储能科学与技术 ›› 2024, Vol. 13 ›› Issue (2): 436-461.doi: 10.19799/j.cnki.2095-4239.2023.0501

李珂1( ), 郝奕帆1, 方振华2, 王静1(

), 郝奕帆1, 方振华2, 王静1( ), 张松通3, 祝夏雨3, 邱景义3, 明海3(

), 张松通3, 祝夏雨3, 邱景义3, 明海3( )

)

收稿日期:2023-07-24

修回日期:2023-09-22

出版日期:2024-02-28

发布日期:2024-03-01

通讯作者:

王静,明海

E-mail:15518814937@163.com;jwang6027@ysu.edu.cn;hai.mingenergy@hotmail.com

作者简介:李珂(1998—),女,硕士研究生,研究方向为化学电源,E-mail:15518814937@163.com;

基金资助:

Ke LI1( ), Yifan HAO1, Zhenhua FANG2, Jing WANG1(

), Yifan HAO1, Zhenhua FANG2, Jing WANG1( ), Songtong ZHANG3, Xiayu ZHU3, Jingyi QIU3, Hai MING3(

), Songtong ZHANG3, Xiayu ZHU3, Jingyi QIU3, Hai MING3( )

)

Received:2023-07-24

Revised:2023-09-22

Online:2024-02-28

Published:2024-03-01

Contact:

Jing WANG, Hai MING

E-mail:15518814937@163.com;jwang6027@ysu.edu.cn;hai.mingenergy@hotmail.com

摘要:

在全面电动化的背景下,各类电子产品应用的时空域快速转变对所配备的电池供电能力提出了更为苛刻的工况和环境适应要求,亟待发展充电时间短、小体积大电流输出的电源系统。本综述对近年来受到广泛关注的高功率化学电源体系在大倍率充放电领域的进展进行了梳理,包括锂离子电池、钠离子电池、赝电容电容器、离子型电容器(锂/钠/钾离子等)、铅炭电池等,分别从电极材料、电解质调控和电池结构等角度出发,重点分析了当前影响各电源体系在其功率性能方面的发展瓶颈、能力水平以及亟待突破的关键技术,并对其在低温启动、动力供电和脉冲响应等军事应用领域及所增益效能进行了分析研究。综合分析表明,针对不同的应用场景,为进一步遴选性能更好、更匹配的化学电源体系服务于装备的迭代升级和应用创新,通过构筑高稳定性和导电性的电极材料,宽温域、高电导率的电解质材料和改良电池结构从而减小内阻的途径,显著提升功率性能,并明确提出高功率电池存在最佳工作区间和最优工作策略的问题,尤其是在大电流充放电和脉冲工况下,这对于后续如何根据实际工况用好电池具有借鉴意义。有望在提升各化学电源体系的功率性能的同时,以最佳的系统管控方法和应用策略进一步提升电池的循环寿命、能量转换效率、安全性和可靠性,获得满足市场所需和军民急用的高功率电源产品。

中图分类号:

李珂, 郝奕帆, 方振华, 王静, 张松通, 祝夏雨, 邱景义, 明海. 高功率化学电源体系发展及军事应用分析[J]. 储能科学与技术, 2024, 13(2): 436-461.

Ke LI, Yifan HAO, Zhenhua FANG, Jing WANG, Songtong ZHANG, Xiayu ZHU, Jingyi QIU, Hai MING. Development and military application analysis of high-power chemical power supply system[J]. Energy Storage Science and Technology, 2024, 13(2): 436-461.

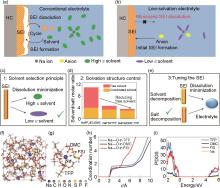

图10

高稳定高压SIB抑制SEI溶解的电解液设计原理:(a), (b)在传统的电解液(a)中,SEI的溶解导致SEI的形成和电解液分解的持续副反应,低CEs和不可逆的容量损失,在低溶剂化电解液(b)中,稳定钠盐阴离子(FSI-)衍生的SEI抑制SEI溶解以稳定电池长循环性能;(c)~(e)抑制SEI溶解的三个主要设计原则:通过选择低介电常数溶剂(c),通过操纵溶剂化结构(d)和不溶性成分的盐衍生SEI减少自由溶剂量(e);(f)~(i)从头计算分子动力学(AIMD)模拟NaFSI/DMC∶TFP电解质:电解质分子系统的快照AIMD模拟(f)和代表Na+ 溶剂化结构提取从AIMD模拟(g),配位数(h)和预计状态密度(PDOS)(任意单位)(i)(NaFSI/DMC∶TFP电解质,在PDOS分析中,费米能级被设置为0 eV)(Nat Energy 拥有图片版权)[26]"

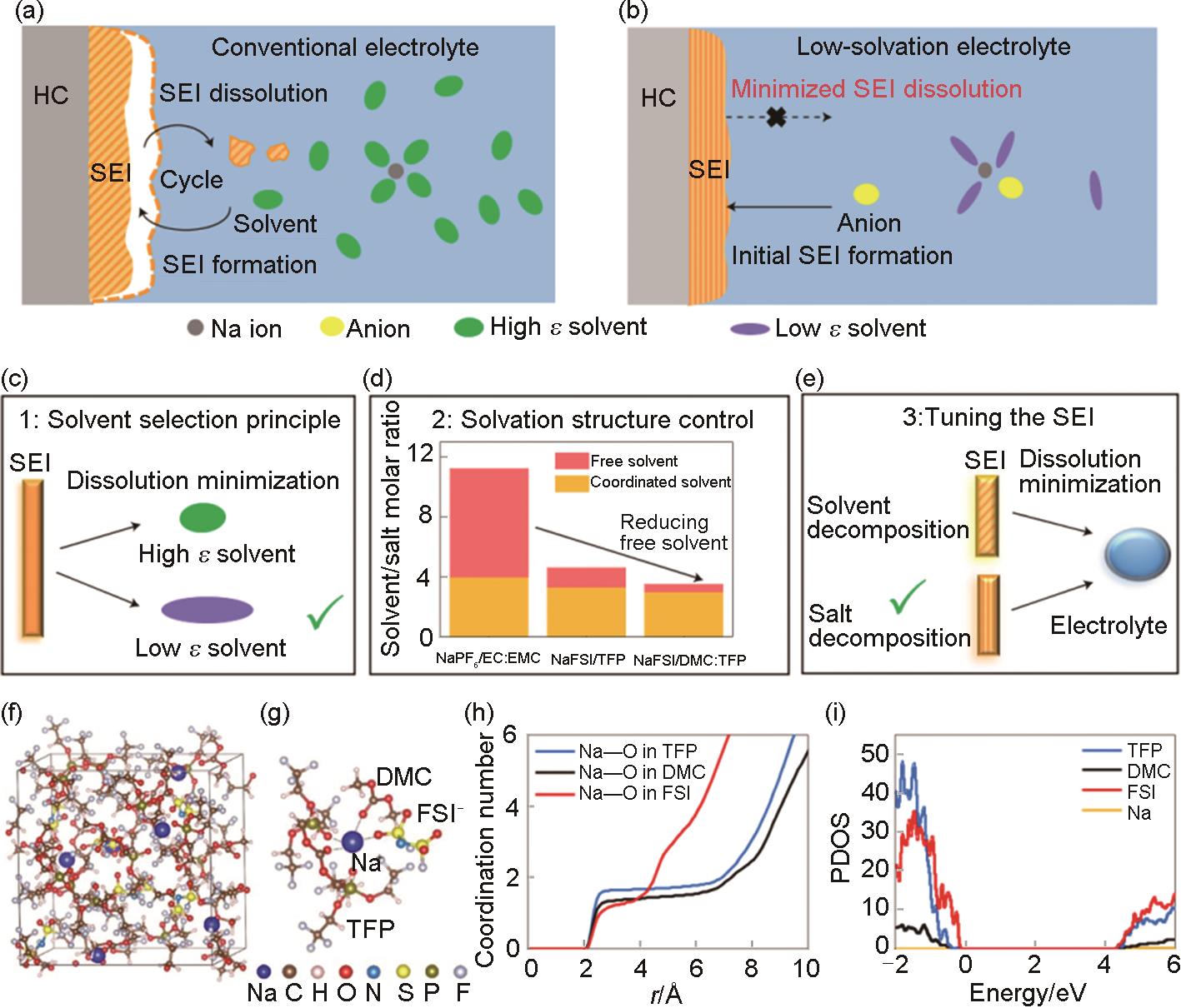

图12

GNC || 1T-MoS2/d-Ti3C2T x || LIC的电化学性能:(a)GNC || 1T-MoS2/d-Ti3C2T x LIC储能机制示意图。在0.1 ~ 4V的宽电压范围内,GNC || 1T-MoS2/d-Ti3C2T x LIC的(b)循环伏安曲线和(c)GCD曲线;(d)GNC || 1T-MoS2/d-Ti3C2T x LIC的比电容和比容量随电流密度的变化;(e)GNC || 1T-MoS2/d-Ti3C2T x LIC的拉贡图;(f)GNC || 1T-MoS2/d-Ti3C2T x LIC在5000次循环中的容量保持和库仑效率(AdvancedFunctional Materials 拥有图片版权)[44]"

表1

近年来文献中涉及到的碳种类及相关电化学性能"

| 序号 | 引入碳 | 电化学测试 | 文献 |

|---|---|---|---|

| 1 | 多孔炭 | 0.1 C下放电比容量为183 mAh/g(高于空白电池151 mAh/g),1 C循环600次后的容量保持率为50.1% | [ |

| 2 | 稻壳基多级多孔炭 | 在PS℃操作下,初始100%放电深度(DOD)容量为4.40Ah,90个循环后放电容量下降到2.75 Ah | [ |

| 3 | 稻壳基活性炭(RHAC) | 在HRPS℃和150%荷电状态下60次深循环后的容量保持率分别提高了49.12%和47.2% | [ |

| 4 | 多级管状多孔炭(HTPC) | 含1.2% HTPC的LCB在0.1 C时的放电比容量为165.4 mAh/g(而空白样品的放电比容量为140.5 mAh/g),在HRPS℃条件下,LCB的循环寿命比对照组延长了3.17倍 | [ |

| 5 | N掺杂还原氧化石墨烯(N-rGO) | 与具有相同含量 rGO 添加剂的电池(7742次循环)和不含任何碳添加剂的电池(2777次循环)相比,含0.50%(质量分数) N-rGO/PbO 添加剂的电池显示17390次循环 | [ |

表2

典型高功率化学电源体系的性能对比"

| 项目 | 锂离子电池 | 钠离子电池 | 赝电容电容器 | 离子型电容器 | 铅炭电池 |

|---|---|---|---|---|---|

| 能量密度/( Wh/kg) | 150~300 | 100~160 | 5~50 | 10~50 | 40~60 |

| 快充/放 | 以分钟为单位 | 以分钟为单位 | 以秒为单位 | 以秒为单位 | 以分钟为单位 |

| 内阻 | 较高 | 较高 | 低 | 低 | 低 |

| 工作温度/℃ | -20~60 | -40~80 | -40~80 | -40~70 | -40~50 |

| 循环寿命 | 3000~15000 | 2000~10000 | 十万次以上 | 万次以上 | 3000 |

| 安全性 | 一般 | 一般 | 较好 | 一般 | 良好 |

| 应用(功率/能量) | 中功率 (高能量) | 高功率 (高能量) | 高功率 (中等能量) | 高功率 (中等能量) | 低功率 (中等能量) |

| 典型产品 | 1.法国GAIA公司研制的341440 NCA高功率电池 2.日本东芝生产的“SCiB”钛酸锂电池 3.比亚迪的刀片磷酸铁锂电池 | 1.Natron Energy 的专利Prussian Blue电极 2.华宇新能源科技公司发布了第一代SIB——“极钠1号” 3.中科海纳建立国内首座100 kWh SIB储能电站示范应用 | 1.Maxwell科技公司生产的3 V/3000 F超级电容器 2.俄罗斯ESMA公司开发的是混合型NiO||AC超级电容器 3.上海奥威的28000F单体 | 1.JM Energy的锂离子电容器ULTIMO 2.东莞市科尼盛电子有限公司出品的Burstcap LIC 3.中国中车集团与Maxwell合作开发的锂离子电容器 | 1.美国EXIDE公司用于SUV汽车起动的轻型EXTREM系列 2.日本古河生产的双极型蓄电池 3.山东圣阳研发的FCP铅炭电池 |

| 应用场景 | 1.无人机等航空航天领域 2.电动汽车 3.储能 4.便携式电子产品 | 1.储能 2.低速电动车 3.低温启动 | 1.穿戴或柔性电子产品 2.地铁驱动电源 3.UPS电源 | 1.脉冲响应 2.能量回收及启停 3.功率调节 | 1.智能电网,微网电站 2.混合动力汽车 3.低温启动 |

| 1 | PIERRE MWIZERWA J, LIU C Y, XU K, et al. Activated carbon/reduced graphene oxide wrapped LiFePO4 cathode for Li-ion batteries with ultrahigh capacities and high specific energy density[J]. FlatChem, 2022, 34: 100393. |

| 2 | GUAN Y B, SHEN J R, WEI X F, et al. LiFePO4/activated carbon/graphene composite with capacitive-battery characteristics for superior high-rate lithium-ion storage[J]. Electrochimica Acta, 2019, 294: 148-155. |

| 3 | CHEN X F, WANG Y H, CAO G P, et al. Synergistic and capacitance effects in nanocarbon based capacitor batteries designed for superior rate capability and long-cycle stability[J]. Journal of Colloid and Interface Science, 2022, 626: 395-404. |

| 4 | CHEN X F, MU Y, CAO G P, et al. Structure-activity relationship of carbon additives in cathodes for advanced capacitor batteries[J]. Electrochimica Acta, 2022, 413: 140165. |

| 5 | KIM U H, PARK J H, AISHOVA A, et al. Microstructure engineered Ni-rich layered cathode for electric vehicle batteries[J]. Advanced Energy Materials, 2021, 11(25): 2100884. |

| 6 | CHEN K H, GOEL V, NAMKOONG M J, et al. Enabling 6C fast charging of Li-ion batteries with graphite/hard carbon hybrid anodes[J]. Advanced Energy Materials, 2021, 11(5): 2003336. |

| 7 | NI X P, CUI Z, JIANG N, et al. Hollow multi-nanochannel carbon nanofiber/MoS2 nanoflower composites as binder-free lithium-ion battery anodes with high capacity and ultralong-cycle life at large current density[J]. Journal of Materials Science & Technology, 2021, 77: 169-177. |

| 8 | WU D B, WANG C, WU H J, et al. Synthesis of hollow Co3O4 nanocrystals in situ anchored on holey graphene for high rate lithium-ion batteries[J]. Carbon, 2020, 163: 137-144. |

| 9 | GAO N, KIM S, CHINNAM P, et al. Methodologies for design, characterization and testing of electrolytes that enable extreme fast charging of lithium-ion cells[J]. Energy Storage Materials, 2022, 44: 296-312. |

| 10 | GUO H X, TIAN Y, LIU Y M, et al. Inner lithium fluoride (LiF)-rich solid electrolyte interphase enabled by a smaller solvation sheath for fast-charging lithium batteries[J]. ACS Applied Materials & Interfaces, 2023, 15(1): 1201-1209. |

| 11 | 出鞘·安天下——比亚迪"刀片电池" 引领全球动力电池安全新高度[J]. 城市公共交通, 2020(5): 96-97. |

| Take out the sheath and secure the world-BYD's "blade battery" leads the global power battery safety to a new height[J]. Urban Public Transport, 2020(5): 96-97. | |

| 12 | 金一丹. 宁德时代第三代CTP麒麟电池落地[N].中国证券报, 2022-08-27(A05). |

| JIN Y. CATL third generation CTP Kirin battery landing [N]. China Securities Journal, 2022-08-27 (A05). | |

| 13 | 赫炎. 从CTP、CTC、CTB浅谈电动汽车动力电池集成技术[J]. 世界汽车, 2022(6): 70-71. |

| HE Y. Discussion on power battery integration technology of electric vehicle from CTP, CTC and CTB[J]. World Auto, 2022(6): 70-71. | |

| 14 | 张静, 赵程, 高玉双, 等. 钛酸锂电池技术在国内外的发展状况分析[J]. 科技创新导报, 2019, 16(29): 237, 239. |

| ZHANG J, ZHAO C, GAO Y S, et al. Analysis on the development of lithium titanate battery technology at home and abroad[J]. Science and Technology Innovation Herald, 2019, 16(29): 237, 239. | |

| 15 | MA C, LI X L, YUE X Y, et al. Suppressing O3-O'3 phase transition in NaCrO2 cathode enabling high rate capability for sodium-ion batteries by Sb substitution[J]. Chemical Engineering Journal, 2022, 432: 134305. |

| 16 | SUBRAMANIAN Y, OH W, CHOI W, et al. Optimizing high voltage Na3V2(PO4)2F3 cathode for achieving high rate sodium-ion batteries with long cycle life[J]. Chemical Engineering Journal, 2021, 403: 126291. |

| 17 | SHI Q H, QI R J, FENG X C, et al. Niobium-doped layered cathode material for high-power and low-temperature sodium-ion batteries[J]. Nature Communications, 2022, 13: 3205. |

| 18 | ZHANG W, WU Y, XU Z, et al. Rationally designed sodium chromium vanadium phosphate cathodes with multi‐electron reaction for fast-charging sodium-ion batteries[J]. Advanced Energy Materials, 2022, 12(25): 2201065. |

| 19 | JIANG C L, FANG Y, ZHANG W Y, et al. A multi-ion strategy towards rechargeable sodium-ion full batteries with high working voltage and rate capability[J]. Angewandte Chemie International Edition, 2018, 57(50): 16370-16374. |

| 20 | YIN X P, LU Z X, WANG J, et al. Enabling fast Na+ transfer kinetics in the whole-voltage-region of hard-carbon anodes for ultrahigh-rate sodium storage[J]. Advanced Materials, 2022, 34(13): e2109282. |

| 21 | WANG G, SHAO M, DING H R, et al. Multiple active sites of carbon for high-rate surface-capacitive sodium-ion storage[J]. Angewandte Chemie (International Ed in English), 2019, 58(38): 13584-13589. |

| 22 | NI D, SUN W, WANG Z H, et al. Heteroatom-doped mesoporous hollow carbon spheres for fast sodium storage with an ultralong cycle life[J]. Advanced Energy Materials, 2019, 9(19): 1900036. |

| 23 | CHEN W M, CHEN C J, XIONG X Q, et al. Coordination of surface-induced reaction and intercalation: Toward a high-performance carbon anode for sodium-ion batteries[J]. Advanced Science, 2017, 4(6): 1600500. |

| 24 | KIM Y H, AN J H, KIM S Y, et al. Enabling 100C fast-charging bulk Bi anodes for Na-ion batteries[J]. Advanced Materials, 2022, 34(27): e2201446. |

| 25 | XIONG P X, BAI P X, LI A, et al. Bismuth Nanoparticle@Carbon composite anodes for ultralong cycle life and high-rate sodium-ion batteries[J]. Advanced Materials, 2019, 31(48): e1904771. |

| 26 | JIN Y, LE P M L, GAO P Y, et al. Low-solvation electrolytes for high-voltage sodium-ion batteries[J]. Nature Energy, 2022, 7: 718-725. |

| 27 | TANG Z, WANG H, WU P F, et al. Electrode-electrolyte interfacial chemistry modulation for ultra-high rate sodium-ion batteries[J]. Angewandte Chemie (International Ed in English), 2022, 61(18): e202200475. |

| 28 | PAN J, ZHANG Y C, SUN F, et al. Designing solvated double-layer polymer electrolytes with molecular interactions mediated stable interfaces for sodium ion batteries[J]. Angewandte Chemie (International Ed in English), 2023, 62(17): e202219000. |

| 29 | SUN H, ZHU G Z, XU X T, et al. A safe and non-flammable sodium metal battery based on an ionic liquid electrolyte[J]. Nature Communications, 2019, 10: 3302. |

| 30 | 高驰. 宁德时代发布第一代钠离子电池,未来可期[J]. 汽车与配件, 2021(15): 55. |

| GAO C. Contemporary Amperex Technology Co., Limited released the first generation of sodium ion batteries, which can be expected in the future[J]. Automobile & Parts, 2021(15): 55. | |

| 31 | 唐琳, 王佳雯. 胡勇胜: 在电池研究应用领域走少有人走的路[J]. 科学新闻, 2021, 23(1): 27-29. |

| TANG L, WANG J W. HU Yongsheng: Take the road that few people take in the field of battery research and application[J]. Science News, 2021, 23(1): 27-29. | |

| 32 | 祁鹏, 陈爱英. 浅谈赝电容电极材料的研究进展[J]. 电源技术, 2020, 44(8): 1235-1238. |

| QI P, CHEN A Y. Talking about research progress of electrode materials for pseudocapacitor[J]. Chinese Journal of Power Sources, 2020, 44(8): 1235-1238. | |

| 33 | ZHAO S S, CHEN C F, ZHAO X, et al. Flexible Nb4C3Tx film with large interlayer spacing for high-performance supercapacitors[J]. Advanced Functional Materials, 2020, 30(47): 2000815. |

| 34 | WANG L K, HAN M K, SHUCK C E, et al. Adjustable electrochemical properties of solid-solution MXenes[J]. Nano Energy, 2021, 88: 106308. |

| 35 | BARIK R, TANWAR V, KUMAR R, et al. A high energy density and high rate capability flexible supercapacitor based on electro-spun highly porous SnO2@carbon nanofibers[J]. Journal of Materials Chemistry A, 2020, 8(30): 15110-15121. |

| 36 | XIE B Q, YU M Y, LU L H, et al. Pseudocapacitive Co9S8/graphene electrode for high-rate hybrid supercapacitors[J]. Carbon, 2019, 141: 134-142. |

| 37 | MENG C X, ZHOU F, LIU H Q, et al. Water-in-salt ambipolar redox electrolyte extraordinarily boosting high pseudocapacitive performance of micro-supercapacitors[J]. ACS Energy Letters, 2022, 7(5): 1706-1711. |

| 38 | CHEN Y Y, QING L Y, LIU T T, et al. Tuning interfacial ion distribution to improve energy density of supercapacitors[J]. Nano Energy, 2022, 102: 107660. |

| 39 | 郭雪飞, 孙洋洲, 刘强, 等. 石墨烯储能应用的技术进展及产业化现状[J]. 炭素技术, 2020, 39(1): 19-23. |

| GUO X F, SUN Y Z, LIU Q, et al. Technology progress and industrialization status of graphene in energy storage[J]. Carbon Techniques, 2020, 39(1): 19-23. | |

| 40 | 刘义波, 李峰, 胡静. 超级电容器研究进展及应用分析[J]. 电源技术, 2015, 39(9): 2028-2030. |

| LIU Y B, LI F, HU J. Research progress and application analysis of supercapacitors[J]. Chinese Journal of Power Sources, 2015, 39(9): 2028-2030. | |

| 41 | QIN L, ZHU S H, CHENG C, et al. Single-crystal nano-subunits assembled accordion-shape WNb2O8 framework with high ionic/electronic conductivities towards Li-ion capacitors[J]. Small, 2022, 18(13): e2107987. |

| 42 | YUAN T, LUO S N, SOULE L K, et al. A hierarchical Ti2Nb10O29 composite electrode for high-power lithium-ion batteries and capacitors[J]. Materials Today, 2021, 45: 8-19. |

| 43 | LUO J M, ZHANG W K, YUAN H D, et al. Pillared structure design of MXene with ultralarge interlayer spacing for high-performance lithium-ion capacitors[J]. ACS Nano, 2017, 11(3): 2459-2469. |

| 44 | WANG L, ZHANG X, XU Y N, et al. Tetrabutylammonium-intercalated 1T-MoS2 nanosheets with expanded interlayer spacing vertically coupled on 2D delaminated MXene for high-performance lithium-ion capacitors[J]. Advanced Functional Materials, 2021, 31(36): 2104286. |

| 45 | LIU W J, ZHANG X, XU Y N, et al. 2D graphene/MnO heterostructure with strongly stable interface enabling high-performance flexible solid-state lithium-ion capacitors[J]. Advanced Functional Materials, 2022, 32(30): 2202342. |

| 46 | LE Z Y, LIU F, NIE P, et al. Pseudocapacitive sodium storage in mesoporous single-crystal-like TiO2-graphene nanocomposite enables high-performance sodium-ion capacitors[J]. ACS Nano, 2017, 11(3): 2952-2960. |

| 47 | QIAN J, WU F, YE Y S, et al. Boosting fast sodium storage of a large-scalable carbon anode with an ultralong cycle life[J]. Advanced Energy Materials, 2018, 8(16): 1703159. |

| 48 | LV X J, SONG J X, LAI Y Q, et al. Ultrafine nanoparticles assembled Mo2C nanoplates as promising anode materials for sodium ion batteries with excellent performance[J]. Journal of Energy Storage, 2016, 8: 205-211. |

| 49 | JIANG Y L, SHEN Y H, DONG J, et al. Surface pseudocapacitive mechanism of molybdenum phosphide for high-energy and high-power sodium-ion capacitors[J]. Advanced Energy Materials, 2019, 9(27): 1900967. |

| 50 | JIANG Y L, WANG H, DONG J, et al. Mo2C nanoparticles embedded in carbon nanowires with surface pseudocapacitance enables high-energy and high-power sodium ion capacitors[J]. Small, 2022, 18(24): 2200805. |

| 51 | TAN J F, ZHU W H, GUI Q Y, et al. Weak ionization induced interfacial deposition and transformation towards fast-charging NaTi2(PO4)3 nanowire bundles for advanced aqueous sodium-ion capacitors[J]. Advanced Functional Materials, 2021, 31(23): 2101027. |

| 52 | CHEN J T, YANG B J, HOU H J, et al. Disordered, large interlayer spacing, and oxygen-rich carbon nanosheets for potassium ion hybrid capacitor[J]. Advanced Energy Materials, 2019, 9(19): 1803894. |

| 53 | YI Y Y, SUN Z T, LI C, et al. Designing 3D biomorphic nitrogen-doped MoSe2/graphene composites toward high-performance potassium-ion capacitors[J]. Advanced Functional Materials, 2020, 30(4): 1903878. |

| 54 | LIANG G J, LI X L, WANG Y B, et al. Building durable aqueous K-ion capacitors based on MXene family[J]. Nano Research Energy, 2022, 1: e9120002. |

| 55 | YIN J, LIN N, ZHANG W L, et al. Highly reversible lead-carbon battery anode with lead grafting on the carbon surface[J]. Journal of Energy Chemistry, 2018, 27(6): 1674-1683. |

| 56 | LI J C, HU Y T, ZHANG Y S, et al. Construction of a novel three-dimensional porous lead-carbon network for improving the reversibility of deep discharge lead-carbon batteries[J]. Journal of Electroanalytical Chemistry, 2021, 883: 115065. |

| 57 | SUN X F, LIU Y J, ZHAO Y, et al. Investigation of lead particles loading on the surface of activated carbon on the performance of lead carbon batteries and its potential mechanisms[J]. Journal of Energy Storage, 2023, 60: 106641. |

| 58 | LIU X, TAO D W, LI Z M, et al. N-doped reduced graphene oxide loading nano lead oxide as negative additive for enhanced properties of lead-carbon batteries[J]. Electrochemistry Communications, 2023, 146: 107422. |

| 59 | HE P Q, TU J, YANG Y, et al. Hierarchical tubular porous carbon derived from mulberry branches for long-life lead-carbon battery[J]. Journal of Energy Storage, 2023, 64: 107162. |

| 60 | WANG Z D, TUO X P, ZHOU J Q, et al. Performance study of large capacity industrial lead-carbon battery for energy storage[J]. Journal of Energy Storage, 2022, 55: 105398. |

| 61 | NARESH V, ELIAS L, GAFFOOR S A, et al. Corrosion resistant polypyrrole coated lead-alloy positive grids for advanced lead-acid batteries[J]. Journal of the Electrochemical Society, 2019, 166(2): A74. |

| 62 | LANNELONGUE J, CUGNET M, GUILLET N, et al. Electrochemistry of thin-plate lead-carbon batteries employing alternative current collectors[J]. Journal of Power Sources, 2017, 352: 194-207. |

| 63 | 黄伟国, 王鹏伟, 陈理, 等. 极耳排布对AGM铅炭电池性能的影响[J]. 储能科学与技术, 2020, 9(4): 1060-1065. |

| HUANG W G, WANG P W, CHEN L, et al. Study on the effect of electrode lugs arrangement on the performance of AGM lead-carbon batteries[J]. Energy Storage Science and Technology, 2020, 9(4): 1060-1065. | |

| 64 | 梁乔栩. 国外先进水下电池应用发展分析[EB/OL]. (2023-02-08)[2023-09-20]. https://www.163.com/dy/article/HT3910P10515E3KM.html. |

| LIANG Q.Application and development analysis of advanced underwater batteries abroad[EB/OL].(2023-02-08)[2023-09-20].https://www.163.com/dy/article/HT3910P10515E3KM.html. | |

| 65 | FISH S, SAVOIE T, VANICEK H. Modeling hybrid electric HMMWV power system performance[J]. IEEE Transactions on Magnetics, 2001, 37(1): 480-484. |

| 66 | SAFT. Li-ion batteries power F-35 lightning ii joint strike fighter through LRIP programme[C]//Press Release, Paris, France, June 15, 2009. |

| 67 | SITZMAN A, SURLS D, MALLICK J. Design, construction, and testing of an inductive pulsed-power supply for a small railgun[J]. IEEE Transactions on Magnetics, 2007, 43(1): 270-274. |

| 68 | ALLEN R, NERI J. A battery powered, 200-kW rapid capacitor charger for a portable railgun in burst mode operation at 3 RPS[C]//2007 16th IEEE International Pulsed Power Conference. Albuquerque, NM, USA. IEEE, 2007: 1500-1504. |

| 69 | NUNNALLY C, MAYES J R, HATFIELD C W, et al. Design and performance of an ultra-compact 1.8-kJ, 600-kV pulsed power system[C]//2009 IEEE Pulsed Power Conference. Washington, DC, USA. IEEE, 2009: 930-933. |

| 70 | DRAGT A J, ELIZONDO J M. Compact battery-powered, 400-kV, 40-Joule Marx generator[C]//PPPS-2001 Pulsed Power Plasma Science 2001.28th IEEE International Conference on Plasma Science and 13th IEEE International Pulsed Power Conference. Digest of Papers (Cat. No.01CH37251). Las Vegas, NV, USA. IEEE, 2002: 1555-1558. |

| 71 | CADILHON B, CASSANY B, DIOT J C, et al. Self-contained, hand-portable, and repetitive ultrawideband radiation source[J]. IEEE Transactions on Plasma Science, 2011, 39(6): 1549-1559. |

| [1] | 李校磊, 高健, 周伟东, 李泓. COMSOL Multiphysics在锂离子电池中的应用[J]. 储能科学与技术, 2024, 13(2): 546-567. |

| [2] | 彭可, 张志成, 胡有章, 张旭辉, 周稼辉, 李彬. 基于有限元的热力耦合场匣钵运动分析与优化[J]. 储能科学与技术, 2024, 13(2): 634-642. |

| [3] | 雷旗开, 余胤, 彭鹏, 陈满, 金凯强, 王青松. 隔热材料布局方式对280 Ah磷酸铁锂电池热失控传播抑制效果的影响[J]. 储能科学与技术, 2024, 13(2): 495-502. |

| [4] | 段双明, 张胜利. 基于自适应多层RLS的锂离子电池参数辨识[J]. 储能科学与技术, 2024, 13(2): 712-720. |

| [5] | 刘新, 毛喜玲, 闫欣雨, 王俊强, 李孟委. 三维孔道NiMn-MOF电极材料制备及电化学性能研究[J]. 储能科学与技术, 2024, 13(2): 361-369. |

| [6] | 唐盼春, 严嵘, 张灿, 孙泽. 堆叠式车载超级电容器热管理方式分析[J]. 储能科学与技术, 2024, 13(2): 483-491. |

| [7] | 宋元明, 刘亚杰, 金光, 周星, 黄旭程. 锂离子电池/超级电容器混合储能系统能量管理方法综述[J]. 储能科学与技术, 2024, 13(2): 652-668. |

| [8] | 徐铖杰, 黄玉林, 林中飞雨, 林志铭, 方辰希, 张卫军, 黄志高, 李加新. 纳米硅的砂磨宏量制备及其碳纤维复合负极的储锂性能研究[J]. 储能科学与技术, 2024, 13(1): 1-11. |

| [9] | 张怡, 葛筱渔, 李真, 黄云辉. 用于锂电池监测的声学和光学传感技术研究进展[J]. 储能科学与技术, 2024, 13(1): 167-177. |

| [10] | 童文欣, 黄中垣, 王睿, 邓司浩, 何伦华, 肖荫果. 基于空间分辨中子衍射方法的锂离子电池电化学反应均匀性研究[J]. 储能科学与技术, 2024, 13(1): 72-81. |

| [11] | 廖雅贇, 周峰, 张颖曦, 吕途安, 何阳, 陈晓燕, 霍开富. 锂离子电池快充石墨负极材料研究进展[J]. 储能科学与技术, 2024, 13(1): 130-142. |

| [12] | 靳欣, 张建茹, 王其钰, 张锐, 王碧童, 张中洋, 俞海龙, 禹习谦, 李泓. 混合固液锂离子电池的热失控行为研究[J]. 储能科学与技术, 2024, 13(1): 48-56. |

| [13] | 肖也, 徐磊, 闫崇, 黄佳琦. 锂电池用参比电极的设计与应用[J]. 储能科学与技术, 2024, 13(1): 82-91. |

| [14] | 戴雪娇, 闫婕, 王管, 董浩天, 蒋丹枫, 魏泽威, 孟凡星, 刘松涛, 张海涛. 铌基低温电池关键材料研究进展[J]. 储能科学与技术, 2024, 13(1): 311-324. |

| [15] | 杜文, 王君雷, 徐运飞, 李世龙, 王昆. 火焰喷雾热解法生产锂离子电池高镍三元正极材料的技术经济分析[J]. 储能科学与技术, 2024, 13(1): 345-357. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||