Energy Storage Science and Technology ›› 2025, Vol. 14 ›› Issue (9): 3354-3372.doi: 10.19799/j.cnki.2095-4239.2025.0147

• Energy Storage Materials and Devices • Previous Articles Next Articles

Tuo DENG( ), Haiping ZHOU(

), Haiping ZHOU( ), Yu LIU, Chang LIU, Zikai LI, Mengqiang WU

), Yu LIU, Chang LIU, Zikai LI, Mengqiang WU

Received:2025-02-22

Revised:2025-03-19

Online:2025-09-28

Published:2025-09-05

Contact:

Haiping ZHOU

E-mail:1281471718@qq.com;haipzhou@uestc.edu.cn

CLC Number:

Tuo DENG, Haiping ZHOU, Yu LIU, Chang LIU, Zikai LI, Mengqiang WU. Research progress in the preparation of silicon-carbons anode by chemical vapor deposition[J]. Energy Storage Science and Technology, 2025, 14(9): 3354-3372.

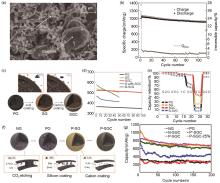

Fig.3

(a) SEM images of nano silicon/graphite composite electrodes; (b) Cyclic behavior of composite electrode containing 20% nano silicon in EC∶DMC (1∶1), 1 mol/L LiPF6, 2% VC[52]; (c) Hybrid manufacturing processes for SGC; (d) Reversible discharge capacity and cycle diagram of PG, SG, SGC, 9%-SGC and B-Si/G for 100 cycles at 0.5 C[53]; (e) Increased rate capacity of SGC from 0.2 C to 5 C compared to PG, SG and B-Si/G; (f) Schematic illustration of the synthesis process of the p-SGC composites; (g) Cycling performance of NG, PG, n-SGC, p'-SGC, p-SGC and p-SGC-25% electrodes at 0.2 C[54]"

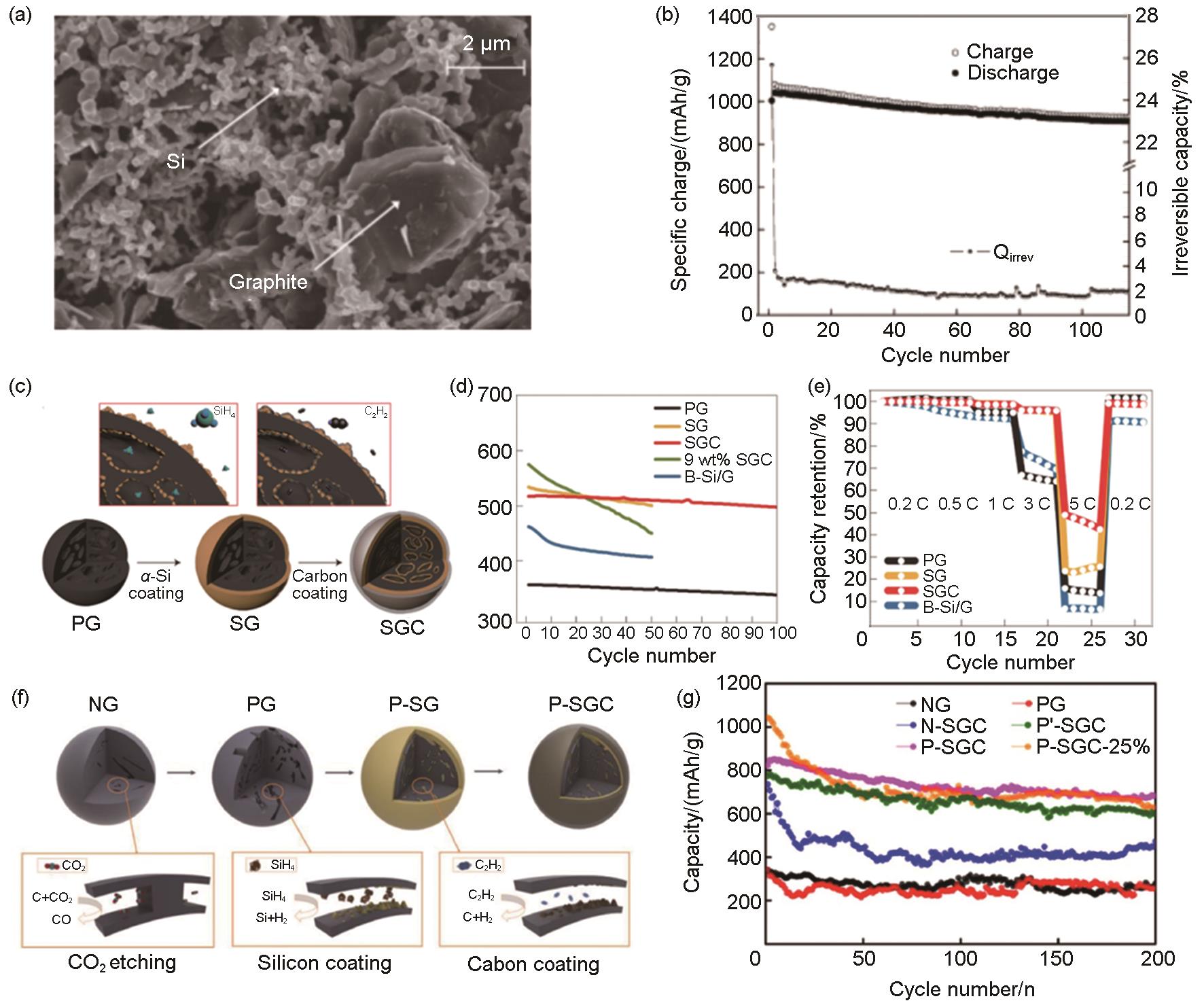

Fig.4

(a) A schematic of the silicon/carbon nanotube hybrid nanostructure prepared by growing an initial vertically aligned carbon nanotube using a liquid injection CVD, followed by the subsequent deposition of silicon; (b) Discharge/charge capacity and coulomb efficiency maps for 25 cycles[21]; (c) Schematic diagram of fabrication of a silicon nanowire array on a carbon nanotube (SiNW-CNT) array on a collector (stainless steel substrate); (d) The area capacities of Si NW-CNT and Si NWs as working electrodes were compared at 0.05 C (210 mA/g) in the first cycle and 0.5 C (2100 mA/g) in the remaining cycles at a constant current between 0.02 and 1.5 V[61]; (e)Si/CNTs manufacturing process diagram; (f) Cycle performance of soft pack batteries at 0.5 C (Si/CNTsS/ Graphite vs NCA and graphite vs LCO) [62]; (g) A schematic diagram for the synthesis of GC@Si-C microspheres; (h) long cycling performance at 0.5 A/g; (i) 1 C cycling performance of the GC@Si-2/G||NCM811 full cell"

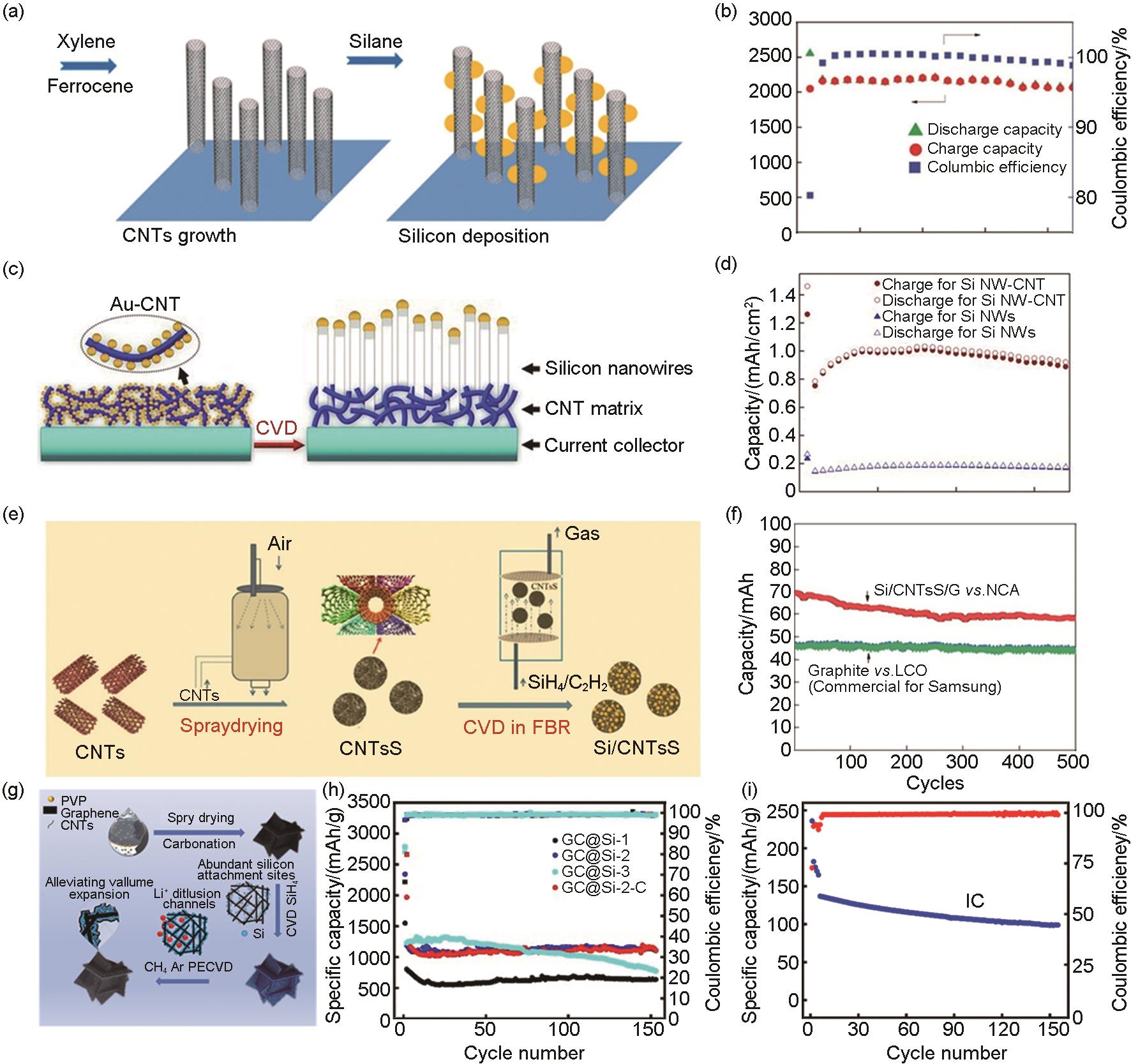

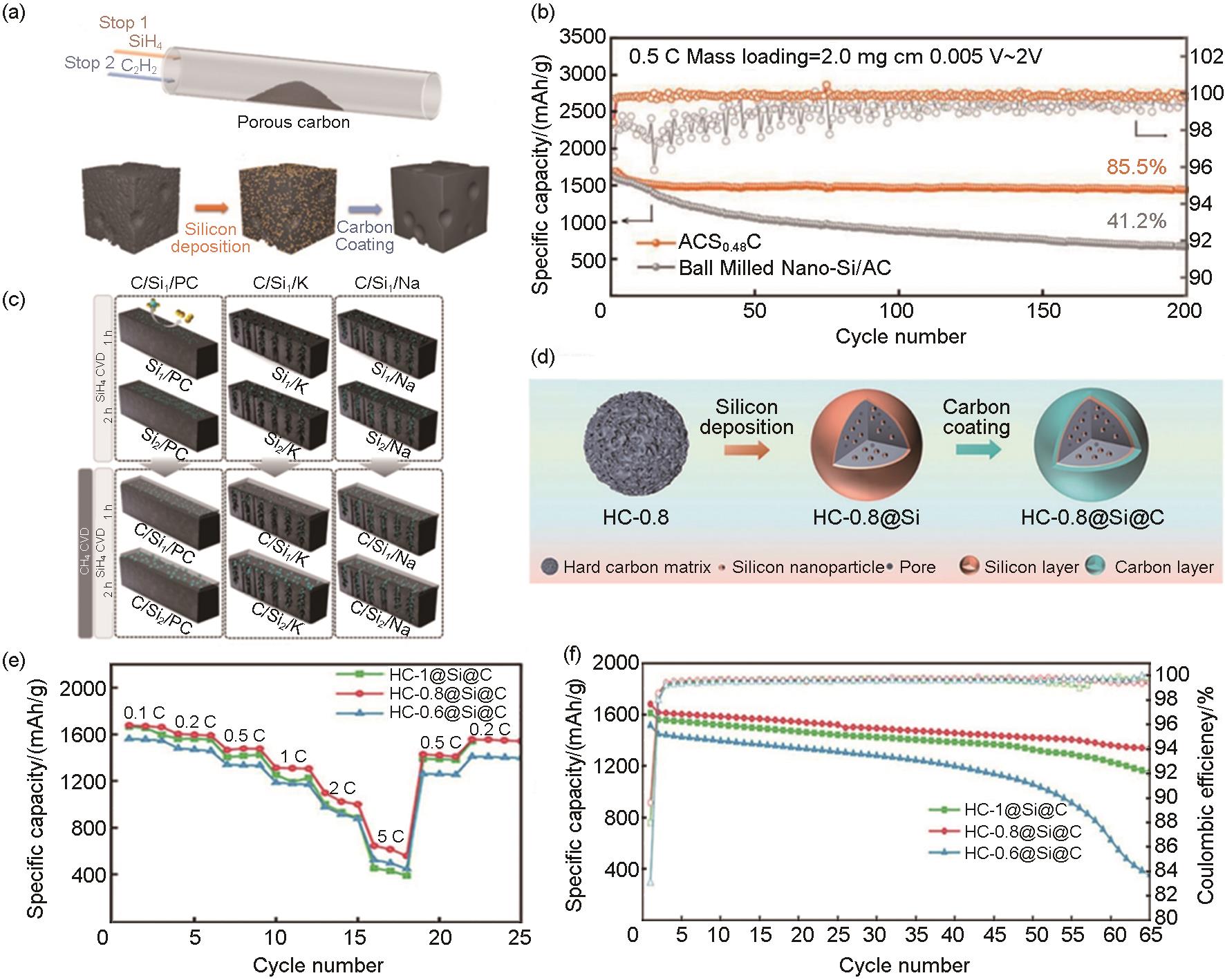

Fig.5

(a) Schematic diagram of the synthesis method of ACSC composites; (b) Cyclic performance of ACS0.48C (1 C=1700 mAh/g); (c) Silicon loading behavior determined by the surface morphology and pore structure of the carbon carrier; (d) Schematic diagram of HC-0.8@Si@C composite material; (e) rate performance of HC-1@Si@C、HC-0.8@Si@C和HC-0.6@Si@C (1 C = 1500 mAh/g); (f) Cycle performance at 0.2 C"

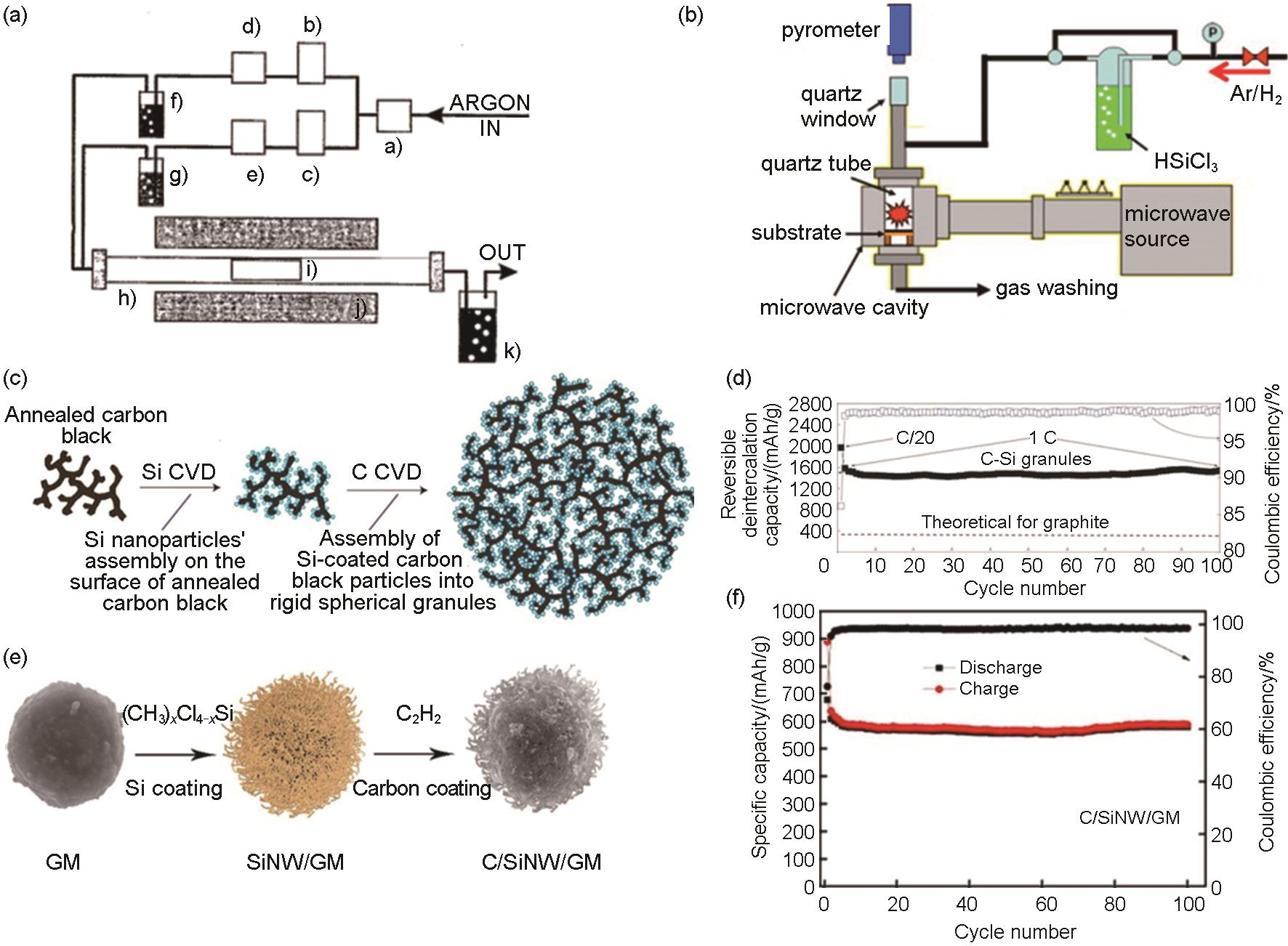

Fig.6

(a) Schematic diagram of the CVD device, where a) is an automatic flow controller; b) and c) are manual flow controllers; d) and e) are digital flowmeters; f) and g) are stainless steel source bottles; h) the reaction tube; i) The tubular insert is aligned with the hot area of the furnace; j) for the furnace; k) oil bubbler[73]; (b) Experimental setup of silicon CVD on carbon fiber substrate in microwave plasma CVD reactor[71]; (c) Schematic diagram of the formation of silicon nanocomposite particles assembled from the bottom up; (d) The relationship between the reversible delithiation capacity and coulomb efficiency of the C-Si particle electrode and the number of cycles compared with the theoretical capacity of graphite[74]; (e) Structural diagram of C/SiNW/GM composites; (f) Long cycle and rate performance of C/SiNW/GM[40]"

Fig.7

(a) Schematic diagram of LPCVD and PECVD processes; (b) The full battery of NCA vs PECVD-Si-SWCNT cycles at 40% DOD, and the charge and discharge ratios are C/2 and 2C/3, respectively; (c) Simulation of the behaviour of silicon growth inhibitors; (d) 110 Ah prismatic battery using C (5)Si-G/Gra/NCM811[76]; (e) A: Schematic diagram of the decomposition of silane into nanoporous carbon particles by the CVD process; B: Diagram of a tube furnace with toner and silane flowing from right to left[77]"

| [1] | STADIE N P, WANG S T, KRAVCHYK K V, et al. Zeolite-templated carbon as an ordered microporous electrode for aluminum batteries[J]. ACS Nano, 2017, 11(2): 1911-1919. DOI: 10.1021/acsnano.6b07995. |

| [2] | THACKERAY M M, WOLVERTON C, ISAACS E D. Electrical energy storage for transportation—Approaching the limits of, and going beyond, lithium-ion batteries[J]. Energy & Environmental Science, 2012, 5(7): 7854-7863. DOI: 10.1039/C2EE21892E. |

| [3] | SHARMA R A, SEEFURTH R N. Thermodynamic properties of the lithium-silicon system[J]. Journal of the Electrochemical Society, 1976, 123(12): 1763-1768. DOI: 10.1149/1.2132692. |

| [4] | TAO W, WANG P, YOU Y, et al. Strategies for improving the storage performance of silicon-based anodes in lithium-ion batteries[J]. Nano Research, 2019, 12(8): 1739-1749. DOI: 10. 1007/s12274-019-2361-4. |

| [5] | CHOI S, KWON T W, COSKUN A, et al. Highly elastic binders integrating polyrotaxanes for silicon microparticle anodes in lithium ion batteries[J]. Science, 2017, 357(6348): 279-283. DOI: 10.1126/science.aal4373. |

| [6] | WU H, CUI Y. Designing nanostructured Si anodes for high energy lithium ion batteries[J]. Nano Today, 2012, 7(5): 414-429. DOI: 10.1016/j.nantod.2012.08.004. |

| [7] | WANG C, WEN J C, LUO F, et al. Anisotropic expansion and size-dependent fracture of silicon nanotubes during lithiation[J]. Journal of Materials Chemistry A, 2019, 7(25): 15113-15122. DOI: 10.1039/C9TA00519F. |

| [8] | PAN H, WANG L, SHI Y, et al. A solid-state lithium-ion battery with micron-sized silicon anode operating free from external pressure[J]. Nature Communications, 2024, 15: 2263. DOI: 10. 1038/s41467-024-46472-9. |

| [9] | KANG W, ZHANG Q X, JIA Y F, et al. Enhancing the cycling stability of commercial silicon nanoparticles by carbon coating and thin layered single-walled carbon nanotube webbing[J]. Journal of Power Sources, 2024, 602: 234338. DOI: 10.1016/j.jpowsour.2024.234338. |

| [10] | 梁晓杜, 丁玉峰. 锂离子电池用硅基材料的研究进展[J]. 船电技术, 2024, 44(12): 87-91, 96. DOI: 10.13632/j.meee.2024.12.021. |

| LIANG X D, DING Y F. Research progress of silicon-based materials for lithium-ion batteries[J]. Marine Electric & Electronic Engineering, 2024, 44(12): 87-91, 96. DOI: 10.13632/j.meee. 2024. 12.021. | |

| [11] | 王娟, 张香兰. 锂离子电池硅碳负极材料的应用研究进展[J]. 化学工业与工程, 2024, 41(6): 75-90. DOI: 10.13353/j.issn. 1004. 9533. 20230508. |

| WANG J, ZHANG X L. Research progress on the application of silicon-carbon anode materials in lithium-ion batteries[J]. Chemical Industry and Engineering, 2024, 41(6): 75-90. DOI: 10. 13353/j.issn.1004.9533.20230508. | |

| [12] | LIU X H, ZHONG L, HUANG S, et al. Size-dependent fracture of silicon nanoparticles during lithiation[J]. ACS Nano, 2012, 6(2): 1522-1531. DOI: 10.1021/nn204476h. |

| [13] | KO M, CHAE S, JEONG S, et al. Elastic a-silicon nanoparticle backboned graphene hybrid as a self-compacting anode for high-rate lithium ion batteries[J]. ACS Nano, 2014, 8(8): 8591-8599. DOI: 10.1021/nn503294z. |

| [14] | AN Y L, TIAN Y, ZHANG Y C, et al. Two-dimensional silicon/carbon from commercial alloy and CO2 for lithium storage and flexible Ti3C2Tx MXene-based lithium-metal batteries[J]. ACS Nano, 2020, 14(12): 17574-17588. DOI: 10.1021/acsnano.0c08336. |

| [15] | LI Y Z, YAN K, LEE H W, et al. Growth of conformal graphene cages on micrometre-sized silicon particles as stable battery anodes[J]. Nature Energy, 2016, 1: 15029. DOI: 10.1038/nenergy. 2015.29. |

| [16] | ZHANG Z D, ZHOU H P, FENG T T, et al. A plasma strategy for high-quality Si/C composite anode: From tailoring the current collector to preparing the active materials[J]. Electrochimica Acta, 2020, 347: 136222. DOI: 10.1016/j.electacta.2020.136222. |

| [17] | ZHANG Z D, ZHOU H P, XUE W D, et al. Nitrogen-plasma doping of carbon film for a high-quality layered Si/C composite anode[J]. Journal of Colloid and Interface Science, 2022, 605: 463-471. DOI: 10.1016/j.jcis.2021.06.147. |

| [18] | LI X H, WU M Q, FENG T T, et al. Graphene enhanced silicon/carbon composite as anode for high performance lithium-ion batteries[J]. RSC Advances, 2017, 7(76): 48286-48293. DOI: 10. 1039/C7RA09818A. |

| [19] | QIN J G, WU M Q, FENG T T, et al. High rate capability and long cycling life of graphene-coated silicon composite anodes for lithium ion batteries[J]. Electrochimica Acta, 2017, 256: 259-266. DOI: 10.1016/j.electacta.2017.10.022. |

| [20] | WANG R, CAO J W, XU C Y, et al. Low-temperature electrolytes based on linear carboxylic ester co-solvents for SiOx/graphite composite anodes[J]. RSC Advances, 2023, 13(20): 13365-13373. DOI: 10.1039/D3RA01111A. |

| [21] | WANG W, KUMTA P N. Nanostructured hybrid silicon/carbon nanotube heterostructures: Reversible high-capacity lithium-ion anodes[J]. ACS Nano, 2010, 4(4): 2233-2241. DOI: 10.1021/nn901632g. |

| [22] | TAO H C, XIONG L Y, ZHU S C, et al. Porous Si/C/reduced graphene oxide microspheres by spray drying as anode for Li-ion batteries[J]. Journal of Electroanalytical Chemistry, 2017, 797: 16-22. DOI: 10.1016/j.jelechem.2017.05.010. |

| [23] | ZHANG J Q, CHEN Y F, CHEN X Q, et al. Preparation of graphene-like carbon attached porous silicon anode by magnesiothermic and nickel-catalyzed reduction reactions[J]. Ionics, 2020, 26(12): 5941-5950. DOI: 10.1007/s11581-020-03746-8. |

| [24] | CABELLO M, GUCCIARDI E, HERRÁN A, et al. Towards a high-power Si@graphite anode for lithium ion batteries through a wet ball milling process[J]. Molecules, 2020, 25(11): 2494. DOI: 10. 3390/molecules25112494. |

| [25] | WAN W W, MAI Y, GUO D, et al. A novel Sol-gel process to encapsulate micron silicon with a uniformly Ni-doped graphite carbon layer by coupling for use in lithium ion batteries[J]. Synthetic Metals, 2021, 274: 116717. DOI: 10.1016/j.synthmet. 2021.116717. |

| [26] | GE M Y, LU Y H, ERCIUS P, et al. Large-scale fabrication, 3D tomography, and lithium-ion battery application of porous silicon[J]. Nano Letters, 2014, 14(1): 261-268. DOI: 10.1021/nl403923s. |

| [27] | CHO G B, CHOI S Y, NOH J P, et al. Dependence of milling time on electrochemical properties of nano Si electrodes prepared by ball-milling[J]. Journal of Nanoscience and Nanotechnology, 2011, 11(7): 6262-6265. DOI: 10.1166/jnn.2011.4332. |

| [28] | LI Z J, DU M J, GUO X, et al. Research progress of SiOx-based anode materials for lithium-ion batteries[J]. Chemical Engineering Journal, 2023, 473: 145294. DOI: 10.1016/j.cej.2023.145294. |

| [29] | WU J X, DONG Q W, ZHANG Q, et al. Fundamental understanding of the low initial coulombic efficiency in SiOx anode for lithium-ion batteries: Mechanisms and solutions[J]. Advanced Materials, 2024, 36(33): 2405751. DOI: 10.1002/adma. 202405751. |

| [30] | ZHOU H P, YANG B, ZHANG Z D, et al. Fastly PECVD-Grown vertical carbon nanosheets for a composite SiOx-C anode material[J]. Applied Surface Science, 2022, 605: 154627. DOI: 10.1016/j.apsusc.2022.154627. |

| [31] | ZHOU H, ZHOU H P, YANG B, et al. Carbon nano-Onions/tubes catalyzed by Ni nanoparticles on SiOx for superior lithium storage[J]. Applied Surface Science, 2023, 640: 158355. DOI: 10.1016/j.apsusc.2023.158355. |

| [32] | ZHOU H, YANG B, ZHOU H P, et al. Carbon shells and carbon nanotubes jointly modified SiOx anodes for superior lithium storage[J]. ACS Applied Energy Materials, 2024, 7(22): 10307-10316. DOI: 10.1021/acsaem.4c01513. |

| [33] | YUE H C, ZHANG S, FENG T T, et al. Understanding of the mechanism enables controllable chemical prelithiation of anode materials for lithium-ion batteries[J]. ACS Applied Materials & Interfaces, 2021, 13(45): 53996-54004. DOI: 10.1021/acsami. 1c16842. |

| [34] | LI H D, LI H Y, LAI Y Z, et al. Revisiting the preparation progress of nano-structured Si anodes toward industrial application from the perspective of cost and scalability[J]. Advanced Energy Materials, 2022, 12(7): 2102181. DOI: 10.1002/aenm.202102181. |

| [35] | 涂志强, 侯果林, 林伟国, 等. 锂离子电池硅碳负极材料应用前景光明[J]. 中国石化, 2024(4): 42-45. |

| TU Z Q, HOU G L, LIN W G, et al. Silicon-carbon anode materials for lithium ion batteries have bright application prospects[J]. Sinopec Monthly, 2024(4): 42-45. | |

| [36] | 蒋运才, 曹昌蝶, 刘岚君, 等. 化学气相沉积法制备二维材料研究进展[J]. 化工新型材料, 2021, 49(11): 59-62. DOI: 10.19817/j.cnki.issn1006-3536.2021.11.013. |

| JIANG Y C, CAO C D, LIU L J, et al. Research progress on 2D material prepared by chemical vapor deposition[J]. New Chemical Materials, 2021, 49(11): 59-62. DOI: 10.19817/j.cnki.issn1006-3536.2021.11.013. | |

| [37] | ZHANG T, FU L. Controllable chemical vapor deposition growth of two-dimensional heterostructures[J]. Chem, 2018, 4(4): 671-689. DOI: 10.1016/j.chempr.2017.12.006. |

| [38] | LIU X, CAO L Z, GUO Z, et al. A review of perovskite photovoltaic materials' synthesis and applications via chemical vapor deposition method[J]. Materials, 2019, 12(20): 3304. DOI: 10. 3390/ma12203304. |

| [39] | WILSON A M, DAHN J R. Lithium insertion in carbons containing nanodispersed silicon[J]. Journal of the Electrochemical Society, 1995, 142(2): 326-332. DOI: 10.1149/1.2043994. |

| [40] | LIU B, HUANG P, XIE Z Y, et al. Large-scale production of a silicon nanowire/graphite composites anode via the CVD method for high-performance lithium-ion batteries[J]. Energy & Fuels, 2021, 35(3): 2758-2765. DOI: 10.1021/acs.energyfuels.0c03725. |

| [41] | ZHANG X Y, HAYASHIDA R, TANAKA M, et al. Synthesis of carbon-coated silicon nanoparticles by induction thermal plasma for lithium ion battery[J]. Powder Technology, 2020, 371: 26-36. DOI: 10.1016/j.powtec.2020.05.084. |

| [42] | PARK S W, HA J H, CHO B W, et al. Designing of high capacity Si nanosheets anode electrodes for lithium batteries[J]. Surface and Coatings Technology, 2021, 421: 127358. DOI: 10.1016/j.surfcoat.2021.127358. |

| [43] | QI C L, LI S P, YANG Z P, et al. Suitable thickness of carbon coating layers for silicon anode[J]. Carbon, 2022, 186: 530-538. DOI: 10.1016/j.carbon.2021.10.062. |

| [44] | HAN J, TANG X N, GE S F, et al. Si/C particles on graphene sheet as stable anode for lithium-ion batteries[J]. Journal of Materials Science & Technology, 2021, 80: 259-265. DOI: 10. 1016/j.jmst.2020.11.054. |

| [45] | SU H P, LI X R, LIU C W, et al. Scalable synthesis of micrometer-sized porous silicon/carbon composites for high-stability lithium-ion battery anodes[J]. Chemical Engineering Journal, 2023, 451: 138394. DOI: 10.1016/j.cej.2022.138394. |

| [46] | ŁACH Ł, SVYETLICHNYY D. Recent progress in heat and mass transfer modeling for chemical vapor deposition processes[J]. Energies, 2024, 17(13): 3267. DOI: 10.3390/en17133267. |

| [47] | CHAE S, CHOI S H, KIM N, et al. Integration of graphite and silicon anodes for the commercialization of high-energy lithium-ion batteries[J]. Angewandte Chemie International Edition, 2020, 59(1): 110-135. DOI: 10.1002/anie.201902085. |

| [48] | LI P, KIM H, MYUNG S T, et al. Diverting exploration of silicon anode into practical way: A review focused on silicon-graphite composite for lithium ion batteries[J]. Energy Storage Materials, 2021, 35: 550-576. DOI: 10.1016/j.ensm.2020.11.028. |

| [49] | WETJEN M, PRITZL D, JUNG R, et al. Differentiating the degradation phenomena in silicon-graphite electrodes for lithium-ion batteries[J]. Journal of the Electrochemical Society, 2017, 164(12): A2840-A2852. DOI: 10.1149/2.1921712jes. |

| [50] | YAN Z L, YI S, LI X D, et al. A scalable silicon/graphite anode with high silicon content for high-energy lithium-ion batteries[J]. Materials Today Energy, 2023, 31: 101225. DOI: 10.1016/j.mtener. 2022.101225. |

| [51] | ZHANG Y, JIANG Y Z, LI Y D, et al. Preparation of nanographite sheets supported Si nanoparticles by in situ reduction of fumed SiO2 with magnesium for lithium ion battery[J]. Journal of Power Sources, 2015, 281: 425-431. DOI: 10.1016/j.jpowsour. 2015. 02.020. |

| [52] | HOLZAPFEL M, BUQA H, SCHEIFELE W, et al. A new type of nano-sized silicon/carbon composite electrode for reversible lithium insertion[J]. Chemical Communications, 2005(12): 1566-1568. DOI: 10.1039/B417492E. |

| [53] | KO M, CHAE S, MA J, et al. Scalable synthesis of silicon-nanolayer-embedded graphite for high-energy lithium-ion batteries[J]. Nature Energy, 2016, 1: 16113. DOI: 10.1038/nenergy.2016.113. |

| [54] | ZHU S J, LIN Y F, YAN Z L, et al. Novel design of uniform Si@graphite@C composite as high-performance Li-ion battery anodes[J]. Electrochimica Acta, 2021, 377: 138092. DOI: 10. 1016/j.electacta.2021.138092. |

| [55] | WANG F L, CHEN G, ZHANG N, et al. Engineering of carbon and other protective coating layers for stabilizing silicon anode materials[J]. Carbon Energy, 2019, 1(2): 219-245. DOI: 10.1002/cey2.24. |

| [56] | LI P, HWANG J Y, SUN Y K. Nano/microstructured silicon-graphite composite anode for high-energy-density Li-ion battery[J]. ACS Nano, 2019, 13(2): 2624-2633. DOI: 10.1021/acsnano. 9b00169. |

| [57] | NAZARIAN-SAMANI M, NAZARIAN-SAMANI M, HAGHIGHAT-SHISHAVAN S, et al. Efficient stress alleviation and interface regulation in Cu4SiP8-CNT hybrid for ultra-durable Li and Na storage[J]. Nano Energy, 2021, 86: 106134. DOI: 10.1016/j.nanoen.2021.106134. |

| [58] | SCHULZE M C, BELSON R M, KRAYNAK L A, et al. Electrodeposition of Sb/CNT composite films as anodes for Li- and Na-ion batteries[J]. Energy Storage Materials, 2020, 25: 572-584. DOI: 10.1016/j.ensm.2019.09.025. |

| [59] | NGUYEN T, SU Y S. A self-assembled carbon nanotube/silicon composite battery anode stabilized with chemically reduced graphene oxide sheets[J]. Materials & Design, 2024, 240: 112861. DOI: 10.1016/j.matdes.2024.112861. |

| [60] | WANG S Z, LIAO J X, WU M Q, et al. High rate and long cycle life of a CNT/rGO/Si nanoparticle composite anode for lithium-ion batteries[J]. Particle & Particle Systems Characterization, 2017, 34(10): 1700141. DOI: 10.1002/ppsc.201700141. |

| [61] | LI X L, CHO J H, LI N, et al. Carbon nanotube-enhanced growth of silicon nanowires as an anode for high-performance lithium-ion batteries[J]. Advanced Energy Materials, 2012, 2(1): 87-93. DOI: 10.1002/aenm.201100519. |

| [62] | ZHAO H, TU N, ZHANG W B, et al. Novel synthesis of silicon/carbon nanotubes microspheres as anode additives through chemical vapor deposition in fluidized bed reactors[J]. Scripta Materialia, 2021, 192: 49-54. DOI: 10.1016/j.scriptamat. 2020. 09.048. |

| [63] | LIU C, ZHOU H P, ZHOU H, et al. Highly Si loading on three-dimensional carbon skeleton via CVD method for a stable SiC composite anode[J]. Journal of Energy Storage, 2025, 116: 116083. DOI: 10.1016/j.est.2025.116083. |

| [64] | LI K X, CHEN W, YANG H P, et al. Mechanism of biomass activation and ammonia modification for nitrogen-doped porous carbon materials[J]. Bioresource Technology, 2019, 280: 260-268. DOI: 10.1016/j.biortech.2019.02.039. |

| [65] | XU X T, MU X, HUANG T, et al. Robust silicon/carbon composite anode materials with high tap density and excellent cycling performance for lithium-ion batteries[J]. Journal of Power Sources, 2024, 614: 234992. DOI: 10.1016/j.jpowsour. 2024. 234992. |

| [66] | KIM K N, KANG S C, SEO S W, et al. Effects of macrostructure of carbon support in preparation of C/Six/C anode materials for lithium-ion batteries via silane decomposition[J]. Carbon Letters, 2024, 34(9): 2305-2316. DOI: 10.1007/s42823-024-00756-8. |

| [67] | SCHÄUFELE R S, VAZQUEZ-PUFLEAU M, PENDASHTEH A, et al. Controlling reaction paths for ultra-fast growth of inorganic nanowires floating in the gas phase[J]. Nanoscale, 2022, 14(1): 55-64. DOI: 10.1039/D1NR07261G. |

| [68] | XIAO Y M, YI S, YAN Z L, et al. Benchmarking the match of porous carbon substrate pore volume on silicon anode materials for lithium-ion batteries[J]. Small, 2024, 20(45): 2404440. DOI: 10.1002/smll.202404440. |

| [69] | HU M F, WU H Z, ZHANG G J. High-performance silicon/graphite anode prepared by CVD using SiCl4 as precursor for Li-ion batteries[J]. Chemical Physics Letters, 2023, 833: 140917. DOI: 10.1016/j.cplett.2023.140917. |

| [70] | HUANG P, LIU B, ZHANG J L, et al. Silicon/carbon composites based on natural microcrystalline graphite as anode for lithium-ion batteries[J]. Ionics, 2021, 27(5): 1957-1966. DOI: 10.1007/s11581-021-03977-3. |

| [71] | WOLF H, PAJKIC Z, GERDES T, et al. Carbon-fiber-silicon-nanocomposites for lithium-ion battery anodes by microwave plasma chemical vapor deposition[J]. Journal of Power Sources, 2009, 190(1): 157-161. DOI: 10.1016/j.jpowsour.2008.07.035. |

| [72] | CHEN Z D, SOLTANI A, CHEN Y G, et al. Emerging organic surface chemistry for Si anodes in lithium-ion batteries: Advances, prospects, and beyond[J]. Advanced Energy Materials, 2022, 12(32): 2200924. DOI: 10.1002/aenm. 202200924. |

| [73] | WILSON A M, WAY B M, DAHN J R, et al. Nanodispersed silicon in pregraphitic carbons[J]. Journal of Applied Physics, 1995, 77(6): 2363-2369. DOI: 10.1063/1.358759. |

| [74] | MAGASINSKI A, DIXON P, HERTZBERG B, et al. High-performance lithium-ion anodes using a hierarchical bottom-up approach[J]. Nature Materials, 2010, 9(4): 353-358. DOI: 10. 1038/nmat2725. |

| [75] | FORNEY M W, DILEO R A, RAISANEN A, et al. High performance silicon free-standing anodes fabricated by low-pressure and plasma-enhanced chemical vapor deposition onto carbon nanotube electrodes[J]. Journal of Power Sources, 2013, 228: 270-280. DOI: 10.1016/j.jpowsour.2012.11.109. |

| [76] | SUNG J, KIM N, MA J, et al. Subnano-sized silicon anode via crystal growth inhibition mechanism and its application in a prototype battery pack[J]. Nature Energy, 2021, 6(12): 1164-1175. DOI: 10.1038/s41560-021-00945-z. |

| [77] | HAN Z N, WILD J F, CHEN J J, et al. Modeling silane deposition in nanoporous carbon for high-capacity Si/C composite anodes[J]. Energy Material Advances, 2024, 5: 111. DOI: 10.34133/energymatadv.0111. |

| [78] | ZHAN X, LI M, LI S, et al. Challenges and opportunities towards silicon-based all-solid-state batteries[J]. Energy Storage Materials, 2023, 61: 102875. DOI: 10.1016/j.ensm.2023.102875. |

| [79] | HUO H Y, JANEK J. Silicon as emerging anode in solid-state batteries[J]. ACS Energy Letters, 2022, 7(11): 4005-4016. DOI: 10.1021/acsenergylett.2c01950. |

| [80] | LI J C, DOZIER A K, LI Y C, et al. Crack pattern formation in thin film lithium-ion battery electrodes[J]. Journal of the Electrochemical Society, 2011, 158(6): A689. DOI: 10.1149/1.3574027. |

| [81] | ZHOU M, LI X L, WANG B, et al. High-performance silicon battery anodes enabled by engineering graphene assemblies[J]. Nano Letters, 2015, 15(9): 6222-6228. DOI: 10.1021/acs.nanolett. 5b02697. |

| [82] | FERRARESI G, EL KAZZI M, CZORNOMAZ L, et al. Electrochemical performance of all-solid-state Li-ion batteries based on garnet electrolyte using silicon as a model electrode[J]. ACS Energy Letters, 2018, 3(4): 1006-1012. DOI: 10.1021/acsenergylett.8b00264. |

| [83] | CHEN C, LI Q, LI Y Q, et al. Sustainable interfaces between Si anodes and garnet electrolytes for room-temperature solid-state batteries[J]. ACS Applied Materials & Interfaces, 2018, 10(2): 2185-2190. DOI: 10.1021/acsami.7b16385. |

| [84] | PING W W, YANG C P, BAO Y H, et al. A silicon anode for garnet-based all-solid-state batteries: Interfaces and nanomechanics[J]. Energy Storage Materials, 2019, 21: 246-252. DOI: 10.1016/j.ensm. 2019.06.024. |

| [1] | Zheng CHEN, Jingyuan HU, Zhigang ZHAO, Jiangwei SHEN, Xuelei XIA, Fuxing WEI. Thermal characteristics study and optimization of air-cooling structures for dual-system battery packs [J]. Energy Storage Science and Technology, 2025, 14(9): 3463-3475. |

| [2] | Bin YANG, Jun YANG, Lang XU, Haowei WEN, Dengfeng LIU, Dianbo RUAN. Ball-head indentation-induced safety evaluation of capacitive lithium-ion batteries [J]. Energy Storage Science and Technology, 2025, 14(8): 3090-3099. |

| [3] | Wei WANG, Huishi LIANG, Miangang LI, Kui ZHOU, Wei WANG, Ziyao WANG, Zinan SHI. Method for monitoring irreversible lithium plating in lithium batteries using transfer learning [J]. Energy Storage Science and Technology, 2025, 14(7): 2698-2706. |

| [4] | Zheng CHEN, Gongdong DUO, Jiangwei SHEN, Shiquan SHEN, Yu LIU, Fuxing WEI. State of health estimation for lithium battery based on incremental capacity analysis and VMD-GWO-KELM [J]. Energy Storage Science and Technology, 2025, 14(6): 2476-2487. |

| [5] | Jingjing RUAN, Xiangkun WU, Yonghui LI, Chongchong ZHAO, Shenshen LI, Tongfei WANG, Shengjie LIANG, Guihong GAO. Preparation and performance studies of low-cost graphite thick dry electrodes [J]. Energy Storage Science and Technology, 2025, 14(6): 2248-2255. |

| [6] | Dandan HAN, Wuwei ZHANG, Liang ZHANG, Zongjiang WANG. Design and electrochemical performance of LiMn1-y Fe y PO4/C cathode materials with a core-shell structure [J]. Energy Storage Science and Technology, 2025, 14(6): 2215-2222. |

| [7] | Zhoulan ZENG, Lei SHANG, Zhijin HU, Zongfan WANG, Xiaochao XIN, Ying LIU. Li5FeO4@C high capacity prelithium cathode materials for lithium-ion batteries [J]. Energy Storage Science and Technology, 2025, 14(5): 1875-1883. |

| [8] | Yingjian CHEN, Shang WU, Yuancheng CAO, Baoshuai DU, Zhenxing WANG, Zhongwen OUYANG, Shun TANG. Application of magnetic separation in the recycling of cathode and anode materials from spent lithium batteries [J]. Energy Storage Science and Technology, 2025, 14(5): 1918-1927. |

| [9] | Xiaolan WU, Pengjie MA, Zhifeng BAI, Chenglong LIU, Guifang GUO, Jinhua ZHANG. A kind of intelligent PID double-layer active balancing control method for lithium-ion battery pack [J]. Energy Storage Science and Technology, 2025, 14(3): 1150-1159. |

| [10] | Nan LI, Jing MA, Tingxiu HUANG, Yixing SHEN, Min SHEN, Yiyi JIANG, Tao HONG, Guoqiang MA, Zifeng MA. Research progress on nitrile compounds in high potential electrolytes [J]. Energy Storage Science and Technology, 2025, 14(3): 997-1009. |

| [11] | Chencheng XU, Zhan WANG, Shuang LI, Jiangmin JIANG, Zhicheng JU. Research progress and engineering application prospects of prelithiation technology for lithium-ion batteries [J]. Energy Storage Science and Technology, 2025, 14(3): 930-946. |

| [12] | Liping ZHOU, Deqing ZHOU, Fenghua ZHENG, Qichang PAN, Sijiang HU, Yongjie JIANG, Hongqiang WANG, Qingyu LI. Preparation and application of Si@void@C composite anode materials for lithium-ion batteries [J]. Energy Storage Science and Technology, 2025, 14(3): 1115-1122. |

| [13] | Jiabo LI, Zhixuan WANG, Di TIAN, Zhonglin SUN. Prediction method for remaining service life of lithium batteries using SSA-LSTM combination under variable mode decomposition [J]. Energy Storage Science and Technology, 2025, 14(2): 659-670. |

| [14] | Jianru ZHANG, Qiyu WANG, Yinghui JI, Xin GAO, Xiqian YU, Hong LI. Application of Auger electron spectroscopy in the analysis of lithium-ion batteries [J]. Energy Storage Science and Technology, 2025, 14(2): 755-769. |

| [15] | Heyu LI, Xiaobo HONG, Zihan CHEN, Dianbo RUAN. The effect of porous heat insulation plate on the heat spread barrier of lithium-ion battery module [J]. Energy Storage Science and Technology, 2025, 14(2): 479-487. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||