Energy Storage Science and Technology ›› 2025, Vol. 14 ›› Issue (10): 3848-3858.doi: 10.19799/j.cnki.2095-4239.2025.0267

• Energy Storage System and Engineering • Previous Articles Next Articles

Xiaohai ZHANG1,2( ), Xinyu SUN2, Zishuo MENG1, Haiyang BIAN2, Haolan ZHAO1, Wenzhe ZHANG2, Pan CHU1(

), Xinyu SUN2, Zishuo MENG1, Haiyang BIAN2, Haolan ZHAO1, Wenzhe ZHANG2, Pan CHU1( ), Mingtao LI2(

), Mingtao LI2( )

)

Received:2025-03-18

Revised:2025-05-14

Online:2025-10-28

Published:2025-10-20

Contact:

Pan CHU, Mingtao LI

E-mail:zxh01@petrochina.com.cn;chupan@petrochina.com.cn;mingtao@mail.xjtu.edu.cn

CLC Number:

Xiaohai ZHANG, Xinyu SUN, Zishuo MENG, Haiyang BIAN, Haolan ZHAO, Wenzhe ZHANG, Pan CHU, Mingtao LI. Gas-liquid-interconversion compressed carbon dioxide energy storage driven by waste heat from the ethylene process for industrial steam production[J]. Energy Storage Science and Technology, 2025, 14(10): 3848-3858.

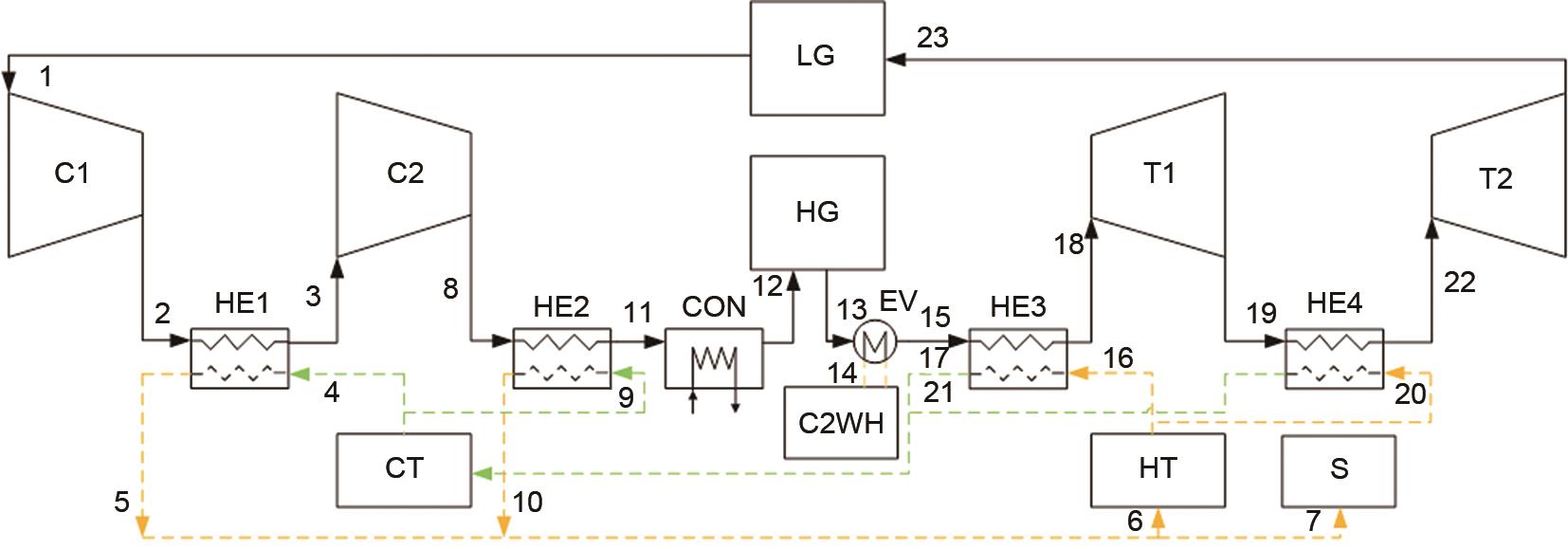

Fig. 1

Schematic structure of gas-liquid interconversion compressed carbon dioxide energy storage system coupled with ethylene process waste heatLG—Low pressure gas storage device, HG—High pressure gas storage device, C1—Low pressure compressor, C2—High pressure compressor, HE—Heat exchanger, CON—Condenser, EV— Evaporator, C2WH—Waste heat from ethylene process, T1—High pressure turbine, T2—Low pressure turbine, CT—Cryogenic tank, HT—High temperature tank, S—Steam"

Table 1

Summary table of main parameters of system design working conditions"

| 参数 | 数值 | 参数 | 数值 |

|---|---|---|---|

| 余热温度/K | 323.15 | 压缩机效率 | 0.90 |

| 低压侧工质温度/K | 293.15(气态) | 透平机工质入口温度/K | 413.15(工况一)/383.15(工况二)/ 473.15(工况三) |

| 低压侧工质压力/MPa | 0.1 | 透平机工质入口流量/(kg/s) | 40 |

| 高压侧工质温度/K | 300.15(液态) | 一段透平机工质入口压力/MPa | 6.75 |

| 高压侧工质压力/MPa | 6.75 | 透平段总膨胀比 | 67.5 |

| 压缩机工质入口温度/K | 293.15 | 透平段各级膨胀比 | 8.22 |

| 压缩机工质入口流量/(kg/s) | 40 | 透平机效率 | 0.9 |

| 一段压缩机工质入口压力/MPa | 0.1 | 换热装置能效 | 0.95 |

| 压缩段总压缩比 | 67.5 | 储能/h | 8 |

| 压缩机各级压缩比 | 8.22 | 释能/h | 8 |

Table 2

Comparison table of simulation values in this paper with literature values"

| 参数 | 仿真值 | 文献值[ | 相对误差/% |

|---|---|---|---|

| 电-电循环效率/% | 78.70 | 77.70 | 1.29 |

| 压缩机入口工质温度/K | 288.15 | 288.15 | — |

| 压缩机入口工质压力/MPa | 0.1 | 0.1 | — |

| 压缩机出口工质温度/K | 721.06 | 720.57 | 0.11 |

| 压缩机出口工质压力/MPa | 6.86 | 6.86 | — |

| 压缩机耗电量/MWh | 23.48 | 23.63 | -0.63 |

| 冷却换热末端出口工质温度/K | 297.65 | 297.65 | — |

| 冷却换热量/MWh | 34.47 | 35.28 | -2.30 |

| 高压储液温度/K | 297.65 | 297.65 | — |

| 加热换热器末端出口工质温度/K | 705.74 | 705.74 | — |

| 加热换热量/MWh | 33.75 | 34.45 | -2.03 |

| 透平机入口工质温度/K | 705.74 | 705.74 | — |

| 透平机入口工质压力/MPa | 5.42 | 5.42 | — |

| 透平机出口工质温度/K | 358.75 | 359.90 | -1.33 |

| 透平机出口工质压力/MPa | 0.1 | 0.1 | — |

| 透平机发电量/MWh | 18.58 | 18.36 | 1.20 |

| CO2质量流量/(kg/s) | 54 | 54 | — |

| 充/放电时长/h | 1 | — |

Table 3

Summary of the main simulation results for the coupled system under 1-hour charge/discharge conditions"

| 参数 | 工况一:绝热系统 | 工况二:产汽工况 | 工况三:产电工况 |

|---|---|---|---|

| 电-电循环效率/% | 76.12 | 71.06 | 86.89 |

| 热量循环效率/% | 100.44 | 59.57 | 73.30 |

| 压缩机总功耗/MWh | 13.04 | 13.04 | 13.04 |

| 压缩机出口温度/K | 487.15 | 487.15 | 487.15 |

| 压缩热回收值/MWh | 12.48 | 12.48 | 12.48 |

| 蒸汽输出量/MWh | 0 | 6.19(8 t) | 0.76(1 t) |

| 余热消耗值/MWh | 0 | 4.27 | 4.27 |

| 透平机总发电/MWh | 9.93 | 9.27 | 11.33 |

| 透平机入口温度/K | 413.15 | 383.15 | 473.15 |

| 热量需求值/MWh | 12.43 | 10.56 | 15.99 |

| 储能密度/(kWh/m3) | 1.38 | 1.29 | 1.57 |

| 循环收益/元 | 4965 | 5355 | 5755 |

| 备注 | 自身热平衡 | 余热:气化潜热 | 余热:气化潜热 |

Table A1

Summary of the main simulation results for the coupled system under 8-hour daily charge/discharge conditions"

| 参数 | 工况一:绝热系统 | 工况二:产汽工况 | 工况三:产电工况 |

|---|---|---|---|

| 电-电循环效率/% | 76.12 | 71.07 | 86.89 |

| 热量循环效率/% | 100.44 | 59.57 | 73.3 |

| 压缩机总功耗/MWh | 104.34 | 104.34 | 104.34 |

| 热量回收值/MWh | 99.87 | 99.87 | 99.87 |

| 透平机总发电/MWh | 79.42 | 74.16 | 90.64 |

| 热量需求值/MWh | 99.44 | 84.48 | 127.92 |

| 压缩机:一段压缩 | |||

| 出口工质温度/K | 487.42 | 487.42 | 487.42 |

| 出口工质压力/MPa | 0.82 | 0.82 | 0.82 |

| 压缩机功耗/MWh | 52.88 | 52.88 | 52.88 |

| 换热器-冷却-一段压缩 | |||

| 工质放热量-显热/MWh | -57.60 | -57.60 | -57.60 |

| 换热器换热量/MWh | -54.72 | -54.72 | -54.72 |

| 压缩机:二段压缩 | |||

| 出口工质温度/K | 461.73 | 461.73 | 461.73 |

| 出口工质压力/MPa | 6.75 | 6.75 | 6.75 |

| 压缩机功耗/MWh | 51.46 | 51.46 | 51.46 |

| 换热器-冷却-二段压缩 | |||

| 工质放热量-显热/MWh | -47.52 | -47.52 | -47.52 |

| 工质放热量-潜热(不回收)/MWh | -32.43 | -32.43 | -32.43 |

| 工质相变温度/K | 300.24 | 300.24 | 300.24 |

| 工质放热量-总量/MWh | -79.96 | -79.96 | -79.96 |

| 换热器换热量/MWh | -75.96 | -75.96 | -75.96 |

| 换热器-加热-一段膨胀 | |||

| 工质吸热量-潜热/MWh | 32.43 | 32.43 | 32.43 |

| 工质吸热量-显热/MWh | 32.57 | 23.52 | 51.28 |

| 工质吸热量-总量/MWh | 65.00 | 56 | 83.76 |

| 换热器换热量/MWh | 68.42 | 58.96 | 88.16 |

| 透平机:一段膨胀 | |||

| 入口工质温度/K | 413.15 | 383.15 | 473.15 |

| 出口工质温度/K | 311.58 | 297.58 | 348.61 |

| 出口工质压力/MPa | 0.82 | 0.82 | 0.82 |

| 透平机做功/MWh | 40.53 | 38.16 | 45.84 |

| 换热器-加热-二段膨胀 | |||

| 工质吸热量-显热/MWh | 29.47 | 24.24 | 37.76 |

| 换热器换热量/MWh | 31.02 | 25.52 | 39.76 |

| 透平机:二段膨胀 | |||

| 入口工质温度/K | 413.15 | 383.15 | 473.15 |

| 出口工质温度/K | 288.75 | 266.23 | 334.70 |

| 出口工质压力/MPa | 0.10 | 0.10 | 0.10 |

| 透平机做功/MWh | 38.89 | 35.92 | 44.8 |

| [1] | 成林. 加快我国新型储能发展的思考[J]. 能源研究与管理, 2023(2): 148-152, 159. DOI: 10.16056/j.2096-7705.2023.02.022. |

| CHENG L. Thoughts on accelerating the development of new energy storage in China[J]. Energy Research and Management, 2023(2): 148-152, 159. DOI: 10.16056/j.2096-7705.2023.02.022. | |

| [2] | 陈海生. "双碳" 目标下的储能发展[J]. 中国电力企业管理, 2021(22): 23-24. |

| CHEN H S. Energy storage development under the goal of "double carbon" [J]. China Power Enterprise Management, 2021(22): 23-24. | |

| [3] | 陈海生, 李泓, 马文涛, 等. 2021年中国储能技术研究进展[J]. 储能科学与技术, 2022, 11(3): 1052-1076. DOI: 10.19799/j.cnki.2095-4239.2022.0105. |

| CHEN H S, LI H, MA W T, et al. Research progress of energy storage technology in China in 2021[J]. Energy Storage Science and Technology, 2022, 11(3): 1052-1076. DOI: 10.19799/j.cnki. 2095-4239.2022.0105. | |

| [4] | 郝佳豪, 越云凯, 张家俊, 等. 二氧化碳储能技术研究现状与发展前景[J]. 储能科学与技术, 2022, 11(10): 3285-3296. DOI: 10.19799/j.cnki.2095-4239.2022.0199. |

| HAO J H, YUE Y K, ZHANG J J, et al. Research status and development prospect of carbon dioxide energy-storage technology[J]. Energy Storage Science and Technology, 2022, 11(10): 3285-3296. DOI: 10.19799/j.cnki.2095-4239.2022.0199. | |

| [5] | 李阳海, 梅欣, 徐万兵, 等. 采用不同工质的压缩气体储能系统热力性能对比分析[J]. 动力工程学报, 2023, 43(2): 269-274. DOI: 10. 19805/j.cnki.jcspe.2023.02.019. |

| LI Y H, MEI X, XU W B, et al. Comparative analysis of thermal performance of compressed gas energy storage systems using different working fluids[J]. Journal of Chinese Society of Power Engineering, 2023, 43(2): 269-274. DOI: 10.19805/j.cnki.jcspe. 2023.02.019. | |

| [6] | 吴思成. 压缩CO2储能的系统分析及实验验证[D]. 天津: 天津商业大学, 2019. |

| [7] | 郑平洋, 郝佳豪, 常鸿, 等. 基于不同液化方式的液态二氧化碳储能系统研究进展[J]. 南方能源建设, 2024, 11(2): 102-111. DOI: 10.16516/j.ceec.2024.2.10. |

| ZHENG P Y, HAO J H, CHANG H, et al. Research progress of liquid carbon dioxide energy storage system based on different liquefaction methods[J]. Southern Energy Construction, 2024, 11(2): 102-111. DOI: 10.16516/j.ceec.2024.2.10. | |

| [8] | 刘辉. 超临界压缩二氧化碳储能系统热力学特性与热经济性研究[D]. 北京: 华北电力大学, 2017. DOI: 10.27140/d.cnki.ghbbu. 2017. 000045. |

| LIU H. Research on thermodynamic and thermoeconomic properties of super-critical compressed carbon dioxide energy storage[D]. Beijing: North China Electric Power University, 2017. DOI: 10.27140/d.cnki.ghbbu.2017.000045. | |

| [9] | DEWEVRE F, LACROIX C, LOUBAR K, et al. Carbon dioxide energy storage systems: Current researches and perspectives[J]. Renewable Energy, 2024, 224: 120030. DOI: 10.1016/j.renene. 2024.120030. |

| [10] | 王鼎, 刘仕桢, 施东波, 等. 新型气液相变压缩二氧化碳储能系统性能分析[J]. 动力工程学报, 2024, 44(3): 339-347. DOI: 10.19805/j.cnki.jcspe.2024.230648. |

| WANG D, LIU S Z, SHI D B, et al. Performance analysis of a novel compressed carbon dioxide energy storage system based on gas-liquid phase change[J]. Journal of Chinese Society of Power Engineering, 2024, 44(3): 339-347. DOI: 10.19805/j.cnki.jcspe.2024.230648. | |

| [11] | FU H L, HE Q, SONG J T, et al. Thermodynamic of a novel solar heat storage compressed carbon dioxide energy storage system[J]. Energy Conversion and Management, 2021, 247: 114757. DOI: 10.1016/j.enconman.2021.114757. |

| [12] | 郝银萍. 跨临界压缩二氧化碳储能系统热力学特性及技术经济性研究[D]. 北京: 华北电力大学, 2021. DOI: 10.27140/d.cnki.ghbbu. 2021.000057. |

| HAO Y P. Research on thermodynamic and techno-economic properties of trans-critical compressed carbon dioxide energy storage system[D]. Beijing: North China Electric Power University, 2021. DOI: 10.27140/d.cnki.ghbbu.2021.000057. | |

| [13] | XU M J, ZHAO P, HUO Y W, et al. Thermodynamic analysis of a novel liquid carbon dioxide energy storage system and comparison to a liquid air energy storage system[J]. Journal of Cleaner Production, 2020, 242: 118437. DOI: 10.1016/j.jclepro. 2019.118437. |

| [14] | CHEN K Q, PU W H, ZHANG Q, et al. Thermodynamic and economic assessment on the supercritical compressed carbon dioxide energy storage system coupled with solar thermal storage[J]. Journal of Energy Storage, 2021, 41: 102959. DOI: 10.1016/j.est.2021.102959. |

| [15] | 严晓生, 王小东, 韩旭, 等. 液态压缩二氧化碳储能与火电机组耦合方案研究[J]. 热力发电, 2023, 52(2): 90-100. DOI: 10.19666/j.rlfd. 202205122. |

| YAN X S, WANG X D, HAN X, et al. Study on coupling scheme of liquid compressed carbon dioxide energy storage system and thermal power unit[J]. Thermal Power Generation, 2023, 52(2): 90-100. DOI: 10.19666/j.rlfd.202205122. | |

| [16] | 杨尔辅, 胡益锋, 周强, 等. 乙烯生产过程建模及控制和优化技术综述[J]. 石油化工自动化, 2002, 38(2): 1-6, 11. DOI: 10.3969/j.issn. 1007-7324.2002.02.001. |

| YANG E F, HU Y F, ZHOU Q, et al. Survey on modeling, control and optimization techniques for ethylene process[J]. Automation in Petro-Chemical Industry, 2002, 38(2): 1-6, 11. DOI: 10.3969/j.issn.1007-7324.2002.02.001. | |

| [17] | 王松汉, 何细藕. 乙烯工艺与技术[M]. 北京: 中国石化出版社, 2000.WANG S H, HE X O. Ethylene process and technology[M]. Beijing: China Petrochemical Press, 2000. |

| [18] | 李春梅. 乙烯装置急冷系统优化节能改造[J]. 炼油与化工, 2024, 35(4): 61-66. DOI: 10.16049/j.cnki.lyyhg.2024.04.013. |

| LI C M. Optimization and energy-saving renovation of quench cooling system of ethylene plant[J]. Refining and Chemical Industry, 2024, 35(4): 61-66. DOI: 10.16049/j.cnki.lyyhg. 2024. 04.013. | |

| [19] | 顾发. 梯级泵站优化模型及参数敏感性分析[J]. 陕西水利, 2023(8): 164-166. DOI: 10.16747/j.cnki.cn61-1109/tv.2023.08.061. |

| GU F. Optimization model and parameter sensitivity analysis of cascade pumping stations[J]. Shaanxi Water Resources, 2023(8): 164-166. DOI: 10.16747/j.cnki.cn61-1109/tv.2023.08.061. | |

| [20] | ASTOLFI M, RIZZI D, MACCHI E, et al. A novel energy storage system based on carbon dioxide unique thermodynamic properties[J]. Journal of Engineering for Gas Turbines and Power, 2022, 144(8): 081012. DOI: 10.1115/1.4054750. |

| [1] | Xiaopeng WANG, Xiuao ZHANG, Hongxia ZHAO, Qiuyan SUN, Hao ZHANG, Gongming XIN, Chao BAI. Thermodynamic analysis of a coupled energy storage system in a coal-fired power plant [J]. Energy Storage Science and Technology, 2025, 14(9): 3509-3520. |

| [2] | Jijin LIN, Qian LIU, Tao QU, Jingkun LI, Dongyong HUANG, Xiaoqing ZHU, Xing JU. Technical and economic analysis of liquid immersion cooling for lithium-ion battery energy storage system [J]. Energy Storage Science and Technology, 2025, 14(9): 3622-3635. |

| [3] | Wenrui WANG, Jiahao HAO, Pingyang Zheng, Yunkai YUE, Junling YANG, Zhentao ZHANG. Design and thermoeconomic assessments of CO2 Carnot battery employing sensible heat storage at high temperatures [J]. Energy Storage Science and Technology, 2025, 14(7): 2714-2728. |

| [4] | Lei WANG, Ruitao YAN, Fan ZHANG, Na YAN, Fen YUE, Xu FU, Mengchen LIU, Yunzhang YANG. Economic analysis of independent energy-storage project participation based on the optimization model of in-spot power market and primary frequency regulation markets [J]. Energy Storage Science and Technology, 2025, 14(2): 834-845. |

| [5] | Qingshan WANG, Yan LI, Qun ZHANG, Decheng WANG. A comparative analysis for various scaled mechanical energy storage technologies applied to power systems with a high share of renewable energy sources [J]. Energy Storage Science and Technology, 2025, 14(2): 854-867. |

| [6] | Qili LIN, Zhen CHEN, Xiaohu WANG, Hongxun QI, Wei WANG. Economic analysis of large-scale hydrogen energy storage based on the “electric-hydrogen-electric” process [J]. Energy Storage Science and Technology, 2024, 13(6): 2068-2077. |

| [7] | Tao ZHANG, Jiakai LIU, Tianle DAI, Cheng XU. Comparative analysis of thermal performance of electrothermal energy storage and liquid energy storage based on carbon dioxide [J]. Energy Storage Science and Technology, 2024, 13(5): 1554-1563. |

| [8] | Liugan ZHANG, Yingchi ZHOU, Wenbing SUN, Kai YE, Longxiang CHEN. Performance of precooled CAES system using ORC-VCR to recover compression heat [J]. Energy Storage Science and Technology, 2024, 13(2): 611-622. |

| [9] | Zhenkun XIAO, Zhen CHEN, Zhuang YANG, Hongxun QI, Jun YAN. Thermodynamic analysis of an advanced high-temperature heat pump energy storage unit based on phase-change heat storage [J]. Energy Storage Science and Technology, 2024, 13(12): 4330-4338. |

| [10] | Wen DU, Junlei WANG, Yunfei XU, Shilong LI, Kun WANG. Techno-economic analysis for the preparation of Li-ion battery's ternary cathode material using flame spray pyrolysis [J]. Energy Storage Science and Technology, 2024, 13(1): 345-357. |

| [11] | Jiajun ZHANG, Xiaoqiong LI, Zhentao ZHANG, Jiahao HAO, Pingyang ZHENG, Ze YU, Junling YANG, Yanan JING, Yunkai YUE. Research progress of compressed carbon dioxide energy storage system [J]. Energy Storage Science and Technology, 2023, 12(6): 1928-1945. |

| [12] | Weiling ZHANG, Han GU, Chao ZHANG, Ang GE, Yuanxu YING. Technical economic characteristics and development trends of compressed air energy storage [J]. Energy Storage Science and Technology, 2023, 12(4): 1295-1301. |

| [13] | Fuchao LI, Mingbiao CHEN, Qun DU, Yongzhen CHEN, Wenji SONG, Wenye LIN, Ziping FENG. Research on in-situ remote offshore wind-power consumption based on ice-slurry cold storage [J]. Energy Storage Science and Technology, 2023, 12(12): 3730-3739. |

| [14] | ZHANG Ping, KANG Libin, WANG Mingju, ZHAO Guang, LUO Zhenhua, TANG Kun, LU Yaxiang, HU Yongsheng. Technology feasibility and economic analysis of Na-ion battery energy storage [J]. Energy Storage Science and Technology, 2022, 11(6): 1892-1901. |

| [15] | Li SHENG, Xinjie XUE, Yanjun BO, Changying ZHAO. Simulation and analysis of pumped thermal electricity storage system based on phase change energy storage medium [J]. Energy Storage Science and Technology, 2022, 11(11): 3649-3657. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||