Energy Storage Science and Technology ›› 2025, Vol. 14 ›› Issue (3): 913-929.doi: 10.19799/j.cnki.2095-4239.2025.0006

• Emerging Investigator Issue of Energy Storage • Previous Articles Next Articles

Xinyuan JIA( ), Xianfu ZHANG(

), Xianfu ZHANG( ), Long ZHANG(

), Long ZHANG( )

)

Received:2025-01-02

Revised:2025-03-15

Online:2025-03-28

Published:2025-04-28

Contact:

Long ZHANG

E-mail:M202310308@xs.ustb.edu.cn;Zhang-xf2022@163.com;zhanglong25@mail.sysu.edu.cn

CLC Number:

Xinyuan JIA, Xianfu ZHANG, Long ZHANG. Research progress on micromodification and macrodesign of Zn powder anodes in aqueous Zn metal batteries[J]. Energy Storage Science and Technology, 2025, 14(3): 913-929.

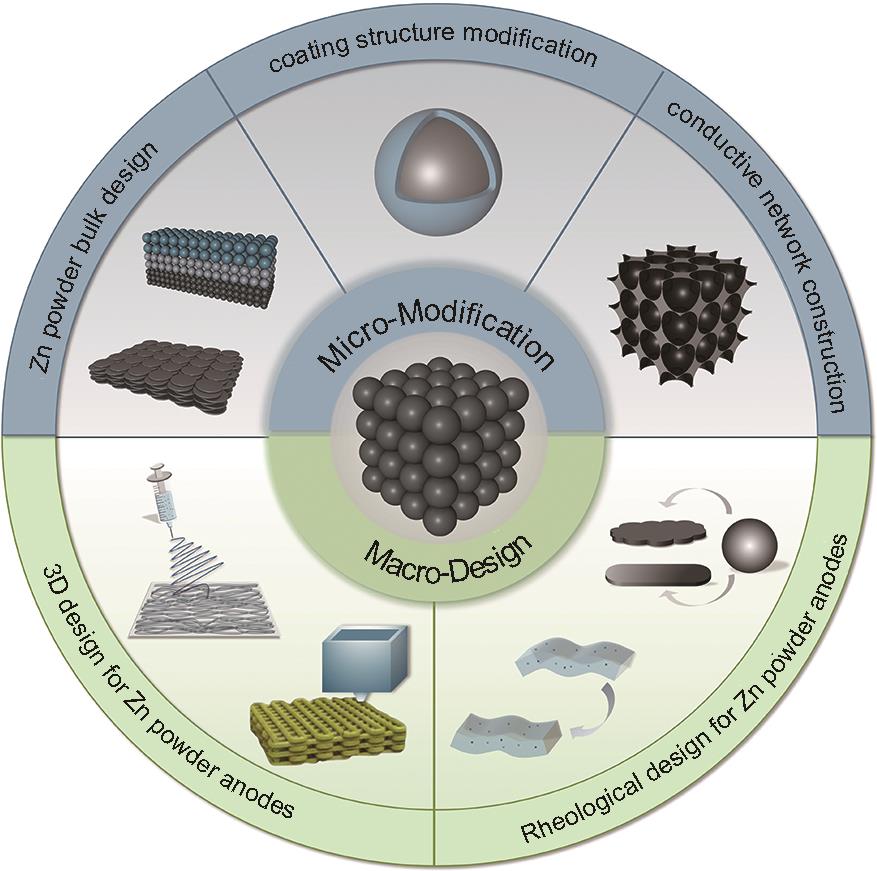

Fig.1

Construction strategies for Zn powder anodes. Zn powder bulk design: dimensional reduction strategy and gradient construction; Coating structure modification; Conductive network construction; 3D design for Zn powder anodes: 3D printing and electrospinning; Rheological design for Zn powder anodes: Semi-liquid anodes and soft solid anodes"

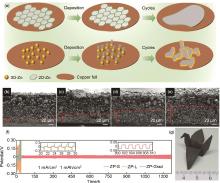

Fig. 2

Bulk design of Zn powder anodes. (a) A strategy for obtaining two-dimensional (2D) Zn powders by dimensionality reduction engineering[27]; Gradient designed Zn powder anodes[28]: (b)—(e) Cross-sectional SEM images of the gradient Zn powder anode following Zn deposition of 3 h, 6 h, 9 h, and 12 h; (f) Comparison of cycling performance of symmetric cells with different Zn powder anodes at 1 mA/cm2/1 mAh/cm2; (g) A digital photograph showing the flexibility of the gradient Zn powder anode"

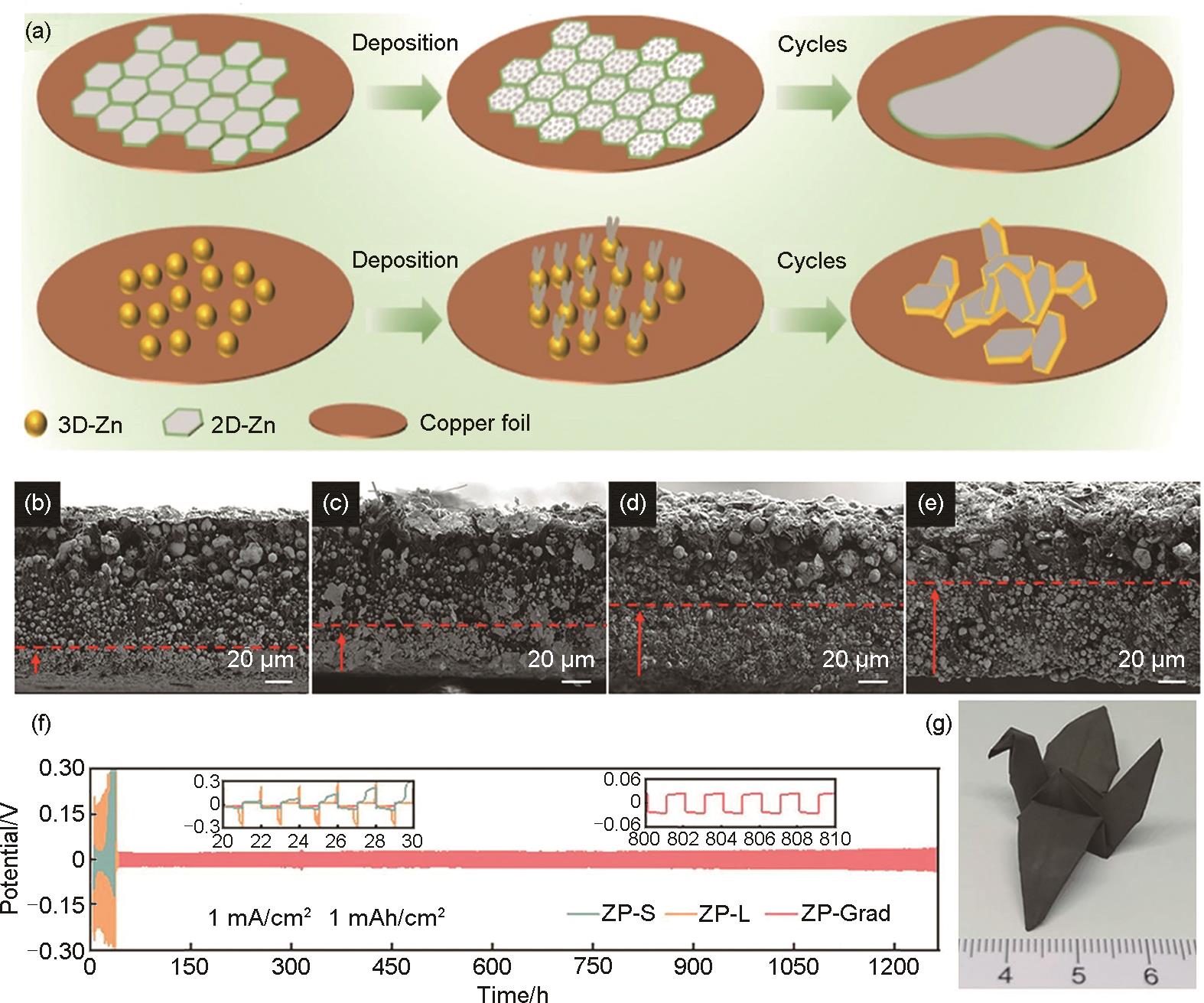

Fig. 3

The mechanism of In in Zn powder anodes. (a) Schematic diagram of Zn@In powder anodes inhibiting hydrogen evolution and corrosion processes; (b) Calculation of charge densities and binding energies of Zn atoms on Zn and In substrates; (c) Cycling performance (285 h) of the pZn/In symmetric cell at 10 mA/cm2 and 2.5 mAh/cm2[29]; (d) CA curves of Zn foil and In-coated Zn powder anode[30]; (e) Activation energy values of Zn powder anode and In-coated Zn powder anode; (f) SEM image of the In-coated Zn powder anode after 1000 cycles[31]; (g) Schematic diagram of the preparation of Zn-EGaIn capillary suspension[32]"

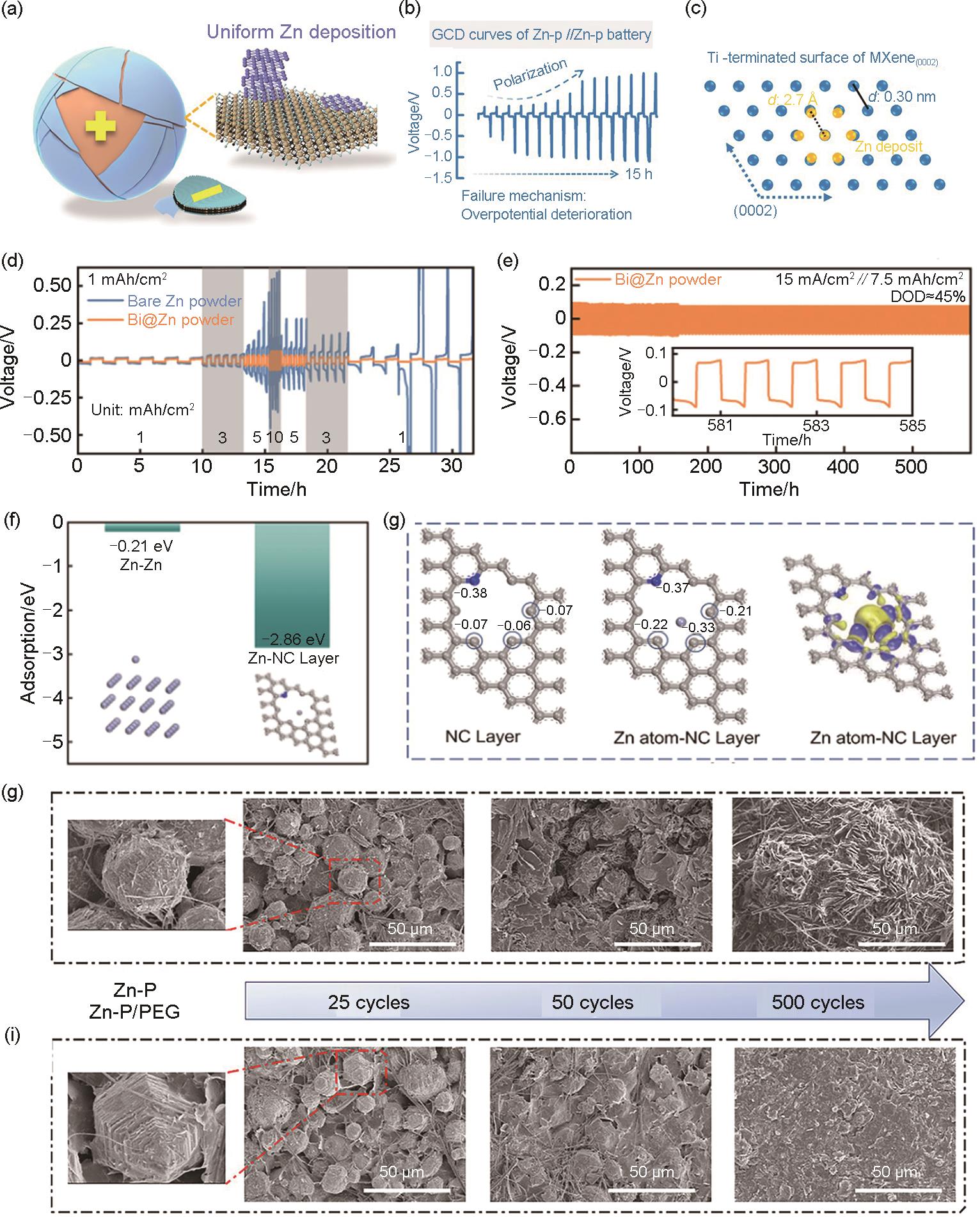

Fig. 4

The mechanism of different coating materials on Zn powder anodes. MXene@Zn composite[33]: (a) Schematic illustration of the MXene@Zn composite; (b) Typical electrochemical galvanostatic charge-discharge profiles of symmetric Zn-P batteries at 1 mAh/cm2; (c) Atomic arrangements of Ti terminated surface of Ti3C2T x (0002) and Zn deposits (0002) and their small lattice mismatch; Bi@Zn composite[34]: (d) Rate performance of the Bi@Zn powder anode and the bare Zn powder anode; (e) Cycling performance (585 h) of the Bi@Zn symmetric cell at 15 mA/cm2 and 7.5 mAh/cm2 (DOD=45%); Nitrogen doped carbon (NC)[35]: (f) The adsorption energies of the Zn atom on both the Zn (002) surface and the NC layer; (g) Models of NC layer and Zn atom-NC layer, and interfacial charge-density model of Zn atom-NC layer; Polyethylene glycol coating on the Zn powder surface[36]: (h), (i) SEM images of Zn-P and Zn-P/PEG after different cycles"

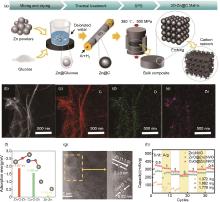

Fig. 5

Construction of the conductive networks in Zn powder anodes. (a) Fabrication process and structural characteristics of the 3D conductive carbon networks[40]; (b)—(e) Elemental mappings of C, O and Zn elements in the Zn powder-graphene composite anode[41]; Construction of the conductive networks by coating the surface of Zn powder with CuO[42]: (f) Adsorption energies of Zn2+ with different substrates; (g) HRTEM image of the CuO@Zn powder; (h) Rate performance of full cells at different current densities (0.5—3 A/g)"

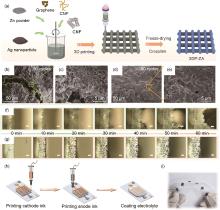

Fig. 6

3D printed Zn powder anodes. Application of traditional 3D printing technology in Zn powder anodes[43]: (a) Schematic of the fabrication process of 3D printed Zn powder anodes; Morphology comparison after 50 cycles between (b), (c) bare Zn powder anode and (d), (e) 3D printed Zn powder anode; Hydrogel-modified 3D printed anodes[44]: In-situ optical microscopy images of (f) 3D printed Zn and (g) 3D Zn@ZAP during the deposition process; Application of 3D printed Zn powder anodes in Zn micro-batteries[45]: (h) Illustration of 3D printing of micro-electrodes; (i) Digital image of 3D printed micro-electrodes"

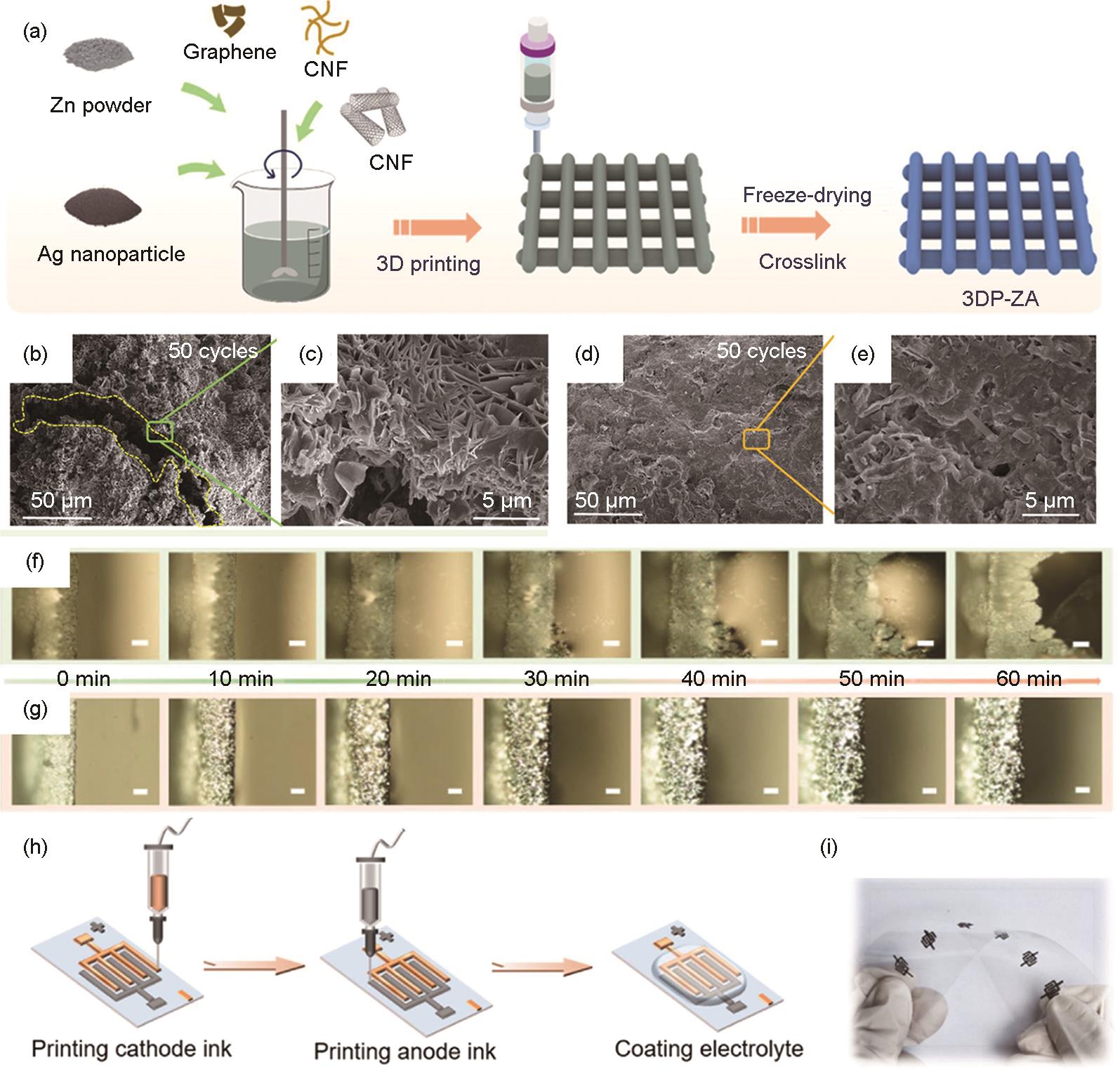

Fig. 7

Novel 3D-printed Zn powder anodes. 3D cold-trap environment printed Zn powder anodes[46]: (a) Schematic of the process of 3D cold-trap environment printed Zn powder anodes; SEM images of (b) 3D-printed MXene/Zn-P aerogel, (c) 3DCPP-MXene/Zn-P aerogel, and (d) 3DCEP-MXene/Zn-P aerogel; Microfluidic-assisted 3D printed Zn powder anodes[47]: (e) Schematic of the preparation process of microfluidic synthesis 3D printing Zn powder anode; (f) Schematic illustration of the synthesis mechanism for MXene/CuTHBQ; (g) The differential charge density at the interfacial region between MXene and Cu-THBQ; (h) Schematic of the EDL structure of bare Zn and M3DP-MXene/Cu-THBQ/Zn-P"

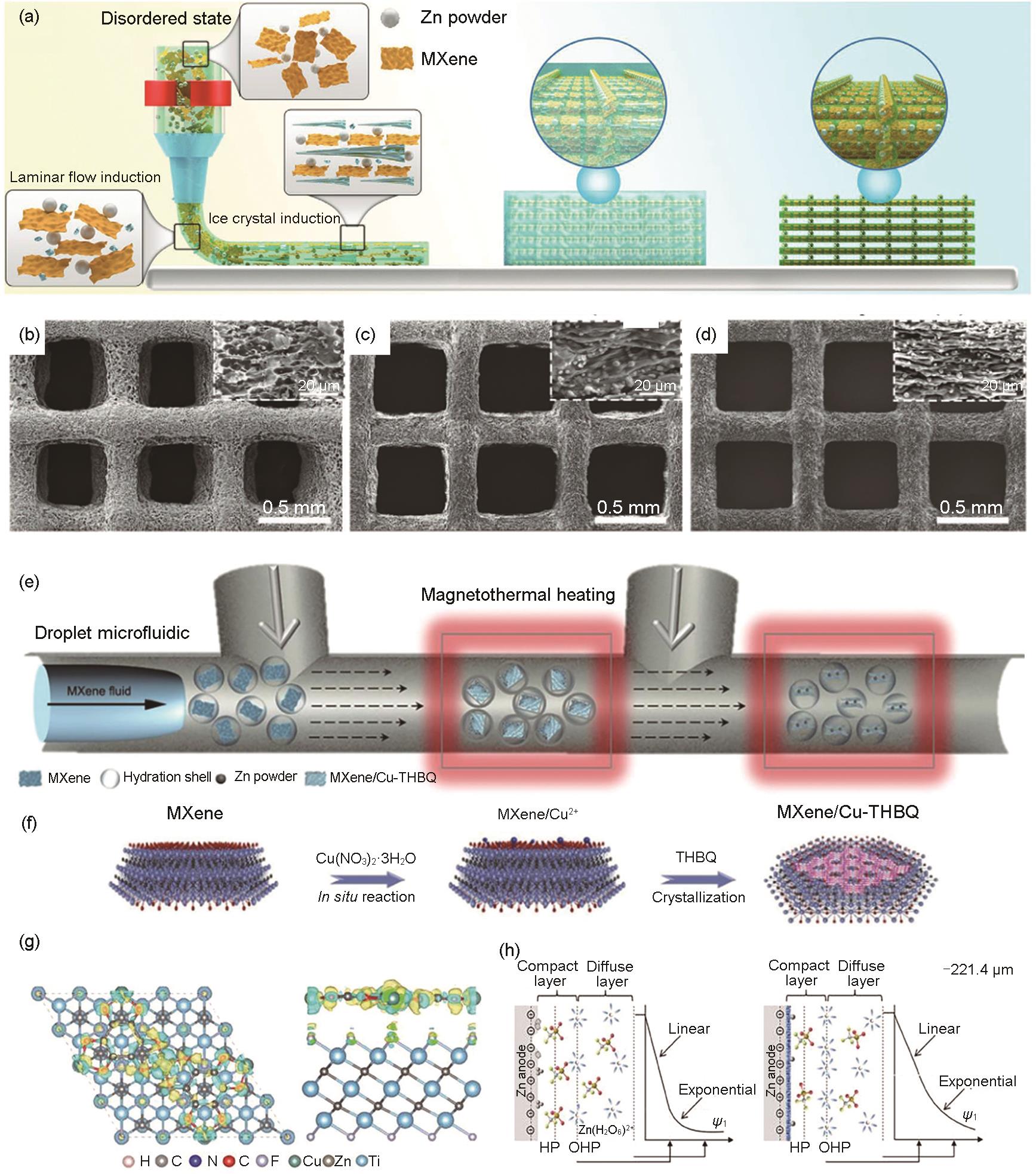

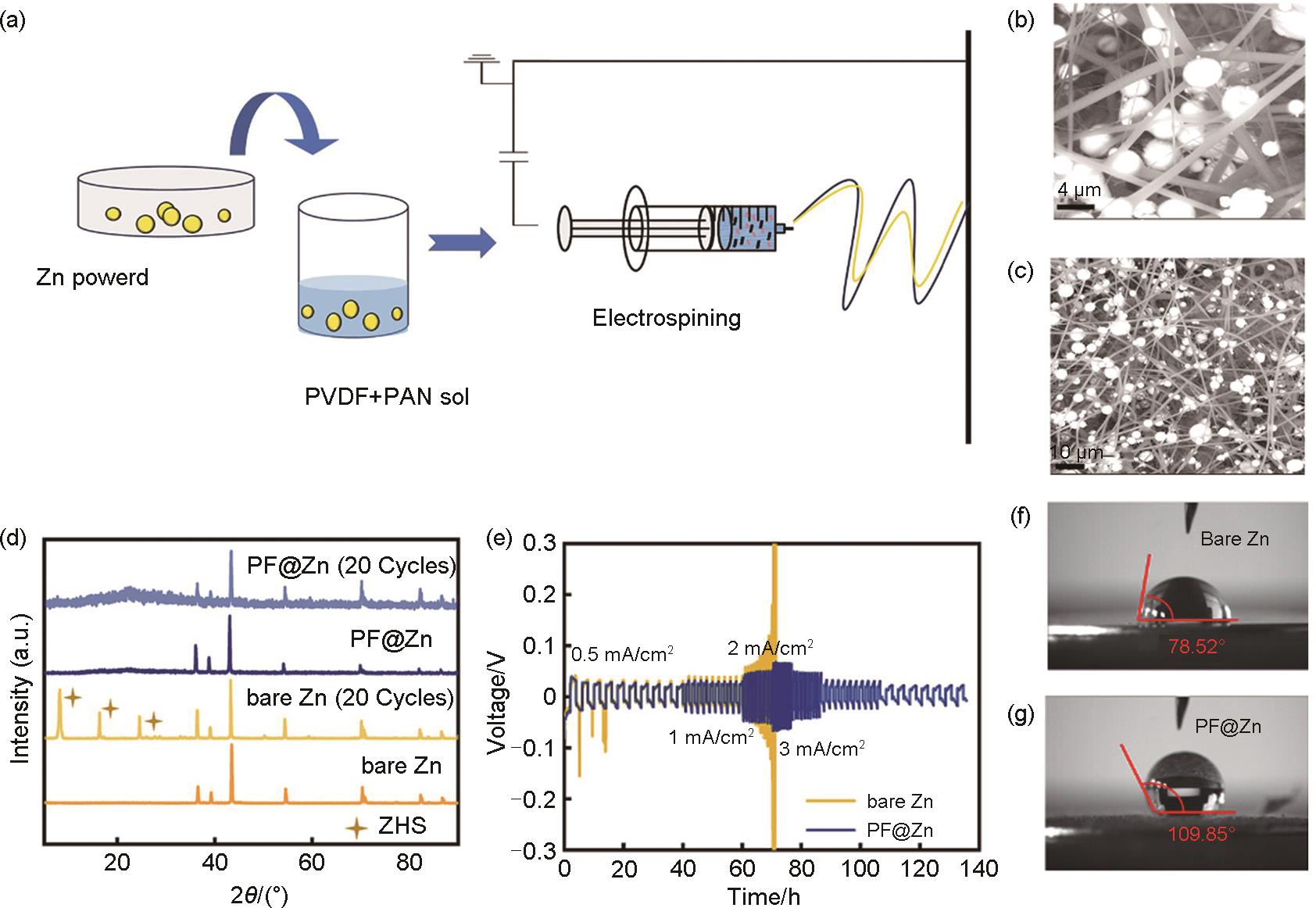

Fig. 8

Electrospinning strategy for Zn powder anodes[48]: (a) 3D porous Zn anodes (PF@Zn) prepared by electrospinning; (b), (c) SEM images of PF@Zn; (d) XRD patterns of bare Zn and PF@Zn before and after 20 cycles; (e) Rate performance of bare Zn and PF@Zn(0.5—3 mA/cm2); Contact angle tests of (f) bare Zn and (g) PF@Zn"

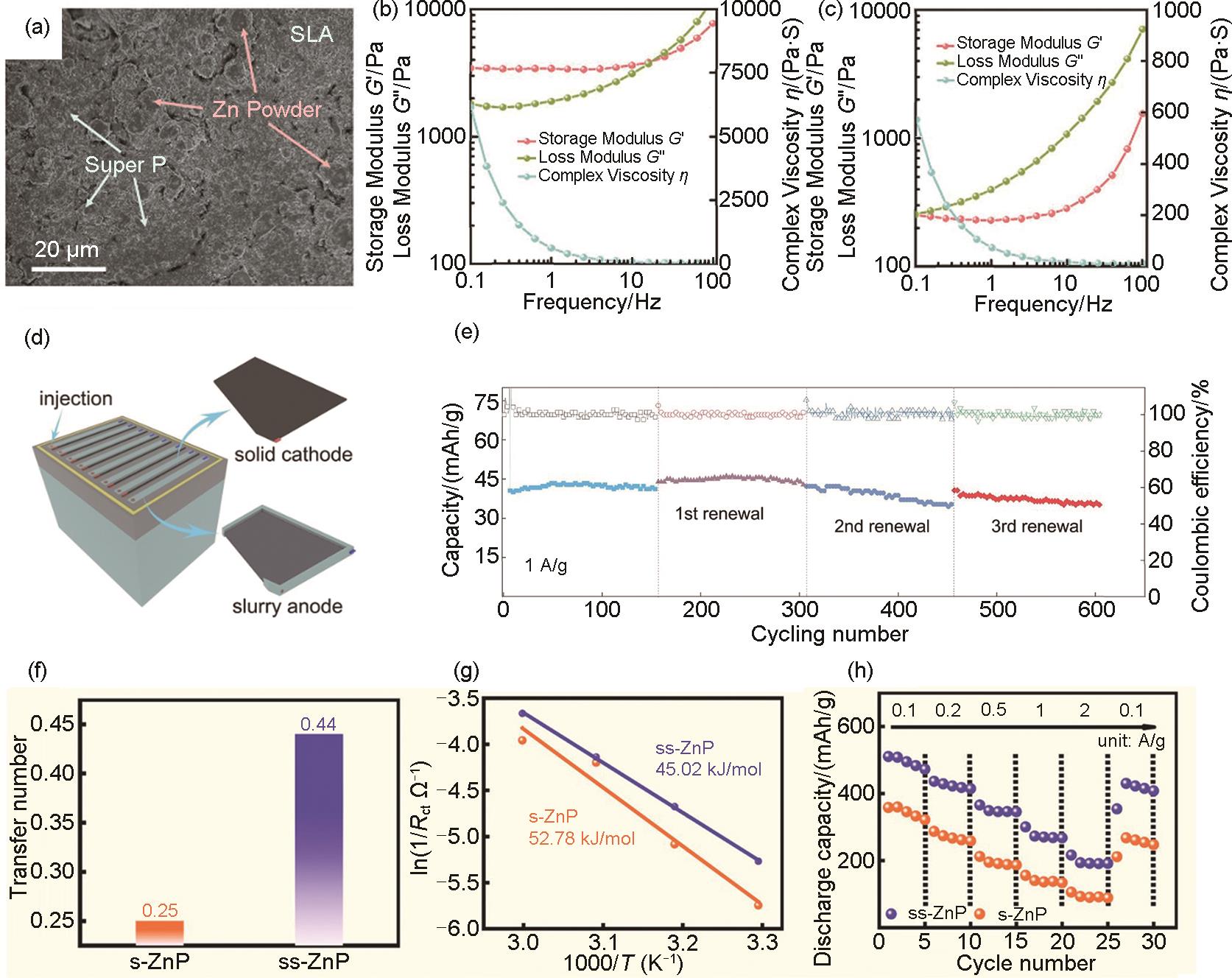

Fig. 9

Rheological structure design of Zn powder anodes. (a) SEM image of SLA; Rheological properties of SLA at (b) 1% and (c) 10% strain[49]; (d) Schematic of a full cell using the semi-solid Zn powder-based slurry anode; (e) Cycling stability of the full cell with replaceable slurry measured every 150 cycles at 1 A/g[50]; (f) Ion transfer numbers and (g) Arrhenius curves and activation energies of ss-ZnP and s-ZnP; (h) Rate performance of the NH4V4O10 ‖ss-ZnP and NH4V4O10 ‖s-ZnP full cells[51]"

| 1 | 史冬梅, 王晶. 中国、日本、韩国电池技术和产业发展战略态势分析[J]. 储能科学与技术, 2023, 12(2): 615-628. DOI: 10.19799/j.cnki.2095-4239.2022.0641. |

| SHI D M, WANG J. Analysis of battery technology and industry development strategy and trend in China, Japan, and South Korea[J]. Energy Storage Science and Technology, 2023, 12(2): 615-628. DOI: 10.19799/j.cnki.2095-4239.2022.0641. | |

| 2 | WANG G Y, ZHANG Q K, ZHANG X Q, et al. Electrolyte additive for interfacial engineering of lithium and zinc metal anodes[J]. Advanced Energy Materials, 2025, 15(2): 2304557. DOI: 10.1002/aenm.202304557. |

| 3 | 徐冲, 徐宁, 蒋志敏, 等. 锂离子电池产气机制及基于电解液的抑制策略[J]. 储能科学与技术, 2023, 12(7): 2119-2133. DOI: 10.19799/j.cnki.2095-4239.2023.0212. |

| XU C, XU N, JIANG Z M, et al. Mechanisms of gas evolution and suppressing strategies based on the electrolyte in lithium-ion batteries[J]. Energy Storage Science and Technology, 2023, 12(7): 2119-2133. DOI: 10.19799/j.cnki.2095-4239.2023.0212. | |

| 4 | JIANG D, WANG X F, YIN S, et al. Solid-state electrolytes with vertically aligned Li+ transport channels for lithium batteries: A comprehensive review[J]. Energy Storage Materials, 2025, 74: 103986. DOI: 10.1016/j.ensm.2024.103986. |

| 5 | ZHANG X F, ZHANG L, JIA X Y, et al. Design strategies for aqueous zinc metal batteries with high zinc utilization: From metal anodes to anode-free structures[J]. Nano-Micro Letters, 2024, 16(1): 75. DOI: 10.1007/s40820-023-01304-1. |

| 6 | ZHU Y H, LIANG G J, CUI X, et al. Engineering hosts for Zn anodes in aqueous Zn-ion batteries[J]. Energy & Environmental Science, 2024, 17(2): 369-385. DOI: 10.1039/D3EE03584K. |

| 7 | CHEN S, OUYANG K F, LIU Y F, et al. Non-epitaxial electrodeposition of overall 99% (002) plane achieves extreme and direct utilization of 95% Zn anode and by-product as cathode[J]. Angewandte Chemie International Edition, 2024, 63(42): e202409303. DOI: 10.1002/anie.202409303. |

| 8 | 鲁杰, 杜娴, 师玉璞, 等. 高稳定水系锌离子电池PANI包覆钒化合物阴极材料[J]. 储能科学与技术, 2025, 14(1): 42-53. DOI: 10.19799/j.cnki.2095-4239.2024.0621. |

| LU J, DU X, SHI Y P, et al. PANI-coated vanadium compound as high-stable aqueous zinc-ion batteries cathode material[J]. Energy Storage Science and Technology, 2025, 14(1): 42-53. DOI: 10.19799/j.cnki.2095-4239.2024.0621. | |

| 9 | GAO Y, YANG N T, BU F, et al. Double-sided engineering for space-confined reversible Zn anodes[J]. Energy & Environmental Science, 2024, 17(5): 1894-1903. DOI: 10.1039/D3EE04292H. |

| 10 | ZHANG M H, HUA H M, DAI P P, et al. Dynamically interfacial pH-buffering effect enabled by N-methylimidazole molecules as spontaneous proton pumps toward highly reversible zinc-metal anodes[J]. Advanced Materials, 2023, 35(15): 2208630. DOI: 10.1002/adma.202208630. |

| 11 | ZHENG X W, SONG Z Y, ZHANG D, et al. Biomimetic quasi-skin-capillary structure engineering of ionic-electronic conducting full-chain networks for stable zinc powder anodes[J]. Advanced Functional Materials, 2025, 35(4): 2413990. DOI: 10.1002/adfm.202413990. |

| 12 | YAO R, ZHAO Y X, WANG L M, et al. A corrosion-free zinc metal battery with an ultra-thin zinc anode and high depth of discharge[J]. Energy & Environmental Science, 2024, 17(9): 3112-3122. DOI: 10.1039/D3EE04320G. |

| 13 | 吴贤文, 龙凤妮, 向延鸿, 等. 中性或弱酸性体系下锌基水系电池负极材料研究进展[J]. 化学进展, 2021, 33(11): 1983-2001. DOI: 10.7536/PC210453. |

| WU X W, LONG F N, XIANG Y H, et al. Research progress of anode materials for zinc-based aqueous battery in a neutral or weak acid system[J]. Progress in Chemistry, 2021, 33(11): 1983-2001. DOI: 10.7536/PC210453. | |

| 14 | LIU G G, TANG Y C, WEI Y, et al. Hydrophobic ion barrier-enabled ultradurable Zn (002) plane orientation towards long-life anode-less Zn batteries[J]. Angewandte Chemie International Edition, 2024, 63(40): e202407639. DOI: 10.1002/anie.202407639. |

| 15 | YANG F H, YUWONO J A, HAO J N, et al. Understanding H2 evolution electrochemistry to minimize solvated water impact on zinc-anode performance[J]. Advanced Materials, 2022, 34(45): 2206754. DOI: 10.1002/adma.202206754. |

| 16 | YU H M, CHEN D P, LI Q Y, et al. In situ construction of anode-molecule interface via lone-pair electrons in trace organic molecules additives to achieve stable zinc metal anodes[J]. Advanced Energy Materials, 2023, 13(22): 2300550. DOI: 10.1002/aenm.202300550. |

| 17 | ZHANG S J, HAO J N, WU H, et al. Protein interfacial gelation toward shuttle-free and dendrite-free Zn-iodine batteries[J]. Advanced Materials, 2024, 36(35): 2404011. DOI: 10.1002/adma.202404011. |

| 18 | ZONG Q, LI R L, WANG J Y, et al. Tailoring the whole deposition process from hydrated Zn2+ to Zn0 for stable and reversible Zn anode[J]. Angewandte Chemie International Edition, 2024, 63(41): e202409957. DOI: 10.1002/anie.202409957. |

| 19 | FU B, LIU G Q, ZHANG Y J, et al. Zn powder-based anodes for aqueous Zn metal batteries: Strategies, structures, and perspectives[J]. ACS Energy Letters, 2024, 9(7): 3292-3307. DOI: 10.1021/acsenergylett.4c00628. |

| 20 | ZHANG Z C, WANG X W, KE J Q, et al. Approaching 100% comprehensive utilization rate of ultra-stable Zn metal anodes by constructing chitosan-based homologous gel/solid synergistic interface[J]. Advanced Functional Materials, 2024, 34(17): 2313150. DOI: 10.1002/adfm.202313150. |

| 21 | LI Q, TANG S H, LUO R Y, et al. Regulating the local chemical environment of Zn powder surface by multi-site anchoring effect to achieve highly-stable Zn anode[J]. Energy Storage Materials, 2024, 66: 103229. DOI: 10.1016/j.ensm.2024.103229. |

| 22 | LI Q, WANG Y B, MO F N, et al. Calendar life of Zn batteries based on Zn anode with Zn powder/current collector structure[J]. Advanced Energy Materials, 2021, 11(14): 2003931. DOI: 10.1002/aenm.202003931. |

| 23 | LIU D S, XU X L, MENG S B, et al. Harnessing the potential of Zn powder anodes: Innovations and future directions in aqueous zinc-ion batteries[J]. Batteries & Supercaps, 2024, 7(6): e202400071. DOI: 10.1002/batt.202400071. |

| 24 | XIAO J, YUAN C B, XIANG L, et al. Design strategies toward high-utilization zinc anodes for practical zinc-metal batteries[J]. Chemistry-A European Journal, 2024, 30(21): e202304149. DOI: 10.1002/chem.202304149. |

| 25 | YANG Z X, WANG Z Y, CAO J L, et al. Stabilizing zinc powder anodes via bifunctional MXene towards flexible zinc-ion batteries[J]. Journal of Colloid and Interface Science, 2025, 680(Pt A): 657-664. DOI: 10.1016/j.jcis.2024.10.145. |

| 26 | HUANG J Y, FENG R Q, WU J C, et al. Structural design strategies of zinc powder anode towards rechargeable zinc-based batteries[J]. Energy Storage Materials, 2025, 74: 103934. DOI: 10.1016/j.ensm.2024.103934. |

| 27 | CAO P H, MENG Q, LI C C, et al. Dimensionality reduction engineering to construct a highly stable Zn powder anode in aqueous Zn-ion batteries[J]. ACS Applied Energy Materials, 2024, 7(2): 479-486. DOI: 10.1021/acsaem.3c02385. |

| 28 | ZHAO X, GAO Y, CAO Q H, et al. A high-capacity gradient Zn powder anode for flexible Zn-ion batteries[J]. Advanced Energy Materials, 2023, 13(38): 2301741. DOI: 10.1002/aenm.202301741. |

| 29 | LI J B, CHENG Z X, LI Z, et al. Rational design of zinc powder anode with high utilization and long cycle life for advanced aqueous Zn-S batteries[J]. Materials Horizons, 2023, 10(7): 2436-2444. DOI: 10.1039/D3MH00278K. |

| 30 | WU J C, SHEN X C, ZHOU H T, et al. Zn-In alloying powder solvent free electrode toward high-load ampere-hour aqueous Zn-Mn secondary batteries[J]. Small, 2024, 20(17): 2308541. DOI: 10.1002/smll.202308541. |

| 31 | LI A X, CHEN M F, TIAN Q H, et al. Conquering poor reversibility of zinc powder electrode through in situ surface engineering towards long-life zinc-ion batteries[J]. Journal of Alloys and Compounds, 2023, 965: 171337. DOI: 10.1016/j.jallcom.2023.171337. |

| 32 | KANG H, KIM S H, AHN D B, et al. Liquid metal-skinned Zn powder anodes enabled by capillary suspension[J]. ACS Energy Letters, 2024, 9(6): 2816-2825. DOI: 10.1021/acsenergylett.4c01009. |

| 33 | LI X L, LI Q, HOU Y, et al. Toward a practical Zn powder anode: Ti3C2Tx MXene as a lattice-match electrons/ions redistributor[J]. ACS Nano, 2021, 15(9): 14631-14642. DOI: 10.1021/acsnano. 1c04354. |

| 34 | CHEN H L, ZHANG W Y, YI S, et al. Zinc iso-plating/stripping: Toward a practical Zn powder anode with ultra-long life over 5600 h[J]. Energy & Environmental Science, 2024, 17(9): 3146-3156. DOI: 10.1039/D3EE04333A. |

| 35 | LIN Y H, ZHANG M, HU Y Z, et al. Nitrogen-doped carbon coated zinc as powder-based anode with PVA-gel electrolyte enhancing cycling performance for zinc-ion batteries[J]. Chemical Engineering Journal, 2023, 472: 145136. DOI: 10.1016/j.cej.2023.145136. |

| 36 | HUYAN X D, YI Z H, SANG Z Y, et al. Polyethylene glycol coating on zinc powder surface: Applications in dendrite-free zinc anodes with enhanced utilization rate[J]. Applied Surface Science, 2023, 614: 156209. DOI: 10.1016/j.apsusc.2022.156209. |

| 37 | BAYAGUUD A, LUO X, FU Y P, et al. Cationic surfactant-type electrolyte additive enables three-dimensional dendrite-free zinc anode for stable zinc-ion batteries[J]. ACS Energy Letters, 2020, 5(9): 3012-3020. DOI: 10.1021/acsenergylett.0c01792. |

| 38 | YAN M D, DONG N, ZHAO X S, et al. Tailoring the stability and kinetics of Zn anodes through trace organic polymer additives in dilute aqueous electrolyte[J]. ACS Energy Letters, 2021, 6(9): 3236-3243. DOI: 10.1021/acsenergylett.1c01418. |

| 39 | ZHANG Q, LUAN J Y, FU L, et al. The three-dimensional dendrite-free zinc anode on a copper mesh with a zinc-oriented polyacrylamide electrolyte additive[J]. Angewandte Chemie International Edition, 2019, 58(44): 15841-15847. DOI: 10.1002/anie.201907830. |

| 40 | WANG J X, ZHANG H, YANG L Z, et al. In situ implanting 3D carbon network reinforced zinc composite by powder metallurgy for highly reversible Zn-based battery anodes[J]. Angewandte Chemie International Edition, 2024, 63(10): e202318149. DOI: 10.1002/anie.202318149. |

| 41 | LIN Y H, HU Y Z, ZHANG S, et al. Binder-free freestanding 3D Zn-graphene anode induced from commercial zinc powders and graphene oxide for zinc ion battery with high utilization rate[J]. ACS Applied Energy Materials, 2022, 5(12): 15222-15232. DOI: 10.1021/acsaem.2c02872. |

| 42 | LIU G Q, FU B, LIU Z X, et al. Copper oxide-modified highly reversible Zn powder anode for aqueous Zn metal batteries[J]. Rare Metals, 2024, 43(10): 5005-5016. DOI: 10.1007/s12598-024-02869-5. |

| 43 | ZENG L, HE J, YANG C Y, et al. Direct 3D printing of stress-released Zn powder anodes toward flexible dendrite-free Zn batteries[J]. Energy Storage Materials, 2023, 54: 469-477. DOI: 10.1016/j.ensm.2022.10.061. |

| 44 | YANG J Y, XU X, GAO Y, et al. Ultra-stable 3D-printed Zn powder-based anode coated with a conformal ion-conductive layer[J]. Advanced Energy Materials, 2023, 13(40): 2301997. DOI: 10.1002/aenm.202301997. |

| 45 | ZHU J B, HU W X, NI J F, et al. High areal energy zinc-ion micro-batteries enabled by 3D printing[J]. Journal of Materials Science & Technology, 2024, 196: 183-189. DOI: 10.1016/j.jmst.2024.01.053. |

| 46 | LU H Y, HU J S, ZHANG Y, et al. 3D cold-trap environment printing for long-cycle aqueous Zn-ion batteries[J]. Advanced Materials, 2023, 35(9): 2209886. DOI: 10.1002/adma.202209886. |

| 47 | LU H Y, HU J S, ZHANG K Q, et al. Microfluidic-assisted 3D printing zinc powder anode with 2D conductive MOF/MXene heterostructures for high-stable zinc-organic battery[J]. Advanced Materials, 2024, 36(6): 2309753. DOI: 10.1002/adma.202309753. |

| 48 | SHA L, SUI B B, WANG P F, et al. 3D network of zinc powder woven into fibre filaments for dendrite-free zinc battery anodes[J]. Chemical Engineering Journal, 2024, 481: 148393. DOI: 10.1016/j.cej.2023.148393. |

| 49 | LIU Q, YU Z L, ZHOU R, et al. A semi-liquid electrode toward stable Zn powder anode[J]. Advanced Functional Materials, 2023, 33(5): 2210290. DOI: 10.1002/adfm.202210290. |

| 50 | YANG Z F, ZHANG Q, LI W B, et al. A semi-solid zinc powder-based slurry anode for advanced aqueous zinc-ion batteries[J]. Angewandte Chemie International Edition, 2023, 62(3): e202215306. DOI: 10.1002/anie.202215306. |

| 51 | CAO C H, ZHOU K Q, DU W C, et al. Designing soft solid-like viscoelastic zinc powder anode toward high-performance aqueous zinc-ion batteries[J]. Advanced Energy Materials, 2023, 13(38): 2301835. DOI: 10.1002/aenm.202301835. |

| 52 | HUANG X Y, HOU H Q, YU B B, et al. Fully biodegradable and long-term operational primary zinc batteries as power sources for electronic medicine[J]. ACS Nano, 2023, 17(6): 5727-5739. DOI: 10.1021/acsnano.2c12125. |

| 53 | QIN L, ZHOU J Q, SUN M Z, et al. Comprehensive review for zinc powder anodes: Significance, optimizing design, and industrial feasibility in zinc-ion batteries[J]. Energy Storage Materials, 2025, 74: 103917. DOI: 10.1016/j.ensm.2024.103917. |

| [1] | Huiming CHEN, Yijia CAI, Wenji YIN, Meifeng CHEN, Youguo HUANG, Sijiang HU, Hongqiang WANG, Qingyu LI. Cr/Mo co-doped regulation on structure and electrochemical performance in Li-rich manganese-based cathode materials [J]. Energy Storage Science and Technology, 2025, 14(3): 1123-1132. |

| [2] | Jianru ZHANG, Qiyu WANG, Qinghao LI, Xianying ZHANG, Bitong WANG, Xiqian YU, Hong LI. Physical characterization techniques and applications in lithium battery failure analysis [J]. Energy Storage Science and Technology, 2025, 14(1): 286-309. |

| [3] | Fanfeng LIU, Tingting WU, Shengyao WEN, Jianhang GAO, Meng CHEN, Chi LI. A study on dissolution of transition metal ions and influence on the cycling performance of LiMn0.6Fe0.4PO4 [J]. Energy Storage Science and Technology, 2025, 14(1): 13-20. |

| [4] | Wenjing ZHANG, Wei XIAO, Yahui YI, Liqin QIAN. Progress on safety modification strategies for lithium-ion batteries [J]. Energy Storage Science and Technology, 2025, 14(1): 104-123. |

| [5] | Jinqiao DU, Yi ZHANG, Jie TIAN, Kai HUANG, Yue SHEN. Strain evolution and state of charge estimation in graphite-lithium iron phosphate pouch cells during cycling [J]. Energy Storage Science and Technology, 2025, 14(1): 310-318. |

| [6] | Yijie YAO, Junwei ZHANG, Yanjun ZHAO, Hongcheng LIANG, Dongni ZHAO. Effect of interfacial dynamics on low temperature performance of sodium-ion batteries [J]. Energy Storage Science and Technology, 2025, 14(1): 30-41. |

| [7] | Cuihong ZENG, Xiujuan CHEN, Man LI, Wenji YIN, Jiming PENG, Sijiang HU, Youguo HUANG, Hongqiang WANG, Qingyu LI. Investigation of W-doped P2-Na0.6Li0.27Mn0.73O2 cathode materials for sodium-ion batteries [J]. Energy Storage Science and Technology, 2024, 13(11): 3731-3741. |

| [8] | Shirong TAN, Wenji YIN, Cuihong ZENG, Xiaoqiong LI, Shuo QI, Fangli JI, Sijiang HU, Hongqiang WANG, Qingyu LI. Role of high temperature quenching in structure and performance of Mn-based layered cathode materials for sodium-ion batteries [J]. Energy Storage Science and Technology, 2024, 13(7): 2399-2406. |

| [9] | Renchao FENG, Yu DONG, Xinyu ZHU, Cai LIU, Sheng CHEN, Da LI, Ruoyu GUO, Bin WANG, Jionghui WANG, Ning LI, Yuefeng SU, Feng WU. Research progress on graphite oxide-based anodes for sodium-ion batteries [J]. Energy Storage Science and Technology, 2024, 13(6): 1835-1848. |

| [10] | Zhaocai LYU, Yuxi WANG, Zhitao WANG, Xiaohui SUN, Jingkang LI. Influence of heated calendering process on cathode film performance of lithium-ion batteries [J]. Energy Storage Science and Technology, 2024, 13(5): 1443-1450. |

| [11] | Min SHI, Pengjie JIANG, Chen XU, Xin HE, Xiao LIANG. Advancements in electrolyte optimization strategies for inhibiting lithium dendrite growth [J]. Energy Storage Science and Technology, 2024, 13(5): 1620-1634. |

| [12] | Yimei OUYANG, Mengmeng ZHAO, Guiming ZHONG, Zhangquan PENG. Nuclear magnetic resonance spectroscopy for probing interfaces in electrochemical energy storage systems [J]. Energy Storage Science and Technology, 2024, 13(1): 157-166. |

| [13] | Qingfei MENG, Rui YANG, Chenglong JIN, Yuliang CAO, Wenjie LI, Zhou ZHOU, Jiliang WU. Preparation and performance of high-capacity Cr8O21 as a cathode material for lithium batteries [J]. Energy Storage Science and Technology, 2023, 12(10): 3049-3055. |

| [14] | Zhihao LIU, Tong DU, Ruirui LI, Tao DENG. Developments of wide temperature range, high voltage and safe EC-free electrolytes [J]. Energy Storage Science and Technology, 2023, 12(8): 2504-2525. |

| [15] | Kangkang QU, Yahua LIU, Die HONG, Zhaoxi SHEN, Xiaozhao HAN, Xu ZHANG. Research progress on positive electrolytes for neutral aqueous organic redox flow battery [J]. Energy Storage Science and Technology, 2023, 12(5): 1570-1588. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||