储能科学与技术 ›› 2024, Vol. 13 ›› Issue (10): 3596-3612.doi: 10.19799/j.cnki.2095-4239.2024.0290

吴超( ), 王罗亚, 袁子杰, 马昌龙, 叶季蕾(

), 王罗亚, 袁子杰, 马昌龙, 叶季蕾( ), 吴宇平, 刘丽丽

), 吴宇平, 刘丽丽

收稿日期:2024-04-01

修回日期:2024-04-24

出版日期:2024-10-28

发布日期:2024-10-30

通讯作者:

叶季蕾

E-mail:wu1207655278@163.com;yejilei@njtech.edu.cn

作者简介:吴超(1999—),男,硕士研究生,研究方向为储能电池热管理,E-mail:wu1207655278@163.com;

基金资助:

Chao WU( ), Luoya WANG, Zijie YUAN, Changlong MA, Jilei YE(

), Luoya WANG, Zijie YUAN, Changlong MA, Jilei YE( ), Yuping WU, Lili LIU

), Yuping WU, Lili LIU

Received:2024-04-01

Revised:2024-04-24

Online:2024-10-28

Published:2024-10-30

Contact:

Jilei YE

E-mail:wu1207655278@163.com;yejilei@njtech.edu.cn

摘要:

随着锂离子电池技术的进步和成本的降低,大规模锂离子电池储能电站从示范逐渐走向商业化应用。电池热管理系统的优化设计是提升储能系统集成综合性能的关键技术,通过温度的控制不仅可以有效延长储能电池寿命、提升放电容量等,而且可以确保电站安全运行。电池作为大型电化学储能电站的载体,热安全问题的解决刻不容缓。本文对比了风冷、液冷、相变材料冷却和热管冷却4种散热技术的温降、温度均一性、系统结构、技术成熟度等,液冷散热系统在大容量锂离子电池储能系统中更具优势。液冷散热系统设计包括冷却剂通道、冷板形状、冷却液等关键参数设计,并可通过与其他散热方式进行复合优化设计,进一步提升系统的电热性能;通过控制目标、控制算法的优化,可实现电池模块温度的智能化、精准化控制,并提高热管理系统效率。液冷散热技术仍需从系统关键参数设计、控制策略优化、应用需求进行多角度优化,从而既能实现温度控制的效果,又能满足经济高效的应用目标。

中图分类号:

吴超, 王罗亚, 袁子杰, 马昌龙, 叶季蕾, 吴宇平, 刘丽丽. 液冷散热技术在电化学储能系统中的研究进展[J]. 储能科学与技术, 2024, 13(10): 3596-3612.

Chao WU, Luoya WANG, Zijie YUAN, Changlong MA, Jilei YE, Yuping WU, Lili LIU. Research progress in liquid cooling and heat dissipation technologies for electrochemical energy storage systems[J]. Energy Storage Science and Technology, 2024, 13(10): 3596-3612.

表1

储能电站起火事件原因分析"

| 编号 | 地点 | 电池类型 | 容量/MWh | 起火原因 | 时间 |

|---|---|---|---|---|---|

| 1 | 弗里蒙特,美国 | 三元 | — | 液压油与熔融铝接触 | 2021.03.12 |

| 2 | 北京,中国 | 磷酸铁锂 | 25 | 内部短路 | 2021.04.16 |

| 3 | 吉朗,澳大利亚 | 三元 | 450 | 液体冷却剂泄漏造成短路 | 2021.07.30 |

| 4 | 蒙特雷,美国 | 三元 | 1200 | 管道少量接头故障,水喷到电池,导致短路 | 2021.09.04 |

| 5 | 蔚山,韩国 | 三元 | — | 内部短路 | 2022.01.12 |

| 6 | 阿德莱德,澳大利亚 | — | — | 暴露在过热环境或是被刺穿 | 2022.02.13 |

| 7 | 圣迭戈,美国 | 三元 | 560 | 电气故障产生了烟雾,触发了保护系统 | 2022.04.05 |

| 8 | 洛坎普顿,澳大利亚 | 磷酸铁锂 | 100 | 储能单元交流电力线路接线问题引发故障,扩散到电池模块 | 2023.09.26 |

表2

典型冷板性能特点"

| 冷板形状 | 结构图 | 设计关键因素 | 特点 | 参考文献 |

|---|---|---|---|---|

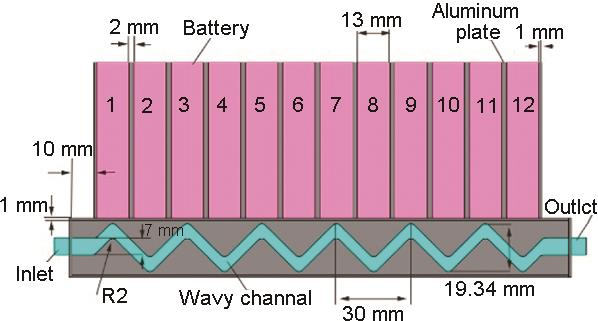

| 波形 |  | 波形通常与其他形状冷板复合且波形弯曲角应与电池相契合 | 冷却液进口方向对电池最高温度影响不大,最高温度仅降低2℃ | [ |

| 波形 |  | 复合通道减小了横向温度,最高温度降低了6.8% | [ | |

| 波形 |  | 波形曲率与锂电池相匹配,最高温度仅为39 ℃ | [ | |

| 蛇形 |  | 折角处的宽度、弯曲半径以及冷板布局 | 不同的电池组以及冷却液流量都会有与之对应的最佳冷板设计,温度下降约15% | [ |

| 蛇形 |   | 与宽通道相比,长通道有很好的冷却效果,最高温度仅为40.796 ℃ | [ | |

| 蛇形 |  | 定义通道宽度lv、通道弯曲半径ri | [ | |

| 斜翅片形 |  | 鳍角、鳍长以及宽度 | 对斜翅片角度及宽度优化,温度维持在50 ℃以下 | [ |

| 斜翅片形 |  | 提高热导率以及改变电池模组与冷板接触面积 | [ | |

| 斜翅片形 |  | 翅片长度以及角度调整,温度维持在50 ℃以下 | [ | |

| 斜翅片形 |  | 对不同鳍角以及鳍长优化,提高温度均一性 | [ |

表4

不同变量对温度的影响"

| 电池 | 通道形状 | 冷却剂 | 影响因素 | 温度结果 | 结论 | |

|---|---|---|---|---|---|---|

| 最高温度Tmax | 最大温差ΔTmax | |||||

| 50 Ah方形LiFePO4电池 | 蛇形 | 50%乙二醇水溶液 | 通道宽度lw、通道弯道内半径ri | lw=20 mm ri=8 mm Tmax=323K | lw=20 mm ri=8 mm ΔTmax=17K | lw和ri增大有利于传热和压力损失的减小 |

| 40 Ah方形LiFePO4电池 | 斜翅片形 | — | 鳍角(15°、30°、45°)、鳍长L(8 mm、10 mm、12 mm) | ɑ=30° L=12mm Tmax=306.91K | ɑ=30° L=12mm ΔTmax=2.5 K | 翅片长度和角度增加会导致压力损失 |

| 2.75 Ah圆形18650镍钴铝氧化物(NCA)电池 | 波形 | 53%乙二醇水溶液 | 充/放电速率(1C、1.5C、2C)、流量 (18 L/min、23 L/min、36 L/min) | 在流量为36 L/min的2C放电速率下,Tmax=312 K | 在流量为36 L/min的2C放电速率下,ΔTmax=11 K | 研发电动汽车电池组热模型并对充/放电倍率以及冷却液流量进行参数化研究 |

| 20 Ah袋式 LiNi0.5Co0.2Mn0.3O2电池 | 仿生叶脉分支 | 50%乙二醇水溶液 | 入口流量(M)、流道角(ɑ)、流道数(N)、流道宽度(D) | M=0.10 m/s α=159° N=15 D=2.6 mm Tmax=30.31 ℃ | M=0.10 m/s α=159° N=15 D=2.6mm ΔTmax=2.87 ℃ | M和D是影响冷却性能的主要因素,ɑ和N是次要因素 |

表7

控制策略概括总结"

| 序号 | 控制目标 | 控制算法 | 研究类型 | 结果 | 参考文献 | ||||

|---|---|---|---|---|---|---|---|---|---|

| 温度 | 寿命 | 能耗 | 重量 | 调节时间 | |||||

| 1 | 温度、能耗 | NMPC | 仿真 | 温度偏差仅有0.5 K,温度不一致性小于1.2 K | — | 在新欧洲驾驶循环周期(NEDC)和激烈驾驶(US06)工况下,相较于PID,NMPC冷却剂消耗量分别减少了17.1%、10.3% | — | — | [ |

| 2 | 温度、调节时长 | 模糊+PID | 仿真 | 温度偏差由1.24 K降至0.14 K | — | — | — | 调节时间361 s缩短至215 s | [ |

| 3 | 温度、能耗 | NASGA2+神经网络 | 仿真 | 最高温度降低7.5 K | — | 减少了26% | — | — | [ |

| 4 | 温度、寿命、能耗 | 神经网络+智能模型预测控制策略(IMPC) | 实验 | 实际与目标温度最大差值仅为0.66 ℃,平均温差为1.03 ℃ | 延长约0.010% | 减少了14.1% | — | — | [ |

| 5 | 温度、系统重量 | NASGA2 | 仿真 | 最高温度为36 ℃,温差为0.65 ℃ | — | — | 减轻10.25% | — | [ |

| 1 | 中国能源研究会储能专业委员会. 储能产业研究白皮书[R]. 中关村储能产业技术联盟, 2024: 1-3. |

| 2 | CHA E, YUN J H, PONRAJ R, et al. A mechanistic review of lithiophilic materials: Resolving lithium dendrites and advancing lithium metal-based batteries[J]. Materials Chemistry Frontiers, 2021, 5(17): 6294-6314. DOI: 10.1039/D1QM00579K. |

| 3 | 朱董军. 锂电池储能电站运行期安全风险管理研究[D]. 北京: 北京交通大学, 2023. DOI: 10.26944/d.cnki.gbfju.2023.003208. |

| ZHU D J. Research on safety risk management of lithium battery energy storage power station during operation period[D]. Beijing: Beijing Jiaotong University, 2023. DOI: 10.26944/d.cnki.gbfju.2023.003208. | |

| 4 | 李明, 焦春雷, 李晓龙, 等. 储能安全标准研究及储能在构网型新场景中的应用[J]. 高压电器, 2023, 59(7): 20-29, 38. DOI: 10.13296/j.1001-1609.hva.2023.07.003. |

| LI M, JIAO C L, LI X L, et al. Research on energy storage safety standard and application of energy storage system in grid-forming scenario[J]. High Voltage Apparatus, 2023, 59(7): 20-29, 38. DOI: 10.13296/j.1001-1609.hva.2023.07.003. | |

| 5 | ZALOSH R, GANDHI P, BAROWY A. Lithium-ion energy storage battery explosion incidents[J]. Journal of Loss Prevention in the Process Industries, 2021, 72: 104560. DOI: 10.1016/j.jlp.2021. 104560. |

| 6 | FENG X N, OUYANG M G, LIU X, et al. Thermal runaway mechanism of lithium ion battery for electric vehicles: A review[J]. Energy Storage Materials, 2018, 10: 246-267. DOI: 10.1016/j.ensm.2017.05.013. |

| 7 | 王博石. 锂离子动力电池充电控制策略研究[D]. 长春: 吉林大学, 2022. DOI: 10.27162/d.cnki.gjlin.2022.007602. |

| WANG B S. Research on charging control strategy of lithium-ion power battery[D]. Changchun: Jilin University, 2022. DOI: 10.27162/d.cnki.gjlin.2022.007602. | |

| 8 | 白庆华, 王健雁, 周亚鹏. 储能电站电池管理系统研究现状和发展趋势[J]. 无线互联科技, 2023, 20(23): 78-80. DOI: 10.3969/j.issn.1672-6944.2023.23.021. |

| BAI Q H, WANG J Y, ZHOU Y P. Research status and development trend of battery management system for energy storage power station[J]. Wireless Internet Technology, 2023, 20(23): 78-80. DOI: 10.3969/j.issn.1672-6944.2023.23.021. | |

| 9 | 李建, 阮迪. 多样化算力对服务器的散热挑战分析[J]. 信息通信技术与政策, 2024(2): 46-54. |

| LI J, RUAN D. Analysis of thermal challenges in servers for diverse computing power[J]. Information and Communications Technology and Policy, 2024(2): 46-54. | |

| 10 | 张晓彤, 张营, 姜睿智, 等. 液冷机箱散热性能数值研究[J]. 机电元件, 2024, 44(1): 48-50, 63. |

| ZHANG X T, ZHANG Y, JIANG R Z, et al. Numerical study on the heat dissipation performance of liquid cooled chassis[J]. Electromechanical Components, 2024, 44(1): 48-50, 63. | |

| 11 | 胡明龙. 液冷一体式吹胀型均热板制造及其传热性能研究[D]. 广州: 华南理工大学, 2021. DOI: 10.27151/d.cnki.ghnlu.2021.001634. |

| HU M L. Manufacture and heat transfer performance of liquid-cooled integrated inflatable vapor chamber[D]. Guangzhou: South China University of Technology, 2021. DOI: 10.27151/d.cnki.ghnlu.2021.001634. | |

| 12 | 王晓宇, 宋分平, 谢李高, 等. 微通道换热器两级均液竖直集管设计及两相分配特性[J/OL]. 制冷学报, 2024 (2024-02-09). https://kns.cnki.net/kcms/detail/11.2182.TB.20240206.1327.004.html. |

| WANG X Y, SONG F P, XIE L G, et al. Design and two-phase distribution characteristics of two-stage liquid equalization vertical header of microchannel heat exchanger[J/OL]. Journal of Refrigeration, 2024 (2024-02-09). https://kns.cnki.net/kcms/detail/11.2182.TB.20240206.1327.004.html. | |

| 13 | ZHAO J T, RAO Z H, LI Y M. Thermal performance of mini-channel liquid cooled cylinder based battery thermal management for cylindrical lithium-ion power battery[J]. Energy Conversion and Management, 2015, 103: 157-165. DOI: 10.1016/j.enconman.2015.06.056. |

| 14 | AN Z, SHAH K, JIA L, et al. A parametric study for optimization of minichannel based battery thermal management system[J]. Applied Thermal Engineering, 2019, 154: 593-601. DOI: 10.1016/j.applthermaleng.2019.02.088. |

| 15 | LAN C J, XU J, QIAO Y, et al. Thermal management for high power lithium-ion battery by minichannel aluminum tubes[J]. Applied Thermal Engineering, 2016, 101: 284-292. DOI: 10.1016/j.applthermaleng.2016.02.070. |

| 16 | MAO S, AN Z J, DU X Z, et al. Coupling analysis on the thermophysical parameters and the performance of liquid cooling-based thermal management system for lithium-ion batteries[J]. Energies, 2022, 15(19): 6865. DOI: 10.3390/en15196865. |

| 17 | LIU F F, CHEN Y Y, QIN W, et al. Optimal design of liquid cooling structure with bionic leaf vein branch channel for power battery[J]. Applied Thermal Engineering, 2023, 218: 119283. DOI: 10.1016/j.applthermaleng.2022.119283. |

| 18 | ZHANG Y T, ZUO W, E J Q, et al. Performance comparison between straight channel cold plate and inclined channel cold plate for thermal management of a prismatic LiFePO4 battery[J]. Energy, 2022, 248: 123637. DOI: 10.1016/j.energy.2022.123637. |

| 19 | 杨书斌. 电场与相分离结构协同作用下微细通道流动沸腾强化传热及均温性研究[D]. 广州: 华南理工大学, 2022. DOI: 10.27151/d.cnki.ghnlu.2022.005341. |

| YANG S B. Study on heat transfer enhancement and temperature uniformity of micro-channel flow boiling under the synergistic effect of electric field and phase separation structure[D]. Guangzhou: South China University of Technology, 2022. DOI: 10.27151/d.cnki.ghnlu.2022.005341. | |

| 20 | DING Y Z, JI H C, WEI M X, et al. Effect of liquid cooling system structure on lithium-ion battery pack temperature fields[J]. International Journal of Heat and Mass Transfer, 2022, 183: 122178. DOI: 10.1016/j.ijheatmasstransfer.2021.122178. |

| 21 | REHMAN M U, SIDDIQUE W, HAQ I, et al. CFD analysis of the influence of guide ribs/vanes on the heat transfer enhancement of a trapezoidal channel[J]. Applied Thermal Engineering, 2016, 102: 570-585. DOI: 10.1016/j.applthermaleng.2016.03.043. |

| 22 | 吴圣红, 余理, 赵陈磊. 新能源汽车电池热管理技术探讨[J]. 南方农机, 2024, 55(4): 155-158. |

| WU S H, YU L, ZHAO C L. Discussion on battery thermal management technology for new energy vehicles[J]. China Southern Agricultural Machinery, 2024, 55(4): 155-158. | |

| 23 | LI B, MAO Z Y, SONG B W, et al. Study on battery thermal management of autonomous underwater vehicle by bionic wave channels with liquid cooling[J]. International Journal of Energy Research, 2021, 45(9): 13269-13283. DOI: 10.1002/er.6652. |

| 24 | DONG J H, LU X P, SUN Y, et al. Design of battery thermal management system with considering the longitudinal and transverse temperature difference[J]. Energies, 2022, 15(19): 7448. DOI: 10.3390/en15197448. |

| 25 | CAO W J, ZHAO C R, WANG Y W, et al. Thermal modeling of full-size-scale cylindrical battery pack cooled by channeled liquid flow[J]. International Journal of Heat and Mass Transfer, 2019, 138: 1178-1187. DOI: 10.1016/j.ijheatmasstransfer.2019.04.137. |

| 26 | 欧阳灿, 高学农, 尹辉斌, 等. 高效液冷技术在电子元件热控制中的应用[J]. 电子与封装, 2008, 8(10): 37-41. DOI: 10.16257/j.cnki.1681-1070.2008.10.004. |

| OUYANG C, GAO X N, YIN H B, et al. Advances in application of efficient liquid cooling technique for electronic component thermal control[J]. Electronics & Packaging, 2008, 8(10): 37-41. DOI: 10.16257/j.cnki.1681-1070.2008.10.004. | |

| 27 | JARRETT A, KIM I Y. Influence of operating conditions on the optimum design of electric vehicle battery cooling plates[J]. Journal of Power Sources, 2014, 245: 644-655. DOI: 10.1016/j.jpowsour.2013.06.114. |

| 28 | DENG T, ZHANG G D, RAN Y. Study on thermal management of rectangular Li-ion battery with serpentine-channel cold plate[J]. International Journal of Heat and Mass Transfer, 2018, 125: 143-152. DOI: 10.1016/j.ijheatmasstransfer.2018.04.065. |

| 29 | E J Q, XU S J, DENG Y W, et al. Investigation on thermal performance and pressure loss of the fluid cold-plate used in thermal management system of the battery pack[J]. Applied Thermal Engineering, 2018, 145: 552-568. DOI: 10.1016/j.applthermaleng.2018.09.048. |

| 30 | LEE Y J, SINGH P K, LEE P S. Fluid flow and heat transfer investigations on enhanced microchannel heat sink using oblique fins with parametric study[J]. International Journal of Heat and Mass Transfer, 2015, 81: 325-336. DOI: 10.1016/j.ijheatmasstransfer. 2014.10.018. |

| 31 | JIN L W, LEE P S, KONG X X, et al. Ultra-thin minichannel LCP for EV battery thermal management[J]. Applied Energy, 2014, 113: 1786-1794. DOI: 10.1016/j.apenergy.2013.07.013. |

| 32 | FU J Q, XU X M, LI R Z. Battery module thermal management based on liquid cold plate with heat transfer enhanced fin[J]. International Journal of Energy Research, 2019, 43(9): 4312-4321. DOI: 10.1002/er.4556. |

| 33 | XIA B Z, LIU Y F, HUANG R, et al. Thermal analysis and improvements of the power battery pack with liquid cooling for electric vehicles[J]. Energies, 2019, 12(16): 3045. DOI: 10.3390/en12163045. |

| 34 | ALDOSRY A M, ZULKIFLI R, WAN GHOPA W A. Heat transfer enhancement of liquid cooled copper plate with oblique fins for electric vehicles battery thermal management[J]. World Electric Vehicle Journal, 2021, 12(2): 55. DOI: 10.3390/wevj12020055. |

| 35 | 李啸龙. 冬日的温暖, 夏日的凉爽——说说防冻液那些事儿[J]. 汽车与驾驶维修(汽车版), 2012(2): 174-177. |

| LI X L. Warm in winter, cool in summer—Talk about antifreeze[J]. Auto Driving & Service, 2012(2): 174-177. | |

| 36 | AL-ZAREER M, DINCER I, ROSEN M A. Heat and mass transfer modeling and assessment of a new battery cooling system[J]. International Journal of Heat and Mass Transfer, 2018, 126: 765-778. DOI: 10.1016/j.ijheatmasstransfer.2018.04.157. |

| 37 | WANG Y, GAO Q, WANG H W. Structural design and its thermal management performance for battery modules based on refrigerant cooling method[J]. International Journal of Energy Research, 2021, 45(3): 3821-3837. DOI: 10.1002/er.6035. |

| 38 | WANG Z R, HUANG L P, HE F. Design and analysis of electric vehicle thermal management system based on refrigerant-direct cooling and heating batteries[J]. Journal of Energy Storage, 2022, 51: 104318. DOI: 10.1016/j.est.2022.104318. |

| 39 | 张向阳, 郭衍锦, 张苗苗, 等. 氢氟醚类有机朗肯循环低温热源工质合成研究进展[J]. 化工生产与技术, 2023, 29(1): 23-28, 8-9. |

| ZHANG X Y, GUO Y J, ZHANG M M, et al. Research progress in synthesis of low-temperature heat source working fluid for hydrofluoroether organic Rankine cycle[J]. Chemical Production and Technology, 2023, 29(1): 23-28, 8-9. | |

| 40 | TAN X J, LYU P X, FAN Y Q, et al. Numerical investigation of the direct liquid cooling of a fast-charging lithium-ion battery pack in hydrofluoroether[J]. Applied Thermal Engineering, 2021, 196: 117279. DOI: 10.1016/j.applthermaleng.2021.117279. |

| 41 | HIRANO H, TAJIMA T, HASEGAWA T, et al. Boiling liquid battery cooling for electric vehicle[C]//2014 IEEE Conference and Expo Transportation Electrification Asia-Pacific (ITEC Asia-Pacific). August 31-September 3, 2014, Beijing, China. IEEE, 2014: 1-4. DOI: 10.1109/ITEC-AP.2014.6940931. |

| 42 | AN Z J, JIA L, LI X J, et al. Experimental investigation on lithium-ion battery thermal management based on flow boiling in mini-channel[J]. Applied Thermal Engineering, 2017, 117: 534-543. DOI: 10.1016/j.applthermaleng.2017.02.053. |

| 43 | CHOI S U S, EASTMAN J A. Enhancing thermal conductivity of fluids with nanoparticles[C]//ASME International mechanical engineering congress and exposition, San Francisco, CA, United States, 1995: 99-105. |

| 44 | MONDAL B, LOPEZ C F, MUKHERJEE P P. Exploring the efficacy of nanofluids for lithium-ion battery thermal management[J]. International Journal of Heat and Mass Transfer, 2017, 112: 779-794. DOI: 10.1016/j.ijheatmasstransfer.2017.04.130. |

| 45 | HUO Y T, RAO Z H. The numerical investigation of nanofluid based cylinder battery thermal management using lattice Boltzmann method[J]. International Journal of Heat and Mass Transfer, 2015, 91: 374-384. DOI: 10.1016/j.ijheatmasstransfer. 2015.07.128. |

| 46 | WANG S N, LI Y H, LI Y Z, et al. A forced gas cooling circle packaging with liquid cooling plate for the thermal management of Li-ion batteries under space environment[J]. Applied Thermal Engineering, 2017, 123: 929-939. DOI: 10.1016/j.applthermaleng. 2017.05.159. |

| 47 | YANG W, ZHOU F, ZHOU H B, et al. Thermal performance of cylindrical lithium-ion battery thermal management system integrated with mini-channel liquid cooling and air cooling[J]. Applied Thermal Engineering, 2020, 175: 115331. DOI: 10.1016/j.applthermaleng.2020.115331. |

| 48 | LI M, LIU F, HAN B, et al. Research on temperature control performance of battery thermal management system composited with multi-channel parallel liquid cooling and air cooling[J]. Ionics, 2021, 27(6): 2685-2695. DOI: 10.1007/s11581-021-04033-w. |

| 49 | ZHANG W C, LIANG Z C, YIN X X, et al. Avoiding thermal runaway propagation of lithium-ion battery modules by using hybrid phase change material and liquid cooling[J]. Applied Thermal Engineering, 2021, 184: 116380. DOI: 10.1016/j.applthermaleng.2020.116380. |

| 50 | RAO Z H, WANG Q C, HUANG C L. Investigation of the thermal performance of phase change material/mini-channel coupled battery thermal management system[J]. Applied Energy, 2016, 164: 659-669. DOI: 10.1016/j.apenergy.2015.12.021. |

| 51 | YANG W, ZHOU F, LIU Y C, et al. Thermal performance of honeycomb-like battery thermal management system with bionic liquid mini-channel and phase change materials for cylindrical lithium-ion battery[J]. Applied Thermal Engineering, 2021, 188: 116649. DOI: 10.1016/j.applthermaleng.2021.116649. |

| 52 | HE L F, TANG X W, LUO Q L, et al. Structure optimization of a heat pipe-cooling battery thermal management system based on fuzzy grey relational analysis[J]. International Journal of Heat and Mass Transfer, 2022, 182: 121924. DOI: 10.1016/j.ijheatmasstransfer. 2021.121924. |

| 53 | TANG W, XU X M, DING H, et al. Sensitivity analysis of the battery thermal management system with a reciprocating cooling strategy combined with a flat heat pipe[J]. ACS Omega, 2020, 5(14): 8258-8267. DOI: 10.1021/acsomega.0c00552. |

| 54 | LI Y, GUO H, QI F, et al. Investigation on liquid cold plate thermal management system with heat pipes for LiFePO4 battery pack in electric vehicles[J]. Applied Thermal Engineering, 2021, 185: 116382. DOI: 10.1016/j.applthermaleng.2020.116382. |

| 55 | 吕艳宗, 韩冰, 王宏宇, 等. 基于空调的有轨电车动力电池热管理控制[J]. 储能科学与技术, 2022, 11(10): 3231-3238. DOI: 10.19799/j.cnki.2095-4239.2022.0130. |

| LV Y Z, HAN B, WANG H Y, et al. Thermal management control of tram power battery using on air conditioner[J]. Energy Storage Science and Technology, 2022, 11(10): 3231-3238. DOI: 10.19799/j.cnki.2095-4239.2022.0130. | |

| 56 | HUA Y, ZHOU S D, CUI H G, et al. A comprehensive review on inconsistency and equalization technology of lithium-ion battery for electric vehicles[J]. International Journal of Energy Research, 2020, 44(14): 11059-11087. DOI: 10.1002/er.5683. |

| 57 | XIE Y, WANG C Y, HU X S, et al. An MPC-based control strategy for electric vehicle battery cooling considering energy saving and battery lifespan[J]. IEEE Transactions on Vehicular Technology, 2020, 69(12): 14657-14673. DOI: 10.1109/TVT.2020.3032989. |

| 58 | FAN Y Q, ZUO X G, ZHAN D, et al. A novel control strategy for active battery thermal management systems based on dynamic programming and a genetic algorithm[J]. Applied Thermal Engineering, 2023, 233: 121113. DOI: 10.1016/j.applthermaleng. 2023.121113. |

| 59 | GUO Z C, XU J, XU Z M, et al. A lightweight multichannel direct contact liquid-cooling system and its optimization for lithium-ion batteries[J]. IEEE Transactions on Transportation Electrification, 2022, 8(2): 2334-2345. DOI: 10.1109/TTE.2021.3131718. |

| 60 | WANG H T, XU W J, MA L. Actively controlled thermal management of prismatic Li-ion cells under elevated temperatures[J]. International Journal of Heat and Mass Transfer, 2016, 102: 315-322. DOI: 10.1016/j.ijheatmasstransfer.2016.06.033. |

| 61 | 杨铮鑫, 王凯, 张达, 等. 压电悬臂碳纤维层合板的振动控制研究[J]. 塑料科技, 2024, 52(2): 25-30. DOI: 10.15925/j.cnki.issn1005-3360.2024.02.005. |

| YANG Z X, WANG K, ZHANG D, et al. Research on vibration control of piezoelectric cantilever carbon fiber laminated plate[J]. Plastics Science and Technology, 2024, 52(2): 25-30. DOI: 10.15925/j.cnki.issn1005-3360.2024.02.005. | |

| 62 | CEN J W, JIANG F M. Li-ion power battery temperature control by a battery thermal management and vehicle cabin air conditioning integrated system[J]. Energy for Sustainable Development, 2020, 57: 141-148. DOI: 10.1016/j.esd.2020.06.004. |

| 63 | ZHANG Y Z, TONG L. Regenerative braking-based hierarchical model predictive cabin thermal management for battery life extension of autonomous electric vehicles[J]. Journal of Energy Storage, 2022, 52: 104662. DOI: 10.1016/j.est.2022.104662. |

| 64 | ZHU C, LU F, ZHANG H, et al. Robust predictive battery thermal management strategy for connected and automated hybrid electric vehicles based on thermoelectric parameter uncertainty[J]. IEEE Journal of Emerging and Selected Topics in Power Electronics, 2018, 6(4): 1796-1805. DOI: 10.1109/JESTPE. 2018.2852218. |

| 65 | GUO R, LI L, SUN Z Y, et al. An integrated thermal management strategy for cabin and battery heating in range-extended electric vehicles under low-temperature conditions[J]. Applied Thermal Engineering, 2023, 228: 120502. DOI: 10.1016/j.applthermaleng. 2023.120502. |

| 66 | 孙腾超, 陈焕明. 基于深度强化学习的自主换道控制模型[J/OL]. 农业装备与车辆工程, 2024 (2024-03-09). https://kns.cnki.net/kcms/detail/37.1433.th.20240307.1007.004.html. |

| SUN T C, CHEN H M. Autonomous lane change control model based on deep reinforcement learning[J/OL]. Agricultural Equipment and Vehicle Engineering, 2024 (2024-03-09). https://kns.cnki.net/kcms/detail/37.1433.th.20240307.1007.004.html. | |

| 67 | CHENG H Y, JUNG S, KIM Y B. Battery thermal management system optimization using Deep reinforced learning algorithm[J]. Applied Thermal Engineering, 2024, 236: 121759. DOI: 10.1016/j.applthermaleng.2023.121759. |

| 68 | HUANG G, ZHAO P, ZHANG G L. Real-time battery thermal management for electric vehicles based on deep reinforcement learning[J]. IEEE Internet of Things Journal, 2022, 9(15): 14060-14072. DOI: 10.1109/JIOT.2022.3145849. |

| 69 | WANG Y L, CHEN X J, LI C L, et al. Temperature prediction of lithium-ion battery based on artificial neural network model[J]. Applied Thermal Engineering, 2023, 228: 120482. DOI: 10.1016/j.applthermaleng.2023.120482. |

| 70 | CHEN S Q, BAO N S, GARG A, et al. A fast charging–cooling coupled scheduling method for a liquid cooling-based thermal management system for lithium-ion batteries[J]. Engineering, 2021, 7(8): 1165-1176. DOI: 10.1016/j.eng.2020.06.016. |

| 71 | 马彦, 丁浩, 牟洪元, 等. 基于模糊PID算法的动力电池液体冷却策略[J]. 控制理论与应用, 2021, 38(5): 549-560. DOI: 10.7641/CTA.2020.00373. |

| MA Y, DING H, MOU H Y, et al. Liquid cooling strategy of power battery based on fuzzy PID algorithm[J]. Control Theory & Applications, 2021, 38(5): 549-560. DOI: 10.7641/CTA.2020.00373. | |

| 72 | CHANG K F, LI Y Z, HOU X F, et al. Numerical study of fuzzy-PID dual-layer coordinated control strategy for high temperature uniformity of space lithium-ion battery pack based on thermoelectric coolers[J]. Journal of Energy Storage, 2022, 56: 105952. DOI: 10.1016/j.est.2022.105952. |

| 73 | LIU Z, LIU Z X, LIU J Z, et al. Thermal management with fast temperature convergence based on optimized fuzzy PID algorithm for electric vehicle battery[J]. Applied Energy, 2023, 352: 121936. DOI: 10.1016/j.apenergy.2023.121936. |

| 74 | XIE J H, YANG R F, GOOI H B, et al. PID-based CNN-LSTM for accuracy-boosted virtual sensor in battery thermal management system[J]. Applied Energy, 2023, 331: 120424. DOI: 10.1016/j.apenergy.2022.120424. |

| 75 | 张甫仁, 易孟斐, 汪鹏伟, 等. 锂离子电池复合热管理系统的多目标优化[J]. 重庆交通大学学报(自然科学版), 2022, 41(9): 147-154. DOI: 10.3969/j.issn.1674-0696.2022.09.21. |

| ZHANG F R, YI M F, WANG P W, et al. Multi-objective optimization of composite thermal management system of lithium-ion battery[J]. Journal of Chongqing Jiaotong University (Natural Science), 2022, 41(9): 147-154. DOI: 10.3969/j.issn.1674-0696.2022.09.21. | |

| 76 | 蒋喆斌. 基于风液结合的锂电池热管理系统设计与优化[D]. 武汉: 江汉大学, 2023. DOI: 10.27800/d.cnki.gjhdx.2023.000479. |

| JIANG Z B. Design and optimization of thermal management system for lithium battery based on wind-liquid combination[D]. Wuhan: Jianghan University, 2023. DOI: 10.27800/d.cnki.gjhdx. 2023.000479. | |

| 77 | XIN S J, WANG C, XI H. Thermal management scheme and optimization of cylindrical lithium-ion battery pack based on air cooling and liquid cooling[J]. Applied Thermal Engineering, 2023, 224: 120100. DOI: 10.1016/j.applthermaleng.2023.120100. |

| 78 | 翟磊. 基于相变与液冷耦合的电池热管理系统研究[J]. 汽车电器, 2022(2): 22-27. DOI: 10.13273/j.cnki.qcdq.2022.02.019. |

| ZHAI L. Research on battery thermal management system based on phase change and liquid cooling coupling[J]. Auto Electric Parts, 2022(2): 22-27. DOI: 10.13273/j.cnki.qcdq.2022.02.019. | |

| 79 | ZHAO D, CHEN M B, LV J, et al. Multi-objective optimization of battery thermal management system combining response surface analysis and NSGA-II algorithm[J]. Energy Conversion and Management, 2023, 292: 117374. DOI: 10.1016/j.enconman. 2023.117374. |

| 80 | 段志勇, 马菁. 锂电池热管-液冷板式冷却结构多目标优化[J]. 汽车工程, 2023, 45(11): 2047-2057. DOI: 10.19562/j.chinasae.qcgc.2023.11.006. |

| DUAN Z Y, MA J. Multi-objective optimization of lithium battery composite cooling structure based on heat pipes and liquid cooling plate[J]. Automotive Engineering, 2023, 45(11): 2047-2057. DOI: 10.19562/j.chinasae.qcgc.2023.11.006. | |

| 81 | CHEN J H, XUAN D J, CHEN C, et al. Structure optimization of air-cooled battery thermal management system based on neural network[J]. Ionics, 2023, 29(7): 2773-2782. DOI: 10.1007/s11581-023-05040-9. |

| 82 | ZHU C, LU F, ZHANG H, et al. A real-time battery thermal management strategy for connected and automated hybrid electric vehicles (CAHEVs) based on iterative dynamic programming[J]. IEEE Transactions on Vehicular Technology, 2018, 67(9): 8077-8084. DOI: 10.1109/TVT.2018.2844368. |

| 83 | ZHOU L, GARG A, LI W, et al. Intelligent temperature control framework of lithium-ion battery for electric vehicles[J]. Applied Thermal Engineering, 2024, 236: 121577. DOI: 10.1016/j.applthermaleng.2023.121577. |

| 84 | 曹益忠, 袁豪, 哈达, 等. 基于模糊自调整PID的全液压矫直机位置控制研究[J/OL]. 轧钢, 2024 (2024-03-26). https://kns.cnki.net/kcms/detail/11.2466.tf.20240325.1535.007.html. |

| CAO Y Z, YUAN H, HA D, et al. Research on position control of full hydraulic straightener based on fuzzy self-adjusting PID[J/OL]. Roll steel, 2024 (2024-03-26). https://kns.cnki.net/kcms/detail/11.2466.tf.20240325.1535.007.html. | |

| 85 | MA Y, DING H, MOU H Y, et al. Battery thermal management strategy for electric vehicles based on nonlinear model predictive control[J]. Measurement, 2021, 186: 110115. DOI: 10.1016/j.measurement.2021.110115. |

| 86 | ZHUANG W C, LIU Z T, SU H Y, et al. An intelligent thermal management system for optimized lithium-ion battery pack[J]. Applied Thermal Engineering, 2021, 189: 116767. DOI: 10.1016/j.applthermaleng.2021.116767. |

| [1] | 陈悦林, 马宏忠, 朱沐雨, 宣文婧, 王思涵. 磷酸铁锂电池组在电网调峰工况下的液冷技术研究[J]. 储能科学与技术, 2024, 13(8): 2704-2712. |

| [2] | 宋旭, 孙楠楠, 曹恒超, 朱桂香, 李孟涵, 刘晓日, 饶中浩. 基于并联蛇形流道的动力电池冷媒直冷热管理系统研究[J]. 储能科学与技术, 2024, 13(8): 2726-2736. |

| [3] | 陈国贺, 吕培召, 李孟涵, 饶中浩. 锂离子电池热失控传播特性及其抑制策略研究进展[J]. 储能科学与技术, 2024, 13(7): 2470-2482. |

| [4] | 刘松燕, 王卫良, 彭世亮, 吕俊复. 兼顾高/低温环境性能的动力电池热管理系统设计[J]. 储能科学与技术, 2024, 13(7): 2181-2191. |

| [5] | 孙琦, 彭豪, 孟庆国, 孔德凯, 冯睿. 极限工况下储能电池包热适应性[J]. 储能科学与技术, 2024, 13(6): 2039-2043. |

| [6] | 张雅新, 张泉, 娄旭静, 周浩, 陈志文, 龙刚. 集装箱式储能电站两相冷板液冷系统的温控效果研究[J]. 储能科学与技术, 2024, 13(6): 1921-1928. |

| [7] | 张云峰, 张学文, 钟威, 蒋杜伟, 陈泽伟, 张杰. 石蜡与低熔点合金双级联相变材料强化板翅式散热器换热性能的数值模拟[J]. 储能科学与技术, 2024, 13(5): 1460-1470. |

| [8] | 廖琪, 曹小林, 邓谊柏, 杨耀林, 陈挺. 有轨电车超级电容模组液冷散热仿真分析[J]. 储能科学与技术, 2024, 13(2): 702-711. |

| [9] | 宋梦琼, 彭宇, 廖自强. 基于电化学热耦合模型的电池热管理研究[J]. 储能科学与技术, 2024, 13(2): 578-585. |

| [10] | 徐鑫甜, 张碧霄, 朱信龙, 杨凯杰. 基于电池箱体开孔的储能电池系统精细化热设计优化研究[J]. 储能科学与技术, 2024, 13(2): 515-525. |

| [11] | 唐盼春, 严嵘, 张灿, 孙泽. 堆叠式车载超级电容器热管理方式分析[J]. 储能科学与技术, 2024, 13(2): 483-491. |

| [12] | 张斌洋, 任晓龙, 赵江铭, 丁顺良. 锂离子电池双螺旋结构流道液冷板数值优化[J]. 储能科学与技术, 2024, 13(10): 3545-3555. |

| [13] | 曾少鸿, 吴伟雄, 刘吉臻, 汪双凤, 叶石丰, 冯振宇. 锂离子电池浸没式冷却技术研究综述[J]. 储能科学与技术, 2023, 12(9): 2888-2903. |

| [14] | 唐程波, 锁要红, 何昭坤. 基于正弦函数的液冷板上流体流向对锂离子电池散热性能的影响[J]. 储能科学与技术, 2023, 12(8): 2547-2555. |

| [15] | 刘书琴, 王小燕, 张振东, 段振霞. 锂离子电池组液冷式热管理系统的设计及优化[J]. 储能科学与技术, 2023, 12(7): 2155-2165. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||