Energy Storage Science and Technology ›› 2025, Vol. 14 ›› Issue (3): 1097-1106.doi: 10.19799/j.cnki.2095-4239.2024.1131

• Emerging Investigator Issue of Energy Storage • Previous Articles Next Articles

Boyu LIU( ), Tengfei WANG, Qing PANG, Kaiyu CHEN, Hongyu WANG(

), Tengfei WANG, Qing PANG, Kaiyu CHEN, Hongyu WANG( )

)

Received:2024-11-27

Revised:2024-12-29

Online:2025-03-28

Published:2025-04-28

Contact:

Hongyu WANG

E-mail:lby1755825225@163.com;HYuWang26@163.com

CLC Number:

Boyu LIU, Tengfei WANG, Qing PANG, Kaiyu CHEN, Hongyu WANG. Preparation and electrochemical performance of Mg-Cr co-doped LiNi0.5Mn1.5O4 cathode material[J]. Energy Storage Science and Technology, 2025, 14(3): 1097-1106.

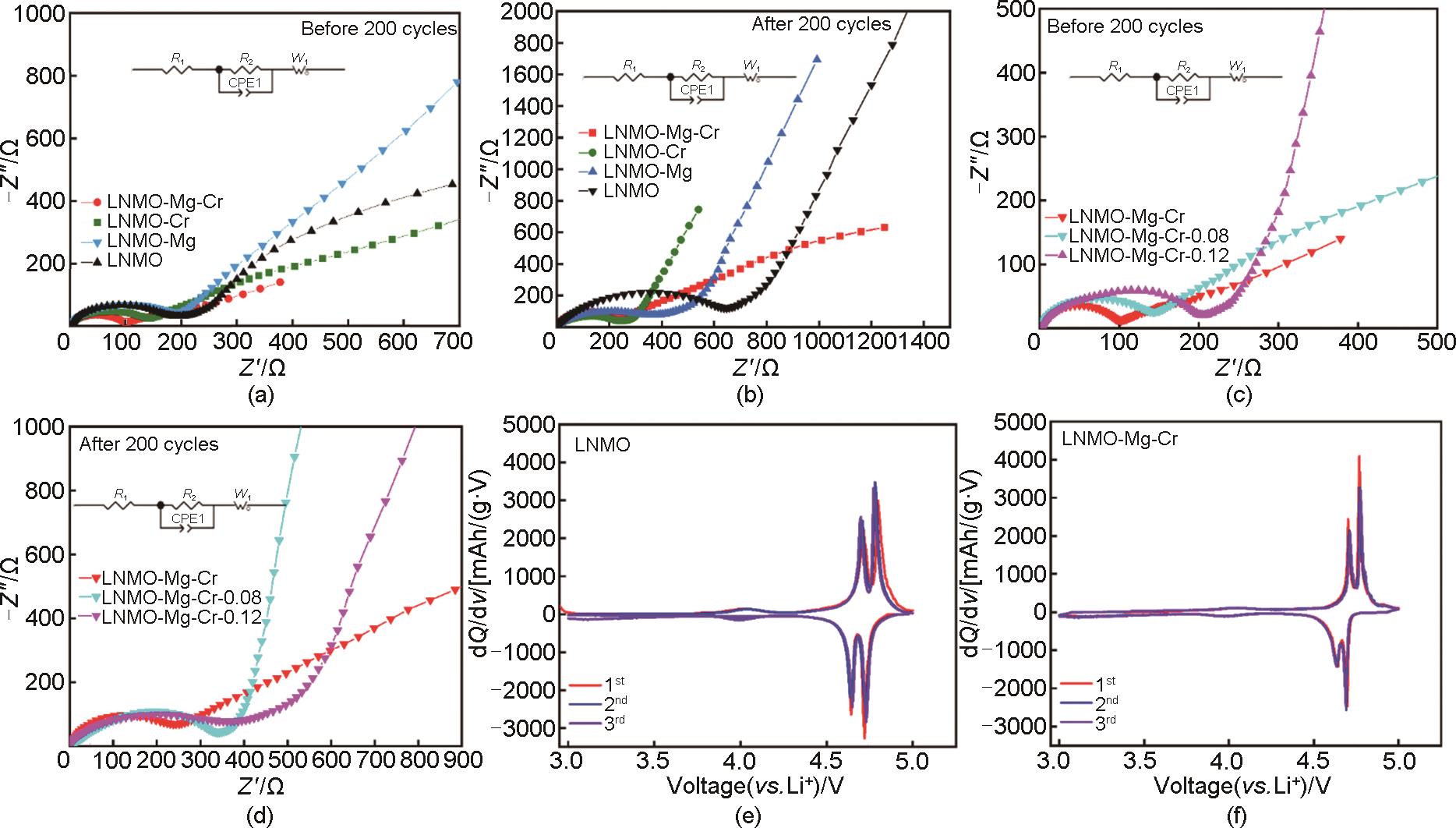

Fig. 8

The EIS images of (a) the first cycle and (b) the EIS images after 200 cycles of the samples with different doping elements; (c) EIS images of the first cycle of samples with different doping amounts and (d) EIS images after 200 cycles; (e) dQ/dV curve of LNMO; (f) dQ/dV curve of LNMO-Mg-Cr"

| 1 | 刘博宇, 庞青, 王腾飞, 等. 高镍三元正极材料LiNi0.8Co0.1Mn0.1O2在高压下的研究进展[J]. 储能科学与技术, 2024, 13(11): 3784-3795. DOI: 10.19799/j.cnki.2095-4239.2024.0432. |

| LIU B Y, PANG Q, WANG T F, et al. Advancements in the modification of high-voltage Ni-rich ternary cathode material LiNi0.8Co0.1Mn0.1O2 for lithium-ion batteries[J]. Energy Storage Science and Technology, 2024, 13(11): 3784-3795. DOI: 10.19799/j.cnki.2095-4239.2024.0432. | |

| 2 | 李晋, 王青松, 孔得朋, 等. 锂离子电池储能安全评价研究进展[J]. 储能科学与技术, 2023, 12(7): 2282-2301. DOI: 10.19799/j.cnki.2095-4239.2023.0252. |

| LI J, WANG Q S, KONG D P, et al. Research progress on the safety assessment of lithium-ion battery energy storage[J]. Energy Storage Science and Technology, 2023, 12(7): 2282-2301. DOI: 10.19799/j.cnki.2095-4239.2023.0252. | |

| 3 | 伍鹏, 郭盼龙, 郭力铭, 等. 高镍正极材料LiNi0.83Co0.12Mn0.05O2双包覆改性及软包锂离子电池应用研究[J]. 材料研究与应用, 2022, 16(5): 812-818. DOI: 10.20038/j.cnki.mra.2022.000514. |

| WU P, GUO P L, GUO L M, et al. Dual-coating of LiNi0.83Co0.12Mn0.05O2 with nanosized ZrO2 and B2O3 for lithium-ion pouch cell application[J]. Materials Research and Application, 2022, 16(5): 812-818. DOI: 10.20038/j.cnki.mra.2022.000514. | |

| 4 | 李军, 黄慧民, 李大光, 等. 锂离子电池纳米阴极材料的研究进展[J]. 材料研究与应用, 2007, 1(3): 165-168. DOI: 10.3969/j.issn.1673-9981.2007.03.002. |

| LI J, HUANG H M, LI D G, et al. Research progress of nano-scale cathode materials in lithium ion battery[J]. Materials Research and Application, 2007, 1(3): 165-168. DOI: 10.3969/j.issn.1673-9981.2007.03.002. | |

| 5 | FU T J, LU D, YAO Z Q, et al. Advances in modification methods and the future prospects of high-voltage spinel LiNi0.5Mn1.5O4 — A review[J]. Journal of Materials Chemistry A, 2023, 11(26): 13889-13915. DOI: 10.1039/D3TA01777J. |

| 6 | SANTHANAM R, RAMBABU B. Research progress in high voltage spinel LiNi0.5Mn1.5O4 material[J]. Journal of Power Sources, 2010, 195(17): 5442-5451. DOI: 10.1016/j.jpowsour. 2010.03.067. |

| 7 | HU M, PANG X L, ZHOU Z. Recent progress in high-voltage lithium ion batteries[J]. Journal of Power Sources, 2013, 237: 229-242. DOI: 10.1016/j.jpowsour.2013.03.024. |

| 8 | VERSACI D, COLOMBO R, MONTINARO G, et al. Tailoring cathode materials: A comprehensive study on LNMO/LFP blending for next generation lithium-ion batteries[J]. Journal of Power Sources, 2024, 613: 234955. DOI: 10.1016/j.jpowsour. 2024.234955. |

| 9 | GAO C, LIU H P, BI S F, et al. Insights for the new function of N,N-dimethylpyrrolidone in preparation of a high-voltage spinel LiNi0.5Mn1.5O4 cathode[J]. ACS Applied Materials & Interfaces, 2021, 13(17): 20014-20023. DOI: 10.1021/acsami.1c01283. |

| 10 | TALYOSEF Y, MARKOVSKY B, SALITRA G, et al. The study of LiNi0.5Mn1.5O4 5 V cathodes for Li-ion batteries[J]. Journal of Power Sources, 2005, 146(1/2): 664-669. DOI: 10.1016/j.jpowsour.2005.03.064. |

| 11 | CHANG B, YUN D H, HWANG I, et al. Carrageenan as a sacrificial binder for 5 V LiNi0.5Mn1.5O4 cathodes in lithium-ion batteries[J]. Advanced Materials, 2023, 35(45): e2303787. DOI: 10.1002/adma.202303787. |

| 12 | LIANG G M, WU Z B, DIDIER C, et al. A long cycle-life high-voltage spinel lithium-ion battery electrode achieved by site-selective doping[J]. Angewandte Chemie International Edition, 2020, 59(26): 10594-10602. DOI: 10.1002/anie.202001454. |

| 13 | GONG J J, YAN S P, LANG Y Q, et al. Effect of Cr3+ doping on morphology evolution and electrochemical performance of LiNi0.5Mn1.5O4 material for Li-ion battery[J]. Journal of Alloys and Compounds, 2021, 859: 157885. DOI: 10.1016/j.jallcom. 2020.157885. |

| 14 | WANG J, LIN W Q, WU B H, et al. Syntheses and electrochemical properties of the Na-doped LiNi0.5Mn1.5O4 cathode materials for lithium-ion batteries[J]. Electrochimica Acta, 2014, 145: 245-253. DOI: 10.1016/j.electacta.2014.07.140. |

| 15 | ZHANG J, CAO L H, LI J P, et al. One thousandth of quaternity slurry additive enables one thousand cycle of 5V LNMO cathode[J]. Energy Storage Materials, 2024, 64: 103060. DOI: 10.1016/j.ensm.2023.103060. |

| 16 | ZI X F, HUANG X, SONG J L, et al. Sr-Y co-doped LiNi0.5Mn1.5O4 cathode material with modified crystal and improved electrochemical performance[J]. Journal of Materials Science, 2023, 58(30): 12271-12287. DOI: 10.1007/s10853-023-08793-w. |

| 17 | OH S W, PARK S H, KIM J H, et al. Improvement of electrochemical properties of LiNi0.5Mn1.5O4 spinel material by fluorine substitution[J]. Journal of Power Sources, 2006, 157(1): 464-470. DOI: 10.1016/j.jpowsour.2005.07.056. |

| 18 | LUO Y Y, CUI Z, WU C X, et al. Enhanced electrochemical performance of a Ti-Cr-doped LiMn1.5Ni0.5O4 cathode material for lithium-ion batteries[J]. ACS Omega, 2023, 8(25): 22721-22731. DOI: 10.1021/acsomega.3c01524. |

| 19 | LIN F C, GUO J B, WANG L Y, et al. Synergistic effect of Mg and Y co-dopants on enhancement of electrochemical properties of LiNi0.5Mn1.5O4 spinel[J]. Electrochimica Acta, 2021, 399: 139433. DOI: 10.1016/j.electacta.2021.139433. |

| 21 | WANG J, NIE P, XU G Y, et al. High-voltage LiNi0.45Cr0.1Mn1.45O4 cathode with superlong cycle performance for wide temperature lithium-ion batteries[J]. Advanced Functional Materials, 2018, 28(4): 1704808. DOI: 10.1002/adfm.201704808. |

| 22 | ZHU R N, ZHANG S J, GUO Q X, et al. More than just a protection layer: Inducing chemical interaction between Li3BO3 and LiNi0.5Mn1.5O4 to achieve stable high-rate cycling cathode materials[J]. Electrochimica Acta, 2020, 342: 136074. DOI: 10.1016/j.electacta.2020.136074. |

| 23 | CHENG J F, LI M X, WANG Y T, et al. Effects of Al and Co doping on the structural stability and high temperature cycling performance of LiNi0.5Mn1.5O4 spinel cathode materials[J]. Chinese Journal of Chemical Engineering, 2023, 61: 201-209. DOI: 10.1016/j.cjche.2023.02.020. |

| 24 | CHLADIL L, KUNICKÝ D, KAZDA T, et al. In-situ XRD study of a chromium doped LiNi0.5Mn1.5O4 cathode for Li-ion battery[J]. Journal of Energy Storage, 2021, 41: 102907. DOI: 10.1016/j.est.2021.102907. |

| 25 | LIU M H, HUANG H T, LIN C M, et al. Mg gradient-doped LiNi0.5Mn1.5O4 as the cathode material for Li-ion batteries[J]. Electrochimica Acta, 2014, 120: 133-139. DOI: 10.1016/j.electacta.2013.12.065. |

| 26 | MANTHIRAM A, CHEMELEWSKI K, LEE E S. A perspective on the high-voltage LiMn1.5Ni0.5O4 spinel cathode for lithium-ion batteries[J]. Energy & Environmental Science, 2014, 7(4): 1339-1350. DOI: 10.1039/C3EE42981D. |

| 27 | CUI X, ZHOU X, LIANG W, et al. Exploring the action mechanism of magnesium in different cations sites for LiNi0.5Mn1.5O4 cathode materials[J]. Materials Today Sustainability, 2022, 17: 100105. DOI: 10.1016/j.mtsust.2021.100105. |

| 28 | LI D J, XIAO B, DAI X Y, et al. One-step in situ construction of Mg0.5Ti2(PO4)3 coating and cation doped modified LiNi0.5Mn1.5O4[J]. Surface and Coatings Technology, 2024, 489: 131080. DOI: 10.1016/j.surfcoat.2024.131080. |

| 29 | WEI A J, LI W, CHANG Q, et al. Effect of Mg2+/F- co-doping on electrochemical performance of LiNi0.5Mn1.5O4 for 5 V lithium-ion batteries[J]. Electrochimica Acta, 2019, 323: 134692. DOI: 10.1016/j.electacta.2019.134692. |

| 30 | STÜBLE P, GEßWEIN H, INDRIS S, et al. On the electrochemical properties of the Fe-Ti doped LNMO material LiNi0.5Mn1.37Fe0.1Ti0.03O3.95[J]. Journal of Materials Chemistry A, 2022, 10(16): 9010-9024. DOI: 10.1039/D2TA00299J. |

| 31 | MAO J, DAI K H, XUAN M J, et al. Effect of chromium and niobium doping on the morphology and electrochemical performance of high-voltage spinel LiNi0.5Mn1.5O4 cathode material[J]. ACS Applied Materials & Interfaces, 2016, 8(14): 9116-9124. DOI: 10.1021/acsami.6b00877. |

| 32 | PANG W K, LU C Z, LIU C E, et al. Crystallographic origin of cycle decay of the high-voltage LiNi0.5Mn1.5O4 spinel lithium-ion battery electrode[J]. Physical Chemistry Chemical Physics, 2016, 18(26): 17183-17189. DOI: 10.1039/c6cp00947f. |

| [1] | Xinxin ZHANG, Guanjun CEN, Ronghan QIAO, Jing ZHU, Junfeng HAO, Qiangfu SUN, Mengyu TIAN, Zhou JIN, Yuanjie ZHAN, Yong YAN, Liubin BEN, Hailong YU, Yanyan LIU, Hong ZHOU, Xuejie HUANG. Reviews of 100 selected recent papers on lithium batteries (December 1, 2024 to January 31, 2025) [J]. Energy Storage Science and Technology, 2025, 14(3): 1310-1330. |

| [2] | Lishuai ZHANG, Yifei ZHANG, Yiyang MA, Sibo ZHAO, Hongquan LIU, Shengting SHI, Yanjun ZHONG. Research progress on sodium-ion battery cathode materials based on iron-based prussian blue analogues [J]. Energy Storage Science and Technology, 2025, 14(2): 525-543. |

| [3] | Junfeng HAO, Guanjun CEN, Ronghan QIAO, Jing ZHU, Qiangfu SUN, Xinxin ZHANG, Mengyu TIAN, Zhou JIN, Yuanjie ZHAN, Yong YAN, Liubin BEN, Hailong YU, Yanyan LIU, Hong ZHOU, Xuejie HUANG. Reviews of selected 100 recent papers for lithium batteries (Oct. 1, 2024 to Nov. 30, 2024) [J]. Energy Storage Science and Technology, 2025, 14(1): 388-405. |

| [4] | Xinxin ZHANG, Guanjun CEN, Ronghan QIAO, Jing ZHU, Junfeng HAO, Qiangfu SUN, Mengyu TIAN, Zhou JIN, Yuanjie ZHAN, Yong YAN, Liubin BEN, Hailong YU, Yanyan LIU, Hong ZHOU, Xueji HUANG. In-depth review of 100 pioneering studies on lithium batteries: Key innovations from June 1, 2024 to July 31, 2024 [J]. Energy Storage Science and Technology, 2024, 13(9): 3226-3244. |

| [5] | Xiaoyu CHEN, Yu LIU, Yifan BAI, Jiajun YING, Ying LV, Lijia WAN, Junping HU, Xiaoling Chen. Preparation and performance of nickel cobalt hydroxide cathode material for nickel zinc batteries [J]. Energy Storage Science and Technology, 2024, 13(7): 2377-2385. |

| [6] | Weiqi LIN, Qiaoyu LU, Yuhong CHEN, Linyuan QIU, Yurong JI, Lianyu GUAN, Xiang DING. Advances in cathode materials for low-temperature sodium-ion batteries [J]. Energy Storage Science and Technology, 2024, 13(7): 2348-2360. |

| [7] | Junfeng HAO, Jing ZHU, Xiaoyu SHEN, Guanjun CEN, Ronghan QIAO, Xinxin ZHANG, Mengyu TIAN, Zhou JIN, Yuanjie ZHAN, Qiangfu SUN, Yong YAN, Liubin BEN, Hailong YU, Yanyan LIU, Xuejie HUANG. A review of 100 selected recent studies on lithium batteries (April 1, 2024—May 31, 2024) [J]. Energy Storage Science and Technology, 2024, 13(7): 2361-2376. |

| [8] | Wanrui LI, Wenjun LI, Xiaoqing WANG, Shengli LU, Xilian XU. Research progress of manganese/vanadium-based oxide heterostructure cathodes for zinc-ion batteries [J]. Energy Storage Science and Technology, 2024, 13(5): 1496-1515. |

| [9] | Yinbao MIAO, Wenhua ZHANG, Weihao LIU, Shuai WANG, Zhe CHEN, Wang PENG, Jie ZENG. Preparation and performance of lithium-rich cathode material Li1.2Ni0.13Co0.13Mn0.54O2 [J]. Energy Storage Science and Technology, 2024, 13(5): 1427-1434. |

| [10] | Jing ZHU, Junfeng HAO, Qiangfu SUN, Xinxin ZHANG, Xiaoyu SHEN, Guanjun CEN, Ronghan QIAO, Mengyu TIAN, Zhou JIN, Yuanjie ZHAN, Yong YAN, Liubin BEN, Hailong YU, Yanyan LIU, Xuejie HUANG. Reviews of selected 100 recent papers for lithium batteries (Feb. 1, 2024 to Mar. 31, 2024) [J]. Energy Storage Science and Technology, 2024, 13(5): 1398-1416. |

| [11] | Qiangfu SUN, Xiaoyu SHEN, Guanjun CEN, Ronghan QIAO, Jing ZHU, Junfeng HAO, Xinxin ZHANG, Mengyu TIAN, Zhou JIN, Yuanjie ZHAN, Yong YAN, Liubin BEN, Hailong YU, Yanyan LIU, Xuejie HUANG. Reviews of selected 100 recent papers for lithium batteries (Dec. 1, 2023 to Jan. 31, 2024) [J]. Energy Storage Science and Technology, 2024, 13(3): 725-741. |

| [12] | Ke PENG, Zhicheng ZHANG, Youzhang HU, Xuhui ZHANG, Jiahui ZHOU, Bin LI. Finite element-based motion analysis and optimization of sagger in thermo-mechanical coupling field [J]. Energy Storage Science and Technology, 2024, 13(2): 634-642. |

| [13] | Xiuli GUO, Xiaolong ZHOU, Caineng ZOU, Yongbing TANG. Research progress and perspectives of aqueous dual-ions batteries [J]. Energy Storage Science and Technology, 2024, 13(2): 462-479. |

| [14] | Boyu LIU, Qing PANG, Tengfei WANG, Hongyu WANG. Advancements in the modification of high-voltage Ni-rich ternary cathode material LiNi0.8Co0.1Mn0.1O2 for lithium-ion batteries [J]. Energy Storage Science and Technology, 2024, 13(11): 3784-3795. |

| [15] | Qiangfu SUN, Guanjun CEN, Ronghan QIAO, Jing ZHU, Junfeng HAO, Xinxin ZHANG, Mengyu TIAN, Zhou JIN, Yuanjie ZHAN, Yong YAN, Liubin BEN, Hailong YU, Yanyan LIU, Hong ZHOU, Xuejie HUANG. Reviews of selected 100 recent papers for lithium batteries (Aug. 1, 2024 to Sep. 30, 2024) [J]. Energy Storage Science and Technology, 2024, 13(11): 4207-4225. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||