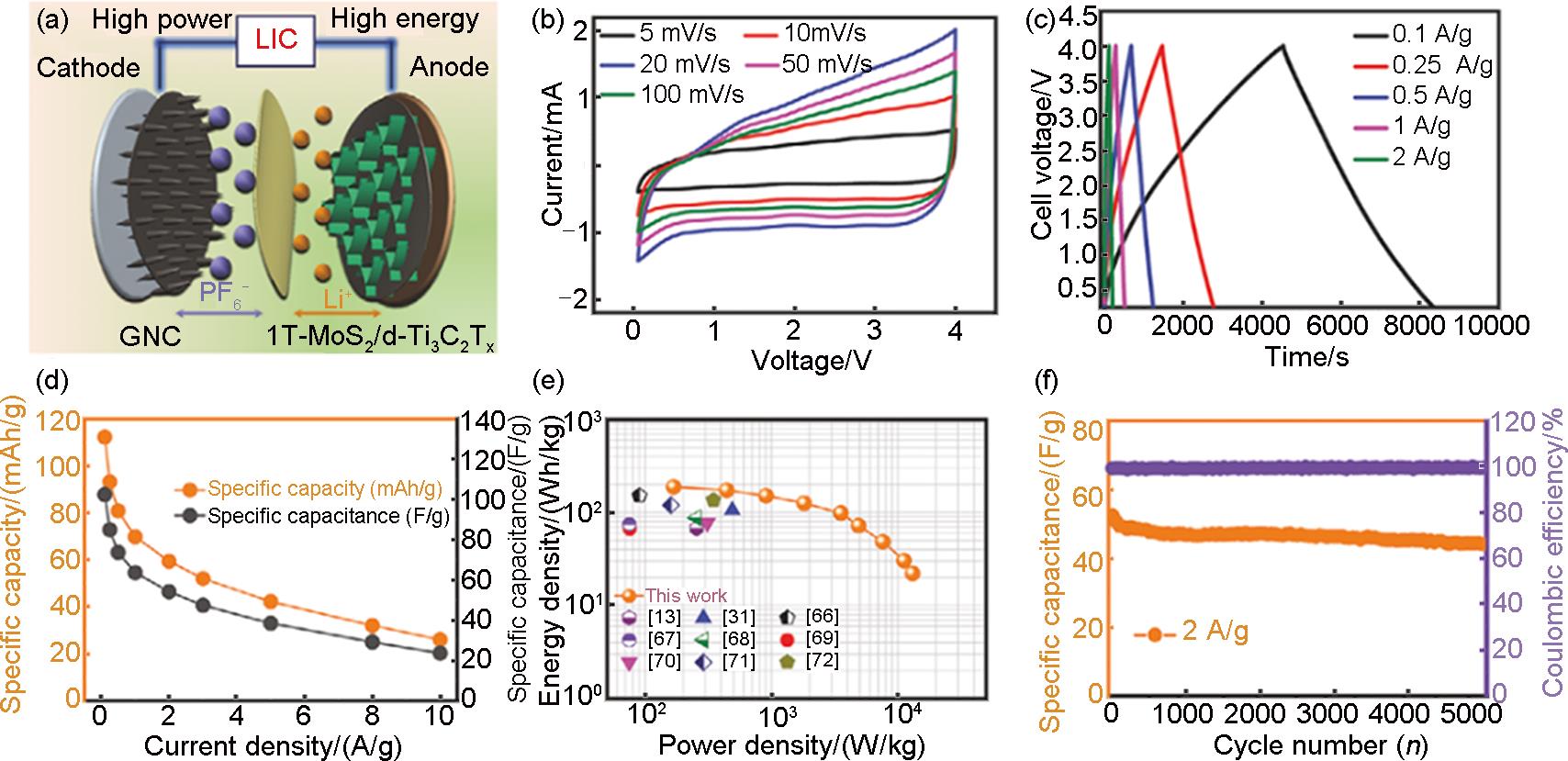

Fig. 12

Electrochemical performance of GNC/1T-MoS2/d-Ti3C2T xLIC:(a)Schematic illustration of the energy-storage mechanism of GNC || 1T-MoS2/d-Ti3C2T x LIC; (b)CV curves and(c)GCD profiles of GNC || 1T-MoS2/d-Ti3C2T x LIC within a wide voltage range of 0.1—4 V; (d)Variation of specific capacitance and capacity with current density for GNC || 1T-MoS2/d-Ti3C2T xLIC; (e)Ragone plot of GNC || 1T-MoS2/d-Ti3C2T x LIC; (f)Capacity retention and Coulombic efficiency of GNC//1T-MoS2/d-Ti3C2T x LIC over 5000 cycles(Advanced Functional Materials has image copyright)[44]"

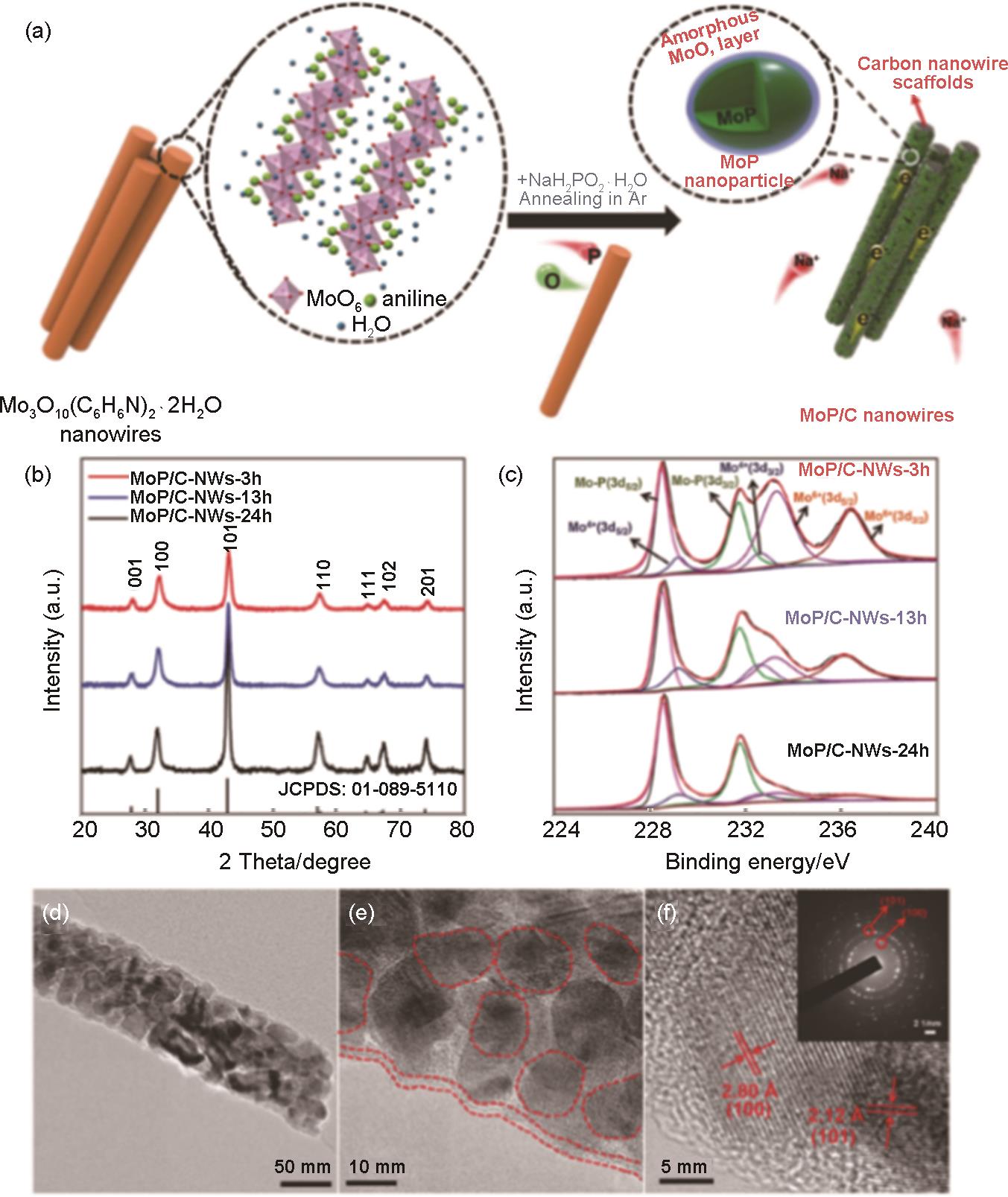

Fig. 14

Material characterizations: (a)Schematic of the transformation from Mo3O10(C6H8N)2·2H2O NWs precursor to MoP/C-NWs (The MoP NPs with amorphous MoO x layers uniformly integrated within conducting carbon scaffolds); (b) XRD patterns and (c) Mo 3D XPS spectra of MoP/C-NWs-3 h, MoP/C-NWs-13 h, and MoP/C-NWs-24 h, respectively; (d), (e)TEM and (f) HRTEM images of MoP/C-NWs-3 h [Insert (f) is the related SAED pattern] (Advanced Energy Materials has image copyright)[49]"

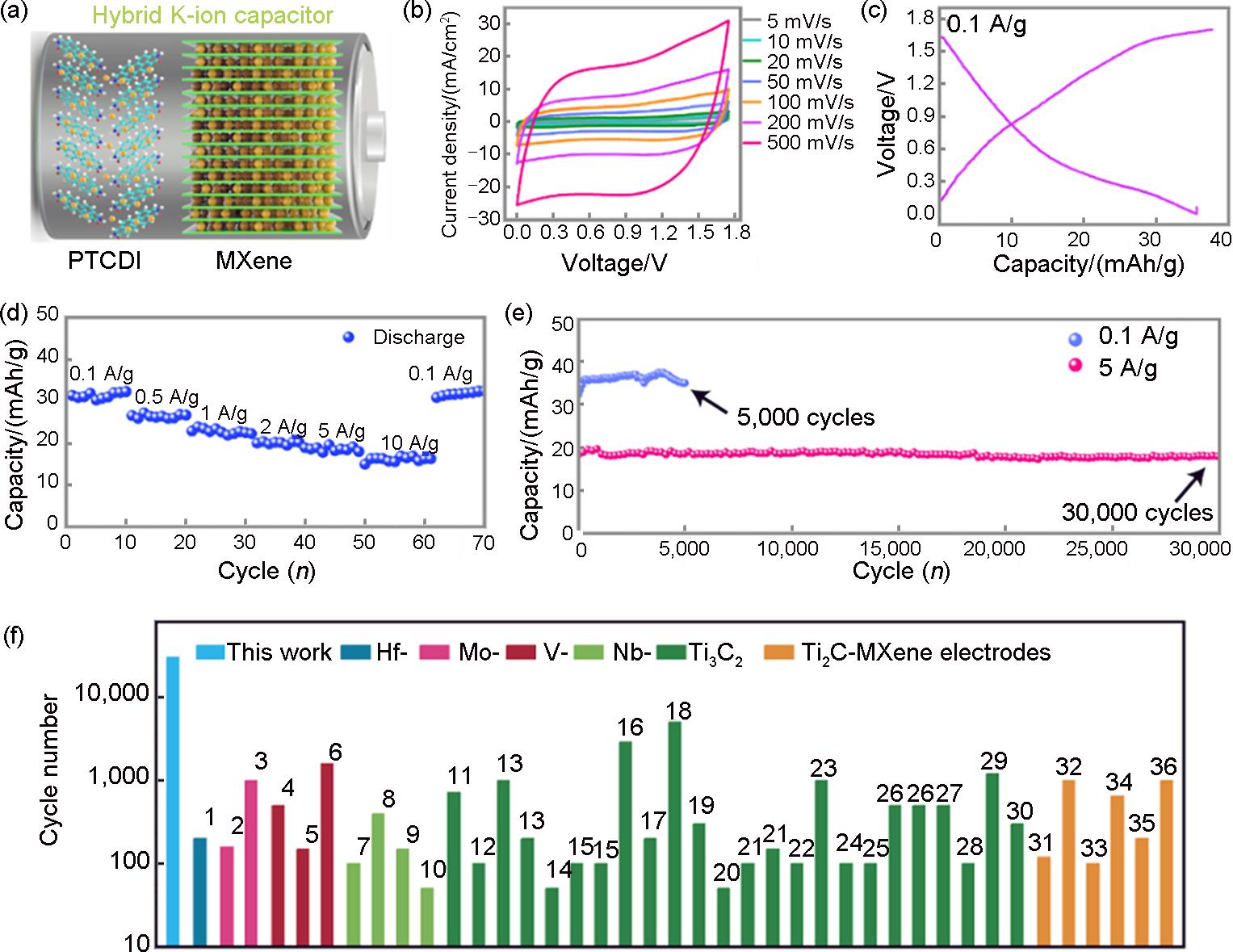

Fig. 16

(a)Schematic illustration of full capacitor based on MXene cathode(here is Nb2C and PTCDI anode); (b)CV curves at different scan rates; (c)GCD curves at 0.1 A/g; (d)Rate performance at different current densities; (e)Cyclic performance at small and large current densities, respectively(Advanced Functional Materialshas image copyright)[54]"

Table 1

Carbon Types and Related Electrochemical Properties Involved in Recent Literature"

| 序号 | 引入碳 | 电化学测试 | 文献 |

|---|---|---|---|

| 1 | 多孔炭 | 0.1 C下放电比容量为183 mAh/g(高于空白电池151 mAh/g),1 C循环600次后的容量保持率为50.1% | [ |

| 2 | 稻壳基多级多孔炭 | 在PS℃操作下,初始100%放电深度(DOD)容量为4.40Ah,90个循环后放电容量下降到2.75 Ah | [ |

| 3 | 稻壳基活性炭(RHAC) | 在HRPS℃和150%荷电状态下60次深循环后的容量保持率分别提高了49.12%和47.2% | [ |

| 4 | 多级管状多孔炭(HTPC) | 含1.2% HTPC的LCB在0.1 C时的放电比容量为165.4 mAh/g(而空白样品的放电比容量为140.5 mAh/g),在HRPS℃条件下,LCB的循环寿命比对照组延长了3.17倍 | [ |

| 5 | N掺杂还原氧化石墨烯(N-rGO) | 与具有相同含量 rGO 添加剂的电池(7742次循环)和不含任何碳添加剂的电池(2777次循环)相比,含0.50%(质量分数) N-rGO/PbO 添加剂的电池显示17390次循环 | [ |

Table 2

Performance comparison of high rate chemical power supply systems"

| 项目 | 锂离子电池 | 钠离子电池 | 赝电容电容器 | 离子型电容器 | 铅炭电池 |

|---|---|---|---|---|---|

| 能量密度/( Wh/kg) | 150~300 | 100~160 | 5~50 | 10~50 | 40~60 |

| 快充/放 | 以分钟为单位 | 以分钟为单位 | 以秒为单位 | 以秒为单位 | 以分钟为单位 |

| 内阻 | 较高 | 较高 | 低 | 低 | 低 |

| 工作温度/℃ | -20~60 | -40~80 | -40~80 | -40~70 | -40~50 |

| 循环寿命 | 3000~15000 | 2000~10000 | 十万次以上 | 万次以上 | 3000 |

| 安全性 | 一般 | 一般 | 较好 | 一般 | 良好 |

| 应用(功率/能量) | 中功率 (高能量) | 高功率 (高能量) | 高功率 (中等能量) | 高功率 (中等能量) | 低功率 (中等能量) |

| 典型产品 | 1.法国GAIA公司研制的341440 NCA高功率电池 2.日本东芝生产的“SCiB”钛酸锂电池 3.比亚迪的刀片磷酸铁锂电池 | 1.Natron Energy 的专利Prussian Blue电极 2.华宇新能源科技公司发布了第一代SIB——“极钠1号” 3.中科海纳建立国内首座100 kWh SIB储能电站示范应用 | 1.Maxwell科技公司生产的3 V/3000 F超级电容器 2.俄罗斯ESMA公司开发的是混合型NiO||AC超级电容器 3.上海奥威的28000F单体 | 1.JM Energy的锂离子电容器ULTIMO 2.东莞市科尼盛电子有限公司出品的Burstcap LIC 3.中国中车集团与Maxwell合作开发的锂离子电容器 | 1.美国EXIDE公司用于SUV汽车起动的轻型EXTREM系列 2.日本古河生产的双极型蓄电池 3.山东圣阳研发的FCP铅炭电池 |

| 应用场景 | 1.无人机等航空航天领域 2.电动汽车 3.储能 4.便携式电子产品 | 1.储能 2.低速电动车 3.低温启动 | 1.穿戴或柔性电子产品 2.地铁驱动电源 3.UPS电源 | 1.脉冲响应 2.能量回收及启停 3.功率调节 | 1.智能电网,微网电站 2.混合动力汽车 3.低温启动 |

| 1 | PIERRE MWIZERWA J, LIU C Y, XU K, et al. Activated carbon/reduced graphene oxide wrapped LiFePO4 cathode for Li-ion batteries with ultrahigh capacities and high specific energy density[J]. FlatChem, 2022, 34: 100393. |

| 2 | GUAN Y B, SHEN J R, WEI X F, et al. LiFePO4/activated carbon/graphene composite with capacitive-battery characteristics for superior high-rate lithium-ion storage[J]. Electrochimica Acta, 2019, 294: 148-155. |

| 3 | CHEN X F, WANG Y H, CAO G P, et al. Synergistic and capacitance effects in nanocarbon based capacitor batteries designed for superior rate capability and long-cycle stability[J]. Journal of Colloid and Interface Science, 2022, 626: 395-404. |

| 4 | CHEN X F, MU Y, CAO G P, et al. Structure-activity relationship of carbon additives in cathodes for advanced capacitor batteries[J]. Electrochimica Acta, 2022, 413: 140165. |

| 5 | KIM U H, PARK J H, AISHOVA A, et al. Microstructure engineered Ni-rich layered cathode for electric vehicle batteries[J]. Advanced Energy Materials, 2021, 11(25): 2100884. |

| 6 | CHEN K H, GOEL V, NAMKOONG M J, et al. Enabling 6C fast charging of Li-ion batteries with graphite/hard carbon hybrid anodes[J]. Advanced Energy Materials, 2021, 11(5): 2003336. |

| 7 | NI X P, CUI Z, JIANG N, et al. Hollow multi-nanochannel carbon nanofiber/MoS2 nanoflower composites as binder-free lithium-ion battery anodes with high capacity and ultralong-cycle life at large current density[J]. Journal of Materials Science & Technology, 2021, 77: 169-177. |

| 8 | WU D B, WANG C, WU H J, et al. Synthesis of hollow Co3O4 nanocrystals in situ anchored on holey graphene for high rate lithium-ion batteries[J]. Carbon, 2020, 163: 137-144. |

| 9 | GAO N, KIM S, CHINNAM P, et al. Methodologies for design, characterization and testing of electrolytes that enable extreme fast charging of lithium-ion cells[J]. Energy Storage Materials, 2022, 44: 296-312. |

| 10 | GUO H X, TIAN Y, LIU Y M, et al. Inner lithium fluoride (LiF)-rich solid electrolyte interphase enabled by a smaller solvation sheath for fast-charging lithium batteries[J]. ACS Applied Materials & Interfaces, 2023, 15(1): 1201-1209. |

| 11 | 出鞘·安天下——比亚迪"刀片电池" 引领全球动力电池安全新高度[J]. 城市公共交通, 2020(5): 96-97. |

| Take out the sheath and secure the world-BYD's "blade battery" leads the global power battery safety to a new height[J]. Urban Public Transport, 2020(5): 96-97. | |

| 12 | 金一丹. 宁德时代第三代CTP麒麟电池落地[N].中国证券报, 2022-08-27(A05). |

| JIN Y. CATL third generation CTP Kirin battery landing [N]. China Securities Journal, 2022-08-27 (A05). | |

| 13 | 赫炎. 从CTP、CTC、CTB浅谈电动汽车动力电池集成技术[J]. 世界汽车, 2022(6): 70-71. |

| HE Y. Discussion on power battery integration technology of electric vehicle from CTP, CTC and CTB[J]. World Auto, 2022(6): 70-71. | |

| 14 | 张静, 赵程, 高玉双, 等. 钛酸锂电池技术在国内外的发展状况分析[J]. 科技创新导报, 2019, 16(29): 237, 239. |

| ZHANG J, ZHAO C, GAO Y S, et al. Analysis on the development of lithium titanate battery technology at home and abroad[J]. Science and Technology Innovation Herald, 2019, 16(29): 237, 239. | |

| 15 | MA C, LI X L, YUE X Y, et al. Suppressing O3-O'3 phase transition in NaCrO2 cathode enabling high rate capability for sodium-ion batteries by Sb substitution[J]. Chemical Engineering Journal, 2022, 432: 134305. |

| 16 | SUBRAMANIAN Y, OH W, CHOI W, et al. Optimizing high voltage Na3V2(PO4)2F3 cathode for achieving high rate sodium-ion batteries with long cycle life[J]. Chemical Engineering Journal, 2021, 403: 126291. |

| 17 | SHI Q H, QI R J, FENG X C, et al. Niobium-doped layered cathode material for high-power and low-temperature sodium-ion batteries[J]. Nature Communications, 2022, 13: 3205. |

| 18 | ZHANG W, WU Y, XU Z, et al. Rationally designed sodium chromium vanadium phosphate cathodes with multi‐electron reaction for fast-charging sodium-ion batteries[J]. Advanced Energy Materials, 2022, 12(25): 2201065. |

| 19 | JIANG C L, FANG Y, ZHANG W Y, et al. A multi-ion strategy towards rechargeable sodium-ion full batteries with high working voltage and rate capability[J]. Angewandte Chemie International Edition, 2018, 57(50): 16370-16374. |

| 20 | YIN X P, LU Z X, WANG J, et al. Enabling fast Na+ transfer kinetics in the whole-voltage-region of hard-carbon anodes for ultrahigh-rate sodium storage[J]. Advanced Materials, 2022, 34(13): e2109282. |

| 21 | WANG G, SHAO M, DING H R, et al. Multiple active sites of carbon for high-rate surface-capacitive sodium-ion storage[J]. Angewandte Chemie (International Ed in English), 2019, 58(38): 13584-13589. |

| 22 | NI D, SUN W, WANG Z H, et al. Heteroatom-doped mesoporous hollow carbon spheres for fast sodium storage with an ultralong cycle life[J]. Advanced Energy Materials, 2019, 9(19): 1900036. |

| 23 | CHEN W M, CHEN C J, XIONG X Q, et al. Coordination of surface-induced reaction and intercalation: Toward a high-performance carbon anode for sodium-ion batteries[J]. Advanced Science, 2017, 4(6): 1600500. |

| 24 | KIM Y H, AN J H, KIM S Y, et al. Enabling 100C fast-charging bulk Bi anodes for Na-ion batteries[J]. Advanced Materials, 2022, 34(27): e2201446. |

| 25 | XIONG P X, BAI P X, LI A, et al. Bismuth Nanoparticle@Carbon composite anodes for ultralong cycle life and high-rate sodium-ion batteries[J]. Advanced Materials, 2019, 31(48): e1904771. |

| 26 | JIN Y, LE P M L, GAO P Y, et al. Low-solvation electrolytes for high-voltage sodium-ion batteries[J]. Nature Energy, 2022, 7: 718-725. |

| 27 | TANG Z, WANG H, WU P F, et al. Electrode-electrolyte interfacial chemistry modulation for ultra-high rate sodium-ion batteries[J]. Angewandte Chemie (International Ed in English), 2022, 61(18): e202200475. |

| 28 | PAN J, ZHANG Y C, SUN F, et al. Designing solvated double-layer polymer electrolytes with molecular interactions mediated stable interfaces for sodium ion batteries[J]. Angewandte Chemie (International Ed in English), 2023, 62(17): e202219000. |

| 29 | SUN H, ZHU G Z, XU X T, et al. A safe and non-flammable sodium metal battery based on an ionic liquid electrolyte[J]. Nature Communications, 2019, 10: 3302. |

| 30 | 高驰. 宁德时代发布第一代钠离子电池,未来可期[J]. 汽车与配件, 2021(15): 55. |

| GAO C. Contemporary Amperex Technology Co., Limited released the first generation of sodium ion batteries, which can be expected in the future[J]. Automobile & Parts, 2021(15): 55. | |

| 31 | 唐琳, 王佳雯. 胡勇胜: 在电池研究应用领域走少有人走的路[J]. 科学新闻, 2021, 23(1): 27-29. |

| TANG L, WANG J W. HU Yongsheng: Take the road that few people take in the field of battery research and application[J]. Science News, 2021, 23(1): 27-29. | |

| 32 | 祁鹏, 陈爱英. 浅谈赝电容电极材料的研究进展[J]. 电源技术, 2020, 44(8): 1235-1238. |

| QI P, CHEN A Y. Talking about research progress of electrode materials for pseudocapacitor[J]. Chinese Journal of Power Sources, 2020, 44(8): 1235-1238. | |

| 33 | ZHAO S S, CHEN C F, ZHAO X, et al. Flexible Nb4C3Tx film with large interlayer spacing for high-performance supercapacitors[J]. Advanced Functional Materials, 2020, 30(47): 2000815. |

| 34 | WANG L K, HAN M K, SHUCK C E, et al. Adjustable electrochemical properties of solid-solution MXenes[J]. Nano Energy, 2021, 88: 106308. |

| 35 | BARIK R, TANWAR V, KUMAR R, et al. A high energy density and high rate capability flexible supercapacitor based on electro-spun highly porous SnO2@carbon nanofibers[J]. Journal of Materials Chemistry A, 2020, 8(30): 15110-15121. |

| 36 | XIE B Q, YU M Y, LU L H, et al. Pseudocapacitive Co9S8/graphene electrode for high-rate hybrid supercapacitors[J]. Carbon, 2019, 141: 134-142. |

| 37 | MENG C X, ZHOU F, LIU H Q, et al. Water-in-salt ambipolar redox electrolyte extraordinarily boosting high pseudocapacitive performance of micro-supercapacitors[J]. ACS Energy Letters, 2022, 7(5): 1706-1711. |

| 38 | CHEN Y Y, QING L Y, LIU T T, et al. Tuning interfacial ion distribution to improve energy density of supercapacitors[J]. Nano Energy, 2022, 102: 107660. |

| 39 | 郭雪飞, 孙洋洲, 刘强, 等. 石墨烯储能应用的技术进展及产业化现状[J]. 炭素技术, 2020, 39(1): 19-23. |

| GUO X F, SUN Y Z, LIU Q, et al. Technology progress and industrialization status of graphene in energy storage[J]. Carbon Techniques, 2020, 39(1): 19-23. | |

| 40 | 刘义波, 李峰, 胡静. 超级电容器研究进展及应用分析[J]. 电源技术, 2015, 39(9): 2028-2030. |

| LIU Y B, LI F, HU J. Research progress and application analysis of supercapacitors[J]. Chinese Journal of Power Sources, 2015, 39(9): 2028-2030. | |

| 41 | QIN L, ZHU S H, CHENG C, et al. Single-crystal nano-subunits assembled accordion-shape WNb2O8 framework with high ionic/electronic conductivities towards Li-ion capacitors[J]. Small, 2022, 18(13): e2107987. |

| 42 | YUAN T, LUO S N, SOULE L K, et al. A hierarchical Ti2Nb10O29 composite electrode for high-power lithium-ion batteries and capacitors[J]. Materials Today, 2021, 45: 8-19. |

| 43 | LUO J M, ZHANG W K, YUAN H D, et al. Pillared structure design of MXene with ultralarge interlayer spacing for high-performance lithium-ion capacitors[J]. ACS Nano, 2017, 11(3): 2459-2469. |

| 44 | WANG L, ZHANG X, XU Y N, et al. Tetrabutylammonium-intercalated 1T-MoS2 nanosheets with expanded interlayer spacing vertically coupled on 2D delaminated MXene for high-performance lithium-ion capacitors[J]. Advanced Functional Materials, 2021, 31(36): 2104286. |

| 45 | LIU W J, ZHANG X, XU Y N, et al. 2D graphene/MnO heterostructure with strongly stable interface enabling high-performance flexible solid-state lithium-ion capacitors[J]. Advanced Functional Materials, 2022, 32(30): 2202342. |

| 46 | LE Z Y, LIU F, NIE P, et al. Pseudocapacitive sodium storage in mesoporous single-crystal-like TiO2-graphene nanocomposite enables high-performance sodium-ion capacitors[J]. ACS Nano, 2017, 11(3): 2952-2960. |

| 47 | QIAN J, WU F, YE Y S, et al. Boosting fast sodium storage of a large-scalable carbon anode with an ultralong cycle life[J]. Advanced Energy Materials, 2018, 8(16): 1703159. |

| 48 | LV X J, SONG J X, LAI Y Q, et al. Ultrafine nanoparticles assembled Mo2C nanoplates as promising anode materials for sodium ion batteries with excellent performance[J]. Journal of Energy Storage, 2016, 8: 205-211. |

| 49 | JIANG Y L, SHEN Y H, DONG J, et al. Surface pseudocapacitive mechanism of molybdenum phosphide for high-energy and high-power sodium-ion capacitors[J]. Advanced Energy Materials, 2019, 9(27): 1900967. |

| 50 | JIANG Y L, WANG H, DONG J, et al. Mo2C nanoparticles embedded in carbon nanowires with surface pseudocapacitance enables high-energy and high-power sodium ion capacitors[J]. Small, 2022, 18(24): 2200805. |

| 51 | TAN J F, ZHU W H, GUI Q Y, et al. Weak ionization induced interfacial deposition and transformation towards fast-charging NaTi2(PO4)3 nanowire bundles for advanced aqueous sodium-ion capacitors[J]. Advanced Functional Materials, 2021, 31(23): 2101027. |

| 52 | CHEN J T, YANG B J, HOU H J, et al. Disordered, large interlayer spacing, and oxygen-rich carbon nanosheets for potassium ion hybrid capacitor[J]. Advanced Energy Materials, 2019, 9(19): 1803894. |

| 53 | YI Y Y, SUN Z T, LI C, et al. Designing 3D biomorphic nitrogen-doped MoSe2/graphene composites toward high-performance potassium-ion capacitors[J]. Advanced Functional Materials, 2020, 30(4): 1903878. |

| 54 | LIANG G J, LI X L, WANG Y B, et al. Building durable aqueous K-ion capacitors based on MXene family[J]. Nano Research Energy, 2022, 1: e9120002. |

| 55 | YIN J, LIN N, ZHANG W L, et al. Highly reversible lead-carbon battery anode with lead grafting on the carbon surface[J]. Journal of Energy Chemistry, 2018, 27(6): 1674-1683. |

| 56 | LI J C, HU Y T, ZHANG Y S, et al. Construction of a novel three-dimensional porous lead-carbon network for improving the reversibility of deep discharge lead-carbon batteries[J]. Journal of Electroanalytical Chemistry, 2021, 883: 115065. |

| 57 | SUN X F, LIU Y J, ZHAO Y, et al. Investigation of lead particles loading on the surface of activated carbon on the performance of lead carbon batteries and its potential mechanisms[J]. Journal of Energy Storage, 2023, 60: 106641. |

| 58 | LIU X, TAO D W, LI Z M, et al. N-doped reduced graphene oxide loading nano lead oxide as negative additive for enhanced properties of lead-carbon batteries[J]. Electrochemistry Communications, 2023, 146: 107422. |

| 59 | HE P Q, TU J, YANG Y, et al. Hierarchical tubular porous carbon derived from mulberry branches for long-life lead-carbon battery[J]. Journal of Energy Storage, 2023, 64: 107162. |

| 60 | WANG Z D, TUO X P, ZHOU J Q, et al. Performance study of large capacity industrial lead-carbon battery for energy storage[J]. Journal of Energy Storage, 2022, 55: 105398. |

| 61 | NARESH V, ELIAS L, GAFFOOR S A, et al. Corrosion resistant polypyrrole coated lead-alloy positive grids for advanced lead-acid batteries[J]. Journal of the Electrochemical Society, 2019, 166(2): A74. |

| 62 | LANNELONGUE J, CUGNET M, GUILLET N, et al. Electrochemistry of thin-plate lead-carbon batteries employing alternative current collectors[J]. Journal of Power Sources, 2017, 352: 194-207. |

| 63 | 黄伟国, 王鹏伟, 陈理, 等. 极耳排布对AGM铅炭电池性能的影响[J]. 储能科学与技术, 2020, 9(4): 1060-1065. |

| HUANG W G, WANG P W, CHEN L, et al. Study on the effect of electrode lugs arrangement on the performance of AGM lead-carbon batteries[J]. Energy Storage Science and Technology, 2020, 9(4): 1060-1065. | |

| 64 | 梁乔栩. 国外先进水下电池应用发展分析[EB/OL]. (2023-02-08)[2023-09-20]. https://www.163.com/dy/article/HT3910P10515E3KM.html. |

| LIANG Q.Application and development analysis of advanced underwater batteries abroad[EB/OL].(2023-02-08)[2023-09-20].https://www.163.com/dy/article/HT3910P10515E3KM.html. | |

| 65 | FISH S, SAVOIE T, VANICEK H. Modeling hybrid electric HMMWV power system performance[J]. IEEE Transactions on Magnetics, 2001, 37(1): 480-484. |

| 66 | SAFT. Li-ion batteries power F-35 lightning ii joint strike fighter through LRIP programme[C]//Press Release, Paris, France, June 15, 2009. |

| 67 | SITZMAN A, SURLS D, MALLICK J. Design, construction, and testing of an inductive pulsed-power supply for a small railgun[J]. IEEE Transactions on Magnetics, 2007, 43(1): 270-274. |

| 68 | ALLEN R, NERI J. A battery powered, 200-kW rapid capacitor charger for a portable railgun in burst mode operation at 3 RPS[C]//2007 16th IEEE International Pulsed Power Conference. Albuquerque, NM, USA. IEEE, 2007: 1500-1504. |

| 69 | NUNNALLY C, MAYES J R, HATFIELD C W, et al. Design and performance of an ultra-compact 1.8-kJ, 600-kV pulsed power system[C]//2009 IEEE Pulsed Power Conference. Washington, DC, USA. IEEE, 2009: 930-933. |

| 70 | DRAGT A J, ELIZONDO J M. Compact battery-powered, 400-kV, 40-Joule Marx generator[C]//PPPS-2001 Pulsed Power Plasma Science 2001.28th IEEE International Conference on Plasma Science and 13th IEEE International Pulsed Power Conference. Digest of Papers (Cat. No.01CH37251). Las Vegas, NV, USA. IEEE, 2002: 1555-1558. |

| 71 | CADILHON B, CASSANY B, DIOT J C, et al. Self-contained, hand-portable, and repetitive ultrawideband radiation source[J]. IEEE Transactions on Plasma Science, 2011, 39(6): 1549-1559. |

| [1] | Xiaolei LI, Jian GAO, Weidong ZHOU, Hong LI. Application of COMSOL multiphysics in lithium-ion batteries [J]. Energy Storage Science and Technology, 2024, 13(2): 546-567. |

| [2] | Ke PENG, Zhicheng ZHANG, Youzhang HU, Xuhui ZHANG, Jiahui ZHOU, Bin LI. Finite element-based motion analysis and optimization of sagger in thermo-mechanical coupling field [J]. Energy Storage Science and Technology, 2024, 13(2): 634-642. |

| [3] | Qi LIAO, Xiaolin CAO, Yibo DENG, Yaolin YANG, Ting CHEN. Heat dissipation simulation of tram supercapacitor module [J]. Energy Storage Science and Technology, 2024, 13(2): 702-711. |

| [4] | Qikai LEI, Yin YU, Peng PENG, Man CHEN, Kaiqiang JIN, Qingsong WANG. Effect of thermal insulation material layout on thermal runaway propagation inhibition effect of 280 Ah lithium-iron phosphate battery [J]. Energy Storage Science and Technology, 2024, 13(2): 495-502. |

| [5] | Shuangming DUAN, Shengli ZHANG. Lithium-ion battery parameter identification based on adaptive multilayer RLS [J]. Energy Storage Science and Technology, 2024, 13(2): 712-720. |

| [6] | Xin LIU, Xiling MAO, Xinyu YAN, Junqiang WANG, Mengwei LI. Preparation and electrochemical properties of NiMn-MOF with 3D pore network electrode materials [J]. Energy Storage Science and Technology, 2024, 13(2): 361-369. |

| [7] | Panchun TANG, Rong YAN, Can ZHANG, Ze SUN. Simulation of air- and liquid-cooled thermal management of stacked automotive supercapacitors [J]. Energy Storage Science and Technology, 2024, 13(2): 483-491. |

| [8] | Mengqiong SONG, Yu PENG, Ziqiang LIAO. Research on battery thermal management based on electrochemical model [J]. Energy Storage Science and Technology, 2024, 13(2): 578-585. |

| [9] | Zhifeng SONG, Weifeng DUAN, Lei MA. Simulation of power storage power regulation system supported by ultracapacitor technology [J]. Energy Storage Science and Technology, 2024, 13(2): 623-625. |

| [10] | Yuanming SONG, Yajie LIU, Guang JIN, Xing ZHOU, Xucheng HUANG. Review of energy management methods for lithium-ion battery/supercapacitor hybrid energy storage systems [J]. Energy Storage Science and Technology, 2024, 13(2): 652-668. |

| [11] | Xuejiao DAI, Jie YAN, Guan WANG, Haotian DONG, Danfeng JIANG, Zewei WEI, Fanxing MENG, Songtao LIU, Haitao ZHANG. Research progress of key materials for niobium-based low temperature batteries [J]. Energy Storage Science and Technology, 2024, 13(1): 311-324. |

| [12] | Yayun LIAO, Feng ZHOU, Yingxi ZHANG, Tu'an LV, Yang HE, Xiaoyan CHEN, Kaifu HUO. Research progress on fast-charging graphite anode materials for lithium-ion batteries [J]. Energy Storage Science and Technology, 2024, 13(1): 130-142. |

| [13] | Xin JIN, Jianru ZHANG, Qiyu WANG, Rui ZHANG, Bitong WANG, Zhongyang ZHANG, Hailong YU, Xiqian YU, Hong LI. Study on thermal runaway of hybrid solid-liquid batteries [J]. Energy Storage Science and Technology, 2024, 13(1): 48-56. |

| [14] | Lin LI. Technological landscape, challenges, and future outlook of the lithium-ion battery industry: An economic perspective [J]. Energy Storage Science and Technology, 2024, 13(1): 358-360. |

| [15] | Ye XIAO, Lei XU, Chong YAN, Jiaqi HUANG. Design and application of reference electrodes for lithium batteries [J]. Energy Storage Science and Technology, 2024, 13(1): 82-91. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||