Energy Storage Science and Technology ›› 2022, Vol. 11 ›› Issue (6): 1760-1771.doi: 10.19799/j.cnki.2095-4239.2022.0193

Previous Articles Next Articles

YAN Qiaoyi1( ), WU Feng1,2(

), WU Feng1,2( ), CHEN Renjie1,2, LI Li1,2(

), CHEN Renjie1,2, LI Li1,2( )

)

Received:2022-04-08

Revised:2022-04-29

Online:2022-06-05

Published:2022-06-13

Contact:

WU Feng, LI Li

E-mail:yanqiaoyi627@163.com;wufeng863@bit.edu.cn;lily863@bit.edu.cn

CLC Number:

YAN Qiaoyi, WU Feng, CHEN Renjie, LI Li. Recovery and resource recycling of graphite anode materials for spent lithium-ion batteries[J]. Energy Storage Science and Technology, 2022, 11(6): 1760-1771.

Fig. 2

(a) Flow chart of inorganic acid recovery process; (b) Low temperature sulfuric acid solidification method; (c) Waste graphite anode before electrolysis, recovered copper foil and anode active material after electrolysis, separation of graphite and copper foil and dissolution of Li+ process and the change of current with electrolysis time; (d) Schematic diagram of organic acid leaching; (e) Water-soluble lithium salt recovery process; (f)SEM images of untreated, heat-treated, heat-treated graphite after subcritical CO2-assisted electrolyte extraction, and heat-treated graphite after supercritical CO2-assisted electrolyte extraction[16,23-24,26,31,37]"

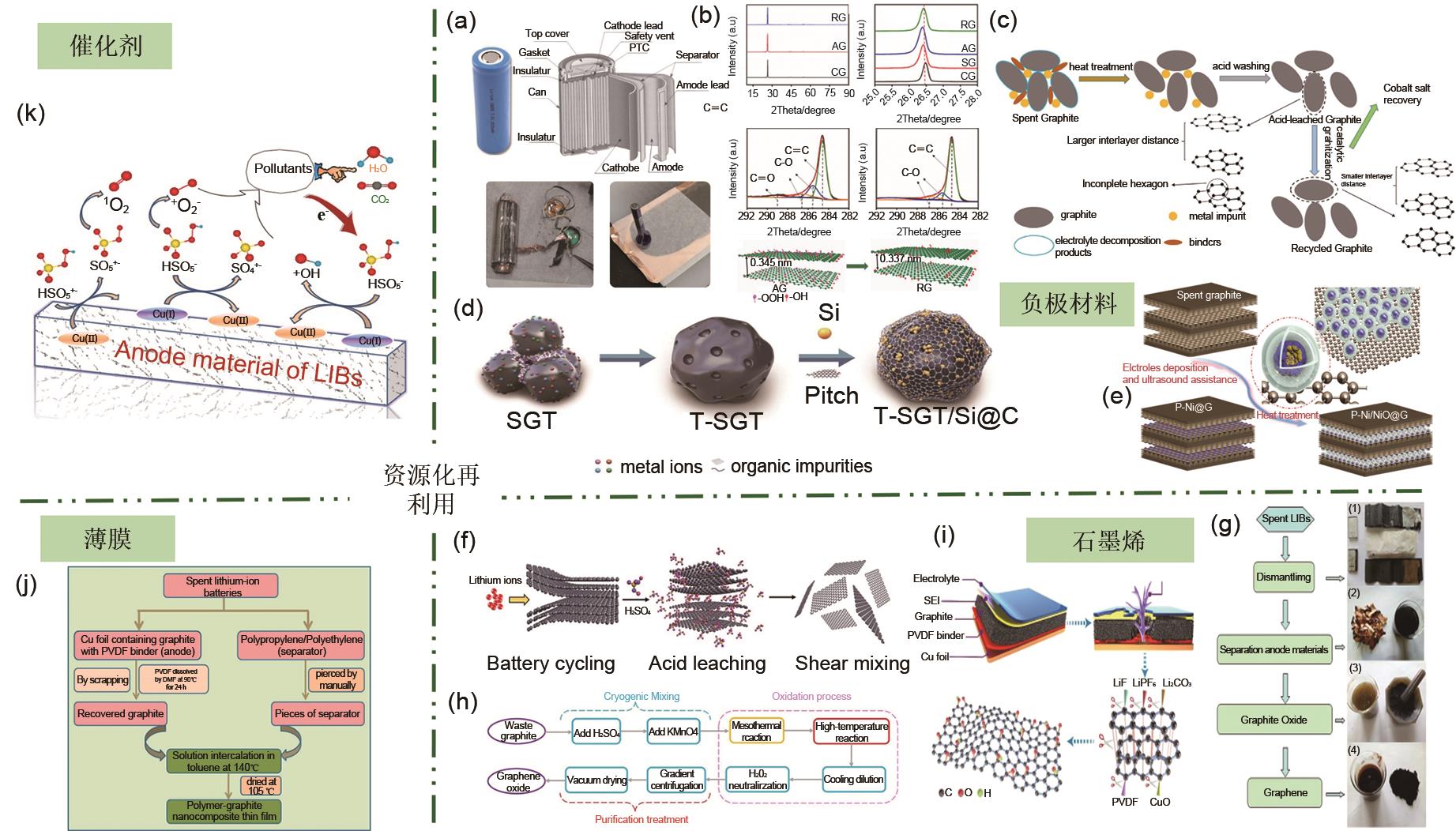

Fig. 3

(a) Schematic diagram of 18650 cell and interior, 18650 cell after removal of upper and lower covers and opening of can, and completion of RAM anode laminate; (b) XRD patterns of CG, AG and RG, (002) peak reflection, XPS high resolution spectra and structural models of AG and RG with different interlayer spacings; (c) Schematic illustration for the regenerating process of graphite from spent LIBs; (d) Schematic diagram of the synthesis process of T-SGT/Si@C anode material; (e) Synthesis process of P-Ni/NiO@G electrode; (f) Schematic diagram of battery cycling and lattice expansion of acid-leached graphite; (g) Preparation method of graphene from waste Li-ion batteries; (h) Schematic diagram of experimental steps for preparing graphene oxide by improved hummers method; (i) Preparation using waste graphite model of graphene oxide; (j) Preparation process of polymer-graphite nanocomposite films; (k) PMS activation in AM/PMS system and reaction mechanism of RhB degradation[38, 42-43, 46-49, 51, 53-54]"

| 1 | 陆浩, 刘柏男, 禇赓, 等. 锂离子电池负极材料产业化技术进展[J]. 储能科学与技术, 2016, 5(2): 109-119. |

| LU Hao, LIU Bonan, CHU Geng, et al. Technology review of anode materials for lithium ion batteries[J]. Energy Storage Science and Technology, 2016, 5(2): 109-119. | |

| 2 | ZHANG B L, XIE H W, LU B H, et al. A green electrochemical process to recover Co and Li from spent LiCoO2-based batteries in molten salts[J]. ACS Sustainable Chemistry & Engineering, 2019, 7(15): 13391-13399. |

| 3 | ETACHERI V, MAROM R, ELAZARI R, et al. Challenges in the development of advanced Li-ion batteries: A review[J]. Energy & Environmental Science, 2011, 4(9): 3243-3262. |

| 4 | DAI Q, SPANGENBERGER J, AHMED S, et al. EverBatt: A closed-loop battery recycling cost and environmental impacts model[R]. Office of Scientific and Technical Information (OSTI), 2019. |

| 5 | COMMISSION E. Critical raw materials resilience: Charting a path towards greater security and sustainability[J/OL]. [2022-01-12].https://ec.europa.eu/docsroom/documents/42849. |

| 6 | 高驰. 中汽协预测:2022年中国汽车销量同比增长5.4%,新能源车突破500万辆[J]. 汽车与配件, 2022(1): 47. |

| 7 | LI L, FAN E S, GUAN Y B, et al. Sustainable recovery of cathode materials from spent lithium-ion batteries using lactic acid leaching system[J]. ACS Sustainable Chemistry & Engineering, 2017, 5(6): 5224-5233. |

| 8 | NIESE N, PIEPER C, ARORA A, et al. The case for a circular economy in electric vehicle batteries[EB/OL]. [2021-08-31]. https://www. bcg. com/en-ca/publications/2020/case-for-circular-economy-in-electricvehicle-batteries, 2020. |

| 9 | HALLEUX V. New EU regulatory framework for batteries—Setting sustainability requirements[J]. European Parliamentary Research Service: Brussels, Belgium, 2021. |

| 10 | SWAIN B. Recovery and recycling of lithium: A review[J]. Separation and Purification Technology, 2017, 172: 388-403. |

| 11 | WU F, XU S M, LI L Y, et al. Recovery of valuable metals from anode material of hydrogen-nickel battery[J]. Transactions of Nonferrous Metals Society of China, 2009, 19(2): 468-473. |

| 12 | ZHANG X X, LI L, FAN E S, et al. Toward sustainable and systematic recycling of spent rechargeable batteries[J]. Chemical Society Reviews, 2018, 47(19): 7239-7302. |

| 13 | DUNN J B, GAINES L, BARNES M, et al. Material and energy flows in the materials production, assembly, and end-of-life stages of the automotive lithium-ion battery life cycle[R]. Office of Scientific and Technical Information (OSTI), 2012. |

| 14 | ZENG X L, LI J H, SINGH N. Recycling of spent lithium-ion battery: A critical review[J]. Critical Reviews in Environmental Science and Technology, 2014, 44(10): 1129-1165. |

| 15 | 高工锂电. 负极石墨化涨价追踪[EB/OL]. [2021-08-31]. https://www.gg-lb.com/art-43416.html. |

| 16 | YANG J B, FAN E S, LIN J, et al. Recovery and reuse of anode graphite from spent lithium-ion batteries via citric acid leaching[J]. ACS Applied Energy Materials, 2021, 4(6): 6261-6268. |

| 17 | BARIK S P, PRABAHARAN G, KUMAR L. Leaching and separation of Co and Mn from electrode materials of spent lithium-ion batteries using hydrochloric acid: Laboratory and pilot scale study[J]. Journal of Cleaner Production, 2017, 147: 37-43. |

| 18 | TAKACOVA Z, HAVLIK T, KUKURUGYA F, et al. Cobalt and lithium recovery from active mass of spent Li-ion batteries: Theoretical and experimental approach[J]. Hydrometallurgy, 2016, 163: 9-17. |

| 19 | WANG F, SUN R, XU J, et al. Recovery of cobalt from spent lithium ion batteries using sulphuric acid leaching followed by solid-liquid separation and solvent extraction[J]. RSC Advances, 2016, 6(88): 85303-85311. |

| 20 | TANONG K, COUDERT L, MERCIER G, et al. Recovery of metals from a mixture of various spent batteries by a hydrometallurgical process[J]. Journal of Environmental Management, 2016, 181: 95-107. |

| 21 | BARBIERI E M S, LIMA E P C, CANTARINO S J, et al. Recycling of spent ion-lithium batteries as cobalt hydroxide, and cobalt oxide films formed under a conductive glass substrate, and their electrochemical properties[J]. Journal of Power Sources, 2014, 269: 158-163. |

| 22 | BARBIERI E M S, LIMA E P C, LELIS M F F, et al. Recycling of cobalt from spent Li-ion batteries as β-Co(OH)2 and the application of Co3O4 as a pseudocapacitor[J]. Journal of Power Sources, 2014, 270: 158-165. |

| 23 | YANG Y, SONG S L, LEI S Y, et al. A process for combination of recycling lithium and regenerating graphite from spent lithium-ion battery[J]. Waste Management, 2019, 85: 529-537. |

| 24 | GAO Y, WANG C Y, ZHANG J L, et al. Graphite recycling from the spent lithium-ion batteries by sulfuric acid curing-leaching combined with high-temperature calcination[J]. ACS Sustainable Chemistry & Engineering, 2020, 8(25): 9447-9455. |

| 25 | YI C X, YANG Y, ZHANG T, et al. A green and facile approach for regeneration of graphite from spent lithium ion battery[J]. Journal of Cleaner Production, 2020, 277: doi 10.1016/j.jclepro.2020.12385. |

| 26 | CAO N, ZHANG Y L, CHEN L L, et al. An innovative approach to recover anode from spent lithium-ion battery[J]. Journal of Power Sources, 2021, 483: doi: 10.1016/j.jpowsur.2020.229163. |

| 27 | WANG F F, ZHANG T, HE Y Q, et al. Recovery of valuable materials from spent lithium-ion batteries by mechanical separation and thermal treatment[J]. Journal of Cleaner Production, 2018, 185: 646-652. |

| 28 | MESHRAM P, PANDEY B D, MANKHAND T R. Extraction of lithium from primary and secondary sources by pre-treatment, leaching and separation: A comprehensive review[J]. Hydrometallurgy, 2014, 150: 192-208. |

| 29 | AN S J, LI J, DANIEL C, et al. The state of understanding of the lithium-ion-battery graphite solid electrolyte interphase (SEI) and its relationship to formation cycling[J]. Carbon, 2016, 105: 52-76. |

| 30 | GUO Y, LI F, ZHU H C, et al. Leaching lithium from the anode electrode materials of spent lithium-ion batteries by hydrochloric acid (HCl)[J]. Waste Management, 2016, 51: 227-233. |

| 31 | LI J L, HE Y Q, FU Y P, et al. Hydrometallurgical enhanced liberation and recovery of anode material from spent lithium-ion batteries[J]. Waste Management, 2021, 126: 517-526. |

| 32 | GRÜTZKE M, KRÜGER S, KRAFT V, et al. Investigation of the storage behavior of shredded lithium-ion batteries from electric vehicles for recycling purposes[J]. ChemSusChem, 2015, 8(20): 3433-3438. |

| 33 | LAIN M J. Recycling of lithium ion cells and batteries[J]. Journal of Power Sources, 2001, 97/98: 736-738. |

| 34 | BANKOLE O E, GONG C X, LEI L X. Battery recycling technologies: Recycling waste lithium ion batteries with the impact on the environment in-view[J]. Journal of Environment and Ecology, 2013, 4(1): 14. |

| 35 | NOWAK S, WINTER M. The role of sub- and supercritical CO2 as "processing solvent" for the recycling and sample preparation of lithium ion battery electrolytes[J]. Molecules (Basel, Switzerland), 2017, 22(3): 403. |

| 36 | GRÜTZKE M, KRAFT V, WEBER W, et al. Supercritical carbon dioxide extraction of lithium-ion battery electrolytes[J]. The Journal of Supercritical Fluids, 2014, 94: 216-222. |

| 37 | ROTHERMEL S, EVERTZ M, KASNATSCHEEW J, et al. Graphite recycling from spent lithium-ion batteries[J]. ChemSusChem, 2016, 9(24): 3473-3484. |

| 38 | SABISCH J E C, ANAPOLSKY A, LIU G, et al. Evaluation of using pre-lithiated graphite from recycled Li-ion batteries for new LiB anodes[J]. Resources, Conservation and Recycling, 2018, 129: 129-134. |

| 39 | ARAVINDAN V, JAYARAMAN S, TEDJAR F, et al. From electrodes to electrodes: Building high-performance Li-ion capacitors and batteries from spent lithium-ion battery carbonaceous materials[J]. ChemElectroChem, 2019, 6(5): 1407-1412. |

| 40 | KAYAKOOL F A, GANGAJA B, NAIR S, et al. Li-based all‑carbon dual-ion batteries using graphite recycled from spent Li-ion batteries[J]. Sustainable Materials and Technologies, 2021, 28: e00262. |

| 41 | ZHANG J, LI X L, SONG D W, et al. Effective regeneration of anode material recycled from scrapped Li-ion batteries[J]. Journal of Power Sources, 2018, 390: 38-44. |

| 42 | LIU K, YANG S L, LUO L Q, et al. From spent graphite to recycle graphite anode for high-performance lithium ion batteries and sodium ion batteries[J]. Electrochimica Acta, 2020, 356: doi: 10.1016/j.electacta.2020.136856. |

| 43 | CHEN Q H, HUANG L W, LIU J B, et al. A new approach to regenerate high-performance graphite from spent lithium-ion batteries[J]. Carbon, 2022, 189: 293-304. |

| 44 | XU L, ZHANG X X, CHEN R J, et al. P-doped Ni/NiO heterostructured yolk-shell nanospheres encapsulated in graphite for enhanced lithium storage[J]. Small, 2022, 18(7): doi: 10.1002/smll.202105897. |

| 45 | YE L, WANG C H, CAO L, et al. Effective regeneration of high-performance anode material recycled from the whole electrodes in spent lithium-ion batteries via a simplified approach[J]. Green Energy & Environment, 2021, 6(5): 725-733. |

| 46 | RUAN D S, WU L, WANG F M, et al. A low-cost silicon-graphite anode made from recycled graphite of spent lithium-ion batteries[J]. Journal of Electroanalytical Chemistry, 2021, 884: doi: 10.1016/j.jelechem.2021.115073. |

| 47 | ZHAO Y L, WANG H, LI X D, et al. Recovery of CuO/C catalyst from spent anode material in battery to activate peroxymonosulfate for refractory organic contaminants degradation[J]. Journal of Hazardous Materials, 2021, 420: doi: 10.1016/j.jhazmat.2021.126552. |

| 48 | ZHANG Y Y, SONG N N, HE J J, et al. Lithiation-aided conversion of end-of-life lithium-ion battery anodes to high-quality graphene and graphene oxide[J]. Nano Letters, 2019, 19(1): 512-519. |

| 49 | YANG L, YANG L, XU G R, et al. Separation and recovery of carbon powder in anodes from spent lithium-ion batteries to synthesize graphene[J]. Scientific Reports, 2019, 9: 9823. |

| 50 | HE K, ZHANG Z Y, ZHANG F S. Synthesis of graphene and recovery of lithium from lithiated graphite of spent Li-ion battery[J]. Waste Management, 2021, 124: 283-292. |

| 51 | YU J D, LIN M S, TAN Q Y, et al. High-value utilization of graphite electrodes in spent lithium-ion batteries: From 3D waste graphite to 2D graphene oxide[J]. Journal of Hazardous Materials, 2021, 401: doi: 10.1016/j.jhazmat.2021.123715. |

| 52 | NATARAJAN S, BAJAJ H C, ARAVINDAN V. Template-free synthesis of carbon hollow spheres and reduced graphene oxide from spent lithium-ion batteries towards efficient gas storage[J]. Journal of Materials Chemistry A, 2019, 7(7): 3244-3252. |

| 53 | NATARAJAN S, LAKSHMI D S, BAJAJ H C, et al. Recovery and utilization of graphite and polymer materials from spent lithium-ion batteries for synthesizing polymer-graphite nanocomposite thin films[J]. Journal of Environmental Chemical Engineering, 2015, 3(4): 2538-2545. |

| 54 | MA X T, CHEN M Y, CHEN B, et al. High-performance graphite recovered from spent lithium-ion batteries[J]. ACS Sustainable Chemistry & Engineering, 2019, 7(24): 19732-19738. |

| 55 | KIRCHAIN R E Jr, GREGORY J R, OLIVETTI E A. Environmental life-cycle assessment[J]. Nature Materials, 2017, 16(7): 693-697. |

| 56 | ARSHAD F, LIN J, MANURKAR N, et al. Life cycle assessment of lithium-ion batteries: A critical review[J]. Resources, Conservation and Recycling, 2022, 180: doi: 10.1016/j.resconrelc.2022.106164. |

| 57 | REY I, VALLEJO C, SANTIAGO G, et al. Environmental impacts of graphite recycling from spent lithium-ion batteries based on life cycle assessment[J]. ACS Sustainable Chemistry & Engineering, 2021, 9(43): 14488-14501. |

| [1] | Shunmin YI, Linbo XIE, Li PENG. Remaining useful life prediction of lithium-ion batteries based on VF-DW-DFN [J]. Energy Storage Science and Technology, 2022, 11(7): 2305-2315. |

| [2] | Qingwei ZHU, Xiaoli YU, Qichao WU, Yidan XU, Fenfang CHEN, Rui HUANG. Semi-empirical degradation model of lithium-ion battery with high energy density [J]. Energy Storage Science and Technology, 2022, 11(7): 2324-2331. |

| [3] | Yuzuo WANG, Jin WANG, Yinli LU, Dianbo RUAN. Study on the effects of pore structure on lithium-storage performances for soft carbon [J]. Energy Storage Science and Technology, 2022, 11(7): 2023-2029. |

| [4] | Guojing LIU, Bingjie LI, Xiaoyan HU, Fen YUE, Jiqiang XU. Australia policy mechanisms and business models for energy storage and their applications to china [J]. Energy Storage Science and Technology, 2022, 11(7): 2332-2343. |

| [5] | Wei KONG, Jingtao JIN, Xipo LU, Yang SUN. Study on cooling performance of lithium ion batteries with symmetrical serpentine channel [J]. Energy Storage Science and Technology, 2022, 11(7): 2258-2265. |

| [6] | WANG Yuzuo, DENG Miao, WANG Jin, YANG Bin, LU Yinli, JIN Ge, RUAN Dianbo. Study on the effects of carbonization temperature on lithium-storage kinetics for soft carbon [J]. Energy Storage Science and Technology, 2022, 11(6): 1715-1724. |

| [7] | YU Chunhui, HE Ziying, ZHANG Chenxi, LIN Xianqing, XIAO Zhexi, WEI Fei. The analyses and suppressing strategies of silicon anode with the electrolyte [J]. Energy Storage Science and Technology, 2022, 11(6): 1749-1759. |

| [8] | WANG Can, MA Pan, ZHU Guoliang, WEI Shuimiao, YANG Zhilu, ZHANG Zhiyu. Effect of lithium acrylic-coated nature graphite on its electrochemical properties [J]. Energy Storage Science and Technology, 2022, 11(6): 1706-1714. |

| [9] | LIU Hangxin, CHEN Xiantao, SUN Qiang, ZHAO Chenxi. Cycle performance characteristics of soft pack lithium-ion batteries under vacuum environment [J]. Energy Storage Science and Technology, 2022, 11(6): 1806-1815. |

| [10] | Guangyu CHENG, Xinwei LIU, Yueni MEI, Honghui GU, Cheng YANG, Ke WANG. Capacity fading analysis of lithium-ion battery after high temperature storage [J]. Energy Storage Science and Technology, 2022, 11(5): 1339-1349. |

| [11] | Yanwen DAI, Aiqing YU. Combined CNN-LSTM and GRU based health feature parameters for lithium-ion batteries SOH estimation [J]. Energy Storage Science and Technology, 2022, 11(5): 1641-1649. |

| [12] | Chunjing LIN, Danhua LI, Haoran WEN, Tianyi MA, Hong CHANG, Peixiang CHANG, Haiqiang LI, Shiqiang LIU. Research on swelling force characteristics of power battery during charging [J]. Energy Storage Science and Technology, 2022, 11(5): 1627-1633. |

| [13] | Qiaomin KE, Jian GUO, Yiwei WANG, Wenjiong CAO, Man CHEN, Fangming JIANG. The effect of liquid-cooled thermal management on thermal runaway of power battery [J]. Energy Storage Science and Technology, 2022, 11(5): 1634-1640. |

| [14] | Zhenkai HU, Bo LEI, Yongqi LI, Youjie SHI, Qikai LEI, Zhipeng HE. Comparative study on safety test and evaluation methods of lithium-ion batteries for energy storage [J]. Energy Storage Science and Technology, 2022, 11(5): 1650-1656. |

| [15] | Jun WANG, Lin RUAN, Yanliang QIU. Research progress on rapid heating methods for lithium-ion battery in low-temperature [J]. Energy Storage Science and Technology, 2022, 11(5): 1563-1574. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||