储能科学与技术 ›› 2025, Vol. 14 ›› Issue (9): 3354-3372.doi: 10.19799/j.cnki.2095-4239.2025.0147

收稿日期:2025-02-22

修回日期:2025-03-19

出版日期:2025-09-28

发布日期:2025-09-05

通讯作者:

周海平

E-mail:1281471718@qq.com;haipzhou@uestc.edu.cn

作者简介:邓拓(2000—),男,硕士研究生,研究方向为锂离子电池,E-mail:1281471718@qq.com;

基金资助:

Tuo DENG( ), Haiping ZHOU(

), Haiping ZHOU( ), Yu LIU, Chang LIU, Zikai LI, Mengqiang WU

), Yu LIU, Chang LIU, Zikai LI, Mengqiang WU

Received:2025-02-22

Revised:2025-03-19

Online:2025-09-28

Published:2025-09-05

Contact:

Haiping ZHOU

E-mail:1281471718@qq.com;haipzhou@uestc.edu.cn

摘要:

硅因具有高的理论比容量、高的元素丰度以及环境友好等特点而成为当前锂离子电池最有潜力的负极之中备受关注的材料,但由于其低导电性、体积膨胀、电极粉化等问题限制了其大规模应用。为解决以上问题,一方面可以通过尺寸效应将硅颗粒纳米化,当粒径小于150 nm时,可显著抑制材料在充放电过程中的粉化现象,同时缓解其体积膨胀效应;另一方面,通过高强度材料的限域作用,束缚硅的体积膨胀并提高导电性。化学气相沉积(CVD)法制备的硅碳复合材料综合了两者优点,通过多孔碳基体的丰富微孔结构实现硅颗粒的原位限域生长,同时得益于碳材料优异的导电性能和机械强度,使得CVD硅碳复合材料作为负极展现出卓越的比容量和循环稳定性。这种独特的结构设计和性能优势使其成为新一代硅碳负极材料领域备受关注的前沿制备技术。然而,当前针对CVD硅碳负极的系统性研究仍显不足,其研究体系尚未形成完整框架,特别是在沉积动力学机制(如碳基体结构对沉积动力学的调控作用、硅沉积的微观结构演变规律)与工程化应用之间的构效关系方面,相关关键机理尚未完全阐明。基于上述研究背景,本文系统梳理了CVD硅碳负极技术的研究体系,建立多维分析框架:①碳基体结构与硅源特性对沉积动力学的协同调控机制;②高能量密度电极的界面工程策略与结构优化方法;③规模化制备工艺的关键技术瓶颈。通过整合现有研究成果,构建了从基础研究到工程应用的知识体系,揭示现阶段产业化进程中的核心矛盾,并提出工艺优化路径,为新一代CVD硅碳负极的理性设计与可控制造提供科学指导。

中图分类号:

邓拓, 周海平, 刘煜, 刘畅, 李梓恺, 吴孟强. 化学气相沉积法制备硅碳负极的研究进展[J]. 储能科学与技术, 2025, 14(9): 3354-3372.

Tuo DENG, Haiping ZHOU, Yu LIU, Chang LIU, Zikai LI, Mengqiang WU. Research progress in the preparation of silicon-carbons anode by chemical vapor deposition[J]. Energy Storage Science and Technology, 2025, 14(9): 3354-3372.

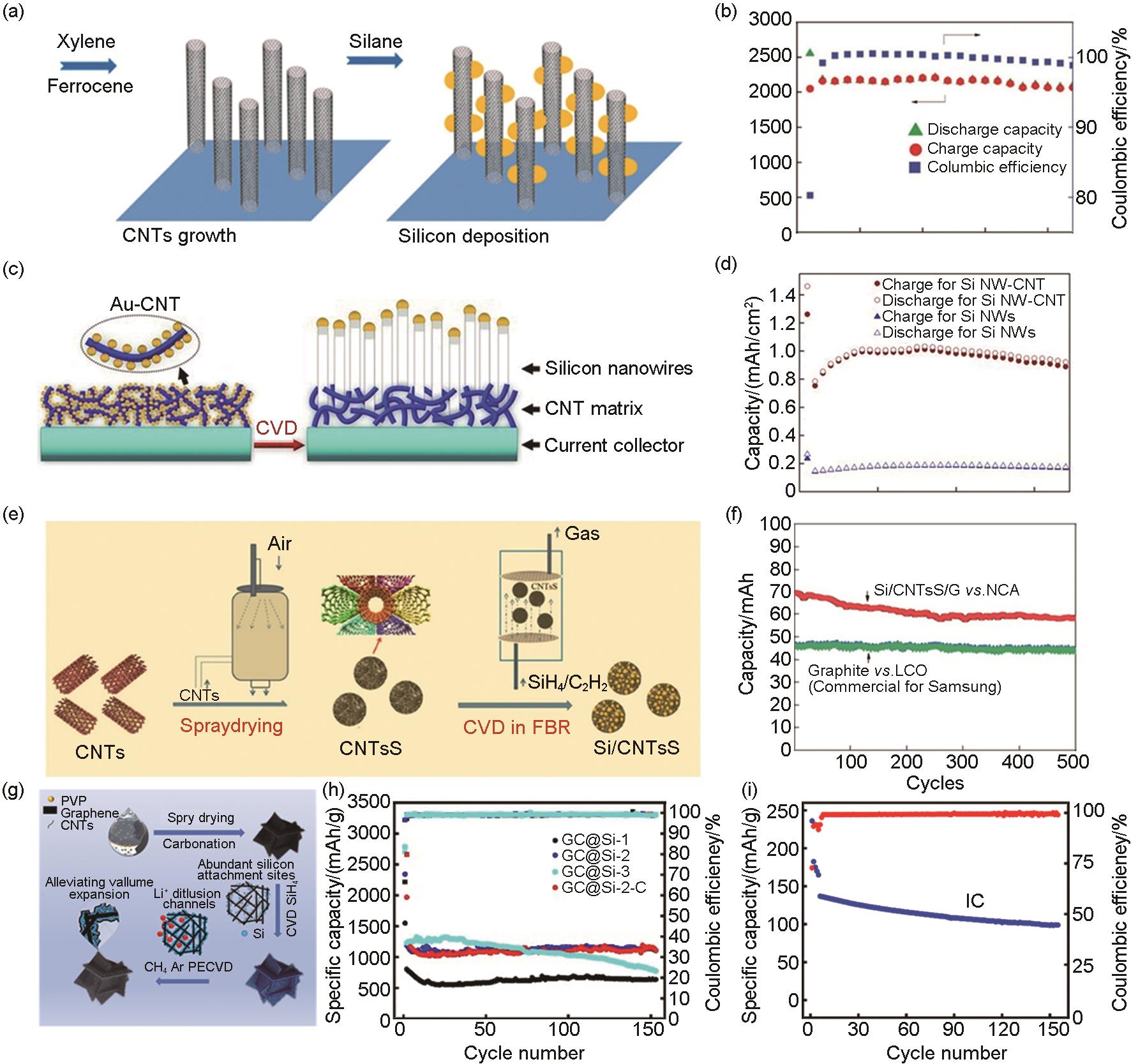

图 4

(a) 使用液体注入CVD生长垂直排列的碳纳米管,随后沉积硅以制备硅/碳纳米管混合纳米结构的示意图; (b) 25个循环的放电/充电容量和库仑效率图[21]; (c) 在集流体(不锈钢基板)上的碳纳米管(SiNW-CNT)阵列上制造硅纳米线阵列的示意图; (d) 比较了以Si NW-CNT和Si NWs作为工作电极的电池在第一圈以0.05 C (210 mA/g),其余圈以0.5 C (2100 mA/g)的恒定电流在0.02和1.5 V之间循环的面积容量[61]; (e) Si/CNTsS的制造工艺示意图; (f) 软包电池在0.5 C下的循环性能(Si/CNTsS/石墨 vs NCA和石墨 vs LCO)[62]; (g) 合成GC@Si-C微球的过程示意图; (h) 0.5 A/g时长循环性能; (i) GC@Si-2/G||NCM811全电池的1 C循环性能"

| [1] | STADIE N P, WANG S T, KRAVCHYK K V, et al. Zeolite-templated carbon as an ordered microporous electrode for aluminum batteries[J]. ACS Nano, 2017, 11(2): 1911-1919. DOI: 10.1021/acsnano.6b07995. |

| [2] | THACKERAY M M, WOLVERTON C, ISAACS E D. Electrical energy storage for transportation—Approaching the limits of, and going beyond, lithium-ion batteries[J]. Energy & Environmental Science, 2012, 5(7): 7854-7863. DOI: 10.1039/C2EE21892E. |

| [3] | SHARMA R A, SEEFURTH R N. Thermodynamic properties of the lithium-silicon system[J]. Journal of the Electrochemical Society, 1976, 123(12): 1763-1768. DOI: 10.1149/1.2132692. |

| [4] | TAO W, WANG P, YOU Y, et al. Strategies for improving the storage performance of silicon-based anodes in lithium-ion batteries[J]. Nano Research, 2019, 12(8): 1739-1749. DOI: 10. 1007/s12274-019-2361-4. |

| [5] | CHOI S, KWON T W, COSKUN A, et al. Highly elastic binders integrating polyrotaxanes for silicon microparticle anodes in lithium ion batteries[J]. Science, 2017, 357(6348): 279-283. DOI: 10.1126/science.aal4373. |

| [6] | WU H, CUI Y. Designing nanostructured Si anodes for high energy lithium ion batteries[J]. Nano Today, 2012, 7(5): 414-429. DOI: 10.1016/j.nantod.2012.08.004. |

| [7] | WANG C, WEN J C, LUO F, et al. Anisotropic expansion and size-dependent fracture of silicon nanotubes during lithiation[J]. Journal of Materials Chemistry A, 2019, 7(25): 15113-15122. DOI: 10.1039/C9TA00519F. |

| [8] | PAN H, WANG L, SHI Y, et al. A solid-state lithium-ion battery with micron-sized silicon anode operating free from external pressure[J]. Nature Communications, 2024, 15: 2263. DOI: 10. 1038/s41467-024-46472-9. |

| [9] | KANG W, ZHANG Q X, JIA Y F, et al. Enhancing the cycling stability of commercial silicon nanoparticles by carbon coating and thin layered single-walled carbon nanotube webbing[J]. Journal of Power Sources, 2024, 602: 234338. DOI: 10.1016/j.jpowsour.2024.234338. |

| [10] | 梁晓杜, 丁玉峰. 锂离子电池用硅基材料的研究进展[J]. 船电技术, 2024, 44(12): 87-91, 96. DOI: 10.13632/j.meee.2024.12.021. |

| LIANG X D, DING Y F. Research progress of silicon-based materials for lithium-ion batteries[J]. Marine Electric & Electronic Engineering, 2024, 44(12): 87-91, 96. DOI: 10.13632/j.meee. 2024. 12.021. | |

| [11] | 王娟, 张香兰. 锂离子电池硅碳负极材料的应用研究进展[J]. 化学工业与工程, 2024, 41(6): 75-90. DOI: 10.13353/j.issn. 1004. 9533. 20230508. |

| WANG J, ZHANG X L. Research progress on the application of silicon-carbon anode materials in lithium-ion batteries[J]. Chemical Industry and Engineering, 2024, 41(6): 75-90. DOI: 10. 13353/j.issn.1004.9533.20230508. | |

| [12] | LIU X H, ZHONG L, HUANG S, et al. Size-dependent fracture of silicon nanoparticles during lithiation[J]. ACS Nano, 2012, 6(2): 1522-1531. DOI: 10.1021/nn204476h. |

| [13] | KO M, CHAE S, JEONG S, et al. Elastic a-silicon nanoparticle backboned graphene hybrid as a self-compacting anode for high-rate lithium ion batteries[J]. ACS Nano, 2014, 8(8): 8591-8599. DOI: 10.1021/nn503294z. |

| [14] | AN Y L, TIAN Y, ZHANG Y C, et al. Two-dimensional silicon/carbon from commercial alloy and CO2 for lithium storage and flexible Ti3C2Tx MXene-based lithium-metal batteries[J]. ACS Nano, 2020, 14(12): 17574-17588. DOI: 10.1021/acsnano.0c08336. |

| [15] | LI Y Z, YAN K, LEE H W, et al. Growth of conformal graphene cages on micrometre-sized silicon particles as stable battery anodes[J]. Nature Energy, 2016, 1: 15029. DOI: 10.1038/nenergy. 2015.29. |

| [16] | ZHANG Z D, ZHOU H P, FENG T T, et al. A plasma strategy for high-quality Si/C composite anode: From tailoring the current collector to preparing the active materials[J]. Electrochimica Acta, 2020, 347: 136222. DOI: 10.1016/j.electacta.2020.136222. |

| [17] | ZHANG Z D, ZHOU H P, XUE W D, et al. Nitrogen-plasma doping of carbon film for a high-quality layered Si/C composite anode[J]. Journal of Colloid and Interface Science, 2022, 605: 463-471. DOI: 10.1016/j.jcis.2021.06.147. |

| [18] | LI X H, WU M Q, FENG T T, et al. Graphene enhanced silicon/carbon composite as anode for high performance lithium-ion batteries[J]. RSC Advances, 2017, 7(76): 48286-48293. DOI: 10. 1039/C7RA09818A. |

| [19] | QIN J G, WU M Q, FENG T T, et al. High rate capability and long cycling life of graphene-coated silicon composite anodes for lithium ion batteries[J]. Electrochimica Acta, 2017, 256: 259-266. DOI: 10.1016/j.electacta.2017.10.022. |

| [20] | WANG R, CAO J W, XU C Y, et al. Low-temperature electrolytes based on linear carboxylic ester co-solvents for SiOx/graphite composite anodes[J]. RSC Advances, 2023, 13(20): 13365-13373. DOI: 10.1039/D3RA01111A. |

| [21] | WANG W, KUMTA P N. Nanostructured hybrid silicon/carbon nanotube heterostructures: Reversible high-capacity lithium-ion anodes[J]. ACS Nano, 2010, 4(4): 2233-2241. DOI: 10.1021/nn901632g. |

| [22] | TAO H C, XIONG L Y, ZHU S C, et al. Porous Si/C/reduced graphene oxide microspheres by spray drying as anode for Li-ion batteries[J]. Journal of Electroanalytical Chemistry, 2017, 797: 16-22. DOI: 10.1016/j.jelechem.2017.05.010. |

| [23] | ZHANG J Q, CHEN Y F, CHEN X Q, et al. Preparation of graphene-like carbon attached porous silicon anode by magnesiothermic and nickel-catalyzed reduction reactions[J]. Ionics, 2020, 26(12): 5941-5950. DOI: 10.1007/s11581-020-03746-8. |

| [24] | CABELLO M, GUCCIARDI E, HERRÁN A, et al. Towards a high-power Si@graphite anode for lithium ion batteries through a wet ball milling process[J]. Molecules, 2020, 25(11): 2494. DOI: 10. 3390/molecules25112494. |

| [25] | WAN W W, MAI Y, GUO D, et al. A novel Sol-gel process to encapsulate micron silicon with a uniformly Ni-doped graphite carbon layer by coupling for use in lithium ion batteries[J]. Synthetic Metals, 2021, 274: 116717. DOI: 10.1016/j.synthmet. 2021.116717. |

| [26] | GE M Y, LU Y H, ERCIUS P, et al. Large-scale fabrication, 3D tomography, and lithium-ion battery application of porous silicon[J]. Nano Letters, 2014, 14(1): 261-268. DOI: 10.1021/nl403923s. |

| [27] | CHO G B, CHOI S Y, NOH J P, et al. Dependence of milling time on electrochemical properties of nano Si electrodes prepared by ball-milling[J]. Journal of Nanoscience and Nanotechnology, 2011, 11(7): 6262-6265. DOI: 10.1166/jnn.2011.4332. |

| [28] | LI Z J, DU M J, GUO X, et al. Research progress of SiOx-based anode materials for lithium-ion batteries[J]. Chemical Engineering Journal, 2023, 473: 145294. DOI: 10.1016/j.cej.2023.145294. |

| [29] | WU J X, DONG Q W, ZHANG Q, et al. Fundamental understanding of the low initial coulombic efficiency in SiOx anode for lithium-ion batteries: Mechanisms and solutions[J]. Advanced Materials, 2024, 36(33): 2405751. DOI: 10.1002/adma. 202405751. |

| [30] | ZHOU H P, YANG B, ZHANG Z D, et al. Fastly PECVD-Grown vertical carbon nanosheets for a composite SiOx-C anode material[J]. Applied Surface Science, 2022, 605: 154627. DOI: 10.1016/j.apsusc.2022.154627. |

| [31] | ZHOU H, ZHOU H P, YANG B, et al. Carbon nano-Onions/tubes catalyzed by Ni nanoparticles on SiOx for superior lithium storage[J]. Applied Surface Science, 2023, 640: 158355. DOI: 10.1016/j.apsusc.2023.158355. |

| [32] | ZHOU H, YANG B, ZHOU H P, et al. Carbon shells and carbon nanotubes jointly modified SiOx anodes for superior lithium storage[J]. ACS Applied Energy Materials, 2024, 7(22): 10307-10316. DOI: 10.1021/acsaem.4c01513. |

| [33] | YUE H C, ZHANG S, FENG T T, et al. Understanding of the mechanism enables controllable chemical prelithiation of anode materials for lithium-ion batteries[J]. ACS Applied Materials & Interfaces, 2021, 13(45): 53996-54004. DOI: 10.1021/acsami. 1c16842. |

| [34] | LI H D, LI H Y, LAI Y Z, et al. Revisiting the preparation progress of nano-structured Si anodes toward industrial application from the perspective of cost and scalability[J]. Advanced Energy Materials, 2022, 12(7): 2102181. DOI: 10.1002/aenm.202102181. |

| [35] | 涂志强, 侯果林, 林伟国, 等. 锂离子电池硅碳负极材料应用前景光明[J]. 中国石化, 2024(4): 42-45. |

| TU Z Q, HOU G L, LIN W G, et al. Silicon-carbon anode materials for lithium ion batteries have bright application prospects[J]. Sinopec Monthly, 2024(4): 42-45. | |

| [36] | 蒋运才, 曹昌蝶, 刘岚君, 等. 化学气相沉积法制备二维材料研究进展[J]. 化工新型材料, 2021, 49(11): 59-62. DOI: 10.19817/j.cnki.issn1006-3536.2021.11.013. |

| JIANG Y C, CAO C D, LIU L J, et al. Research progress on 2D material prepared by chemical vapor deposition[J]. New Chemical Materials, 2021, 49(11): 59-62. DOI: 10.19817/j.cnki.issn1006-3536.2021.11.013. | |

| [37] | ZHANG T, FU L. Controllable chemical vapor deposition growth of two-dimensional heterostructures[J]. Chem, 2018, 4(4): 671-689. DOI: 10.1016/j.chempr.2017.12.006. |

| [38] | LIU X, CAO L Z, GUO Z, et al. A review of perovskite photovoltaic materials' synthesis and applications via chemical vapor deposition method[J]. Materials, 2019, 12(20): 3304. DOI: 10. 3390/ma12203304. |

| [39] | WILSON A M, DAHN J R. Lithium insertion in carbons containing nanodispersed silicon[J]. Journal of the Electrochemical Society, 1995, 142(2): 326-332. DOI: 10.1149/1.2043994. |

| [40] | LIU B, HUANG P, XIE Z Y, et al. Large-scale production of a silicon nanowire/graphite composites anode via the CVD method for high-performance lithium-ion batteries[J]. Energy & Fuels, 2021, 35(3): 2758-2765. DOI: 10.1021/acs.energyfuels.0c03725. |

| [41] | ZHANG X Y, HAYASHIDA R, TANAKA M, et al. Synthesis of carbon-coated silicon nanoparticles by induction thermal plasma for lithium ion battery[J]. Powder Technology, 2020, 371: 26-36. DOI: 10.1016/j.powtec.2020.05.084. |

| [42] | PARK S W, HA J H, CHO B W, et al. Designing of high capacity Si nanosheets anode electrodes for lithium batteries[J]. Surface and Coatings Technology, 2021, 421: 127358. DOI: 10.1016/j.surfcoat.2021.127358. |

| [43] | QI C L, LI S P, YANG Z P, et al. Suitable thickness of carbon coating layers for silicon anode[J]. Carbon, 2022, 186: 530-538. DOI: 10.1016/j.carbon.2021.10.062. |

| [44] | HAN J, TANG X N, GE S F, et al. Si/C particles on graphene sheet as stable anode for lithium-ion batteries[J]. Journal of Materials Science & Technology, 2021, 80: 259-265. DOI: 10. 1016/j.jmst.2020.11.054. |

| [45] | SU H P, LI X R, LIU C W, et al. Scalable synthesis of micrometer-sized porous silicon/carbon composites for high-stability lithium-ion battery anodes[J]. Chemical Engineering Journal, 2023, 451: 138394. DOI: 10.1016/j.cej.2022.138394. |

| [46] | ŁACH Ł, SVYETLICHNYY D. Recent progress in heat and mass transfer modeling for chemical vapor deposition processes[J]. Energies, 2024, 17(13): 3267. DOI: 10.3390/en17133267. |

| [47] | CHAE S, CHOI S H, KIM N, et al. Integration of graphite and silicon anodes for the commercialization of high-energy lithium-ion batteries[J]. Angewandte Chemie International Edition, 2020, 59(1): 110-135. DOI: 10.1002/anie.201902085. |

| [48] | LI P, KIM H, MYUNG S T, et al. Diverting exploration of silicon anode into practical way: A review focused on silicon-graphite composite for lithium ion batteries[J]. Energy Storage Materials, 2021, 35: 550-576. DOI: 10.1016/j.ensm.2020.11.028. |

| [49] | WETJEN M, PRITZL D, JUNG R, et al. Differentiating the degradation phenomena in silicon-graphite electrodes for lithium-ion batteries[J]. Journal of the Electrochemical Society, 2017, 164(12): A2840-A2852. DOI: 10.1149/2.1921712jes. |

| [50] | YAN Z L, YI S, LI X D, et al. A scalable silicon/graphite anode with high silicon content for high-energy lithium-ion batteries[J]. Materials Today Energy, 2023, 31: 101225. DOI: 10.1016/j.mtener. 2022.101225. |

| [51] | ZHANG Y, JIANG Y Z, LI Y D, et al. Preparation of nanographite sheets supported Si nanoparticles by in situ reduction of fumed SiO2 with magnesium for lithium ion battery[J]. Journal of Power Sources, 2015, 281: 425-431. DOI: 10.1016/j.jpowsour. 2015. 02.020. |

| [52] | HOLZAPFEL M, BUQA H, SCHEIFELE W, et al. A new type of nano-sized silicon/carbon composite electrode for reversible lithium insertion[J]. Chemical Communications, 2005(12): 1566-1568. DOI: 10.1039/B417492E. |

| [53] | KO M, CHAE S, MA J, et al. Scalable synthesis of silicon-nanolayer-embedded graphite for high-energy lithium-ion batteries[J]. Nature Energy, 2016, 1: 16113. DOI: 10.1038/nenergy.2016.113. |

| [54] | ZHU S J, LIN Y F, YAN Z L, et al. Novel design of uniform Si@graphite@C composite as high-performance Li-ion battery anodes[J]. Electrochimica Acta, 2021, 377: 138092. DOI: 10. 1016/j.electacta.2021.138092. |

| [55] | WANG F L, CHEN G, ZHANG N, et al. Engineering of carbon and other protective coating layers for stabilizing silicon anode materials[J]. Carbon Energy, 2019, 1(2): 219-245. DOI: 10.1002/cey2.24. |

| [56] | LI P, HWANG J Y, SUN Y K. Nano/microstructured silicon-graphite composite anode for high-energy-density Li-ion battery[J]. ACS Nano, 2019, 13(2): 2624-2633. DOI: 10.1021/acsnano. 9b00169. |

| [57] | NAZARIAN-SAMANI M, NAZARIAN-SAMANI M, HAGHIGHAT-SHISHAVAN S, et al. Efficient stress alleviation and interface regulation in Cu4SiP8-CNT hybrid for ultra-durable Li and Na storage[J]. Nano Energy, 2021, 86: 106134. DOI: 10.1016/j.nanoen.2021.106134. |

| [58] | SCHULZE M C, BELSON R M, KRAYNAK L A, et al. Electrodeposition of Sb/CNT composite films as anodes for Li- and Na-ion batteries[J]. Energy Storage Materials, 2020, 25: 572-584. DOI: 10.1016/j.ensm.2019.09.025. |

| [59] | NGUYEN T, SU Y S. A self-assembled carbon nanotube/silicon composite battery anode stabilized with chemically reduced graphene oxide sheets[J]. Materials & Design, 2024, 240: 112861. DOI: 10.1016/j.matdes.2024.112861. |

| [60] | WANG S Z, LIAO J X, WU M Q, et al. High rate and long cycle life of a CNT/rGO/Si nanoparticle composite anode for lithium-ion batteries[J]. Particle & Particle Systems Characterization, 2017, 34(10): 1700141. DOI: 10.1002/ppsc.201700141. |

| [61] | LI X L, CHO J H, LI N, et al. Carbon nanotube-enhanced growth of silicon nanowires as an anode for high-performance lithium-ion batteries[J]. Advanced Energy Materials, 2012, 2(1): 87-93. DOI: 10.1002/aenm.201100519. |

| [62] | ZHAO H, TU N, ZHANG W B, et al. Novel synthesis of silicon/carbon nanotubes microspheres as anode additives through chemical vapor deposition in fluidized bed reactors[J]. Scripta Materialia, 2021, 192: 49-54. DOI: 10.1016/j.scriptamat. 2020. 09.048. |

| [63] | LIU C, ZHOU H P, ZHOU H, et al. Highly Si loading on three-dimensional carbon skeleton via CVD method for a stable SiC composite anode[J]. Journal of Energy Storage, 2025, 116: 116083. DOI: 10.1016/j.est.2025.116083. |

| [64] | LI K X, CHEN W, YANG H P, et al. Mechanism of biomass activation and ammonia modification for nitrogen-doped porous carbon materials[J]. Bioresource Technology, 2019, 280: 260-268. DOI: 10.1016/j.biortech.2019.02.039. |

| [65] | XU X T, MU X, HUANG T, et al. Robust silicon/carbon composite anode materials with high tap density and excellent cycling performance for lithium-ion batteries[J]. Journal of Power Sources, 2024, 614: 234992. DOI: 10.1016/j.jpowsour. 2024. 234992. |

| [66] | KIM K N, KANG S C, SEO S W, et al. Effects of macrostructure of carbon support in preparation of C/Six/C anode materials for lithium-ion batteries via silane decomposition[J]. Carbon Letters, 2024, 34(9): 2305-2316. DOI: 10.1007/s42823-024-00756-8. |

| [67] | SCHÄUFELE R S, VAZQUEZ-PUFLEAU M, PENDASHTEH A, et al. Controlling reaction paths for ultra-fast growth of inorganic nanowires floating in the gas phase[J]. Nanoscale, 2022, 14(1): 55-64. DOI: 10.1039/D1NR07261G. |

| [68] | XIAO Y M, YI S, YAN Z L, et al. Benchmarking the match of porous carbon substrate pore volume on silicon anode materials for lithium-ion batteries[J]. Small, 2024, 20(45): 2404440. DOI: 10.1002/smll.202404440. |

| [69] | HU M F, WU H Z, ZHANG G J. High-performance silicon/graphite anode prepared by CVD using SiCl4 as precursor for Li-ion batteries[J]. Chemical Physics Letters, 2023, 833: 140917. DOI: 10.1016/j.cplett.2023.140917. |

| [70] | HUANG P, LIU B, ZHANG J L, et al. Silicon/carbon composites based on natural microcrystalline graphite as anode for lithium-ion batteries[J]. Ionics, 2021, 27(5): 1957-1966. DOI: 10.1007/s11581-021-03977-3. |

| [71] | WOLF H, PAJKIC Z, GERDES T, et al. Carbon-fiber-silicon-nanocomposites for lithium-ion battery anodes by microwave plasma chemical vapor deposition[J]. Journal of Power Sources, 2009, 190(1): 157-161. DOI: 10.1016/j.jpowsour.2008.07.035. |

| [72] | CHEN Z D, SOLTANI A, CHEN Y G, et al. Emerging organic surface chemistry for Si anodes in lithium-ion batteries: Advances, prospects, and beyond[J]. Advanced Energy Materials, 2022, 12(32): 2200924. DOI: 10.1002/aenm. 202200924. |

| [73] | WILSON A M, WAY B M, DAHN J R, et al. Nanodispersed silicon in pregraphitic carbons[J]. Journal of Applied Physics, 1995, 77(6): 2363-2369. DOI: 10.1063/1.358759. |

| [74] | MAGASINSKI A, DIXON P, HERTZBERG B, et al. High-performance lithium-ion anodes using a hierarchical bottom-up approach[J]. Nature Materials, 2010, 9(4): 353-358. DOI: 10. 1038/nmat2725. |

| [75] | FORNEY M W, DILEO R A, RAISANEN A, et al. High performance silicon free-standing anodes fabricated by low-pressure and plasma-enhanced chemical vapor deposition onto carbon nanotube electrodes[J]. Journal of Power Sources, 2013, 228: 270-280. DOI: 10.1016/j.jpowsour.2012.11.109. |

| [76] | SUNG J, KIM N, MA J, et al. Subnano-sized silicon anode via crystal growth inhibition mechanism and its application in a prototype battery pack[J]. Nature Energy, 2021, 6(12): 1164-1175. DOI: 10.1038/s41560-021-00945-z. |

| [77] | HAN Z N, WILD J F, CHEN J J, et al. Modeling silane deposition in nanoporous carbon for high-capacity Si/C composite anodes[J]. Energy Material Advances, 2024, 5: 111. DOI: 10.34133/energymatadv.0111. |

| [78] | ZHAN X, LI M, LI S, et al. Challenges and opportunities towards silicon-based all-solid-state batteries[J]. Energy Storage Materials, 2023, 61: 102875. DOI: 10.1016/j.ensm.2023.102875. |

| [79] | HUO H Y, JANEK J. Silicon as emerging anode in solid-state batteries[J]. ACS Energy Letters, 2022, 7(11): 4005-4016. DOI: 10.1021/acsenergylett.2c01950. |

| [80] | LI J C, DOZIER A K, LI Y C, et al. Crack pattern formation in thin film lithium-ion battery electrodes[J]. Journal of the Electrochemical Society, 2011, 158(6): A689. DOI: 10.1149/1.3574027. |

| [81] | ZHOU M, LI X L, WANG B, et al. High-performance silicon battery anodes enabled by engineering graphene assemblies[J]. Nano Letters, 2015, 15(9): 6222-6228. DOI: 10.1021/acs.nanolett. 5b02697. |

| [82] | FERRARESI G, EL KAZZI M, CZORNOMAZ L, et al. Electrochemical performance of all-solid-state Li-ion batteries based on garnet electrolyte using silicon as a model electrode[J]. ACS Energy Letters, 2018, 3(4): 1006-1012. DOI: 10.1021/acsenergylett.8b00264. |

| [83] | CHEN C, LI Q, LI Y Q, et al. Sustainable interfaces between Si anodes and garnet electrolytes for room-temperature solid-state batteries[J]. ACS Applied Materials & Interfaces, 2018, 10(2): 2185-2190. DOI: 10.1021/acsami.7b16385. |

| [84] | PING W W, YANG C P, BAO Y H, et al. A silicon anode for garnet-based all-solid-state batteries: Interfaces and nanomechanics[J]. Energy Storage Materials, 2019, 21: 246-252. DOI: 10.1016/j.ensm. 2019.06.024. |

| [1] | 谈秀雯, 李凌. 局部过热下锂电池热失控特性及其热管理研究[J]. 储能科学与技术, 2025, 14(9): 3521-3529. |

| [2] | 陈峥, 胡竞元, 赵志刚, 申江卫, 夏雪磊, 魏福星. 双体系混装电池组热特性研究及风冷散热结构优化[J]. 储能科学与技术, 2025, 14(9): 3463-3475. |

| [3] | 陈文艳, 贺瑞璘, 常建, 邓永红. 不同形态液态金属电极的储锂机制研究[J]. 储能科学与技术, 2025, 14(9): 3290-3300. |

| [4] | 赵岩, 刘浩, 易宗琳, 李莉, 谢莉婧, 苏方远. FEC与VC在锂离子电池石墨负极界面行为研究[J]. 储能科学与技术, 2025, 14(9): 3249-3258. |

| [5] | 林季锦, 刘倩, 曲涛, 李京鲲, 黄东永, 朱晓庆, 巨星. 锂离子电池储能系统浸没液冷的技术经济性分析[J]. 储能科学与技术, 2025, 14(9): 3622-3635. |

| [6] | 封居强, 张成知, 陈雨杭. 基于数字孪生的高精度SOC和温度联合估计方法[J]. 储能科学与技术, 2025, 14(9): 3567-3580. |

| [7] | 白晓宇, 筵亚静, 张志荣, 孔令丽. 复合石墨锂离子电池性能研究[J]. 储能科学与技术, 2025, 14(9): 3259-3268. |

| [8] | 张磊. 锂离子电池储能电站的运行状态监测与评估[J]. 储能科学与技术, 2025, 14(9): 3538-3540. |

| [9] | 包新宇, 孔祥栋, 吕桃林, 朱志成, 韩雪冰, 来鑫, 郑岳久, 孙涛. 基于产线大数据的电池内阻预测及快速分选方法[J]. 储能科学与技术, 2025, 14(9): 3541-3551. |

| [10] | 杨斌, 杨军, 徐浪, 温浩伟, 刘登锋, 阮殿波. 电容型锂离子电池的球头压痕对其安全性研究[J]. 储能科学与技术, 2025, 14(8): 3090-3099. |

| [11] | 张腾, 常国峰. 基于单体特征参数差异的电池组热特性和热一致性研究[J]. 储能科学与技术, 2025, 14(8): 3194-3206. |

| [12] | 高蕾, 顾洪汇, 张益明, 黄伟, 陆海燕, 周琳, 顾梅嵘. 超高功率锂离子电池脉冲性能研究[J]. 储能科学与技术, 2025, 14(8): 2942-2949. |

| [13] | 徐成善, 孙烨, 杨智凯, 赵明强, 李亚伦, 冯旭宁, 王贺武, 卢兰光, 欧阳明高. 储能锂离子电池系统热失控诱发电弧研究进展[J]. 储能科学与技术, 2025, 14(8): 3037-3050. |

| [14] | 李鹏举, 陈晓宇, 谢佳, 沈佳妮, 贺益君. 锂离子电池功率状态预测方法研究进展[J]. 储能科学与技术, 2025, 14(8): 3028-3036. |

| [15] | 胡力月, 黄威, 周云, 周英强, 邵常政, 王柯. 基于模糊推理的储能系统锂离子电池模组热扩散概率评估方法[J]. 储能科学与技术, 2025, 14(7): 2662-2674. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||