Energy Storage Science and Technology ›› 2025, Vol. 14 ›› Issue (1): 90-103.doi: 10.19799/j.cnki.2095-4239.2024.0574

• Energy Storage Materials and Devices • Previous Articles Next Articles

Wei CAO1( ), Fei CHEN1, Xiangdong KONG2, Zhicheng ZHU1, Xuebing HAN3(

), Fei CHEN1, Xiangdong KONG2, Zhicheng ZHU1, Xuebing HAN3( ), Languang LU3, Yuejiu ZHENG1(

), Languang LU3, Yuejiu ZHENG1( )

)

Received:2024-06-23

Revised:2024-07-23

Online:2025-01-28

Published:2025-02-25

Contact:

Xuebing HAN, Yuejiu ZHENG

E-mail:caowei6790@163.com;hanxuebing@mail.tsinghua.edu.cn;yuejiu_zheng@163.com

CLC Number:

Wei CAO, Fei CHEN, Xiangdong KONG, Zhicheng ZHU, Xuebing HAN, Languang LU, Yuejiu ZHENG. Progress of coating process for lithium-ion battery electrodes[J]. Energy Storage Science and Technology, 2025, 14(1): 90-103.

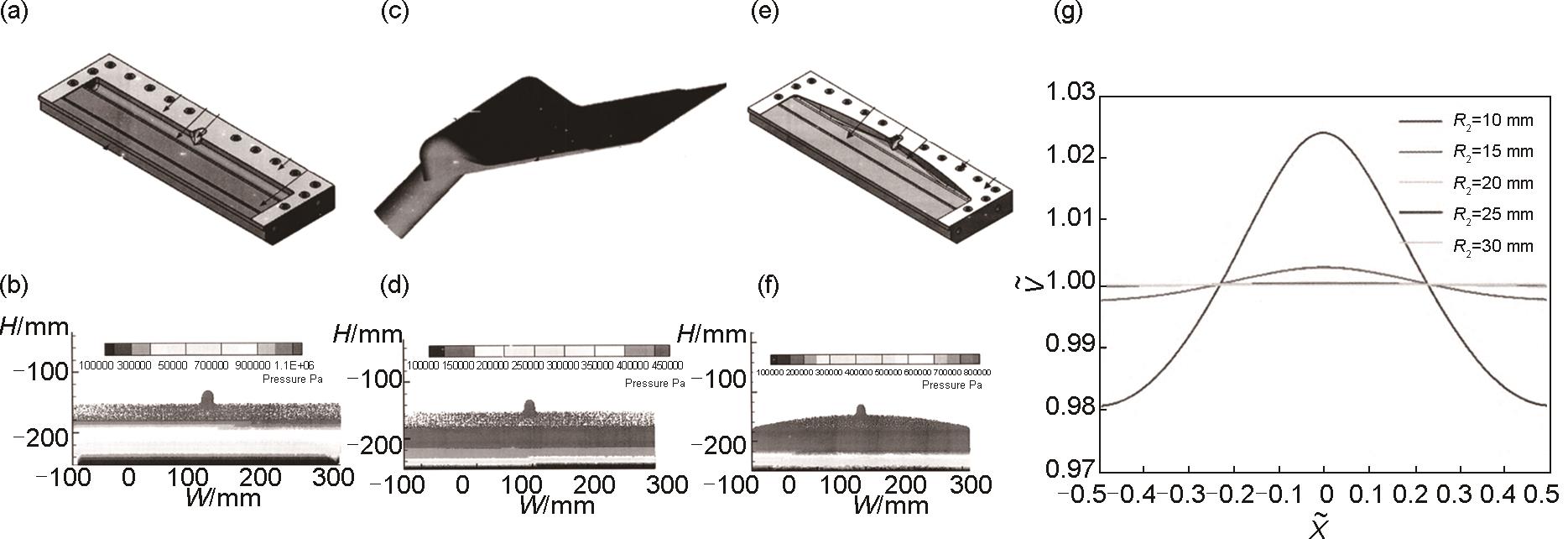

Fig. 8

(a) Dual chamber[27]; (b) Gradient chamber[27]; (c) Hanger type chamber[27]; (d) Cloud view of pressure distribution in dual chamber[27]; (e) Gradient cavity pressure distribution cloud[27]; (f) Hanger type chamber pressure distribution cloud[27]; (g) Velocity distribution for different cavity sizes[39]"

| 1 | STEINSTRAETER M, BUBERGER J, MINNERUP K, et al. Controlling cabin heating to improve range and battery lifetime of electric vehicles[J]. eTransportation, 2022, 13: 100181. DOI: 10.1016/j.etran.2022.100181. |

| 2 | LIU H R, ZHAO M L, BAI X D, et al. An ultrafast rechargeable and high durability lithium metal battery using composite electrolyte with the three-dimensional inorganic framework by Li6.4La3Zr1.4Ta0.6O12 surface functionalization[J]. eTransportation, 2023, 16: 100234. DOI: 10.1016/j.etran.2023.100234. |

| 3 | LAI X, CHEN Q W, TANG X P, et al. Critical review of life cycle assessment of lithium-ion batteries for electric vehicles: A lifespan perspective[J]. eTransportation, 2022, 12: 100169. DOI: 10.1016/j.etran.2022.100169. |

| 4 | GUO S Q, WANG Y B, DAI L, et al. All-electric ship operations and management: Overview and future research directions[J]. eTransportation, 2023, 17: 100251. DOI: 10.1016/j.etran. 2023.100251. |

| 5 | LAI X, GU H H, CHEN Q W, et al. Investigating greenhouse gas emissions and environmental impacts from the production of lithium-ion batteries in China[J]. Journal of Cleaner Production, 2022, 372: 133756. DOI: 10.1016/j.jclepro.2022.133756. |

| 6 | SHARMILI N, NAGI R, WANG P F. A review of research in the Li-ion battery production and reverse supply chains[J]. Journal of Energy Storage, 2023, 68: 107622. DOI: 10.1016/j.est. 2023.107622. |

| 7 | MAULER L, DUFFNER F, LEKER J. Economies of scale in battery cell manufacturing: The impact of material and process innovations[J]. Applied Energy, 2021, 286: 116499. DOI: 10.1016/j.apenergy.2021.116499. |

| 8 | 陈飞, 孔祥栋, 孙跃东, 等. 锂离子电池制造工艺仿真技术进展[J]. 汽车工程, 2023, 45(9): 1516-1529, 1542. DOI: 10.19562/j.chinasae.qcgc.2023.09.002. |

| CHEN F, KONG X D, SUN Y D, et al. Progress in simulation technology of lithium-ion battery manufacturing process[J]. Automotive Engineering, 2023, 45(9): 1516-1529, 1542. DOI: 10.19562/j.chinasae.qcgc.2023.09.002. | |

| 9 | GOODENOUGH J B. How we made the Li-ion rechargeable battery[J]. Nature Electronics, 2018, 1: 204. DOI: 10.1038/s41928-018-0048-6. |

| 10 | 罗雨. 动力锂离子电池制备工艺对一致性影响研究[D]. 长沙: 湖南大学, 2012. |

| LUO Y. Study on the influence of preparation technology of power lithium ion battery on consistency[D]. Changsha: Hunan University, 2012. | |

| 11 | MOHANTY D, HOCKADAY E, LI J, et al. Effect of electrode manufacturing defects on electrochemical performance of lithium-ion batteries: Cognizance of the battery failure sources[J]. Journal of Power Sources, 2016, 312: 70-79. DOI: 10.1016/j.jpowsour.2016.02.007. |

| 12 | ZHENG H H, LI J, SONG X Y, et al. A comprehensive understanding of electrode thickness effects on the electrochemical performances of Li-ion battery cathodes[J]. Electrochimica Acta, 2012, 71: 258-265. DOI: 10.1016/j.electacta. 2012.03.161. |

| 13 | SONG Y Z, WANG X Q, CUI H, et al. Probing the particle size dependence of nonhomogeneous degradation in nickel-rich cathodes for high-energy lithium-ion batteries[J]. eTransportation, 2023, 16: 100223. DOI: 10.1016/j.etran.2022.100223. |

| 14 | SUN Y K, YUAN Y B, LU L G, et al. A comprehensive research on internal short circuits caused by copper particle contaminants on cathode in lithium-ion batteries[J]. eTransportation, 2022, 13: 100183. DOI: 10.1016/j.etran.2022.100183. |

| 15 | YAN B, LIM C, SONG Z B, et al. Analysis of polarization in realistic Li ion battery electrode microstructure using numerical simulation[J]. Electrochimica Acta, 2015, 185: 125-141. DOI: 10.1016/j.electacta.2015.10.086. |

| 16 | SAMYN P, SCHOUKENS G, VAN DEN ABBEELE H, et al. Application of polymer nanoparticle coating for tuning the hydrophobicity of cellulosic substrates[J]. Journal of Coatings Technology and Research, 2011, 8(3): 363-373. DOI: 10.1007/s11998-010-9309-7. |

| 17 | 谢小英. 精密涂布技术的发展状况[J]. 影像技术, 2017, 29(1): 4-7. DOI: 10.3969/j.issn.1001-0270.2017.01.01. |

| XIE X Y. The development of precision coating technology[J]. Image Technology, 2017, 29(1): 4-7. DOI: 10.3969/j.issn.1001-0270.2017.01.01. | |

| 18 | 胡焱清, 李子繁, 孙红旗. 耐水改性聚乙烯醇涂布膜的研究进展及发展前景[J]. 包装工程, 2010, 31(1): 108-110, 114. DOI: 10.19554/j.cnki.1001-3563.2010.01.032. |

| HU Y Q, LI Z F, SUN H Q. Research progress and development prospects of water resistant modified PVA coated films[J]. Packaging Engineering, 2010, 31(1): 108-110, 114. DOI: 10. 19554/j.cnki.1001-3563.2010.01.032. | |

| 19 | 秦睿睿, 许文才, 陈邦设, 等. 涂布技术研究进展[J]. 包装工程, 2012, 33(3): 132-136. DOI: 10.19554/j.cnki.1001-3563.2012.03.032. |

| QIN R R, XU W C, CHEN B S, et al. Progress of coating technology[J]. Packaging Engineering, 2012, 33(3): 132-136. DOI: 10.19554/j.cnki.1001-3563.2012.03.032. | |

| 20 | 赵伯元. 锂离子电池极片涂布技术和设备研究[J]. 电池, 2000, 30(2): 56-58. DOI: 10.3969/j.issn.1001-1579.2000.02.003. |

| ZHAO B Y. Coating technology and equipment for lithium ion electrodes[J]. Battery Bimonthly, 2000, 30(2): 56-58. DOI: 10.3969/j.issn.1001-1579.2000.02.003. | |

| 21 | CHEN F, CHEN T X, WU Z X, et al. Optimizing lithium-ion battery electrode manufacturing: Advances and prospects in process simulation[J]. Journal of Power Sources, 2024, 610: 234717. DOI: 10.1016/j.jpowsour.2024.234717. |

| 22 | COYLE D J, MACOSKO C W, SCRIVEN L E. Film-splitting flows in forward roll coating[J]. Journal of Fluid Mechanics, 1986, 171: 183. DOI: 10.1017/s0022112086001416. |

| 23 | 梁卫华, 吴大勇, 舒均国. 逗号刮刀涂布流场理论分析与数值模拟[J]. 储能科学与技术, 2021, 10(2): 565-576. DOI: 10.19799/j.cnki.2095-4239.2020.0364. |

| LIANG W H, WU D Y, SHU J G. Theoretical analysis and numerical simulation of comma roll coating flow field[J]. Energy Storage Science and Technology, 2021, 10(2): 565-576. DOI: 10.19799/j.cnki.2095-4239.2020.0364. | |

| 24 | KREBS F C. Fabrication and processing of polymer solar cells: A review of printing and coating techniques[J]. Solar Energy Materials and Solar Cells, 2009, 93(4): 394-412. DOI: 10.1016/j.solmat.2008.10.004. |

| 25 | 林黎明. 动力锂电池浆料狭缝式挤压涂布流场数值模拟研究[D]. 郑州: 郑州大学, 2021. DOI: 10.27466/d.cnki.gzzdu.2021.003690. |

| LIN L M. Numerical simulation of flow field in slit extrusion coating of power lithium battery slurry[D]. Zhengzhou: Zhengzhou University, 2021. DOI: 10.27466/d.cnki.gzzdu.2021.003690. | |

| 26 | 包能胜, 刘小山, 马婉, 等. 辊式涂布两辊间隙施涂过程的数值计算分析[J]. 包装工程, 2016, 37(23): 6-12. DOI: 10.19554/j.cnki.1001-3563.2016.23.002. |

| BAO N S, LIU X S, MA W, et al. Numerical calculation and analysis on roll coating process of the clearance between two rollers[J]. Packaging Engineering, 2016, 37(23): 6-12. DOI: 10.19554/j.cnki.1001-3563.2016.23.002. | |

| 27 | 周芸福. 动力锂电池极片挤压式涂布机头研究[D]. 南京: 东南大学, 2014. |

| ZHOU Y F. Research on lithium power battery pole piece extrusion coating head [D]. Nanjing: Southeast University, 2014. | |

| 28 | 古日明. 一种涂布机构: CN209597537U[P]. 2019-11-08. |

| GU R M. A coating mechanism: CN2095975370 [P]. 2019-11-08. | |

| 29 | 迟彩霞, 张双虎, 乔秀丽, 等. 狭缝式涂布技术的研究进展[J]. 应用化工, 2016, 45(2): 360-363, 366. DOI: 10.16581/j.cnki.issn1671-3206.20151224.019. |

| CHI C X, ZHANG S H, QIAO X L, et al. Research progress on slot-die coating technology[J]. Applied Chemical Industry, 2016, 45(2): 360-363, 366. DOI: 10.16581/j.cnki.issn1671-3206.20151224.019. | |

| 30 | KIM S, LEE J, LEE C. Computational fluid dynamics model for thickness and uniformity prediction of coating layer in slot-die process[J]. The International Journal of Advanced Manufacturing Technology, 2019, 104(5): 2991-2997. DOI: 10.1007/s00170-019-04093-3. |

| 31 | HAN G H, LEE S H, AHN W G, et al. Effect of shim configuration on flow dynamics and operability windows in stripe slot coating process[J]. Journal of Coatings Technology and Research, 2014, 11(1): 19-29. DOI: 10.1007/s11998-013-9485-3. |

| 32 | JIN G L, AHN W G, KIM S J, et al. Effect of shim configuration on internal die flows for non-Newtonian coating liquids in slot coating process[J]. Korea-Australia Rheology Journal, 2016, 28(2): 159-164. DOI: 10.1007/s13367-016-0015-6. |

| 33 | CHANG H M, CHANG Y R, LIN C F, et al. Comparison of vertical and horizontal slot die coatings[J]. Polymer Engineering & Science, 2007, 47(11): 1927-1936. DOI: 10.1002/pen.20910. |

| 34 | 董骄, 曹勇, 苏峰, 等. 一种锂离子电池双面涂布装置: CN216225137U[P]. 2022-04-08. |

| 35 | 陈晚成. 电池极片双面同时涂布的设备: CN217222194U[P]. 2022-08-19. |

| 36 | LOMBARDO T, DUQUESNOY M, EL-BOUYSIDY H, et al. Artificial intelligence applied to battery research: Hype or reality?[J]. Chemical Reviews, 2022, 122(12): 10899-10969. DOI: 10.1021/acs.chemrev.1c00108. |

| 37 | 白自艳. 涂布机的挤压模头研究和供料远程监控系统开发[D]. 西安: 长安大学, 2018. |

| BAI Z Y. Research on extrusion die of coating machine and development of remote monitoring system for feeding[D]. Xi'an: Chang'an University, 2018. | |

| 38 | JUNG H, NAM J. Numerical analysis of pulsatile flows in a slot-die manifold[J]. Journal of Coatings Technology and Research, 2019, 16(4): 1141-1151. DOI: 10.1007/s11998-019-00190-w. |

| 39 | 梁军杰, 周华民, 陶波, 等. 双腔式锂电池涂布浆料挤压模头的流场数值模拟与分析[J]. 模具工业, 2016, 42(10): 5-10. DOI: 10.16787/j.cnki.1001-2168.dmi.2016.10.002. |

| LIANG J J, ZHOU H M, TAO B, et al. Numerical simulation and analysis of the flow field in double-cavity extrusion die with coating Li-ion power battery[J]. Die & Mould Industry, 2016, 42(10): 5-10. DOI: 10.16787/j.cnki.1001-2168.dmi.2016.10.002. | |

| 40 | 田坤, 龚根飞, 陈炜. 一种双腔挤压式涂布模头: CN210079946U[P]. 2020-02-18. |

| 41 | BOOY M L. A network flow analysis of extrusion dies and other flow systems[J]. Polymer Engineering & Science, 1982, 22(7): 432-437. DOI: 10.1002/pen.760220707. |

| 42 | GONG X S, HAN J, YAN F, et al. Numerical and experimental investigation on formation of the film for different die lip configurations in lithium-ion battery electrode slot-die coating[J]. Journal of Coatings Technology and Research, 2024, 21(2): 481-492. DOI: 10.1007/s11998-023-00874-4. |

| 43 | HUANG T L, TAN P H, ZHONG Z Y, et al. Numerical and experimental investigation on the defect formation in lithium-ion-battery electrode-slot coating[J]. Chemical Engineering Science, 2022, 258: 117744. DOI: 10.1016/j.ces.2022.117744. |

| 44 | LEE S M, NAM J. Analysis of slot coating flow under tilted die[J]. AIChE Journal, 2015, 61(5): 1745-1758. DOI: 10.1002/aic.14752. |

| 45 | LEE S H, KOH H J, RYU B K, et al. Operability coating windows and frequency response in slot coating flows from a viscocapillary model[J]. Chemical Engineering Science, 2011, 66(21): 4953-4959. DOI: 10.1016/j.ces.2011.04.044. |

| 46 | CHANG Y R, CHANG H M, LIN C F, et al. Three minimum wet thickness regions of slot die coating[J]. Journal of Colloid and Interface Science, 2007, 308(1): 222-230. DOI: 10.1016/j.jcis.2006.11.054. |

| 47 | TAN P H, DIAO S M, HUANG T L, et al. Numerical and experimental study on coating uniformity control in simultaneous double-sided slot coating with a novel contacted slot die[J]. Chemical Engineering Science, 2020, 222: 115716. DOI: 10.1016/j.ces.2020.115716. |

| 48 | 施柳柳, 陈怡沁, 周静红, 等. LiFePO4涂层厚度对锂离子电池电化学性能的影响[J]. 电子元件与材料, 2019, 38(5): 52-56, 62. DOI: 10.14106/j.cnki.1001-2028.2019.05.010. |

| SHI L L, CHEN Y Q, ZHOU J H, et al. Effects of LiFePO4 coating thickness on electrochemical performance of lithium-ion batteries[J]. Electronic Components and Materials, 2019, 38(5): 52-56, 62. DOI: 10.14106/j.cnki.1001-2028.2019.05.010. | |

| 49 | 刘伯峥, 李海婷, 曾涛, 等. LiFePO4涂覆量对锂离子电池性能的影响[J]. 电池, 2021, 51(5): 482-485. DOI: 10.19535/j.1001-1579.2021.05.011. |

| LIU B Z, LI H T, ZENG T, et al. Effect of LiFePO4 coating amount on the performance of Li-ion battery[J]. Battery Bimonthly, 2021, 51(5): 482-485. DOI: 10.19535/j.1001-1579.2021.05.011. | |

| 50 | 汤思佳. 基于激光三角法厚度绝对测量技术研究[D]. 长春: 长春理工大学, 2010. |

| TANG S J. Resrarch on absolute thickness measurement technology based on laser triangulation[D]. Changchun: Changchun University of Science and Technology, 2010. | |

| 51 | MOHANTY D, LI J L, BORN R, et al. Non-destructive evaluation of slot-die-coated lithium secondary battery electrodes by in-line laser caliper and IR thermography methods[J]. Analytical Methods, 2014, 6(3): 674-683. DOI: 10.1039/C3AY41140K. |

| 52 | DVOINISHNIKOV S V, RAKHMANOV V V, MELEDIN V G, et al. Experimental assessment of the applicability of laser triangulators for measurements of the thickness of hot rolled product[J]. Measurement Techniques, 2015, 57(12): 1378-1385. DOI: 10.1007/s11018-015-0638-x. |

| 53 | MCGOVERN M E, BRUDER D D, HUEMILLER E D, et al. A review of research needs in nondestructive evaluation for quality verification in electric vehicle lithium-ion battery cell manufacturing[J]. Journal of Power Sources, 2023, 561: 232742. DOI: 10.1016/j.jpowsour.2023.232742. |

| 54 | LI J L, DU Z J, RUTHER R E, et al. Toward low-cost, high-energy density, and high-power density lithium-ion batteries[J]. JOM, 2017, 69(9): 1484-1496. DOI: 10.1007/s11837-017-2404-9. |

| 55 | ETIEMBLE A, BESNARD N, ADRIEN J, et al. Quality control tool of electrode coating for lithium-ion batteries based on X-ray radiography[J]. Journal of Power Sources, 2015, 298: 285-291. DOI: 10.1016/j.jpowsour.2015.08.030. |

| 56 | 王云辉, 孙青山, 李松鞠. β射线在锂离子电池生产中的应用[J]. 电池, 2018, 48(5): 347-349. DOI: 10.19535/j.1001-1579. 2018. 05.014. |

| WANG Y H, SUN Q S, LI S J. Application of β-ray online measurement technique in Li-ion battery production[J]. Battery Bimonthly, 2018, 48(5): 347-349. DOI: 10.19535/j.1001-1579.2018.05.014. | |

| 57 | 胡玥红. 基于机器视觉的锂电池极片缺陷检测研究[D]. 哈尔滨: 哈尔滨工业大学, 2015. |

| HU Y H. Research on defect detection of lithium battery electrode sheet based on machine vision[D]. Harbin: Harbin Institute of Technology, 2015. | |

| 58 | 肖安七. 基于机器视觉的涂布缺陷检测系统的研究[D]. 武汉: 华中科技大学, 2017. |

| XIAO A Q. Research on coating defect detection system based on machine vision [D]. Wuhan: Huazhong University of Science and Technology, 2017. | |

| 59 | 徐挺, 万达航, 邹志庭, 等. 锂电池极片涂布缺陷明暗场扫描成像检测技术[J]. 激光与光电子学进展, 2022, 59(18): 83-88. |

| XU T, WAN D H, ZOU Z T, et al. Defect inspection of lithium battery electrode coating via bright and dark field scanning imaging techniques[J]. Laser & Optoelectronics Progress, 2022, 59(18): 83-88. | |

| 60 | 倪君仪. 基于机器视觉的锂电池电极片缺陷检测算法研究[D]. 广州: 华南理工大学, 2022. DOI: 10.27151/d.cnki.ghnlu.2022.000201. |

| NI J Y. Research on defect detection algorithm of lithium battery electrode based on machine vision [D]. Guangzhou: South China University of Technology, 2022. DOI: 10.27151/d.cnki.ghnlu. 2022.000201. |

| [1] | Zhiyong WANG, Junyao CAI, Yingqi SHE, Shulin ZHONG, Kanghua PAN. Surface-modification of graphite with N-heterocyclic conducting polymers as high performance anodes for Li-ion batteries [J]. Energy Storage Science and Technology, 2024, 13(8): 2511-2518. |

| [2] | Jingjing LEI, Zehao LI, Binbin CHEN, Denggao HUANG. Estimation of internal battery temperature based on electrochemical impedance spectroscopy [J]. Energy Storage Science and Technology, 2024, 13(8): 2823-2834. |

| [3] | Yinbao MIAO, Wenhua ZHANG, Weihao LIU, Shuai WANG, Zhe CHEN, Wang PENG, Jie ZENG. Preparation and performance of lithium-rich cathode material Li1.2Ni0.13Co0.13Mn0.54O2 [J]. Energy Storage Science and Technology, 2024, 13(5): 1427-1434. |

| [4] | Chunzheng LIU, Peipei LAI, Zhuo SUN, Er NIE, Zhejuan ZHANG. Dented surface on silica-carbon particles to improve the electrochemical performance of lithium-ion battery anode [J]. Energy Storage Science and Technology, 2024, 13(4): 1302-1309. |

| [5] | Yihan Li, Shigang LU, Jing WANG, Wangjun ZHA, Zhenghang DAI, Yitong GUO, Zexi YANG. Effect of irreversible lithium plating at low temperature on the performance degradation of LiFePO4 lithium-ion batteries [J]. Energy Storage Science and Technology, 2024, 13(10): 3656-3665. |

| [6] | Yuchao QIU, Baishuang CHEN, Cheng CHEN, Ruipeng QIAN. Quasi-static constitutive modeling of lithium-ion battery materials under compression [J]. Energy Storage Science and Technology, 2024, 13(10): 3518-3522. |

| [7] | Yue LI, Bo WANG, Nan WU. Preparation and lithium storage performance of graphene/Si/SiO x nanocomposites [J]. Energy Storage Science and Technology, 2023, 12(9): 2752-2759. |

| [8] | Jiangwei SHEN, Canbiao ZHOU, Xing SHU, Zheng CHEN, Yonggang LIU. State of charge estimation for lithium batteries based on an improved electrochemical model at a wide temperature environment [J]. Energy Storage Science and Technology, 2023, 12(9): 2904-2916. |

| [9] | Man CHEN, Zhixiang CHENG, Chunpeng ZHAO, Peng PENG, Qikai LEI, Kaiqiang JIN, Qingsong WANG. Numerical simulation study on explosion hazards of lithium-ion battery energy storage containers [J]. Energy Storage Science and Technology, 2023, 12(8): 2594-2605. |

| [10] | Zenghui HAO, Xunliang LIU, Yuan MENG, Nan MENG, Zhi WEN. Effect of electrode interface microstructure on the performance of solid-state lithium-ion battery [J]. Energy Storage Science and Technology, 2023, 12(7): 2095-2104. |

| [11] | Yikun WU, Jie HE, Le YANG, Weili SONG, Haosen CHEN. Multiscale and multiphysics theoretical model and computational method for lithium-ion batteries [J]. Energy Storage Science and Technology, 2023, 12(7): 2141-2154. |

| [12] | Yuxin CHEN, Jiamu YANG, Cheng LIAN, Honglai LIU. Analysis of stable coating window of lithium battery electrode paste based on phase field models [J]. Energy Storage Science and Technology, 2023, 12(7): 2185-2193. |

| [13] | Jialiang LIU, Cuijing GUO, Huanling WANG. Safety detection and verification of energy storage in lithium-ion battery based on fire fault tree model [J]. Energy Storage Science and Technology, 2023, 12(5): 1695-1704. |

| [14] | Xinyu LI, Xuebing HAN, Languang LU, Jianqiu LI, Minggao OUYANG. Optimization of an impedance model for power Li-ion batteries based on a large multiplier current pulse [J]. Energy Storage Science and Technology, 2023, 12(5): 1686-1694. |

| [15] | Minyuan GUAN, Jianliang SHEN, Guohua XU, Shun TANG, Weixin ZHANG, Yuancheng CAO. Design and performance research of targeted-fire fighting equipment for lithium-ion battery energy storage system [J]. Energy Storage Science and Technology, 2023, 12(4): 1131-1138. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||