Energy Storage Science and Technology ›› 2024, Vol. 13 ›› Issue (7): 2407-2413.doi: 10.19799/j.cnki.2095-4239.2024.0096

• Energy Storage Materials and Devices • Previous Articles Next Articles

Zongxun LI1( ), Qiuqiu LYU2, Haoyu ZHAO2, Jianyu HE2, Yang LIU1, Zaihong SUN1, Kaihua SUN1, Tenglong ZHU2(

), Qiuqiu LYU2, Haoyu ZHAO2, Jianyu HE2, Yang LIU1, Zaihong SUN1, Kaihua SUN1, Tenglong ZHU2( )

)

Received:2024-01-29

Revised:2024-02-15

Online:2024-07-28

Published:2024-07-23

Contact:

Tenglong ZHU

E-mail:lizi5210@126.com;zhutenglong@njust.edu.cn

CLC Number:

Zongxun LI, Qiuqiu LYU, Haoyu ZHAO, Jianyu HE, Yang LIU, Zaihong SUN, Kaihua SUN, Tenglong ZHU. Research of GDC barrier layer applications by hydrothermal insitu growth in industrial-sized SOFC[J]. Energy Storage Science and Technology, 2024, 13(7): 2407-2413.

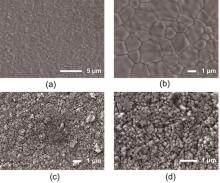

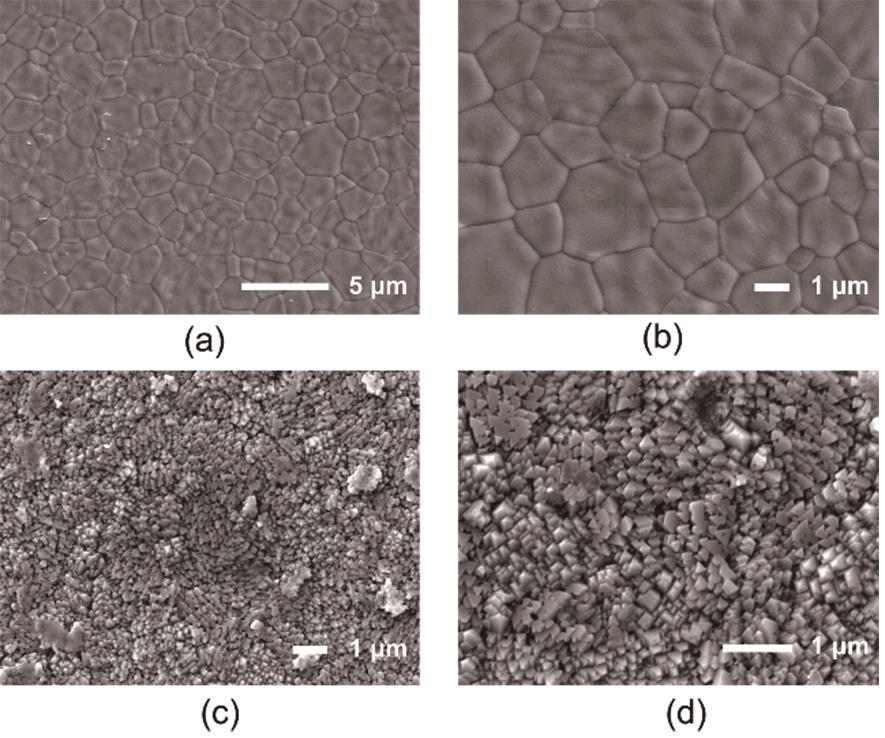

Fig. 4

SEM images of surfaces from YSZ electrolyte and GDC barrier layer by in-situ hydrothermal growth(a) Surface of YSZ electrolyte (5000x); (b) Surface of YSZ electrolyte (10000x); (c) Surface of GDC barrier layer by hydrothermal in-situ growth (10000x); (d) Surface of GDC barrier layer by hydrothermal in-situ growth (20000x)"

| 1 | HE S, JIANG S P. Electrode/electrolyte interface and interface reactions of solid oxide cells: Recent development and advances[J]. Progress in Natural Science: Materials International, 2021, 31(3): 341-372. |

| 2 | BOLDRIN P, BRANDON N P. Progress and outlook for solid oxide fuel cells for transportation applications[J]. Nature Catalysis, 2019, 2: 571-577. |

| 3 | WILLIAMS M C, VORA S D, JESIONOWSKI G. Worldwide status of solid oxide fuel cell technology[J]. ECS Transactions, 2020, 96(1): 1-10. |

| 4 | BIAN W J, WU W, WANG B M, et al. Revitalizing interface in protonic ceramic cells by acid etch[J]. Nature, 2022, 604: 479-485. |

| 5 | MOGENSEN M B, CHEN M, FRANDSEN H L, et al. Reversible solid-oxide cells for clean and sustainable energy[J]. Clean Energy, 2019, 3(3): 175-201. |

| 6 | Lenser C, Udomsilp D, Menzler N H, et al. Solid oxide fuel and electrolysis cells in advanced ceramics for energy conversion and storage[M], Elsevier, 2020: 387-547. |

| 7 | UDOMSILP D, LENSER C, GUILLON O, et al. Performance benchmark of planar solid oxide cells based on material development and designs[J]. Energy Technology, 2021, 9(4): 2001062. |

| 8 | WACHSMAN E D, LEE K T. Lowering the temperature of solid oxide fuel cells[J]. Science, 2011, 334(6058): 935-939. |

| 9 | ZHANG J, LENSER C, RUSSNER N, et al. Boosting intermediate temperature performance of solid oxide fuel cells via a tri-layer ceria-zirconia-ceria electrolyte[J]. Journal of the American Ceramic Society, 2023, 106(1): 93-99. |

| 10 | LI Z P, TOSHIYUKI M, AUCHTERLONIE G J, et al. Mutual diffusion ocurring at the interface between La0.6Sr0.4Co0.8Fe0.2O3 cathode and Gd-doped ceria electrolyte during IT-SOFC cell preparation[J]. ACS Applied Materials & Interfaces, 2011, 3(7): 2772-2778. |

| 11 | FU C, GE X, CHAN S H, et al. Fabrication and characterization of anode-supported low-temperature SOFC based on Gd-doped ceria electrolyte[J]. Fuel Cells, 2012, 12(3): 450-456. |

| 12 | SıNDıRAÇ C, BÜYÜKAKSOY A, AKKURT S. Electrical properties of gadolinia doped ceria electrolytes fabricated by infiltration aided sintering[J]. Solid State Ionics, 2019, 340: 115020. |

| 13 | LYU Q Q, ZHU T L, LI Z X, et al. Enhancement of the cathode/electrolyte interface by a sintering-active barrier layer for solid oxide fuel cells[J]. International Journal of Hydrogen Energy, 2023, 48(40): 15238-15247. |

| 14 | LYU Q Q, ZHU T L, QU H X, et al. Lower down both ohmic and cathode polarization resistances of solid oxide fuel cell via hydrothermal modified gadolinia doped ceria barrier layer[J]. Journal of the European Ceramic Society, 2021, 41(12): 5931-5938. |

| 15 | MATSUDA J, KANAE S, KAWABATA T, et al. TEM and ETEM study on SrZrO3 formation at the LSCF/GDC/YSZ interfaces[J]. Ecs Transactions, 2017, 78(1): 993-1001. |

| 16 | SZÁSZ J, WANKMÜLLER F, WILDE V, et al. Nature and functionality of La0.58Sr0.4Co0.2Fe0.8O3- δ/Gd0.2Ce0.8O2- δ/Y0.16Zr0.84O2- δ interfaces in SOFCs[J]. Journal of the Electrochemical Society, 2018, 165(10): F898-F906. |

| 17 | WILDE V, STÖRMER H, SZÁSZ J, et al. Gd0.2Ce0.8O2 diffusion barrier layer between (La0.58Sr0.4)(Co0.2Fe0.8)O3-δ cathode and Y0.16Zr0.84O2 electrolyte for solid oxide fuel cells: Effect of barrier layer sintering temperature on microstructure[J]. ACS Applied Energy Materials, 2018, 1(12): 6790-6800. |

| 18 | MOLIN S, KARCZEWSKI J, KAMECKI B, et al. Processing of Ce0.8Gd0.2O2- δ barrier layers for solid oxide cells: The effect of preparation method and thickness on the interdiffusion and electrochemical performance[J]. Journal of the European Ceramic Society, 2020, 40(15): 5626-5633. |

| 19 | KHAN M Z, SONG R H, MEHRAN M T, et al. Controlling cation migration and inter-diffusion across cathode/interlayer/electrolyte interfaces of solid oxide fuel cells: A review[J]. Ceramics International, 2021, 47(5): 5839-5869. |

| 20 | JANG I, KIM S, KIM C, et al. Interface engineering of yttrium stabilized zirconia/gadolinium doped ceria bi-layer electrolyte solid oxide fuel cell for boosting electrochemical performance[J]. Journal of Power Sources, 2019, 435: 226776. |

| 21 | MEHRANJANI A S, CUMMING D J, SINCLAIR D C, et al. Low-temperature co-sintering for fabrication of zirconia/ceria bi-layer electrolyte via tape casting using a Fe2O3 sintering aid[J]. Journal of the European Ceramic Society, 2017, 37(13): 3981-3993. |

| 22 | CODDET P, VULLIET J, RICHARD C, et al. Characteristics and properties of a magnetron sputtered gadolinia-doped ceria barrier layer for solid oxide electrochemical cells[J]. Surface and Coatings Technology, 2018, 339: 57-64. |

| 23 | DE VERO J C, DEVELOS-BAGARINAO K, MATSUDA H, et al. Sr and Zr transport in PLD-grown Gd-doped ceria interlayers[J]. Solid State Ionics, 2018 (314): 165-171. |

| 24 | FONSECA F C, UHLENBRUCK S, NEDÉLÉC R, et al. Properties of bias-assisted sputtered gadolinia-doped ceria interlayers for solid oxide fuel cells[J]. Journal of Power Sources, 2010, 195(6): 1599-1604. |

| 25 | MYUNG D H, HONG J, YOON K, et al. The effect of an ultra-thin zirconia blocking layer on the performance of a 1-μm-thick gadolinia-doped ceria electrolyte solid-oxide fuel cell[J]. Journal of Power Sources, 2012, 206: 91-96. |

| 26 | NURK G, VESTLI M, MÖLLER P, et al. Mobility of Sr in gadolinia doped ceria barrier layers prepared using spray pyrolysis, pulsed laser deposition and magnetron sputtering methods[J]. Journal of the Electrochemical Society, 2015, 163(2): F88-F96. |

| 27 | RIEGRAF M, HAN F, SATA N, et al. Intercalation of thin-film Gd-doped ceria barrier layers in electrolyte-supported solid oxide cells: Physicochemical aspects[J]. ACS Applied Materials & Interfaces, 2021, 13(31): 37239-37251. |

| 28 | 赵浩宇, 吕秋秋, 程丽亚, 等. 水热原位生长制备致密氧化铈基固体氧化物燃料电池隔离层[J]. 硅酸盐学报, 2023, 51(4): 1000-1006. |

| ZHAO H Y, LYU Q Q, CHENG L Y, et al. In-situ hydrothermal growth of dense ceria based barrier layer for solid oxide fuel cells[J]. Journal of the Chinese Ceramic Society, 2023, 51(4): 1000-1006. | |

| 29 | 崔同慧, 李航越, 吕泽伟, 等. 大尺寸固体氧化物燃料电池的电极过程解析方法[J]. 物理化学学报, 2022, 38(8): 48-56. |

| CUI T H, LI H Y, LYU Z W, et al. Identification of electrode process in large-size solid oxide fuel cell[J]. Acta Physico-Chimica Sinica, 2022, 38(8): 48-56. | |

| 30 | 王怡戈, 李航越, 吕泽伟, 等. 工业尺寸固体氧化物燃料电池高效及阳极安全运行条件研究[J]. 化学学报, 2022, 80(8): 1091-1101. |

| WANG Y G, LI H Y, LYU Z W, et al. Study of operating conditions for high efficiency and anode safety of industrial-size solid oxide fuel cell[J]. Acta Chimica Sinica, 2022, 80(8): 1091-1101. | |

| 31 | LI H,LYU Z, HAN M. Robust and fast estimation of equivalent circuit model from noisy electrochemical impedance spectra[J]. Electrochimica Acta, 2022 (422): 140474. |

| [1] | Sen JIANG, Long CHEN, Chuangchao SUN, Jinze WANG, Ruhong LI, Xiulin FAN. Low-temperature lithium battery electrolytes: Progress and perspectives [J]. Energy Storage Science and Technology, 2024, 13(7): 2270-2285. |

| [2] | Xiang LI, Dezhong LIU, Kai YUAN, Dapeng CHEN. Solid-state electrolyte for low-temperature lithium metal batteries [J]. Energy Storage Science and Technology, 2024, 13(7): 2327-2347. |

| [3] | Zheng LI, Zhenzhong YANG, Qiong WANG, Renzong HU. Patent intelligence analysis of the research progress in low-temperature electrolytes for Li-ion batteries [J]. Energy Storage Science and Technology, 2024, 13(7): 2317-2326. |

| [4] | Junjie LU, Dan PENG, Wenjing NI, Yuan YANG, Jinglun WANG. Research progress on electrolyte for Li/CF x battery [J]. Energy Storage Science and Technology, 2024, 13(5): 1487-1495. |

| [5] | Xiuli GUO, Xiaolong ZHOU, Caineng ZOU, Yongbing TANG. Research progress and perspectives of aqueous dual-ions batteries [J]. Energy Storage Science and Technology, 2024, 13(2): 462-479. |

| [6] | Yuhang LI, Zhuo HAN, Xufei AN, Danfeng ZHANG, Guorui ZHENG, Ming LIU, Yanbing HE. Progress of ion transport in solid-state battery research based on solid state nuclear magnetic resonance [J]. Energy Storage Science and Technology, 2024, 13(1): 178-192. |

| [7] | Zhuo LI, Xin GUO. Solidification of polymer-based electrolytes for energy-density solid-state batteries [J]. Energy Storage Science and Technology, 2024, 13(1): 212-230. |

| [8] | Yonghao HUANG, Guojing ZANG, Weiya ZHU, Youhao LIAO, Weishan LI. Enhancing interfacial stability between lithium-containing ceramic separator and 4.35 V LiNi0.8Co0.1Mn0.1O2 cathode through LiF additives [J]. Energy Storage Science and Technology, 2023, 12(8): 2361-2369. |

| [9] | Huan LIU, Na PENG, Qingwen GAO, Wenpeng LI, Zhirong YANG, Jingtao WANG. Crown ether-doped polymer solid electrolyte for high-performance all-solid-state lithium batteries [J]. Energy Storage Science and Technology, 2023, 12(8): 2401-2411. |

| [10] | Zhihao LIU, Tong DU, Ruirui LI, Tao DENG. Developments of wide temperature range, high voltage and safe EC-free electrolytes [J]. Energy Storage Science and Technology, 2023, 12(8): 2504-2525. |

| [11] | Zenghui HAO, Xunliang LIU, Yuan MENG, Nan MENG, Zhi WEN. Effect of electrode interface microstructure on the performance of solid-state lithium-ion battery [J]. Energy Storage Science and Technology, 2023, 12(7): 2095-2104. |

| [12] | Jiayi ZHANG, Suting WENG, Zhaoxiang WANG, Xuefeng WANG. Solid electrolyte interphase (SEI) on graphite anode correlated with thermal runaway of lithium-ion batteries [J]. Energy Storage Science and Technology, 2023, 12(7): 2105-2118. |

| [13] | Qixin GAO, Jingteng ZHAO, Guoxing LI. Research progress on fast-charging lithium-ion batteries [J]. Energy Storage Science and Technology, 2023, 12(7): 2166-2184. |

| [14] | Shenran ZHANG, Lihuan XU, Chang SU. Influence of different carbon contents on the electrochemical performance of SiO/C anode [J]. Energy Storage Science and Technology, 2023, 12(6): 1784-1793. |

| [15] | Lingfeng HUANG, Dongmei HAN, Sheng HUANG, Shuanjin WANG, Min XIAO, Yuezhong MENG. Research progress of polymer electrolytes containing organoboron for lithium-ion batteries [J]. Energy Storage Science and Technology, 2023, 12(6): 1815-1830. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||