Energy Storage Science and Technology ›› 2024, Vol. 13 ›› Issue (1): 1-11.doi: 10.19799/j.cnki.2095-4239.2023.0664

Chengjie XU1,2( ), Yulin HUANG1(

), Yulin HUANG1( ), Zhongfeiyu LIN1, Zhiming LIN1, Chenxi FANG1, Weijun ZHANG1,2, Zhigao HUANG1,2, Jiaxin LI1,2(

), Zhongfeiyu LIN1, Zhiming LIN1, Chenxi FANG1, Weijun ZHANG1,2, Zhigao HUANG1,2, Jiaxin LI1,2( )

)

Received:2023-09-26

Revised:2023-11-03

Online:2024-01-05

Published:2024-01-22

Contact:

Jiaxin LI

E-mail:1079854250@qq.com;1527481149@qq.com;lijiaxin@fjnu.edu.cn

CLC Number:

Chengjie XU, Yulin HUANG, Zhongfeiyu LIN, Zhiming LIN, Chenxi FANG, Weijun ZHANG, Zhigao HUANG, Jiaxin LI. Macroscopic fabrication of nano-silicon via sand-milling and investigation of lithium storage performance in carbon fiber composite anodes[J]. Energy Storage Science and Technology, 2024, 13(1): 1-11.

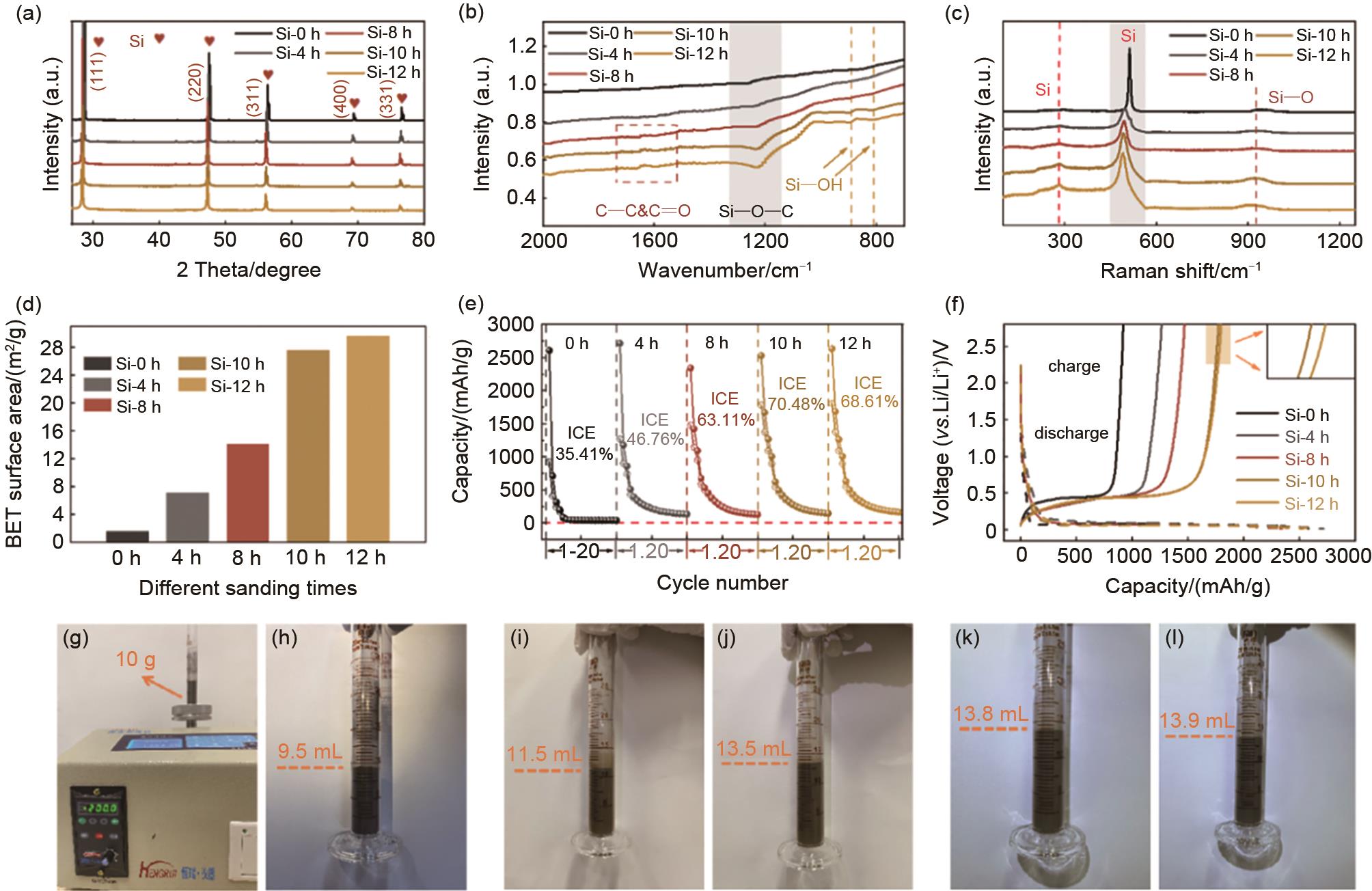

Fig. 3

Silicon materials of different sanding time: (a) X-ray diffraction patterns, (b) Fourier-transform infrared spectra, (c) Raman spectroscopy results, (d) comparative surface area values, (e) cycling results of the initial twenty cycles, (f) initial charge-discharge curves, and (g)—(l) tap density evaluation results"

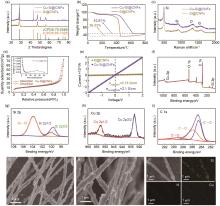

Fig. 4

Si@CNFs juxtaposed with Cu-Si@CNFs composite of (a) X-ray diffraction patterns, (b) thermogravimetric analysis curves, and (c) Raman spectroscopy results, (d) nitrogen adsorption-desorption isotherms and pore size distribution diagrams, (e) I-V curve results, (f)—(i) X-ray photoelectron spectroscopy spectra, (j)—(k) SEM micrographs at various magnifications, and (l) EDS elemental mapping results"

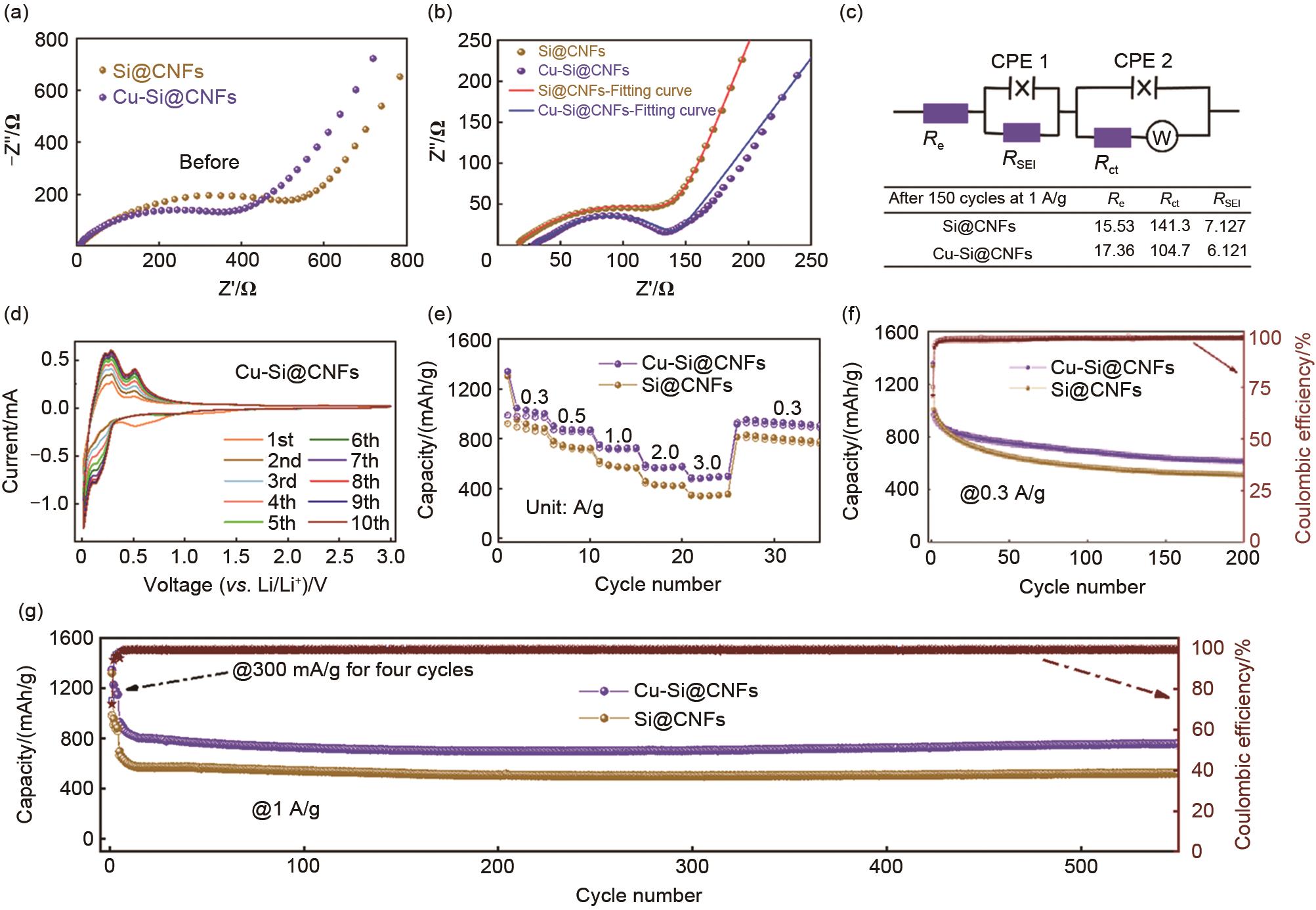

Fig. 5

Si@CNFs and Cu-Si@CNFs electrodes of (a)—(b) alternating current impedance spectra before and after 150 cycles, (c) the corresponding equivalent circuit and impedance fitting value, (d) cyclic voltammetry curves at a scan rate of 0.5 mV/s, (e) rate capability curves at varied current densities, (f) cycling curves at a current density of 0.3 A/g, and (g) cycling performance at a current density of 1 A/g"

| 1 | RYU J, HONG D, LEE H W, et al. Practical considerations of Si-based anodes for lithium-ion battery applications[J]. Nano Research, 2017, 10(12): 3970-4002. |

| 2 | LIU X H, HUANG J Y. In situ TEM electrochemistry of anode materials in lithium ion batteries[J]. Energy & Environmental Science, 2011, 4(10): 3844. |

| 3 | CHAN C K, PENG H L, LIU G, et al. High-performance lithium battery anodes using silicon nanowires[J]. Nature Nanotechnology, 2008, 3(1): 31-35. |

| 4 | WANG J Y, HUANG W, KIM Y S, et al. Scalable synthesis of nanoporous silicon microparticles for highly cyclable lithium-ion batteries[J]. Nano Research, 2020, 13(6): 1558-1563. |

| 5 | WU H, CUI Y. Designing nanostructured Si anodes for high energy lithium ion batteries[J]. Nano Today, 2012, 7(5): 414-429. |

| 6 | ZHU S S, ZHOU J B, GUAN Y, et al. Hierarchical graphene-scaffolded silicon/graphite composites as high performance anodes for lithium-ion batteries[J]. Small, 2018, 14(47): 1802457. |

| 7 | WANG F, SONG C S, ZHAO B X, et al. One-pot solution synthesis of carbon-coated silicon nanoparticles as an anode material for lithium-ion batteries[J]. Chemical Communications, 2020, 56(7): 1109-1112. |

| 8 | JIANG M M, CHEN J L, ZHANG Y B, et al. Assembly: A key enabler for the construction of superior silicon-based anodes[J]. Advanced Science, 2022, 9(30): 2203162. |

| 9 | ZHANG L, WANG C R, DOU Y H, et al. A yolk-shell structured silicon anode with superior conductivity and high tap density for full lithium-ion batteries[J]. Angewandte Chemie International Edition, 2019, 58(26): 8824-8828. |

| 10 | LIU X Y, ZHANG Q L, ZHU Y S, et al. Trash to treasure: Harmful fly ash derived silicon nanoparticles for enhanced lithium-ion batteries[J]. Silicon, 2022, 14(13): 7983-7990. |

| 11 | SU X, WU Q L, LI J C, et al. Silicon-based nanomaterials for lithium-ion batteries: A review[J]. Advanced Energy Materials, 2014, 4(1): 1300882. |

| 12 | SZCZECH J R, JIN S. Nanostructured silicon for high capacity lithium battery anodes[J]. Energy Environ Sci, 2011, 4(1): 56-72. |

| 13 | JIN Y, ZHU B, LU Z D, et al. Challenges and recent progress in the development of Si anodes for lithium-ion battery[J]. Advanced Energy Materials, 2017, 7(23): 1700715. |

| 14 | WANG L B, MEI T, LIU W Q, et al. Low temperature chemical synthesis of silicon nanoparticles as anode materials for lithium-ion batteries[J]. Materials Chemistry and Physics, 2018, 220: 308-312. |

| 15 | CHEN S, ZHENG S S, SHI A D, et al. Distinctive conductivity improvement by embedding Cu nanoparticles in the carbon shell of submicron Si@C anode materials for LIBs[J]. Sustainable Energy & Fuels, 2022, 6(9): 2306-2313. |

| 16 | SALAH M, HALL C, MURPHY P, et al. Doped and reactive silicon thin film anodes for lithium ion batteries: A review[J]. Journal of Power Sources, 2021, 506: 230194. |

| 17 | SHI Q T, ZHOU J H, ULLAH S, et al. A review of recent developments in Si/C composite materials for Li-ion batteries[J]. Energy Storage Materials, 2021, 34: 735-754. |

| 18 | LI J X, LI Z B, HUANG W J, et al. A facile strategy to construct silver-modified, ZnO-incorporated and carbon-coated silicon/porous-carbon nanofibers with enhanced lithium storage[J]. Small, 2019, 15(18): 1900436. |

| 19 | LI J X, HUANG Y C, HUANG W J, et al. Simple designed micro-nano Si-graphite hybrids for lithium storage[J]. Small, 2021, 17(8): 2006373. |

| 20 | HOU Y L, YANG Y, MENG W J, et al. Core-shell structured Si@Cu nanoparticles encapsulated in carbon cages as high-performance lithium-ion battery anodes[J]. Journal of Alloys and Compounds, 2021, 874: 159988. |

| 21 | XU C J, SHEN L, ZHANG W J, et al. Efficient implementation of kilogram-scale, high-capacity and long-life Si-C/TiO2 anodes[J]. Energy Storage Materials, 2023, 56: 319-330. |

| 22 | LI X T, YANG D D, HOU X C, et al. Scalable preparation of mesoporous silicon@C/graphite hybrid as stable anodes for lithium-ion batteries[J]. Journal of Alloys and Compounds, 2017, 728: 1-9. |

| 23 | WANG D K, ZHOU C L, CAO B, et al. One-step synthesis of spherical Si/C composites with onion-like buffer structure as high-performance anodes for lithium-ion batteries[J]. Energy Storage Materials, 2020, 24: 312-318. |

| 24 | KIM S Y, KIM B H, YANG K S. Preparation and electrochemical characteristics of a polyvinylpyrrolidone-stabilized Si/carbon composite nanofiber anode for a lithium ion battery[J]. Journal of Electroanalytical Chemistry, 2013, 705: 52-56. |

| 25 | JIN Y, ZHU B, LU Z D, et al. Challenges and recent progress in the development of Si anodes for lithium-ion battery[J]. Advanced Energy Materials, 2017, 7(23): 1700715-1700731. |

| 26 | WANG Q S, MENG T, LI Y H, et al. Consecutive chemical bonds reconstructing surface structure of silicon anode for high-performance lithium-ion battery[J]. Energy Storage Materials, 2021, 39: 354-364. |

| 27 | TAO J M, YAN Z R, YANG J S, et al. Boosting the cell performance of the SiOx@C anode material via rational design of a Si-valence gradient[J]. Carbon Energy, 2022, 4(2): 129-141. |

| 28 | HU Z L, ZHAO L B, JIANG T, et al. Trifluoropropylene carbonate-driven interface regulation enabling greatly enhanced lithium storage durability of silicon-based anodes[J]. Advanced Functional Materials, 2019, 29(45): doi: 10.1002/adfm.201906548. |

| 29 | LIU Q, JI Y X, YIN X M, et al. Magnesiothermic reduction improved route to high-yield synthesis of interconnected porous Si@C networks anode of lithium ions batteries[J]. Energy Storage Materials, 2022, 46: 384-393. |

| 30 | SONG Y H, ZUO L, CHEN S H, et al. Porous nano-Si/carbon derived from zeolitic imidazolate frameworks@nano-Si as anode materials for lithium-ion batteries[J]. Electrochimica Acta, 2015, 173: 588-594. |

| 31 | WU Y H, HUANG J L, HOU S C, et al. Cu3Si enhanced crystallinity and dopamine derived nitrogen doping into carbon coated micron-sized Si/Cu3Si as anode material in lithium-ion batteries[J]. Electrochimica Acta, 2021, 387: 138495. |

| 32 | YANG Y, YANG H X, WU Y Q, et al. Graphene caging core-shell Si@Cu nanoparticles anchored on graphene sheets for lithium-ion battery anode with enhanced reversible capacity and cyclic performance[J]. Electrochimica Acta, 2020, 341: 136037. |

| 33 | KUTE A D, GAIKWAD R P, WARKAD I R, et al. A review on the synthesis and applications of sustainable copper-based nanomaterials[J]. Green Chemistry, 2022, 24(9): 3502-3573. |

| 34 | GUO J F, PEI S E, HE Z S, et al. Novel porous Si-Cu3Si-Cu microsphere composites with excellent electrochemical lithium storage[J]. Electrochimica Acta, 2020, 348: 136334. |

| 35 | MU Y B, HAN M S, WU B K, et al. Nitrogen, oxygen-codoped vertical graphene arrays coated 3D flexible carbon nanofibers with high silicon content as an ultrastable anode for superior lithium storage[J]. Advanced Science, 2022, 9(6): 2104685-2104697. |

| 36 | XU T, ZHANG J, YANG C Y, et al. Facile synthesis of carbon-coated SiO/Cu composite as superior anode for lithium-ion batteries[J]. Journal of Alloys and Compounds, 2018, 738: 323-330. |

| 37 | SUI D, XIE Y Q, ZHAO W M, et al. A high-performance ternary Si composite anode material with crystal graphite core and amorphous carbon shell[J]. Journal of Power Sources, 2018, 384: 328-333. |

| 38 | SONG H C, WANG H X, LIN Z X, et al. Highly connected silicon-copper alloy mixture nanotubes as high-rate and durable anode materials for lithium-ion batteries[J]. Advanced Functional Materials, 2016, 26(4): 524-531. |

| 39 | LIN N, ZHOU J, ZHOU J B, et al. Synchronous synthesis of a Si/Cu/C ternary nano-composite as an anode for Li ion batteries[J]. Journal of Materials Chemistry A, 2015, 3(34): 17544-17548. |

| 40 | LI P, HWANG J Y, SUN Y K. Nano/microstructured silicon-graphite composite anode for high-energy-density Li-ion battery[J]. ACS Nano, 2019: acsnano.9b00169. |

| [1] | Chen LI, Huilin ZHANG, Jianping ZHANG. Estimated state of health for retired lithium batteries using kernel function and hyperparameter optimization [J]. Energy Storage Science and Technology, 2024, 13(6): 2010-2021. |

| [2] | Chenwei LI, Shiguo XU, Haifeng YU, Songmin YU, Hao JIANG. Synthesis of Mg-doped LiFe0.5Mn0.5PO4/C cathode materials for Li-ion batteries [J]. Energy Storage Science and Technology, 2024, 13(6): 1767-1774. |

| [3] | Qi SUN, Hao PENG, Qingguo MENG, Dekai KONG, Rui FENG. Thermal adaptability of energy storage battery pack in extreme conditions [J]. Energy Storage Science and Technology, 2024, 13(6): 2039-2043. |

| [4] | Yuchao ZHANG, Fengjiao ZHANG, Wei LOU, Feixiang ZAN, Linling WANG, Anxu SHENG, Xiaohui WU, Jing CHEN. Transformation process of valuable metals in the recycling of spent lithium-ion batteries and the potential environmental impact [J]. Energy Storage Science and Technology, 2024, 13(6): 1861-1870. |

| [5] | Runyuan LI, Fu'ao GUO, Gangchao ZHAO. Early warning method for fire safety of containerized lithium-ion battery energy storage systems [J]. Energy Storage Science and Technology, 2024, 13(5): 1595-1602. |

| [6] | Yuanhui TANG, Boxing YUAN, Jie LI, Yunlong ZHANG. Study on the safety of cylindrical lithium-ion batteries under nail penetration conditions [J]. Energy Storage Science and Technology, 2024, 13(4): 1326-1334. |

| [7] | Bingjin LI, Xiaoxia HAN, Wenjie ZHANG, Weiguo ZENG, Jinde WU. Review of the remaining useful life prediction methods for lithium-ion batteries [J]. Energy Storage Science and Technology, 2024, 13(4): 1266-1276. |

| [8] | Jiamu YANG, Yuxin CHEN, Cheng LIAN, Zhi XU, Honglai LIU. Flow field analysis and structural optimization of coating die with electrode slurry [J]. Energy Storage Science and Technology, 2024, 13(4): 1109-1117. |

| [9] | Mingming SUN. Patent analysis of organic-inorganic composite solid-state electrolytes for lithium-ion batteries [J]. Energy Storage Science and Technology, 2024, 13(3): 1096-1105. |

| [10] | Yi ZHANG, Xiaoyu GE, Zhen LI, Yunhui HUANG. Progress on acoustic and optical sensing technologies for lithium rechargeable batteries [J]. Energy Storage Science and Technology, 2024, 13(1): 167-177. |

| [11] | Xiaowei HUANG, Shaopeng LI, Xiaogang ZHANG. Research on the impact and mechanism of the lithium replenishment degree of anode prelithiation on the performance of lithium-ion batteries [J]. Energy Storage Science and Technology, 2023, 12(9): 2727-2734. |

| [12] | Xin GAO, Ruogu WANG, Wenjing GAO, Zejun DENG, Ruiqi LIANG, Kun YANG. Consistency evaluation method of battery pack in energy storage power station based on running data [J]. Energy Storage Science and Technology, 2023, 12(9): 2937-2945. |

| [13] | Yonghao HUANG, Guojing ZANG, Weiya ZHU, Youhao LIAO, Weishan LI. Enhancing interfacial stability between lithium-containing ceramic separator and 4.35 V LiNi0.8Co0.1Mn0.1O2 cathode through LiF additives [J]. Energy Storage Science and Technology, 2023, 12(8): 2361-2369. |

| [14] | Zhiwei CHEN, Weige ZHANG, Junwei ZHANG, Yanru ZHANG. Comprehensive health assessment and screening method of power battery pack based on visual characteristics of charge curves [J]. Energy Storage Science and Technology, 2023, 12(7): 2211-2219. |

| [15] | Chong XU, Ning XU, Zhimin JIANG, Zhongkai LI, Yang HU, Hong YAN, Guoqiang MA. Mechanisms of gas evolution and suppressing strategies based on the electrolyte in lithium-ion batteries [J]. Energy Storage Science and Technology, 2023, 12(7): 2119-2133. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||