Energy Storage Science and Technology ›› 2025, Vol. 14 ›› Issue (7): 2575-2589.doi: 10.19799/j.cnki.2095-4239.2025.0241

• Special Issue on the 13th Energy Storage International Conference and Exhibition • Previous Articles Next Articles

Wenyuan WENG1( ), Bin SHEN2(

), Bin SHEN2( ), Jiangong ZHU1(

), Jiangong ZHU1( ), Yang WANG2, Huapeng LU2, Wuliyasu HE2, Haonan LIU1, Haifeng DAI1, Xuezhe WEI1

), Yang WANG2, Huapeng LU2, Wuliyasu HE2, Haonan LIU1, Haifeng DAI1, Xuezhe WEI1

Received:2025-03-14

Revised:2025-04-06

Online:2025-07-28

Published:2025-07-11

Contact:

Bin SHEN, Jiangong ZHU

E-mail:2332933@tongji.edu.cn;bin.shen@volvocars.com;zhujiangong@tongji.edu.cn

CLC Number:

Wenyuan WENG, Bin SHEN, Jiangong ZHU, Yang WANG, Huapeng LU, Wuliyasu HE, Haonan LIU, Haifeng DAI, Xuezhe WEI. Detecting hazardous lithium plating on anodes of lithium-ion batteries—A review of in situ methods[J]. Energy Storage Science and Technology, 2025, 14(7): 2575-2589.

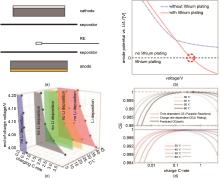

Fig. 4

(a) Schematic diagram of a three-electrode cell; (b) Principle of anode potential measurement; (c) Experimental results under different combinations of temperature, cut-off voltage, and charging rate;(d) Schematic of CE versus charging C rate with both the time-dependent and charging C rate-dependent resolved curves (bottom) and the resulting CE versus rate curve (top) at different temperatures"

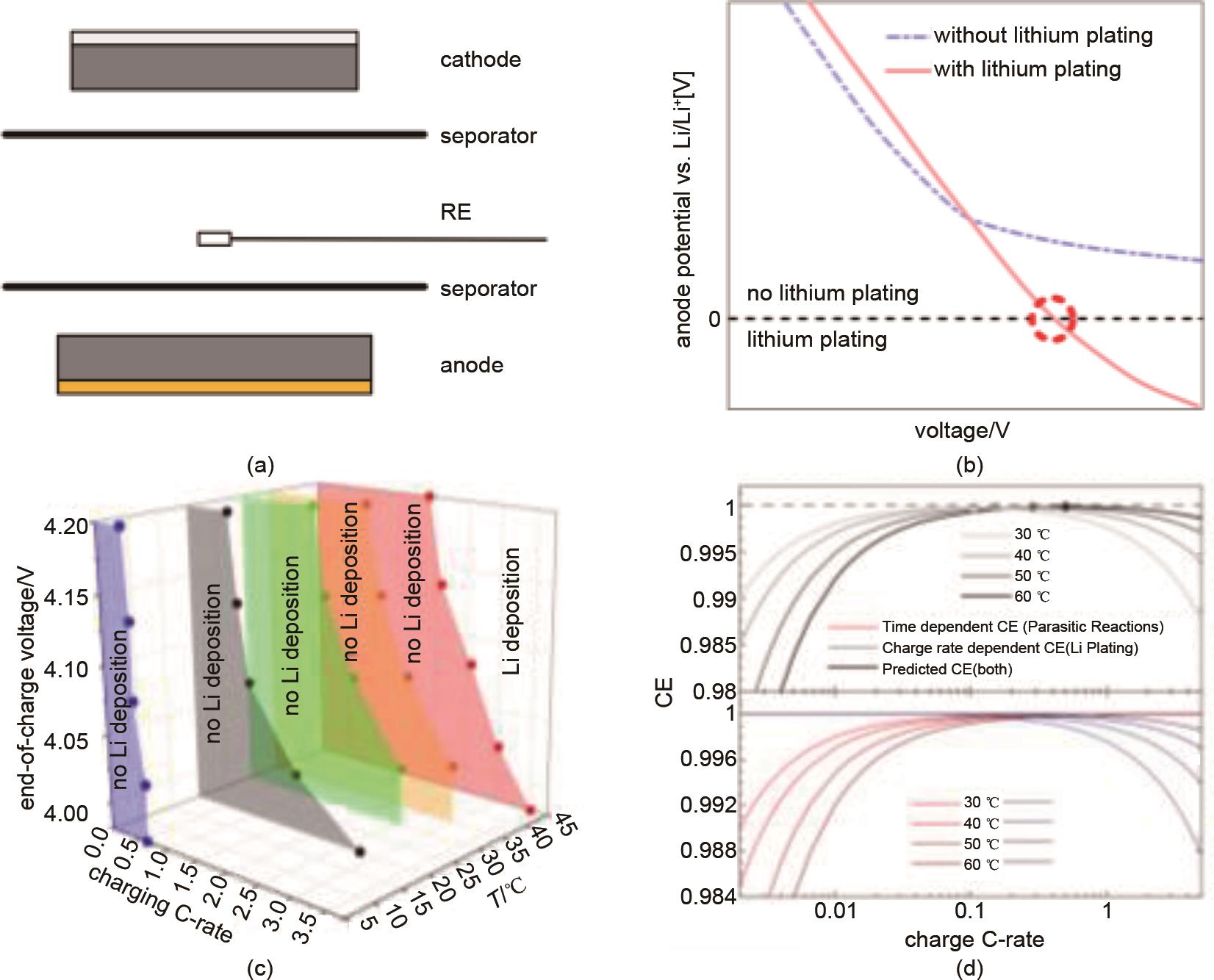

Fig. 7

(a) Three stages of lithium plating; (b) Safety boundary for lithium plating in lithium-ion batteries; (c) Schematic diagram of the boundary between lithium intercalation into graphite and lithium deposition at 0 ℃, the “ x ” symbol represents the inflection points of charge transfer resistance changes at different charging rates at 0 ℃, and the black and red lines are obtained by fitting these inflection points; (d) DSC curve; (e) DSC results of the negative electrodes of different N/P batteries; (f) Critical temperature diagram for battery thermal runaway; (g) Predicted safety status of different N/P batteries based on a warning temperature of 70 ℃, with the safety boundary extended to different charging rates to provide scientific guidance for fast charging, and the green area shown in the figure can serve as a reference for battery design"

| [1] | LIU K L, WEI Z B, ZHANG C H, et al. Towards long lifetime battery: AI-based manufacturing and management[J]. IEEE/CAA Journal of Automatica Sinica, 2022, 9(7): 1139-1165. |

| [2] | LIU Q Q, DU C Y, SHEN B, et al. Understanding undesirable anode lithium plating issues in lithium-ion batteries[J]. RSC Advances, 2016, 6(91): 88683-88700. DOI: 10.1039/C6RA19482F. |

| [3] | YANG X G, GE S, LIU T, et al. A look into the voltage plateau signal for detection and quantification of lithium plating in lithium-ion cells [J]. Electrochemical Energy Storage, 2018, 395: 251-61. |

| [4] | WHITEHEAD A H, PERKINS M, OWEN J R. A graphical aid to evaluation of carbon-based Li-ion electrodes [J]. Journal of the Electrochemical Society, 1997, 144(4): L92-L94. DOI:10.1149/1. 1837564. |

| [5] | VERBRUGGE M W, KOCH B J. The effect of large negative potentials and overcharge on the electrochemical performance of lithiated carbon[J]. Journal of Electroanalytical Chemistry, 1997, 436(1/2): 1-7. DOI: 10.1016/S0022-0728(97)00031-4. |

| [6] | JEON Y, KANG S J, JOO S H, et al. Pyridinic-to-graphitic conformational change of nitrogen in graphitic carbon nitride by lithium coordination during lithium plating[J]. Energy Storage Materials, 2020, 31: 505-514. DOI: 10.1016/j.ensm.2020.06.041. |

| [7] | CHEN K H, WOOD K N, KAZYAK E, et al. Dead lithium: Mass transport effects on voltage, capacity, and failure of lithium metal anodes[J]. Journal of Materials Chemistry A, 2017, 5(23): 11671-11681. DOI: 10.1039/C7TA00371D. |

| [8] | JIANG Y, WANG Z X, XU C X, et al. Atomic layer deposition for improved lithiophilicity and solid electrolyte interface stability during lithium plating[J]. Energy Storage Materials, 2020, 28: 17-26. DOI: 10.1016/j.ensm.2020.01.019. |

| [9] | YANG T Z, SUN Y W, QIAN T, et al. Lithium dendrite inhibition via 3D porous lithium metal anode accompanied by inherent SEI layer[J]. Energy Storage Materials, 2020, 26: 385-390. DOI: 10. 1016/j.ensm.2019.11.009. |

| [10] | CHEN R, MIAO S, JIA Y, et al. A review of detecting Li plating on graphite anodes based on electrochemical methods[J]. Journal of Materials Chemistry A, 2024, 12(48): DOI:10.1039/D4TA05871B. |

| [11] | LIU S, XIONG L, HE C. Long cycle life lithium ion battery with lithium nickel cobalt manganese oxide (NCM) cathode[J]. Journal of Power Sources, 2014, 261: 285-291.DOI:10.1016/j.jpowsour. 2014.03.083. |

| [12] | 邓林旺, 冯天宇, 舒时伟,等. 锂离子电池无损析锂检测研究进展[J]. 储能科学与技术, 2023, 12(1): 263-277. DOI: 10.19799/j.cnki. 2095-4239.2022.0428. |

| DENG L W, FENG T Y, SHU S W, et al. Nondestructive lithium plating online detection for lithium-ion batteries: A review[J]. Energy Storage Science and Technology, 2023, 12(1): 263-277. DOI: 10.19799/j.cnki.2095-4239.2022.0428. | |

| [13] | 王羽, 周星, 王睿茜, 等. 面向BMS应用的锂离子电池析锂诊断方法综述[J]. 中国电机工程学报, 2024, 44(21): 8444-8462. DOI: 10. 13334/j.0258-8013.pcsee.230872. |

| WANG Y, ZHOU X, WANG R X, et al. Lithium plating detection methods in Li-ion batteries for battery management system application: A review[J]. Proceedings of the CSEE, 2024, 44(21): 8444-8462. DOI: 10.13334/j.0258-8013.pcsee.230872. | |

| [14] | 陈佳慧, 王飞, 危荃, 等. 锂电池安全性能无损检测技术研究进展[J]. 无损检测, 2022, 44(12): 72-75. |

| CHEN J H, WANG F, WEI Q, et al. Research progress on nondestructive testing technology of lithium battery safety performance[J]. Nondestructive Testing, 2022, 44(12): 72-75. | |

| [15] | LIU X M, ARNOLD C B. Effects of current density on defect-induced capacity fade through localized plating in lithium-ion batteries[J]. Journal of the Electrochemical Society, 2020, 167(13): 130519. DOI: 10.1149/1945-7111/abb838. |

| [16] | ZHAO X C, YIN Y L, HU Y, et al. Electrochemical-thermal modeling of lithium plating/stripping of Li(Ni0.6Mn0.2Co0.2)O2/carbon lithium-ion batteries at subzero ambient temperatures[J]. Journal of Power Sources, 2019, 418: 61-73. DOI: 10.1016/j.jpowsour. 2019.02.001. |

| [17] | REN D S, SMITH K, GUO D X, et al. Investigation of lithium plating-stripping process in Li-ion batteries at low temperature using an electrochemical model[J]. Journal of the Electrochemical Society, 2018, 165(10): A2167-A2178. DOI: 10.1149/2.0661810jes. |

| [18] | YANG X, ZHANG G, GE S, et al. Fast charging of lithium-ion batteries at all temperatures[J]. Proceedings of the National Academy of Sciences of the United States of America, 2018, 115: DOI:10.1073/pnas.1807115115. |

| [19] | WALDMANN T, HOGG B I, WOHLFAHRT MEHRENS M. Li plating as unwanted side reaction in commercial Li-ion cells—A review [J]. Journal of Power Sources, 2018, 384: 107-124. DOI:10.1016/j.jpowsour.2018.02.063. |

| [20] | TANIM T R, DUFEK E J, DICKERSON C C, et al. Electrochemical quantification of lithium plating: Challenges and considerations[J]. Journal of the Electrochemical Society, 2019, 166(12): A2689-A2696. DOI: 10.1149/2.1581912jes. |

| [21] | RANGARAJAN S P, BARSUKOV Y, P P M. In operando signature and quantification of lithium plating[J]. Journal of Materials Chemistry A, 2019, 7(36): 20683-20695.DOI:10.1039/C9TA07314K. |

| [22] | ZHANG L, ZHANG Z C, REDFERN P C, et al. Molecular engineering towards safer lithium-ion batteries: A highly stable and compatible redox shuttle for overcharge protection[J]. Energy & Environmental Science, 2012, 5(8): 8204-8207. DOI: 10.1039/C2EE21977H. |

| [23] | JUAREZ-ROBLES D, VYAS A A, FEAR C, et al. Overcharge and aging analytics of Li-ion cells[J]. Journal of the Electrochemical Society, 2020, 167(9): 090547. DOI: 10.1149/1945-7111/ab9569. |

| [24] | COSBY M R, CARIGNAN G M, LI Z, et al. operando synchrotron studies of inhomogeneity during anode-free plating of Li metal in pouch cell batteries[J]. Journal of the Electrochemical Society, 2022, 169(2): 020571. DOI: 10.1149/1945-7111/ac5345. |

| [25] | BLOOM I D, JANSEN A N, ABRAHAM D P, et al. Differential voltage analyses of high-power, lithium-ion cells: 1. Technique and application [J]. Journal of Power Sources, 2005, 139(1/2): 295-303. DOI:10.1016/j.jpowsour.2004.07.022. |

| [26] | PETZL M, DANZER M A. Nondestructive detection, characterization, and quantification of lithium plating in commercial lithium-ion batteries [J]. Journal of Power Sources, 2014, 254(15): 80-87.DOI:10.1016/j.jpowsour.2013.12.060. |

| [27] | O'KANE S E J, CAMPBELL I D, MARZOOK M W J, et al. Physical origin of the differential voltage minimum associated with lithium plating in Li-ion batteries[J]. Journal of the Electrochemical Society, 2020, 167(9): 090540. DOI: 10.1149/1945-7111/ab90ac. |

| [28] | CAMPBELL I D, MARZOOK M, MARINESCU M, et al. How observable is lithium plating? Differential voltage analysis to identify and quantify lithium plating following fast charging of cold lithium-ion batteries[J]. Journal of the Electrochemical Society, 2019, 166(4): A725-A739. DOI: 10.1149/2.0821904jes. |

| [29] | UHLMANN C, ILLIG J, ENDER M, et al. In situ detection of lithium metal plating on graphite in experimental cells[J]. Journal of Power Sources, 2015, 279: 428-438. DOI: 10.1016/j.jpowsour. 2015.01.046. |

| [30] | KATZER F, JAHN L, HAHN M, et al. Model-based lithium deposition detection method using differential voltage analysis[J]. Journal of Power Sources, 2021, 512: DOI: 10.1016/j.jpowsour. 2021.230449. |

| [31] | SCHINDLER S, BAUER M, PETZL M, et al. Voltage relaxation and impedance spectroscopy as In-operando methods for the detection of lithium plating on graphitic anodes in commercial lithium-ion cells[J]. Journal of Power Sources, 2016, 304: 170-180. DOI: 10.1016/j.jpowsour.2015.11.044. |

| [32] | KOLETI U R, DINH T Q, MARCO J. A new on-line method for lithium plating detection in lithium-ion batteries [J]. Journal of Power Sources, 2020, 451: DOI:10.1016/j.jpowsour.2020.227798. |

| [33] | JANAKIRAMAN U, GARRICK T R, FORTIER M E. Review-lithium plating detection methods in Li-ion batteries[J]. Journal of The Electrochemical Society, 2020, 167(16): DOI:10.1149/1945-7111/abd3b8. |

| [34] | ANSEÁN D, DUBARRY M, DEVIE A, et al. operando lithium plating quantification and early detection of a commercial LiFePO4 cell cycled under dynamic driving schedule[J]. Journal of Power Sources, 2017, 356: 36-46. DOI: 10.1016/j.jpowsour. 2017.04.072. |

| [35] | YOU H Z, JIANG B, ZHU J G, et al. In-situ quantitative detection of irreversible lithium plating within full-lifespan of lithium-ion batteries[J]. Journal of Power Sources, 2023, 564: 232892. DOI: 10.1016/j.jpowsour.2023.232892. |

| [36] | HE J T, BIAN X L, LIU L C, et al. Comparative study of curve determination methods for incremental capacity analysis and state of health estimation of lithium-ion battery[J]. Journal of Energy Storage, 2020, 29: 101400. DOI: 10.1016/j.est.2020. 101400. |

| [37] | BLANC F, LESKES M, GREY C P. In situ solid-state NMR spectroscopy of electrochemical cells: Batteries, supercapacitors, and fuel cells[J]. Accounts of Chemical Research, 2013, 46(9):1952-63.DOI:10.1021/ar400022u. |

| [38] | XIE P, PENG Y M, LIU X B, et al. Electronegative graphene film based interface-chemistry regulation for stable lithium metal batteries[J]. Chemical Engineering Journal, 2023, 478: 147304. DOI: 10.1016/j.cej.2023.147304. |

| [39] | ARAI J, OKADA Y, SUGIYAMA T, et al. In situ solid state 7Li NMR observation of lithium metal deposition during overcharge in lithium ion battery[J]. Journal of the Electrochemical Society, 2014, 62(1): 159-187. |

| [40] | HSIEH Y C, LEIßING M, NOWAK S, et al. Quantification of dead lithium via in situ nuclear magnetic resonance spectroscopy[J]. Cell Reports Physical Science, 2020, 1(8): 100139. DOI: 10.1016/j.xcrp.2020.100139. |

| [41] | KITADA K, PECHER O, MAGUSIN P C M M, et al. Unraveling the reaction mechanisms of SiO anodes for Li-ion batteries by combining in situ 7Li and ex situ 7Li/29Si solid-state NMR spectroscopy[J]. Journal of the American Chemical Society, 2019, 141(17): 7014-7027. DOI: 10.1021/jacs.9b01589. |

| [42] | HOPE M A, RINKEL B L D, GUNNARSDÓTTIR A B, et al. Selective NMR observation of the SEI-metal interface by dynamic nuclear polarisation from lithium metal[J]. Nature Communications, 2020, 11: 2224. DOI: 10.1038/s41467-020-16114-x. |

| [43] | GEISE N R, KASSE R M, WEKER J N, et al. Quantification of efficiency in lithium metal negative electrodes via operando X-ray diffraction[J]. Chemistry of Materials: A Publication of the American Chemistry Society, 2021, 33(18): 7537-7545. |

| [44] | PAUL P P, THAMPY V, CAO C T, et al. Quantification of heterogeneous, irreversible lithium plating in extreme fast charging of lithium-ion batteries[J]. Energy & Environmental Science, 2021, 14(9): 4979-4988. DOI: 10.1039/D1EE01216A. |

| [45] | SADD M, XIONG S Z, BOWEN J R, et al. Investigating microstructure evolution of lithium metal during plating and stripping via operando X-ray tomographic microscopy[J]. Nature Communications, 2023, 14: 854. DOI: 10.1038/s41467-023-36568-z. |

| [46] | TAIWO O O, FINEGAN D P, PAZ-GARCIA J M, et al. Investigating the evolving microstructure of lithium metal electrodes in 3D using X-ray computed tomography[J]. Physical Chemistry Chemical Physics, 2017, 19(33): 22111-22120. DOI: 10.1039/C7CP02872E. |

| [47] | BURNS J C, STEVENS D A, DAHN J R. In-situ detection of lithium plating using high precision Coulometry[J]. Journal of the Electrochemical Society, 2015, 162(6): A959-A964. DOI: 10.1149/2.0621506jes. |

| [48] | TALIAN S D, BOBNAR J, SINIGOJ A R, et al. Transmission line model for description of the impedance response of Li electrodes with dendritic growth [J]. National Institute of Chemistry, 2019, 123(46): 27997-28007. |

| [49] | KOSEOGLOU M, TSIOUMAS E, FERENTINOU D, et al. Lithium plating detection using dynamic electrochemical impedance spectroscopy in lithium-ion batteries[J]. Journal of Power Sources, 2021, 512: 230508. DOI: 10.1016/j.jpowsour.2021.230508. |

| [50] | WALDMANN T, HOGG B I, KASPER M, et al. Interplay of operational parameters on lithium deposition in lithium-ion cells: Systematic measurements with reconstructed 3-electrode pouch full cells[J]. Journal of the Electrochemical Society, 2016, 163(7): A1232-A1238. DOI: 10.1149/2.0591607jes. |

| [51] | RANGARAJAN S P, BARSUKOV Y, MUKHERJEE P P. In operando signature and quantification of lithium plating[J]. Journal of Materials Chemistry A, 2019, 7(36): 20683-20695. DOI: 10.1039/C9TA07314K. |

| [52] | ABRAHAM D P, POPPEN S D, JANSEN A N, et al. Application of a lithium-tin reference electrode to determine electrode contributions to impedance rise in high-power lithium-ion cells[J]. Electrochimica Acta, 2004, 49(26): 4763-4775. DOI: 10.1016/j.electacta.2004. 05.040. |

| [53] | MANTIA F L, WESSELLS C D, DESHAZER H D, et al. Reliable reference electrodes for lithium-ion batteries[J]. Electrochemistry Communications, 2013, 31: 141-144. DOI: 10.1016/j.elecom. 2013.03.015. |

| [54] | YANG F F, SONG X B, DONG G Z, et al. A Coulombic efficiency-based model for prognostics and health estimation of lithium-ion batteries[J]. Energy, 2019, 171: 1173-1182. DOI: 10.1016/j.energy. 2019.01.083. |

| [55] | TANIM T R, DUFEK E J, DICKERSON C C, et al. Electrochemical quantification of lithium plating: Challenges and considerations[J]. Journal of the Electrochemical Society, 2019, 166(12): A2689-A2696. DOI: 10.1149/2.1581912jes. |

| [56] | PELED E, MENKIN S. Review-SEI: Past, present and future[J]. Journal of the Electrochemical Society, 2017, 164(7): A1703-A1719. DOI: 10.1149/2.1441707jes. |

| [57] | PETZL M, KASPER M, DANZER M A. Lithium plating in a commercial lithium-ion battery—A low-temperature aging study[J]. Journal of Power Sources, 2015, 275: 799-807. DOI: 10.1016/j.jpowsour.2014.11.065. |

| [58] | PASTOR-FERNÁNDEZ C, UDDIN K, CHOUCHELAMANE G H, et al. A comparison between electrochemical impedance spectroscopy and incremental capacity-differential voltage as Li-ion diagnostic techniques to identify and quantify the effects of degradation modes within battery management systems[J]. Journal of Power Sources, 2017, 360: 301-318. DOI: 10.1016/j.jpowsour.2017. 03.042. |

| [59] | SCHINDLER S, BAUER M, PETZL M, et al. Voltage relaxation and impedance spectroscopy as In-operando methods for the detection of lithium plating on graphitic anodes in commercial lithium-ion cells[J]. Journal of Power Sources, 2016, 304: 170-180. DOI: 10.1016/j.jpowsour.2015.11.044. |

| [60] | BROWN D E, MCSHANE E J, KONZ Z M, et al. Detecting onset of lithium plating during fast charging of Li-ion batteries using operando electrochemical impedance spectroscopy[J]. Cell Reports Physical Science, 2021, 2(10): 100589. DOI: 10.1016/j.xcrp.2021.100589. |

| [61] | WANG P, QU W J, SONG W L, et al. Electro-chemo-mechanical issues at the interfaces in solid-state lithium metal batteries[J]. Advanced Functional Materials, 2019, 29(27): 1900950. DOI: 10.1002/adfm.201900950. |

| [62] | HUANG W X, YE Y S, CHEN H, et al. Onboard early detection and mitigation of lithium plating in fast-charging batteries[J]. Nature Communications, 2022, 13: 7091. DOI: 10.1038/s41467-022-33486-4. |

| [63] | KIM S, RAJ A, LI B, et al. Correlation of electrochemical and mechanical responses: Differential analysis of rechargeable lithium metal cells[J]. Journal of Power Sources, 2020, 463: 228180. DOI: 10.1016/j.jpowsour.2020.228180. |

| [64] | BITZER B, GRUHLE A. A new method for detecting lithium plating by measuring the cell thickness [J]. Journal of Power Sources, 2014, 262(4): 297-302. DOI:10.1016/j.jpowsour.2014. 03.142. |

| [65] | WINTER E, SCHMIDT T J, TRABESINGER S. Potentiostatic lithium plating as a fast method for electrolyte evaluation in lithium metal batteries[J]. Electrochimica Acta, 2023, 439: 141547. DOI: 10.1016/j.electacta.2022.141547. |

| [66] | RIEGER B, SCHUSTER S F, ERHARD S V, et al. Multi-directional laser scanning as innovative method to detect local cell damage during fast charging of lithium-ion cells[J]. Journal of Energy Storage, 2016, 8: 1-5. DOI: 10.1016/j.est.2016.09.002. |

| [67] | GRIMSMANN F, GERBERT T, BRAUCHLE F, et al. Determining the maximum charging currents of lithium-ion cells for small charge quantities[J]. Journal of Power Sources, 2017, 365: 12-16. DOI: 10.1016/j.jpowsour.2017.08.044. |

| [68] | ESCHER I, A FERRERO G, GOKTAS M, et al. In situ (operando) electrochemical dilatometry as a method to distinguish charge storage mechanisms and metal plating processes for sodium and lithium ions in hard carbon battery electrodes[J]. Advanced Materials Interfaces, 2022, 9(8): 2100596. DOI: 10.1002/admi. 202100596. |

| [69] | TIAN Y, LIN C, LI H L, et al. Detecting undesired lithium plating on anodes for lithium-ion batteries—A review on the in situ methods[J]. Applied Energy, 2021, 300: 117386. DOI: 10.1016/j.apenergy.2021.117386. |

| [70] | CAI W, YAN C, YAO Y X, et al. The boundary of lithium plating in graphite electrode for safe lithium-ion batteries[J]. Angewandte Chemie, 2021, 60(23): 13007-13012. DOI:10.1002/anie.202102593. |

| [71] | LIN Y, HU W, DING M, et al. Unveiling the three stages of Li plating and dynamic evolution processes in pouch C/LiFePO4 batteries[J]. Advanced Energy Materials. 2024, 2400894.https://doi.org/10.1002/aenm.202400894. |

| [72] | REN D S, LIU X, FENG X N, et al. Model-based thermal runaway prediction of lithium-ion batteries from kinetics analysis of cell components[J]. Applied Energy, 2018, 228: 633-644. DOI: 10.1016/j.apenergy.2018.06.126. |

| [73] | FLEISCHHAMMER M, WALDMANN T, BISLE G, et al. Interaction of cyclic ageing at high-rate and low temperatures and safety in lithium-ion batteries[J]. Journal of Power Sources, 2015, 274: 432-439. DOI: 10.1016/j.jpowsour.2014.08.135. |

| [74] | LI H, JI W J, ZHANG P, et al. Safety boundary of power battery based on quantitative lithium deposition[J]. Journal of Energy Storage, 2022, 52: 104789. DOI: 10.1016/j.est.2022.104789. |

| [75] | FENG X N, ZHENG S Q, REN D S, et al. Investigating the thermal runaway mechanisms of lithium-ion batteries based on thermal analysis database[J]. Applied Energy, 2019, 246: 53-64. DOI: 10.1016/j.apenergy.2019.04.009. |

| [76] | WALDMANN T, WOHLFAHRT-MEHRENS M. Effects of rest time after Li plating on safety behavior-ARC tests with commercial high-energy 18650 Li-ion cells[J]. Electrochimica Acta, 2017, 230: 454-460. DOI: 10.1016/j.electacta.2017.02.036. |

| [77] | ZHOU H W, FEAR C, CARTER R E, et al. Correlating lithium plating quantification with thermal safety characteristics of lithium-ion batteries[J]. Energy Storage Materials, 2024, 66: 103214. DOI: 10.1016/j.ensm.2024.103214. |

| [1] | Liyue HU, Wei HUANG, Yun ZHOU, Yingqiang ZHOU, Changzheng SHAO, Ke WANG. Fuzzy reasoning-based evaluation of the thermal diffusion probability of lithium-ion battery modules for energy storage systems [J]. Energy Storage Science and Technology, 2025, 14(7): 2662-2674. |

| [2] | Wei WANG, Huishi LIANG, Miangang LI, Kui ZHOU, Wei WANG, Ziyao WANG, Zinan SHI. Method for monitoring irreversible lithium plating in lithium batteries using transfer learning [J]. Energy Storage Science and Technology, 2025, 14(7): 2698-2706. |

| [3] | Feng XIONG, Depeng KONG, Ping PING, Yue ZHANG, Xiantong REN, Yao LV. Study on the characteristics of electrothermal coupling-induced thermal runaway of ternary lithium-ion batteries [J]. Energy Storage Science and Technology, 2025, 14(7): 2752-2760. |

| [4] | Zijing ZHANG, Beibei YUAN, Hong LI, Ying GAO. Thermal runaway gas detection and early warning of lithium-ion batteries [J]. Energy Storage Science and Technology, 2025, 14(7): 2820-2832. |

| [5] | Jiahui LIU, Weixiang BIAN, Dawei LI. In situ measurement and analysis of the electromechanical coupling performance of composite graphite electrodes in lithium batteries [J]. Energy Storage Science and Technology, 2025, 14(6): 2240-2247. |

| [6] | Chunling WU, Liding WANG, Yong LU, Limin GENG, Hao CHEN, Jinhao MENG. Lithium-ion batteries SOH estimation based on gaussian processed regression optimized by egret swarm optimization [J]. Energy Storage Science and Technology, 2025, 14(6): 2498-2511. |

| [7] | Gongrui WANG, Anping ZHANG, Xuanxuan REN, Mingzhe YANG, Yuning HAN, Zhongshuai WU. High-voltage lithium cobalt oxide cathode: Key challenges, modification strategies and future prospectives [J]. Energy Storage Science and Technology, 2025, 14(6): 2278-2319. |

| [8] | Haiyang ZHOU, Zhendong ZHANG, Lei SHENG, Zehua ZHU, Xiaojun ZHANG, Chunfeng ZHANG. Simulation of immersion thermal performance regulation and thermal safety experimental study for energy storage lithium batteries [J]. Energy Storage Science and Technology, 2025, 14(5): 1866-1874. |

| [9] | Zhoulan ZENG, Lei SHANG, Zhijin HU, Zongfan WANG, Xiaochao XIN, Ying LIU. Li5FeO4@C high capacity prelithium cathode materials for lithium-ion batteries [J]. Energy Storage Science and Technology, 2025, 14(5): 1875-1883. |

| [10] | Ziming MO, Zongxin RAO, Jianfei YANG, Menghao YANG, Liming CAI. Construction and characteristic analysis of key parameters in a gas-thermal model for thermal runaway in lithium-ion battery based on overcharge [J]. Energy Storage Science and Technology, 2025, 14(5): 1784-1796. |

| [11] | Lei PENG, Zhaopeng NI, Yue YU, Fupeng SUN, Xiulong XIA, Peng ZHANG, Sibo SUN. Experimental study on NCM lithium-ion battery electric vehicle fire caused by overcharging [J]. Energy Storage Science and Technology, 2025, 14(4): 1484-1495. |

| [12] | Jiangwei SHEN, Yixin SHE, Xing SHU, Yonggang LIU, Fuxing WEI, Xuelei XIA, Zheng CHEN. State of health estimation for lithium batteries based on short-term random charging data and optimized convolutional neural network [J]. Energy Storage Science and Technology, 2025, 14(4): 1585-1595. |

| [13] | Ruihao LIU, Xiaole MA, Yuxuan ZHANG, Yueying ZHU, Shiqiang LIU, Guangli BAI. Influencing factors of thermal property parameter testing of lithium-ion batteries based on accelerating rate calorimeters [J]. Energy Storage Science and Technology, 2025, 14(4): 1596-1602. |

| [14] | Zuolin DONG, Jinyan SONG, Zidi MENG. Lithium-ion battery life prediction based on mode decomposition and deep learning [J]. Energy Storage Science and Technology, 2025, 14(4): 1645-1653. |

| [15] | Peng PENG, Chengdong WANG, Man CHEN, Qingsong WANG, Qikai LEI, Kaiqiang JIN. Hazard assessment of thermal runaway in a lithium-titanate battery energy storage power plant [J]. Energy Storage Science and Technology, 2025, 14(4): 1617-1630. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||