Energy Storage Science and Technology ›› 2025, Vol. 14 ›› Issue (5): 1758-1775.doi: 10.19799/j.cnki.2095-4239.2024.1235

• Energy Storage Materials and Devices • Previous Articles Next Articles

Ruilin HE1( ), Tong ZHANG1, Jiachun WU1, Chaoyang WANG3, Yonghong DENG1, Guangzhao ZHANG1(

), Tong ZHANG1, Jiachun WU1, Chaoyang WANG3, Yonghong DENG1, Guangzhao ZHANG1( ), Xiaoxiong XU2(

), Xiaoxiong XU2( )

)

Received:2024-12-26

Revised:2025-01-15

Online:2025-05-28

Published:2025-05-21

Contact:

Guangzhao ZHANG, Xiaoxiong XU

E-mail:12331186@mail.sustech.edu.cn;zhanggz@sustech.edu.cn;xuxx@sustech.edu.cn

CLC Number:

Ruilin HE, Tong ZHANG, Jiachun WU, Chaoyang WANG, Yonghong DENG, Guangzhao ZHANG, Xiaoxiong XU. Design of scaffold materials and their application in lithium batteries[J]. Energy Storage Science and Technology, 2025, 14(5): 1758-1775.

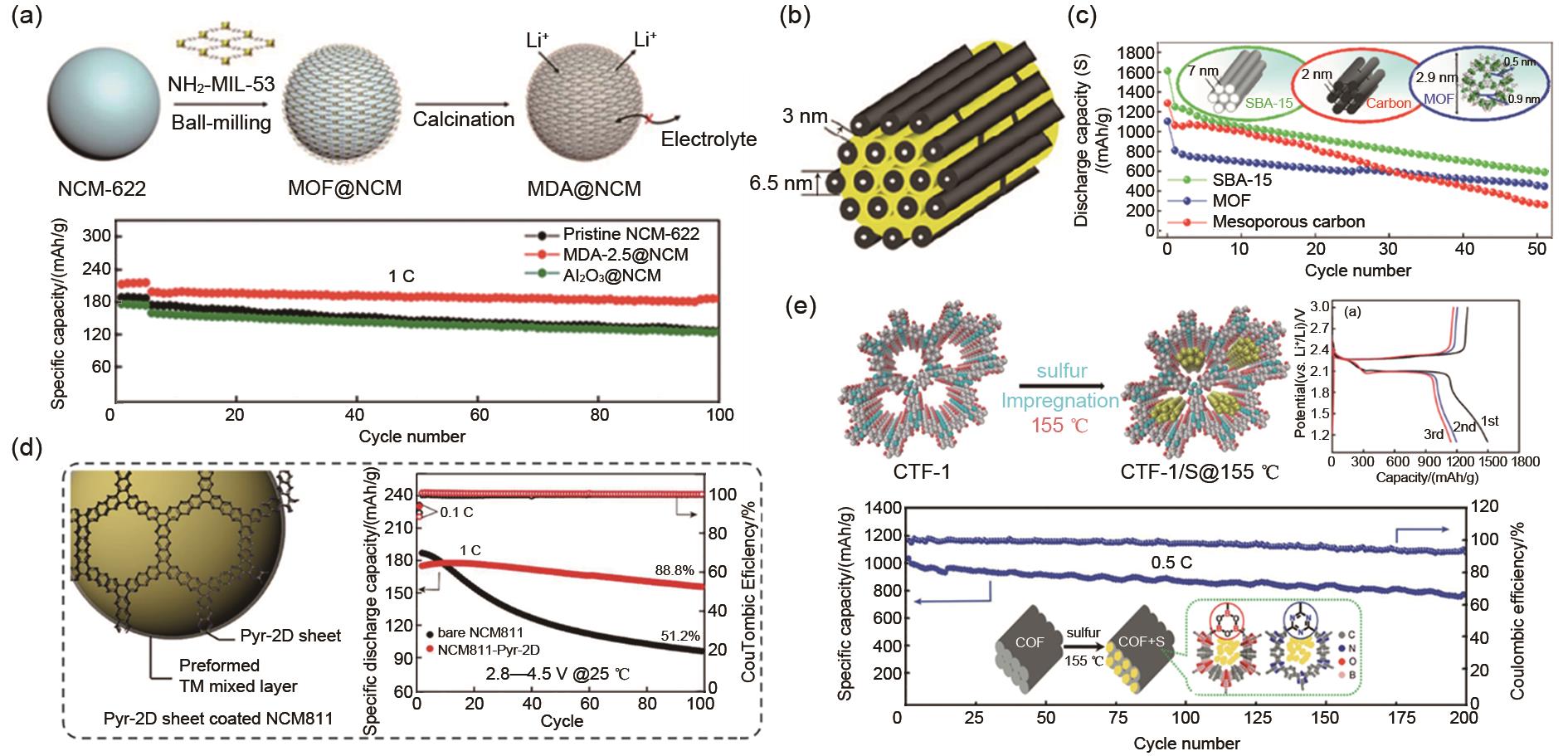

Fig. 4

Protecting cathode using molecular scaffold materials: (a) Inhibiting the dissolution of transition metal ions using MOF; (b) Decreasing the dissolution and shuttle of lithium polysulfide via encapsulation of sulfur in porous carbon materials; (c) Adsorbing and catalyzing lithium polysulfide via MOF scaffolds; (d) Protecting NCM cathodes with COF materials; (e) Inhibiting the dissolution and shuttle of lithium polysulfide via encapsulation of sulfur in porous COF materials"

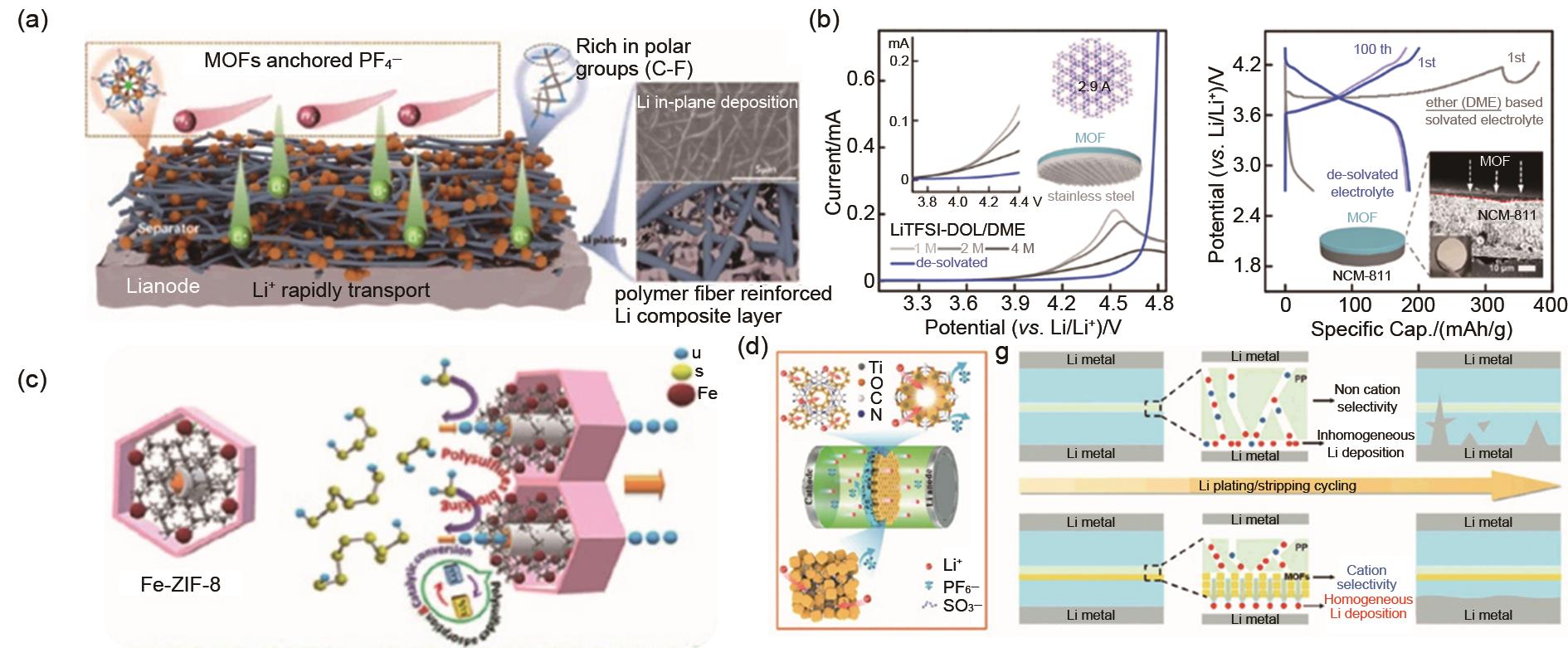

Fig. 5

Porous scaffold materials as separators for lithium batteries: (a) Adsorbing anions by MOF encapsulated porous fiber membrane; (b) Tailoring the Li+ desolvation via MOF coated separators; (c) Bifunctional scaffold materials to inhibit the shuttle of lithium polysulfide; (d) Homogenous Li+ transport using MOF based functional separators"

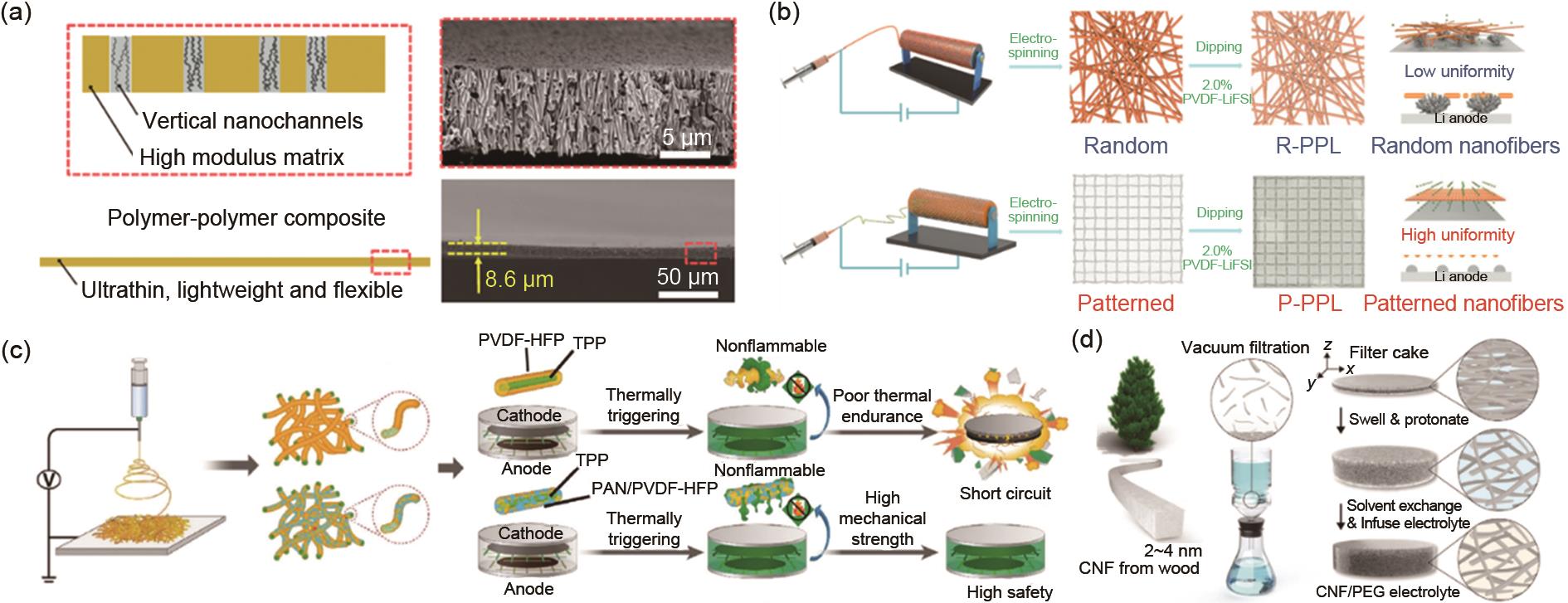

Fig. 6

Scaffold materials for electrolytes: (a) Perfusing polymer electrolytes into the pores of poly(imide) scaffolds; (b) The fabrication of porous fiber membrane via electrostatic spinning; (c) Design of non-flammable electrolyte scaffolds; (d) Polymer electrolytes based on nanocellulose scaffolds"

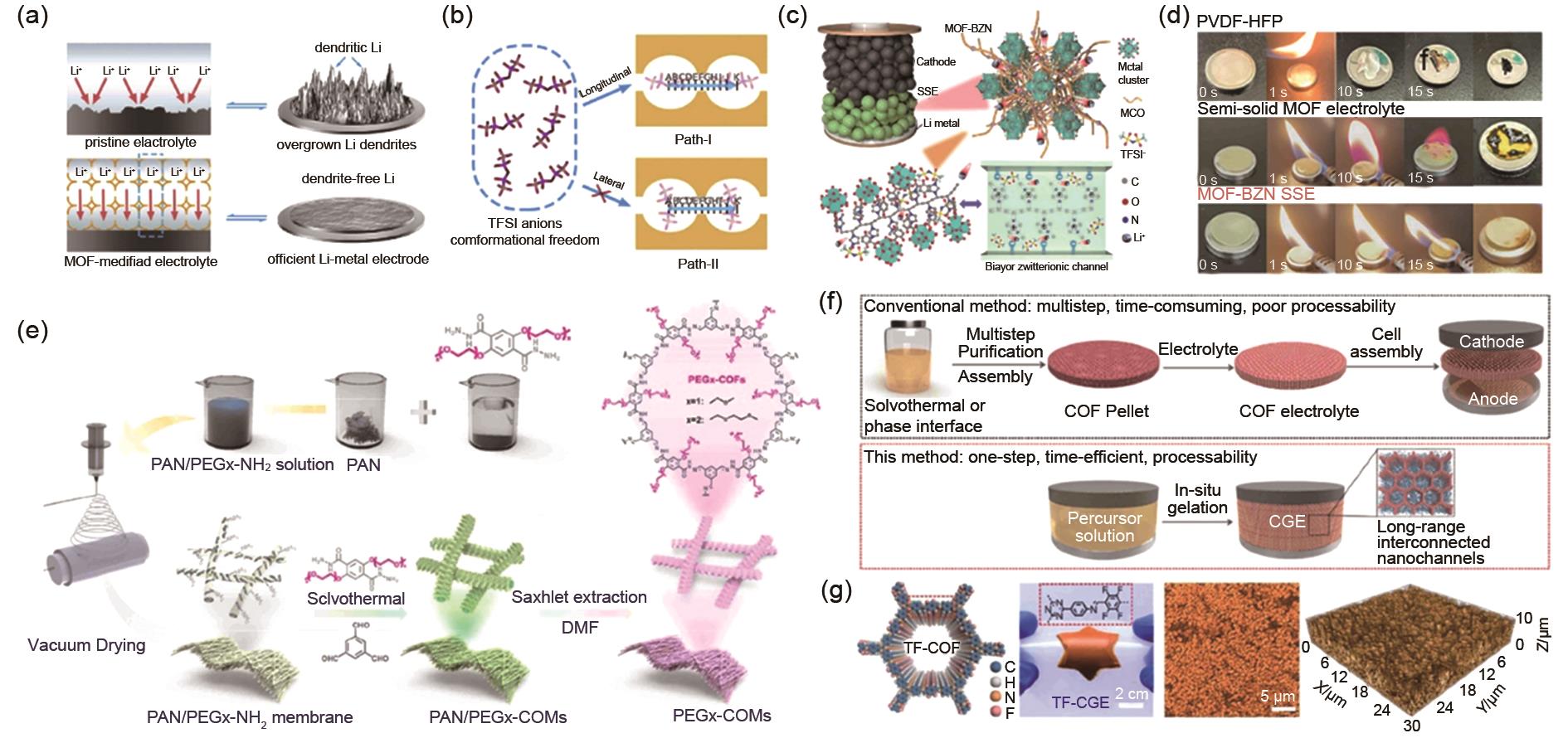

Fig. 7

The application of molecular scaffold materials in electrolytes: (a), (b) Regulating the transport of Li+ via MOF scaffolds; (c), (d) Flame-retardant electrolytes based on MOF scaffolds; (e) Functional COF polymer electrolytes based on electrostatic spinning; (f), (g) COF-based gel electrolytes via in-situ polymerization"

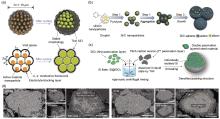

Fig. 10

Application of skeleton materials in silicon-based anode materials: (a) Schematic of the pomegranate-inspired design; (b) Schematic illustration of the formation of onion-like Si/C spheres; (c) Schematic illustration of synthetic procedures of Si@SiO2@C micro-particles; (d) Cross-sectional SEM of u-SCM and SCM bare and after cycles"

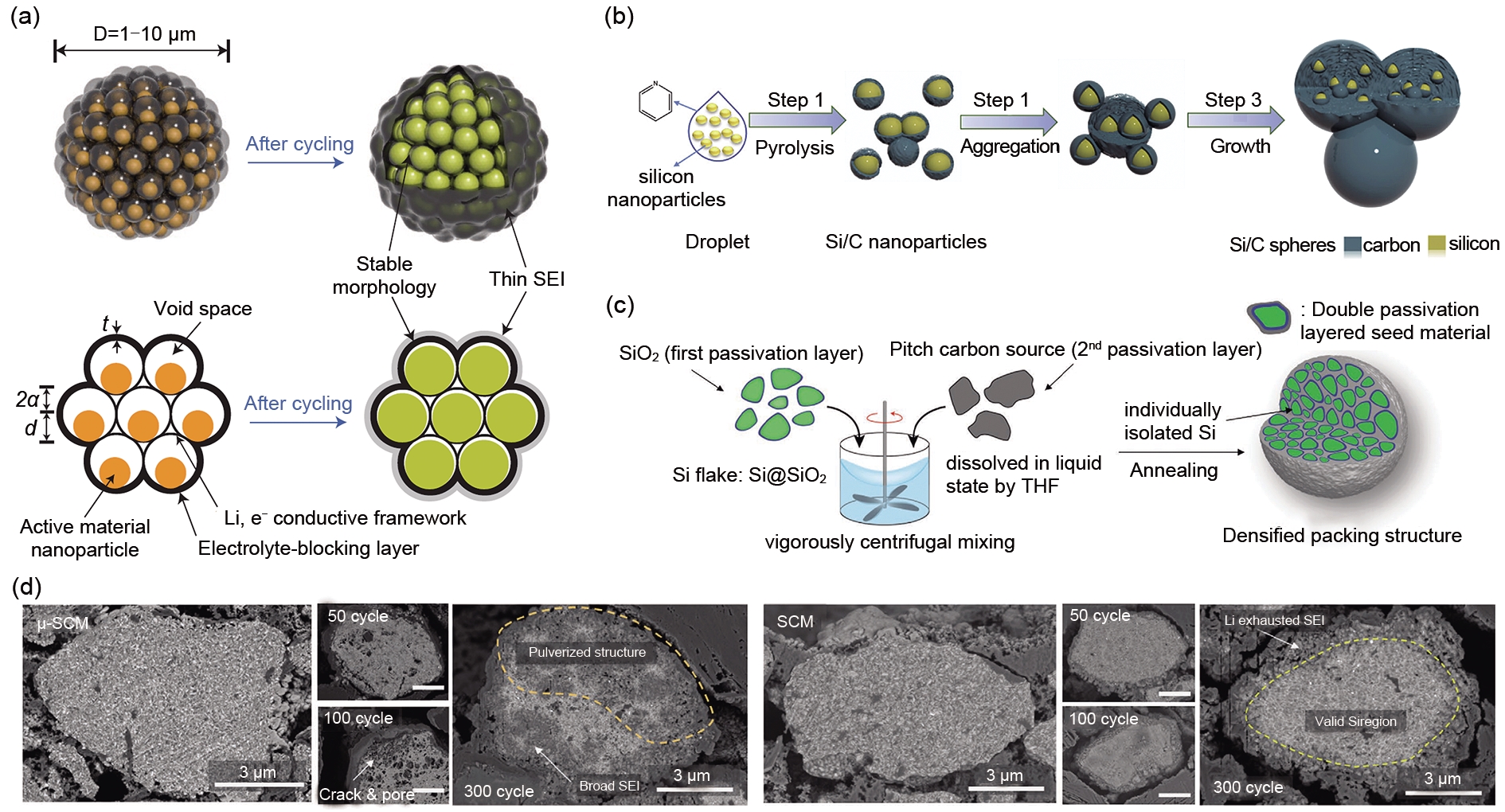

Fig. 11

Function as three dimensional current collectors: (a) The design of pattern-like Cu/SiO2 current collectors; (b) The hollow three dimensional fiber current collectors for lithium metal anodes; (c) Designed current collectors with low Fermi level for anode-free lithium metal batteries; (d) Porous carbon current collectors with multiple and aggregated defects"

| 1 | LI M, LU J, CHEN Z W, et al. 30 years of lithium-ion batteries[J]. Advanced Materials, 2018, 30(33): 1800561. DOI: 10.1002/adma. 201800561. |

| 2 | KIM T, SONG W T, SON D Y, et al. Lithium-ion batteries: Outlook on present, future, and hybridized technologies[J]. Journal of Materials Chemistry A, 2019, 7(7): 2942-2964. DOI: 10.1039/C8TA10513H. |

| 3 | LEI Y K, NI J, HU Z J, et al. Surface modification of Li-rich Mn-based layered oxide cathodes: Challenges, materials, methods, and characterization[J]. Advanced Energy Materials, 2020, 10(41): 2002506. DOI: 10.1002/aenm.202002506. |

| 4 | CHOI J W, AURBACH D. Promise and reality of post-lithium-ion batteries with high energy densities[J]. Nature Reviews Materials, 2016, 1: 16013. DOI: 10.1038/natrevmats.2016.13. |

| 5 | LIU J W, XIE D X, SHI W, et al. Coordination compounds in lithium storage and lithium-ion transport[J]. Chemical Society Reviews, 2020, 49(6): 1624-1642. DOI: 10.1039/c9cs00881k. |

| 6 | SUN J L, XU Y F, LV Y Q, et al. Recent advances in covalent organic framework electrode materials for alkali metal-ion batteries[J]. CCS Chemistry, 2023, 5(6): 1259-1276. DOI: 10. 31635/ccschem. 023.202302808. |

| 7 | LIU C C, WU B R, LIU T, et al. Metal-organic frameworks and their composites for advanced lithium-ion batteries: Synthesis, progress and prospects[J]. Journal of Energy Chemistry, 2024, 89: 449-470. DOI: 10.1016/j.jechem.2023.10.006. |

| 8 | REDDY R C K, LIN X M, ZEB A, et al. Metal-organic frameworks and their derivatives as cathodes for lithium-ion battery applications: A review[J]. Electrochemical Energy Reviews, 2022, 5(2): 312-347. DOI: 10.1007/s41918-021-00101-x. |

| 9 | LI X X, CHENG F Y, ZHANG S N, et al. Shape-controlled synthesis and lithium-storage study of metal-organic frameworks Zn4O(1, 3, 5-benzenetribenzoate)2[J]. Journal of Power Sources, 2006, 160(1): 542-547. DOI: 10.1016/j.jpowsour.2006.01.015. |

| 10 | LI G H, YANG H, LI F C, et al. A coordination chemistry approach for lithium-ion batteries: The coexistence of metal and ligand redox activities in a one-dimensional metal-organic material[J]. Inorganic Chemistry, 2016, 55(10): 4935-4940. DOI: 10.1021/acs.inorgchem.6b00450. |

| 11 | LI H Y, TANG M, WU Y C, et al. Large π-conjugated porous frameworks as cathodes for sodium-ion batteries[J]. The Journal of Physical Chemistry Letters, 2018, 9(12): 3205-3211. DOI: 10.1021/acs.jpclett.8b01285. |

| 12 | LI N, CHANG Z, HUANG H L, et al. Specific K+ binding sites as CO2 traps in a porous MOF for enhanced CO2 selective sorption[J]. Small, 2019, 15(22): 1900426. DOI: 10.1002/smll.201900426. |

| 13 | ZHAO Q, ZHU Z Q, CHEN J. Molecular engineering with organic carbonyl electrode materials for advanced stationary and redox flow rechargeable batteries[J]. Advanced Materials, 2017, 29(48): 1607007. DOI: 10.1002/adma.201607007. |

| 14 | FÉREY G, MILLANGE F, MORCRETTE M, et al. Mixed-valence Li/Fe-based metal-organic frameworks with both reversible redox and sorption properties[J]. Angewandte Chemie International Edition, 2007, 46(18): 3259-3263. DOI: 10.1002/anie.200605163. |

| 15 | WU X Y, SHAO M M, WU C H, et al. Low defect FeFe(CN)6 framework as stable host material for high performance Li-ion batteries[J]. ACS Applied Materials & Interfaces, 2016, 8(36): 23706-23712. DOI: 10.1021/acsami.6b06880. |

| 16 | ASAKURA D, LI C H, MIZUNO Y, et al. Bimetallic cyanide-bridged coordination polymers as lithium ion cathode materials: Core@shell nanoparticles with enhanced cyclability[J]. Journal of the American Chemical Society, 2013, 135(7): 2793-2799. DOI: 10.1021/ja312160v. |

| 17 | COMBELLES C, DOUBLET M L. Structural, magnetic and redox properties of a new cathode material for Li-ion batteries: The iron-based metal organic framework[J]. Ionics, 2008, 14(4): 279-283. DOI: 10.1007/s11581-007-0179-7. |

| 18 | COMBELLES C, BEN YAHIA M, PEDESSEAU L, et al. FeII/FeIII mixed-valence state induced by Li-insertion into the metal-organic-framework Mil53(Fe): A DFT+U study[J]. Journal of Power Sources, 2011, 196(7): 3426-3432. DOI: 10.1016/j.jpowsour. 2010. 08.065. |

| 19 | ZHANG Z Y, YOSHIKAWA H, AWAGA K. Monitoring the solid-state electrochemistry of Cu(2, 7-AQDC) (AQDC=anthraquinone dicarboxylate) in a lithium battery: Coexistence of metal and ligand redox activities in a metal-organic framework[J]. Journal of the American Chemical Society, 2014, 136(46): 16112-16115. DOI: 10.1021/ja508197w. |

| 20 | PENG Z, YI X H, LIU Z X, et al. Triphenylamine-based metal-organic frameworks as cathode materials in lithium-ion batteries with coexistence of redox active sites, high working voltage, and high rate stability[J]. ACS Applied Materials & Interfaces, 2016, 8(23): 14578-14585. DOI: 10.1021/acsami.6b03418. |

| 21 | CHANG C H, LI A C, POPOVS I, et al. Elucidating metal and ligand redox activities of a copper-benzoquinoid coordination polymer as the cathode for lithium-ion batteries[J]. Journal of Materials Chemistry A, 2019, 7(41): 23770-23774. DOI: 10.1039/C9TA05244E. |

| 22 | YANG D H, YAO Z Q, WU D H, et al. Structure-modulated crystalline covalent organic frameworks as high-rate cathodes for Li-ion batteries[J]. Journal of Materials Chemistry A, 2016, 4(47): 18621-18627. DOI: 10.1039/C6TA07606H. |

| 23 | YANG X Y, HU Y M, DUNLAP N, et al. A truxenone-based covalent organic framework as an all-solid-state lithium-ion battery cathode with high capacity[J]. Angewandte Chemie International Edition, 2020, 59(46): 20385-20389. DOI: 10.1002/anie.202008619. |

| 24 | XU S Q, WANG G, BISWAL B P, et al. A nitrogen-rich 2D sp2-carbon-linked conjugated polymer framework as a high-performance cathode for lithium-ion batteries[J]. Angewandte Chemie International Edition, 2019, 58(3): 849-853. DOI: 10. 1002/anie.201812685. |

| 25 | WU M M, ZHAO Y, SUN B Q, et al. A 2D covalent organic framework as a high-performance cathode material for lithium-ion batteries[J]. Nano Energy, 2020, 70: 104498. DOI: 10.1016/j.nanoen.2020.104498. |

| 26 | LI S W, FU X T, ZHOU J W, et al. An effective approach to improve the electrochemical performance of LiNi0.6Co0.2Mn0.2O2 cathode by an MOF-derived coating[J]. Journal of Materials Chemistry A, 2016, 4(16): 5823-5827. DOI: 10.1039/C5TA10773C. |

| 27 | QIAO Q Q, LI G R, WANG Y L, et al. To enhance the capacity of Li-rich layered oxides by surface modification with metal-organic frameworks (MOFs) as cathodes for advanced lithium-ion batteries[J]. Journal of Materials Chemistry A, 2016, 4(12): 4440-4447. DOI: 10.1039/C6TA00882H. |

| 28 | CHAE B J, JUNG Y E, LEE C Y, et al. Metal-organic framework as a multifunctional additive for selectively trapping transition-metal components in lithium-ion batteries[J]. ACS Sustainable Chemistry & Engineering, 2018, 6(7): 8547-8553. DOI: 10.1021/acssuschemeng.8b00867. |

| 29 | DING Y, DENG B W, WANG H, et al. Improved electrochemical performances of LiNi0.6Co0.2Mn0.2O2 cathode material by reducing lithium residues with the coating of Prussian blue[J]. Journal of Alloys and Compounds, 2019, 774: 451-460. DOI: 10.1016/j.jallcom.2018.09.286. |

| 30 | JERNG S E, CHANG B, SHIN H, et al. Pyrazine-linked 2D covalent organic frameworks as coating material for high-nickel layered oxide cathodes in lithium-ion batteries[J]. ACS Applied Materials & Interfaces, 2020, 12(9): 10597-10606. DOI: 10.1021/acsami.0c00643. |

| 31 | XIAO Z B, YANG Z, ZHANG L J, et al. Sandwich-type NbS2@S@I-doped graphene for high-sulfur-loaded, ultrahigh-rate, and long-life lithium-sulfur batteries[J]. ACS Nano, 2017, 11(8): 8488-8498. DOI: 10.1021/acsnano.7b04442. |

| 32 | SUN Z H, ZHANG J Q, YIN L C, et al. Conductive porous vanadium nitride/graphene composite as chemical anchor of polysulfides for lithium-sulfur batteries[J]. Nature Communications, 2017, 8: 14627. DOI: 10.1038/ncomms14627. |

| 33 | MI K, CHEN S W, XI B J, et al. Sole chemical confinement of polysulfides on nonporous nitrogen/oxygen dual-doped carbon at the kilogram scale for lithium-sulfur batteries[J]. Advanced Functional Materials, 2017, 27(1): 1604265. DOI: 10.1002/adfm. 201604265. |

| 34 | PANG Q, NAZAR L F. Long-life and high-areal-capacity Li-S batteries enabled by a light-weight polar host with intrinsic polysulfide adsorption[J]. ACS Nano, 2016, 10(4): 4111-4118. DOI: 10.1021/acsnano.5b07347. |

| 35 | LI Z, ZHANG J T, LOU X W. Hollow carbon nanofibers filled with MnO2 nanosheets as efficient sulfur hosts for lithium-sulfur batteries[J]. Angewandte Chemie, 2015, 127(44): 13078-13082. DOI: 10.1002/ange.201506972. |

| 36 | PANG Q, KUNDU D P, CUISINIER M, et al. Surface-enhanced redox chemistry of polysulphides on a metallic and polar host for lithium-sulphur batteries[J]. Nature Communications, 2014, 5: 4759. DOI: 10.1038/ncomms5759. |

| 37 | JI X L, LEE K T, NAZAR L F. A highly ordered nanostructured carbon-sulphur cathode for lithium-sulphur batteries[J]. Nature Materials, 2009, 8(6): 500-506. DOI: 10.1038/nmat2460. |

| 38 | ZHOU T H, LV W, LI J, et al. Twinborn TiO2-TiN heterostructures enabling smooth trapping-diff-sulfur batteries[J]. Energy & Environmental Science, 2017, 10(7): 1694-1703. DOI: 10.1039/C7EE01430A. |

| 39 | FANG R P, ZHAO S Y, SUN Z H, et al. Polysulfide immobilization and conversion on a conductive polar MoC@MoOx material for lithium-sulfur batteries[J]. Energy Storage Materials, 2018, 10: 56-61. DOI: 10.1016/j.ensm.2017.08.005. |

| 40 | JIN Q, QI X Q, YANG F Y, et al. The failure mechanism of lithium-sulfur batteries under lean-ether-electrolyte conditions[J]. Energy Storage Materials, 2021, 38: 255-261. DOI: 10.1016/j.ensm. 2021. 03.014. |

| 41 | HE B, RAO Z X, CHENG Z X, et al. Rationally design a sulfur cathode with solid-phase conversion mechanism for high cycle-stable Li-S batteries[J]. Advanced Energy Materials, 2021, 11(14): 2003690. DOI: 10.1002/aenm.202003690. |

| 42 | HAO G P, TANG C, ZHANG E, et al. Thermal exfoliation of layered metal-organic frameworks into ultrahydrophilic graphene stacks and their applications in Li-S batteries[J]. Advanced Materials, 2017, 29(37): 1702829. DOI: 10.1002/adma. 201702829. |

| 43 | LIAO H P, DING H M, LI B J, et al. Covalent-organic frameworks: Potential host materials for sulfur impregnation in lithium-sulfur batteries[J]. Journal of Materials Chemistry A, 2014, 2(23): 8854-8858. DOI: 10.1039/C4TA00523F. |

| 44 | ALI GHAZI Z, ZHU L Y, WANG H, et al. Efficient polysulfide chemisorption in covalent organic frameworks for high-performance lithium-sulfur batteries[J]. Advanced Energy Materials, 2016, 6(24): 1601250. DOI: 10.1002/aenm.201601250. |

| 45 | HUANG X Z, HE R, LI M, et al. Functionalized separator for next-generation batteries[J]. Materials Today, 2020, 41: 143-155. DOI: 10.1016/j.mattod.2020.07.015. |

| 46 | BAI S Y, LIU X Z, ZHU K, et al. Metal-organic framework-based separator for lithium-sulfur batteries[J]. Nature Energy, 2016, 1: 16094. DOI: 10.1038/nenergy.2016.94. |

| 47 | ZUO L L, MA Q, XIAO P T, et al. Upgrading the separators integrated with desolvation and selective deposition toward the stable lithium metal batteries[J]. Advanced Materials, 2024, 36(13): 2311529. DOI: 10.1002/adma.202311529. |

| 48 | CHANG Z, YANG H J, PAN A Q, et al. An improved 9 micron thick separator for a 350 Wh/kg lithium metal rechargeable pouch cell[J]. Nature Communications, 2022, 13: 6788. DOI: 10.1038/s41467-022-34584-z. |

| 49 | CHANG Z, QIAO Y, DENG H, et al. A liquid electrolyte with de-solvated lithium ions for lithium-metal battery[J]. Joule, 2020, 4(8): 1776-1789. DOI: 10.1016/j.joule.2020.06.011. |

| 50 | RAZAQ R, DIN M M U, SMÅBRÅTEN D R, et al. Synergistic effect of bimetallic MOF modified separator for long cycle life lithium-sulfur batteries[J]. Advanced Energy Materials, 2024, 14(3): 2302897. DOI: 10.1002/aenm.202302897. |

| 51 | HAO Z D, WU Y, ZHAO Q, et al. Functional separators regulating ion transport enabled by metal-organic frameworks for dendrite-free lithium metal anodes[J]. Advanced Functional Materials, 2021, 31(33): 2102938. DOI: 10.1002/adfm.202102938. |

| 52 | WAN J Y, XIE J, KONG X, et al. Ultrathin, flexible, solid polymer composite electrolyte enabled with aligned nanoporous host for lithium batteries[J]. Nature Nanotechnology, 2019, 14(7): 705-711. DOI: 10.1038/s41565-019-0465-3. |

| 53 | KANG Q, ZHUANG Z C, LIU Y J, et al. Engineering the structural uniformity of gel polymer electrolytes via pattern-guided alignment for durable, safe solid-state lithium metal batteries[J]. Advanced Materials, 2023, 35(38): 2303460. DOI: 10.1002/adma. 202303460. |

| 54 | WANG P, LI H B, LI N, et al. Electrospinning fiber membrane-derived gel polymer electrolytes with high mechanical strength and low swelling effect for high-safety lithium metal batteries[J]. Advanced Functional Materials, 2025, 35(3): 2413544. DOI: 10. 1002/adfm.202413544. |

| 55 | WANG Z, HEASMAN P, ROSTAMI J, et al. Dynamic networks of cellulose nanofibrils enable highly conductive and strong polymer gel electrolytes for lithium-ion batteries[J]. Advanced Functional Materials, 2023, 33(30): 2212806. DOI: 10.1002/adfm. 202212806. |

| 56 | CHANG Z, YANG H J, ZHU X Y, et al. A stable quasi-solid electrolyte improves the safe operation of highly efficient lithium-metal pouch cells in harsh environments[J]. Nature Communications, 2022, 13(1): 1510. DOI: 10.1038/s41467-022-29118-6. |

| 57 | BAI S Y, SUN Y, YI J, et al. High-power Li-metal anode enabled by metal-organic framework modified electrolyte[J]. Joule, 2018, 2(10): 2117-2132. DOI: 10.1016/j.joule.2018.07.010. |

| 58 | OUYANG Y, GONG W, ZHANG Q, et al. Bilayer zwitterionic metal-organic framework for selective all-solid-state superionic conduction in lithium metal batteries[J]. Advanced Materials, 2023, 35(39): 2304685. DOI: 10.1002/adma.202304685. |

| 59 | LIU T T, ZHONG Y, YAN Z W, et al. Fabrication of scalable covalent organic framework membrane-based electrolytes for solid-state lithium metal batteries[J]. Angewandte Chemie International Edition, 2024, 63(50): e202411535. DOI: 10.1002/anie.202411535. |

| 60 | NIU C Q, ZHAO S, XU Y X. In situ gelled covalent organic frameworks electrolyte with long-range interconnected skeletons for superior ionic conductivity[J]. Journal of the American Chemical Society, 2024, 146(5): 3114-3124. DOI: 10.1021/jacs. 3c10312. |

| 61 | ZHANG G, HONG Y, NISHIYAMA Y, et al. Accumulation of glassy poly(ethylene oxide) anchored in a covalent organic framework as a solid-state Li+ electrolyte[J]. Journal of the American Chemical Society, 2019, 141(3): 1227-1234. DOI: 10.1021/jacs. 8b07670. |

| 62 | JEONG K, PARK S, JUNG G Y, et al. Solvent-free, single lithium-ion conducting covalent organic frameworks[J]. Journal of the American Chemical Society, 2019, 141(14): 5880-5885. DOI: 10.1021/jacs.9b00543. |

| 63 | YUAN Y F, ZHANG Z Y, ZHANG Z Y, et al. Highly conductive imidazolate covalent organic frameworks with ether chains as solid electrolytes for lithium metal batteries[J]. Angewandte Chemie International Edition, 2024, 63(18): e202402202. DOI: 10.1002/anie.202402202. |

| 64 | LUO C, HU H, ZHANG T, et al. Roll-to-roll fabrication of zero-volume-expansion lithium-composite anodes to realize high-energy-density flexible and stable lithium-metal batteries[J]. Advanced Materials, 2022, 34(38): 2205677. DOI: 10.1002/adma. 202205677. |

| 65 | CHI S S, WANG Q R, HAN B, et al. Lithiophilic Zn sites in porous CuZn alloy induced uniform Li nucleation and dendrite-free Li metal deposition[J]. Nano Letters, 2020, 20(4): 2724-2732. DOI: 10.1021/acs.nanolett.0c00352. |

| 66 | WEI C H, YAO Z Y, RUAN J, et al. Double-layered skeleton of Li alloy anchored on 3D metal foam enabling ultralong lifespan of Li anode under high rate[J]. Chinese Chemical Letters, 2024, 35(3): 109330. DOI: 10.1016/j.cclet.2023.109330. |

| 67 | QING P, HUANG S Z, NAREN T Y, et al. Interpenetrating LiB/Li3BN2 phases enabling stable composite lithium metal anode[J]. Science Bulletin, 2024, 69(18): 2842-2852. DOI: 10.1016/j.scib. 2024.07.021. |

| 68 | LIU N, LU Z D, ZHAO J, et al. A pomegranate-inspired nanoscale design for large-volume-change lithium battery anodes[J]. Nature Nanotechnology, 2014, 9(3): 187-192. DOI: 10.1038/nnano. 2014.6. |

| 69 | WANG D K, ZHOU C L, CAO B, et al. One-step synthesis of spherical Si/C composites with onion-like buffer structure as high-performance anodes for lithium-ion batteries[J]. Energy Storage Materials, 2020, 24: 312-318. DOI: 10.1016/j.ensm.2019.07.045. |

| 70 | LEE Y, LEE T, HONG J, et al. Stress relief principle of micron-sized anodes with large volume variation for practical high-energy lithium-ion batteries[J]. Advanced Functional Materials, 2020, 30(40): 2004841. DOI: 10.1002/adfm.202004841. |

| 71 | LI D D, HE Y, CHEN B, et al. Electrically active/inert dual-function architecture enabled by screen printing grid-like SiO2 on Cu foil for ultra-long life lithium metal anodes[J]. EcoMat, 2024, 6(8): e12478. DOI: 10.1002/eom2.12478. |

| 72 | LIU L, YIN Y X, LI J Y, et al. Free-standing hollow carbon fibers as high-capacity containers for stable lithium metal anodes[J]. Joule, 2017, 1(3): 563-575. DOI: 10.1016/j.joule.2017.06.004. |

| 73 | ZHANG X L, MA L, CAI Y P, et al. A low-Fermi-level current collector enables anode-free lithium metal batteries with long cycle life[J]. Matter, 2024, 7(2): 583-602. DOI: 10.1016/j.matt. 2023.11.017. |

| 74 | KWON H, LEE J H, ROH Y, et al. An electron-deficient carbon current collector for anode-free Li-metal batteries[J]. Nature Communications, 2021, 12: 5537. DOI: 10.1038/s41467-021-25848-1. |

| [1] | Qiangfu SUN, Guanjun CEN, Ronghan QIAO, Jing ZHU, Junfeng HAO, Xinxin ZHANG, Mengyu TIAN, Zhou JIN, Yuanjie ZHAN, Yong YAN, Liubin BEN, Hailong YU, Yanyan LIU, Hong ZHOU, Xuejie HUANG. Reviews of selected 100 recent papers for lithium batteries (Feb. 1, 2025 to March 31, 2025) [J]. Energy Storage Science and Technology, 2025, 14(5): 1727-1747. |

| [2] | Zixin XIAO, Hong ZHANG, Lin XU. Nanowires modulating ion transport and interfaces in solid-state lithium batteries [J]. Energy Storage Science and Technology, 2025, 14(3): 1026-1039. |

| [3] | Xinxin ZHANG, Guanjun CEN, Ronghan QIAO, Jing ZHU, Junfeng HAO, Qiangfu SUN, Mengyu TIAN, Zhou JIN, Yuanjie ZHAN, Yong YAN, Liubin BEN, Hailong YU, Yanyan LIU, Hong ZHOU, Xuejie HUANG. Reviews of 100 selected recent papers on lithium batteries (December 1, 2024 to January 31, 2025) [J]. Energy Storage Science and Technology, 2025, 14(3): 1310-1330. |

| [4] | Hong ZHOU, Hailong YU, Liping WANG, Xuejie HUANG. Frontier monitoring and topic analysis of lithium batteries based on BERTopic model [J]. Energy Storage Science and Technology, 2025, 14(1): 406-416. |

| [5] | Junfeng HAO, Guanjun CEN, Ronghan QIAO, Jing ZHU, Qiangfu SUN, Xinxin ZHANG, Mengyu TIAN, Zhou JIN, Yuanjie ZHAN, Yong YAN, Liubin BEN, Hailong YU, Yanyan LIU, Hong ZHOU, Xuejie HUANG. Reviews of selected 100 recent papers for lithium batteries (Oct. 1, 2024 to Nov. 30, 2024) [J]. Energy Storage Science and Technology, 2025, 14(1): 388-405. |

| [6] | Xinxin ZHANG, Guanjun CEN, Ronghan QIAO, Jing ZHU, Junfeng HAO, Qiangfu SUN, Mengyu TIAN, Zhou JIN, Yuanjie ZHAN, Yong YAN, Liubin BEN, Hailong YU, Yanyan LIU, Hong ZHOU, Xueji HUANG. In-depth review of 100 pioneering studies on lithium batteries: Key innovations from June 1, 2024 to July 31, 2024 [J]. Energy Storage Science and Technology, 2024, 13(9): 3226-3244. |

| [7] | Junfeng HAO, Jing ZHU, Xiaoyu SHEN, Guanjun CEN, Ronghan QIAO, Xinxin ZHANG, Mengyu TIAN, Zhou JIN, Yuanjie ZHAN, Qiangfu SUN, Yong YAN, Liubin BEN, Hailong YU, Yanyan LIU, Xuejie HUANG. A review of 100 selected recent studies on lithium batteries (April 1, 2024—May 31, 2024) [J]. Energy Storage Science and Technology, 2024, 13(7): 2361-2376. |

| [8] | Yi CHEN, Qi QEN, Long ZHAO, Zikun CHEN, Anning WANG. Analysis of China's patent landscape for new energy storage technologies [J]. Energy Storage Science and Technology, 2024, 13(6): 2089-2098. |

| [9] | Haiou SHI. Fault analysis and application of lithium battery based on deep learning [J]. Energy Storage Science and Technology, 2024, 13(6): 2054-2056. |

| [10] | Jing ZHU, Junfeng HAO, Qiangfu SUN, Xinxin ZHANG, Xiaoyu SHEN, Guanjun CEN, Ronghan QIAO, Mengyu TIAN, Zhou JIN, Yuanjie ZHAN, Yong YAN, Liubin BEN, Hailong YU, Yanyan LIU, Xuejie HUANG. Reviews of selected 100 recent papers for lithium batteries (Feb. 1, 2024 to Mar. 31, 2024) [J]. Energy Storage Science and Technology, 2024, 13(5): 1398-1416. |

| [11] | Qiangfu SUN, Xiaoyu SHEN, Guanjun CEN, Ronghan QIAO, Jing ZHU, Junfeng HAO, Xinxin ZHANG, Mengyu TIAN, Zhou JIN, Yuanjie ZHAN, Yong YAN, Liubin BEN, Hailong YU, Yanyan LIU, Xuejie HUANG. Reviews of selected 100 recent papers for lithium batteries (Dec. 1, 2023 to Jan. 31, 2024) [J]. Energy Storage Science and Technology, 2024, 13(3): 725-741. |

| [12] | Zhaokai YUAN, Qiuhua FAN, Dongqing WANG, Tianmin SUN. State of charge estimation for lithium-ion batteries under multiple temperatures based on the MIAEK algorithm [J]. Energy Storage Science and Technology, 2024, 13(2): 680-690. |

| [13] | Changjie SHEN, Jingjing LI, Haidi JIANG, Yuqiang ZHANG, Haoran DA, Jie YAN, Haitao ZHANG. Research progress on impurity removal and repair regeneration of spent graphite negative electrode powder [J]. Energy Storage Science and Technology, 2024, 13(11): 3796-3810. |

| [14] | Qiangfu SUN, Guanjun CEN, Ronghan QIAO, Jing ZHU, Junfeng HAO, Xinxin ZHANG, Mengyu TIAN, Zhou JIN, Yuanjie ZHAN, Yong YAN, Liubin BEN, Hailong YU, Yanyan LIU, Hong ZHOU, Xuejie HUANG. Reviews of selected 100 recent papers for lithium batteries (Aug. 1, 2024 to Sep. 30, 2024) [J]. Energy Storage Science and Technology, 2024, 13(11): 4207-4225. |

| [15] | Zhaoyang LI, Dinghong LIU, Yanyan ZHAO, Man CHEN, Qikai LEI, Peng PENG, Lei LIU. Nail penetration characteristics of high-energy-density lithium-ion pouch cell [J]. Energy Storage Science and Technology, 2024, 13(1): 57-71. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||